Professional Documents

Culture Documents

Bearings and Lubrication: Sealer Rotating Shaft

Uploaded by

lnina_1Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bearings and Lubrication: Sealer Rotating Shaft

Uploaded by

lnina_1Copyright:

Available Formats

Bearings and Lubrication 463

Sealer

Rotating

shaft

ro r

Recess

To reservoir Oil inlet p To reservoir

Figure 10.3

Schematic representation of a hydrostatic thrust bearing.

The preceding is applicable even if the recess is eliminated. In this case, ro becomes the

radius of the inlet oil-supply pipe.

Hydrostatic bearings are used in various special applications. Some examples are tele-

scopes and radar tracking units subjected to heavy loads at very low speeds as well as the

machine tools and gyroscopes under high speed but light loads. Further details may be

found in [5].

Finally, we note that friction and wear (discussed in Sections 8.3 through 8.6) are signifi-

cant considerations when boundary lubrication or metal-to-metal contact occurs. Recall

that the depth of wear (by letting A = Ap and P = W is given by

Wl

=K (8.3)

HAp

The quantities K, l, and H represent the wear coefficient, length of sliding, and Brinell

hardness of bearing material, respectively. As noted previously, W and Ap designate the

load and projected area (DL) of the bearing. Practically, it is useful to include in this rela-

tionship motion-related and environmental factors depending upon motion type, load, and

speed [10]. Observe that the properties of sliding surfaces of the lubricant are important

factors in limiting wear under lubrication conditions. Table 10.3 of Section 10.11 furnishes

designer limits of the unit bearing load P, sliding velocity V, as well as PV for various

materials. Sliding velocity for continuous motion is V = Dn. Clearly, for an acceptable bear-

ing design configuration, operating values of the preceding quantities must be less than

the values listed in the table. An application of Equation 8.3 is illustrated in the following

numerical problem.

Example 10.1: Preliminary Design of a Boundary-Lubricated Journal Bearing

A 1 in. steel shaft having 450 Bhn with an excellent lubrication rotates continuously

at a load of 40 lb at 20 rpm for 3.5 years in a sleeve of bronzelead having 170 Bhn

(Figure10.4). Estimate the largest length L of the sleeve.

Given: D = 1 in., H = 450 Bhn, n = 30 rpm, W = 40 lb, t = 2years.

You might also like

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Magnetic Circuits Question AnswersDocument3 pagesMagnetic Circuits Question AnswersAtul WadhaiNo ratings yet

- 235notes Chapter11Document4 pages235notes Chapter11Ajmal ArshadNo ratings yet

- Externally Pressurized Bearings Design For ManufactureDocument18 pagesExternally Pressurized Bearings Design For Manufacturebee140676100% (1)

- Prediction of Stiffness and Damping of Gas Foil Journal Bearing For High-Speed RotorDocument11 pagesPrediction of Stiffness and Damping of Gas Foil Journal Bearing For High-Speed RotorBiren Kumar PradhanNo ratings yet

- Problems of Friction, Lubrication, and Rolls in The Rolling Technology Materials ForDocument22 pagesProblems of Friction, Lubrication, and Rolls in The Rolling Technology Materials ForAnurag RamdasNo ratings yet

- Sliding Contact Bearings Sliding Contact Bearings: r c μ n p r c μ n pDocument4 pagesSliding Contact Bearings Sliding Contact Bearings: r c μ n p r c μ n pAditya Varma YalamanchiliNo ratings yet

- Rolling Contact Bearings: Bearing TypesDocument6 pagesRolling Contact Bearings: Bearing Typessofyan samNo ratings yet

- Inno2020 - T4 - Rolling-Contact BearingsDocument9 pagesInno2020 - T4 - Rolling-Contact BearingsGhostNo ratings yet

- DOME 15 Recap Text 1 PDFDocument4 pagesDOME 15 Recap Text 1 PDFAditya Varma YalamanchiliNo ratings yet

- Rolling Element Bearing SlidesDocument39 pagesRolling Element Bearing SlidesVELMURUGAN MNo ratings yet

- Lecture - 11 Bearing IIDocument43 pagesLecture - 11 Bearing IIwkho0007No ratings yet

- Surface Durability of Spur and Helical Gears - KHK GearsDocument12 pagesSurface Durability of Spur and Helical Gears - KHK GearsKalipse FerreiraNo ratings yet

