Professional Documents

Culture Documents

Lug Design

Uploaded by

Fandy SipataCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lug Design

Uploaded by

Fandy SipataCopyright:

Available Formats

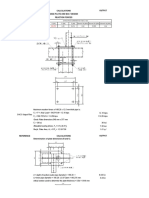

Lifting Lug Design Per ASME BTH-1-2005 (Subjected to Load Lifting Rigging Analysis Especially for 90o Lifting

Condition)

References:

1. ASME. (2006). "Design of below-the-hook lifting devices, BTH-1-2005", New York.

2. Duerr, D. (2008). ASME BTH-1 Pinned Connection Design Provisions. Practice Periodical on Structural Design and Construction, Vol. 13, No. 2, 53-58.

3. Duerr, D. (2006). Pinned connection strength and behavior. J. Struct. Eng., 132(2), 182-194.

Y

N

Y

N

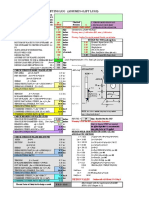

Input:

Nd = 2.00 *) For most lifting devices used in construction Nd = 3.00. See Section 3-1.3 of the ASME code for more information. In certain circumstances a value of 2.00 can be

t= 1.25 inches Lug Plate Thickness justified.

a= 3 inches Dimensional Rules of Thumb:

Dp = 2.75 inches

be = 3 inches Edge Distance = a+Dh/2

Dh = 3 inches Grip = Length of shackle pin available for bearing against lug.

Curved Edge? N Y or N For most lugs this is Y, but N is left as an option. = Clear distance between shackle legs.

Fy = 36 ksi Material Yield Stress Fy = 36 ksi for ASTM A36. Fy = 50 ksi for ASTM A572, Grade 50.

Fu = 58 ksi Material Ultimate Stress Fu = 58 ksi for ASTM A36. Fu = 65 ksi for ASTM A572, Grade 50. For Dp < 2":

Cyclic load? N Subjected to rotating cyclic loading or not

Output: Edge Distance = 1.5 * Dp

Dh = Dp + 1/8"

beff1 = 5.00 inches ASME Equation (3-46).

beff2 = 2.90 inches ASME Equation (3-47). For Dp >= 2":

beff = 2.90 inches

r= 4.5 inches Edge Distance = 1.75 * Dp

R= 4.5 inches Dh = Dp + 1/4"

Z

Z' = 0.00 inches ASME Equation (C3

(C3-2).

2).

Av = 8.60 sq. inches ASME Equation (3-50) modified per Commentary. For all Dp, t = Grip/3. Add cheek plates as required to get desired Pp.

Best practice is to add sufficient cheek plates to insure bearing over 80% of

Pt = 175.21 kips ASME Equation (3-45). the grip. These are only rules of thumb. Deviation from them is allowed.

Pb = 144.09 kips ASME Equation (3-48).

Pv = 145.46 kips ASME Equation (3-49).

Pp = 77.34 kips ASME Equation (3-51)*Dp*t. If the connection is subject to rotating cyclic loading, this value shall be divided by 2 !!!!

Pin Diameter Effect: Note: ASME BTH-1-2005 requires Dh/Dp <= 1.1. When this is not the case it only states that "the effect of the clearance shall be taken into account".

It does not tell you how to take it into account. Reference 2 provides this information.

Dh/Dp = 1 09

1.09

Check All? Y Y or N. Check even when Dh/Dp <= 1.1? (Input) Per ASME BTH-1-2005, this check can be ignored when Dh/Dp < 1.1, but the option to check it anyway is left available to the user.

Cr = 0.890 Reduction Factor Ref. 2 Equation (6)

phi = 50.417 Degrees Ref. 2 Equation (9). This is half the angle of the portion of the pin in contact with the lug.

Z= 3.499 Inches Ref. 2 Equation (20)

Z' = 0.000 Inches Ref. 2 Equation (21)

Av = 8.75 sq. inches

Pt = 155.95 kips

Pb = 128.26 kips

Pv = 147 97

147.97 kips

Pp = 77.34 kips If the connection is subject to rotating cyclic loading, this value shall be divided by 2 !!!!.