- 11 Rolling: ContactbearingsDocument29 pages11 Rolling: ContactbearingsAndres Alberto Osorio YupanquiNo ratings yet

- 1.1 Helicopter Design: Comp. & . Ath . TTH Appls Vol 12A. No. I. PP 85-10 . 1486Document25 pages1.1 Helicopter Design: Comp. & . Ath . TTH Appls Vol 12A. No. I. PP 85-10 . 1486Artur ZubovNo ratings yet

- 1 s2.0 S0263876299718472 MainDocument3 pages1 s2.0 S0263876299718472 Mainاحمد الدلالNo ratings yet

- Design Bladed Darrieus Rotor River Turbines: StraightDocument6 pagesDesign Bladed Darrieus Rotor River Turbines: StraightBorja Garcia SastreNo ratings yet

- Foundation For MBR-flatDocument6 pagesFoundation For MBR-flatjatinNo ratings yet

- Y&B Design - The Disgn of BoatsDocument66 pagesY&B Design - The Disgn of BoatsEuclides Cagnini100% (1)

- Abs Prop ThicknessDocument12 pagesAbs Prop ThicknessAndreas ArapakopoulosNo ratings yet

- 102416081727Document9 pages102416081727Arjun KrishnakumarNo ratings yet

- Numerical Simulation of Aerostatic Bearing Stiffness, Damping and Critical Frequency Properties Using Linear Stability AnalysisDocument8 pagesNumerical Simulation of Aerostatic Bearing Stiffness, Damping and Critical Frequency Properties Using Linear Stability AnalysissenthilNo ratings yet

- Design of BearingsDocument46 pagesDesign of BearingsSatyaprakash Dinesh Vispute100% (1)

- Stuct and Tie Modelling 01Document37 pagesStuct and Tie Modelling 01YUK LAM WONGNo ratings yet

- CH 11: Rolling-Contact Bearings: Bearing TypesDocument9 pagesCH 11: Rolling-Contact Bearings: Bearing TypesBhuwaneshwar DahalNo ratings yet

- 2985 6085 1 PBDocument7 pages2985 6085 1 PBDinizNo ratings yet

- Blade Erato Blue OrıgınDocument14 pagesBlade Erato Blue OrıgınaircarmediaNo ratings yet

- Rolling Element Bearings Childs2014Document53 pagesRolling Element Bearings Childs2014joshuaNo ratings yet

- 1988 - The In-Situ Measurement of The Undrained Shear Strength of Clays Using The Field VaneDocument33 pages1988 - The In-Situ Measurement of The Undrained Shear Strength of Clays Using The Field VaneDaniel Mejia LoeraNo ratings yet

- Characteristics of PropellerDocument46 pagesCharacteristics of PropellerBishop TariganNo ratings yet

- Lubrication & Journal Bearings 1Document11 pagesLubrication & Journal Bearings 1YeabsraNo ratings yet

- Rotor Design Options For Improving Tiltrotor Whirl-Flutter Stability MarginsDocument9 pagesRotor Design Options For Improving Tiltrotor Whirl-Flutter Stability Margins雷黎明No ratings yet

- Bearing From Machine Design Reviewer by Jas TordilloDocument4 pagesBearing From Machine Design Reviewer by Jas TordilloMajo CruzemNo ratings yet

- 393 Part CSR-BT e 20180305Document72 pages393 Part CSR-BT e 20180305Atsil DzakwanNo ratings yet

- Static and Dynamic Analysis of Elastohydrodynamic Elliptical Journal-Nair PDFDocument9 pagesStatic and Dynamic Analysis of Elastohydrodynamic Elliptical Journal-Nair PDFPuneet MathurNo ratings yet

- Torsion Unit3Document22 pagesTorsion Unit3carmelnavinNo ratings yet

- Limit States Design in Structural Steel: Eighth EditionDocument12 pagesLimit States Design in Structural Steel: Eighth EditionJesus OrtizNo ratings yet

- Bearing NoteDocument21 pagesBearing NoteShahir IsmailNo ratings yet

- Proceedings of The Institution of Mechanical Engineers, Part G - Journal of Aerospace Engineering-1999-Luke-337-46Document10 pagesProceedings of The Institution of Mechanical Engineers, Part G - Journal of Aerospace Engineering-1999-Luke-337-46mail_krkNo ratings yet

- TDocument33 pagesTTheodoros AtheridisNo ratings yet

- Analiysis of Propulsion For Various Types of Ships in Aspects of Power RequiredDocument6 pagesAnaliysis of Propulsion For Various Types of Ships in Aspects of Power RequiredAHMETNo ratings yet

- Design of Journal Bearing 1 163542053921876323617a897b9828bDocument8 pagesDesign of Journal Bearing 1 163542053921876323617a897b9828bsai ganeshNo ratings yet

- Anchard WearDocument17 pagesAnchard WearJosue21SNo ratings yet

- Machine Element 11.11.2020 PDFDocument24 pagesMachine Element 11.11.2020 PDFSardar Rehan AhmedNo ratings yet

- Modern Engineering For Design of Liquid (225-325)Document101 pagesModern Engineering For Design of Liquid (225-325)Misha's Kitchen And OtherNo ratings yet

- LIBRO3Document43 pagesLIBRO3Camilo LacoutureNo ratings yet

- US8128376Document11 pagesUS8128376J clerio ClerioNo ratings yet

- Propeller CrackDocument22 pagesPropeller CrackArdhika Hermigo100% (1)

- Large Capacity Screw PilesDocument15 pagesLarge Capacity Screw PilesAnonymous P73cUg73LNo ratings yet

- Bearing SelectionDocument6 pagesBearing SelectiondaryonoNo ratings yet

- Catalogue of Spherical Roller and Special BearingsDocument67 pagesCatalogue of Spherical Roller and Special BearingsVolodymyrNo ratings yet

- Raymondi and Boyd GraphDocument0 pagesRaymondi and Boyd Graphdsathiya100% (1)

- Prakash 1972Document4 pagesPrakash 1972Anas SakimNo ratings yet

- Torque IppleDocument10 pagesTorque IppleMabrouk MosbahiNo ratings yet

- Savonius Blade Profile PDFDocument21 pagesSavonius Blade Profile PDFTushar KarekarNo ratings yet

- Design of Shafts and Housings For Optimum Operation and PerformanceDocument2 pagesDesign of Shafts and Housings For Optimum Operation and Performancemichaeltichon3No ratings yet

- Marine System Design ProjectDocument243 pagesMarine System Design ProjectRishi Sashank100% (1)

- Artigo de MancaisDocument11 pagesArtigo de MancaisAndré MenezesNo ratings yet

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsFrom EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsNo ratings yet

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsFrom EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNo ratings yet

- 11.7 Transmitted Load: Spur GearsDocument1 page11.7 Transmitted Load: Spur Gearslnina_1No ratings yet

- Mechanical Design: of Machine ComponentsDocument1 pageMechanical Design: of Machine Componentslnina_1No ratings yet

- Mechanical Design: of Machine ComponentsDocument1 pageMechanical Design: of Machine Componentslnina_1No ratings yet

- BC546 / BC547 / BC548 / BC549 / BC550 NPN Epitaxial Silicon TransistorDocument7 pagesBC546 / BC547 / BC548 / BC549 / BC550 NPN Epitaxial Silicon TransistorrealaffiliateNo ratings yet

- Black Decker 9078Document1 pageBlack Decker 9078lnina_1No ratings yet

- Flywheel1 DrawingDocument1 pageFlywheel1 Drawinglnina_1No ratings yet

- Flywheel Shaft DrawingDocument1 pageFlywheel Shaft Drawinglnina_1No ratings yet

- Line Post InsulatorDocument1 pageLine Post Insulatorlnina_1No ratings yet

- DSM 15kv 28kvDocument1 pageDSM 15kv 28kvlnina_1No ratings yet

- Cart ModelDocument1 pageCart Modellnina_1No ratings yet

- Energy of FotonDocument6 pagesEnergy of FotonPaul GhingaNo ratings yet

- Chapt2 PDFDocument4 pagesChapt2 PDFDrjasmeet KaurNo ratings yet

- ObjectiveDocument15 pagesObjectivemaniinfant09No ratings yet

- Cable Fault Location Manual - 2021Document343 pagesCable Fault Location Manual - 2021muhd ezadNo ratings yet