Max. P = 77.34 kips

You might also like

- Pveng: Pressure Vessel Engineering LTDDocument5 pagesPveng: Pressure Vessel Engineering LTDBruno TrujilloNo ratings yet

- Fatigue Analysis Tool 1.0Document2 pagesFatigue Analysis Tool 1.0We learnNo ratings yet

- Strength Calculation of Lifting EyeDocument2 pagesStrength Calculation of Lifting EyeJacky Tam0% (1)

- PEC EN STN C 13619 17 Mar 2014Document169 pagesPEC EN STN C 13619 17 Mar 2014Raja RamNo ratings yet

- 吊耳计算Document4 pages吊耳计算huangjlNo ratings yet

- Lifting Analysis - TrunnionDocument3 pagesLifting Analysis - TrunnionMudasir MughalNo ratings yet

- 8" (200A) SCH.80: A 106 Gr.B/EQ A 36 / EQDocument3 pages8" (200A) SCH.80: A 106 Gr.B/EQ A 36 / EQRakeshNo ratings yet

- Facilities On Offshore Installations: Guide For Building and ClassingDocument209 pagesFacilities On Offshore Installations: Guide For Building and ClassingKarthick VenkatswamyNo ratings yet

- ASME SpreaderBar DWGDocument1 pageASME SpreaderBar DWGInspetor SoldagemNo ratings yet

- Design of Fillet Weld (As Per Bs en 1993 1 8, CL 4.5.3) : KN M KN KN M KN KN MMDocument2 pagesDesign of Fillet Weld (As Per Bs en 1993 1 8, CL 4.5.3) : KN M KN KN M KN KN MMGiri DharanNo ratings yet

- Din 4024Document13 pagesDin 4024Muhammad HassanNo ratings yet

- Spreader Bar3 - L.9 M-CertificationDocument10 pagesSpreader Bar3 - L.9 M-CertificationsiagiandobahNo ratings yet

- Comparison of FEM, HMI and CMAA Classifications - ProservCrane GroupDocument3 pagesComparison of FEM, HMI and CMAA Classifications - ProservCrane Groupengin gürayNo ratings yet

- LTA and Dryer Cylinders - Applying Mandatory Appendix 32Document2 pagesLTA and Dryer Cylinders - Applying Mandatory Appendix 32GTpianomanNo ratings yet

- Eccentric Column BucklingDocument10 pagesEccentric Column BucklingMukeshChopraNo ratings yet

- Most Applications, F.S. 5.0) : Calculation ReferenceDocument5 pagesMost Applications, F.S. 5.0) : Calculation ReferenceParthibanNo ratings yet

- Spreader Beam: ASME BTH-1: InputsDocument17 pagesSpreader Beam: ASME BTH-1: InputsGokul AmarnathNo ratings yet

- PV Elite ResultDocument239 pagesPV Elite ResultChaitanya Sai TNo ratings yet

- Overhead Crane Governing Bodies and Specs PDFDocument1 pageOverhead Crane Governing Bodies and Specs PDFscofiel1No ratings yet

- Calculations For Rectangular Storage TankDocument44 pagesCalculations For Rectangular Storage TankSiva ShankarNo ratings yet

- Calculation Lifting LugDocument4 pagesCalculation Lifting Lugelang purbayaNo ratings yet

- Hinge DesignDocument2 pagesHinge Designpare222No ratings yet

- Seismic Load Calculation of The Tank As Per IS 1893Document1 pageSeismic Load Calculation of The Tank As Per IS 1893ParthibanNo ratings yet

- Padeye - 01Document9 pagesPadeye - 01ramNo ratings yet

- Lifting and Tailing StackDocument42 pagesLifting and Tailing StackSudar MyshaNo ratings yet

- Calculation of Lifting ForcesDocument9 pagesCalculation of Lifting ForcesprantikduarahNo ratings yet

- Stresses in Large Horizontal Cylindrical Pressure Vessels On Two Saddle SupportsDocument12 pagesStresses in Large Horizontal Cylindrical Pressure Vessels On Two Saddle SupportsAlexander BlackNo ratings yet

- V-340 OutDocument14 pagesV-340 OutSachin5586No ratings yet

- Avp-2016-021 Cal Life Boat Spreader BarDocument18 pagesAvp-2016-021 Cal Life Boat Spreader BarKrit LaohakunvatitNo ratings yet

- Lifting Lug Design Excel PDFDocument2 pagesLifting Lug Design Excel PDFahamedNo ratings yet

- LIFTCALC 30aDocument101 pagesLIFTCALC 30aareks30% (1)

- Saddle AnalysisDocument17 pagesSaddle AnalysiscutefrenzyNo ratings yet

- Final 175T Crane Spec DT 11.1.16 PDFDocument57 pagesFinal 175T Crane Spec DT 11.1.16 PDFRohan KulkarniNo ratings yet

- Trunnion 6 TonDocument3 pagesTrunnion 6 TonEngr Khurram Jaan RamayNo ratings yet

- TQ-0305-R00 - Calculo Estrutura PDFDocument4 pagesTQ-0305-R00 - Calculo Estrutura PDFPeterson MagroNo ratings yet

- Lifting Lug Design SheetDocument6 pagesLifting Lug Design SheetIjaz AhmedNo ratings yet

- Tailing LugDocument3 pagesTailing LugSajad AbdulNo ratings yet

- Calculation of Lifting Eye: 1. Tear-Out StressDocument2 pagesCalculation of Lifting Eye: 1. Tear-Out StressMirza CaticNo ratings yet

- Davit Cal 2251B Davit Arm CalculationDocument4 pagesDavit Cal 2251B Davit Arm CalculationKarina RoquelNo ratings yet

- Bottom LugDocument7 pagesBottom LugAjiri IvoviNo ratings yet

- Lifting Lug Analysis (Asd) : ASME Notation AISC Preferred Geometry AISC Alternate GeometryDocument2 pagesLifting Lug Analysis (Asd) : ASME Notation AISC Preferred Geometry AISC Alternate GeometryJohn PacelloNo ratings yet

- Lifting Lug Design-MrDocument5 pagesLifting Lug Design-MrMiguelRagasNo ratings yet

- Tank 67M3 Down (27.07.17)Document16 pagesTank 67M3 Down (27.07.17)Tech DesignNo ratings yet

- ISO 898 Grade 10.9Document2 pagesISO 898 Grade 10.9Mihaela NastaseNo ratings yet

- Piping Engineering - Tank Nozzle Loads 1Document1 pagePiping Engineering - Tank Nozzle Loads 1Nasrul AdliNo ratings yet

- Lifting Lug DesignDocument4 pagesLifting Lug DesignRohith V VNo ratings yet

- Jeddah South Thermal Power Plant Stage-I: ProjectDocument18 pagesJeddah South Thermal Power Plant Stage-I: ProjectAmr AbdeinNo ratings yet

- M8 McKissick SheavesDocument18 pagesM8 McKissick Sheavesmahmoud heikal100% (1)

- Base Plate & Bolt DesignDocument2 pagesBase Plate & Bolt DesigndovermanNo ratings yet

- Bottom Failure - Annex K - en 14015 - Rev 3Document3 pagesBottom Failure - Annex K - en 14015 - Rev 3KP SahuNo ratings yet

- Monorail - Aisc 2005 - Bs2853-Rev-11 1ton CapacityDocument74 pagesMonorail - Aisc 2005 - Bs2853-Rev-11 1ton CapacityRAMSINGH CHAUHANNo ratings yet

- Local Stress Calculation Sheet: Not Designed For Engineering PracticeDocument15 pagesLocal Stress Calculation Sheet: Not Designed For Engineering PracticeJ A S JASNo ratings yet

- Calculation Software of WeldingDocument1 pageCalculation Software of WeldinghaharameshNo ratings yet

- SACS Training ProgrammeDocument2 pagesSACS Training ProgrammeLaurentiu TeacaNo ratings yet

- Lifting LugDocument5 pagesLifting LugFarid Tata100% (1)

- PVP2016 Final ProgramDocument76 pagesPVP2016 Final Programthaivinhtuy100% (1)

- Lifting Lug Stress - 4 - Points - Rev - 1 - 5Document11 pagesLifting Lug Stress - 4 - Points - Rev - 1 - 5John PacelloNo ratings yet

- Lifting Beam CalculationDocument2 pagesLifting Beam CalculationAvish ShahNo ratings yet

- Perhitungan Untuk Mencari Alat Bantu AngkatDocument6 pagesPerhitungan Untuk Mencari Alat Bantu AngkatGame Just forNo ratings yet