- Surface Tension AssignmentDocument11 pagesSurface Tension AssignmentShaheer KhanNo ratings yet

- An Artificial Intelligence-Based Design Tool For T PDFDocument18 pagesAn Artificial Intelligence-Based Design Tool For T PDFKarthik MkNo ratings yet

- Fluid Mechanics & Fluid Machines KME302Document37 pagesFluid Mechanics & Fluid Machines KME302Rohit DhimanNo ratings yet

- PPXV An Elegant and Fast Method To Predict The Slow Crack Growth Behaviour of High Density Polyethylene Pipe MaterialsDocument7 pagesPPXV An Elegant and Fast Method To Predict The Slow Crack Growth Behaviour of High Density Polyethylene Pipe MaterialsMehboob ulHaqNo ratings yet

- Metals: A Case Study For The Welding of Dissimilar EN AW 6082 and EN AW 5083 Aluminum Alloys by Friction Stir WeldingDocument9 pagesMetals: A Case Study For The Welding of Dissimilar EN AW 6082 and EN AW 5083 Aluminum Alloys by Friction Stir WeldingArvind ShuklaNo ratings yet

- ENF-VT3 BrochureDocument2 pagesENF-VT3 BrochurezhangjunpingNo ratings yet

- SelectfellowsDocument26 pagesSelectfellowsSougata HalderNo ratings yet

- BP2Document3 pagesBP2insane88No ratings yet

- University of Malaya: Electronic PhysicsDocument6 pagesUniversity of Malaya: Electronic PhysicsMoontasir SoumikNo ratings yet

- JNTUK - B Tech - 2018 - 4 1 - Mar - R16 R13 R10 - MECH - RT41037022018 MATERIAL CHARACTERIZATION TECHNIQUESDocument1 pageJNTUK - B Tech - 2018 - 4 1 - Mar - R16 R13 R10 - MECH - RT41037022018 MATERIAL CHARACTERIZATION TECHNIQUESConor StevensonNo ratings yet

- Product Application - PDF 20190816110105 3833 Interzone 1000 Uk LRDocument2 pagesProduct Application - PDF 20190816110105 3833 Interzone 1000 Uk LRPutra NugrahaNo ratings yet

- Q2 Chem 1 Molecular Geometry HandoutsDocument1 pageQ2 Chem 1 Molecular Geometry Handoutsmikomira21No ratings yet

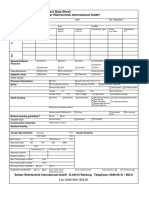

- Agitator Data Sheet Stelzer Rührtechnik International GMBH: CompanyDocument1 pageAgitator Data Sheet Stelzer Rührtechnik International GMBH: CompanyDeepikaNo ratings yet

- 3.1 Thermal PhysicsDocument6 pages3.1 Thermal PhysicsMartinNo ratings yet

- Unit Iv Ce 6405Document13 pagesUnit Iv Ce 6405HanafiahHamzahNo ratings yet

- Optical Communications - Set IIDocument13 pagesOptical Communications - Set IISuresh Reddy GuvvalaNo ratings yet

- Piston V C and P C Combined Vapor Mixture PDFDocument10 pagesPiston V C and P C Combined Vapor Mixture PDFKONDRU SIVAKUMARNo ratings yet

- Laboratory Determination of Resilient Modulus For Flexible Pavement DesignDocument53 pagesLaboratory Determination of Resilient Modulus For Flexible Pavement DesignprmraoNo ratings yet

- Cap. 7 - Skew Bending PDFDocument66 pagesCap. 7 - Skew Bending PDFDacu CiprianNo ratings yet

- Practical Rheology Section 3 PDFDocument42 pagesPractical Rheology Section 3 PDFsiva praneethNo ratings yet

- Natural Convection Heat Transfer From A Vertical CylinderDocument6 pagesNatural Convection Heat Transfer From A Vertical CylinderanbuvrpNo ratings yet

- Handbook Review Temporaywork Deep ExcavationDocument59 pagesHandbook Review Temporaywork Deep ExcavationKen LiewNo ratings yet

- 1 s2.0 S0143749620300865 MainDocument9 pages1 s2.0 S0143749620300865 MainLautaro Teper MarinelliNo ratings yet

- Torsional Shear StrengthDocument7 pagesTorsional Shear Strengthkc olidan0% (1)