- Lifting Lug Design Per ASME BTH-1Document8 pagesLifting Lug Design Per ASME BTH-1luis nunezNo ratings yet

- Preliminary Rencana Awal (Section) - Layout1Document1 pagePreliminary Rencana Awal (Section) - Layout1Fandy SipataNo ratings yet

- 32p Neda Dry CargoDocument36 pages32p Neda Dry CargoFandy SipataNo ratings yet

- Calculating Mast and RiggingDocument18 pagesCalculating Mast and RiggingFandy SipataNo ratings yet

- RINA - Developments in Heavy Transport Design CalculationsDocument12 pagesRINA - Developments in Heavy Transport Design CalculationsdsrfgNo ratings yet

- Sikadur 752 PdsDocument2 pagesSikadur 752 PdsTaufik FiklyNo ratings yet

- AASHTO Flexible Pavement DesignDocument9 pagesAASHTO Flexible Pavement DesignLandon MitchellNo ratings yet

- Dynamic Testing of PilesDocument15 pagesDynamic Testing of PilesFandy SipataNo ratings yet

- Punching Shear Arah Horizontal Tiang - 2Document1 pagePunching Shear Arah Horizontal Tiang - 2Fandy SipataNo ratings yet

- 20160323010442-C50E (Ck50)Document2 pages20160323010442-C50E (Ck50)novkovic1984No ratings yet

- Air Gap Analysis GN Oct18 PDFDocument44 pagesAir Gap Analysis GN Oct18 PDFcbsd24No ratings yet

- IHFoam TutorialDocument40 pagesIHFoam TutorialFandy Sipata100% (1)

- Comparison Between CFD Analysis and Experimental DataDocument4 pagesComparison Between CFD Analysis and Experimental Datalongtrandang5867No ratings yet

- 4188 8285 1 SM PDFDocument11 pages4188 8285 1 SM PDFFandy SipataNo ratings yet

- 3 2 1 PDFDocument4 pages3 2 1 PDFFandy SipataNo ratings yet

- New Fatigue Life and DUrability Analysis MethodDocument7 pagesNew Fatigue Life and DUrability Analysis MethodFandy SipataNo ratings yet

- Bitushield: Field of ApplicationDocument2 pagesBitushield: Field of ApplicationFandy SipataNo ratings yet

- New Fatigue Life and DUrability Analysis MethodDocument7 pagesNew Fatigue Life and DUrability Analysis MethodFandy SipataNo ratings yet

- 02.06b Ch6 PPT SlidesDocument58 pages02.06b Ch6 PPT SlidesFandy SipataNo ratings yet

- Technical Datasheet Moulded Rubber FendersDocument1 pageTechnical Datasheet Moulded Rubber FendersFandy SipataNo ratings yet

- Concrete - Example SpecificationDocument9 pagesConcrete - Example SpecificationArash KamranNo ratings yet

- Stability of Floating BodiesDocument2 pagesStability of Floating BodiesMarc Dared CagaoanNo ratings yet

- Technical Datasheet Moulded Rubber FendersDocument1 pageTechnical Datasheet Moulded Rubber FendersFandy SipataNo ratings yet

- Water: Modeling of Hydrodynamics and Dilution in Coastal WatersDocument17 pagesWater: Modeling of Hydrodynamics and Dilution in Coastal WatersFandy SipataNo ratings yet

- 20160323010442-C50E (Ck50)Document2 pages20160323010442-C50E (Ck50)novkovic1984No ratings yet

- 15 Explosion Calculations Sup1 SiDocument3 pages15 Explosion Calculations Sup1 Sigharavii2063No ratings yet

- Stress Strain Rubber FenderDocument17 pagesStress Strain Rubber FenderFandy SipataNo ratings yet

- Summary of Main Changes For Applicators and SpecifiersDocument20 pagesSummary of Main Changes For Applicators and Specifiersمحمد مقلدNo ratings yet

- Service, Capability and ExperienceDocument12 pagesService, Capability and ExperienceFandy SipataNo ratings yet

- Bitushield: Field of ApplicationDocument2 pagesBitushield: Field of ApplicationFandy SipataNo ratings yet

- Register Pechiko 8ADocument1 pageRegister Pechiko 8AFandy SipataNo ratings yet

- Introduction To Reproduction PDFDocument8 pagesIntroduction To Reproduction PDFLmssvNo ratings yet

- Stokerchapter25lipidmetabolism 160320032037Document29 pagesStokerchapter25lipidmetabolism 160320032037Dawlat SalamaNo ratings yet

- Cateora2ce IM Ch012Document9 pagesCateora2ce IM Ch012Priya ShiniNo ratings yet

- Present Arlypon VPCDocument1 pagePresent Arlypon VPCErcan Ateş100% (1)

- Lecture 20Document10 pagesLecture 20bilal5202050No ratings yet

- Israel StandardDocument15 pagesIsrael StandardDũng Bùi Đức100% (1)

- Celly BoostbkDocument15 pagesCelly BoostbknomikabNo ratings yet

- Resource Access ControlDocument19 pagesResource Access Controlusamadar707No ratings yet

- Under Pass Wing Wall (4.1m)Document12 pagesUnder Pass Wing Wall (4.1m)Naveed NazNo ratings yet

- Age ProblemDocument31 pagesAge ProblemKenny CantilaNo ratings yet

- Deva Surya - 19MF02Document30 pagesDeva Surya - 19MF02SaravananNo ratings yet

- Solomon On Sex - Avoiding Marital Disaster: February 12, 2012Document14 pagesSolomon On Sex - Avoiding Marital Disaster: February 12, 2012baimareanNo ratings yet

- Feature Writing EnglishDocument2 pagesFeature Writing EnglishAldren BababooeyNo ratings yet

- ScheduleDocument1 pageScheduleparag7676No ratings yet

- Fantasy AGE - Spell SheetDocument2 pagesFantasy AGE - Spell SheetpacalypseNo ratings yet

- EY Enhanced Oil RecoveryDocument24 pagesEY Enhanced Oil RecoveryDario Pederiva100% (1)

- Art and Geography: Patterns in The HimalayaDocument30 pagesArt and Geography: Patterns in The HimalayaBen WilliamsNo ratings yet

- ScilabDocument4 pagesScilabAngeloLorenzoSalvadorTamayoNo ratings yet

- 520L0586 MMF044Document48 pages520L0586 MMF044vendas servicosNo ratings yet

- EET - Formulas - Christmas TermDocument3 pagesEET - Formulas - Christmas TermJMDNo ratings yet

- Transfer Case Electrical RMDocument51 pagesTransfer Case Electrical RMDaniel Canales75% (4)

- 1 Introduction To Microsoft VirtualizationDocument36 pages1 Introduction To Microsoft VirtualizationRavinder KantNo ratings yet

- 1 Name of Work:-Improvement of Epum Road (Northern Side) Connecting With Imphal-Saikul Road I/c Pucca DrainDocument1 page1 Name of Work:-Improvement of Epum Road (Northern Side) Connecting With Imphal-Saikul Road I/c Pucca DrainHemam PrasantaNo ratings yet

- Med Chem Exam 2Document24 pagesMed Chem Exam 2cNo ratings yet

- Microsoft Word - IRN Fab Transfer PCN NoticeDocument22 pagesMicrosoft Word - IRN Fab Transfer PCN NoticeJadilson PradoNo ratings yet

- Tamil NaduDocument64 pagesTamil Nadushanpaga priyaNo ratings yet

- BHLP Year Long Plan Required English Medium 2023 24 Batch Final 991676721629413Document3 pagesBHLP Year Long Plan Required English Medium 2023 24 Batch Final 991676721629413A V GamingNo ratings yet

- CAT25256 EEPROM Serial 256-Kb SPI: DescriptionDocument22 pagesCAT25256 EEPROM Serial 256-Kb SPI: DescriptionPolinho DonacimentoNo ratings yet

- InTech-Batteries Charging Systems For Electric and Plug in Hybrid Electric VehiclesDocument20 pagesInTech-Batteries Charging Systems For Electric and Plug in Hybrid Electric VehiclesM VetriselviNo ratings yet

- FENA-01 - 11 - 21 - Ethernet Adapter - User's Manual - Rev BDocument388 pagesFENA-01 - 11 - 21 - Ethernet Adapter - User's Manual - Rev BQUOC LENo ratings yet