Professional Documents

Culture Documents

Inconel 601 Weld Neck WN Forged Flange 300LB 300# ASME B16.5

Uploaded by

Yilia WangCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inconel 601 Weld Neck WN Forged Flange 300LB 300# ASME B16.5

Uploaded by

Yilia WangCopyright:

Available Formats

METALS PIPING - HEBEI METALS INDUSTRIAL LIMITED

SHIJIAZHUANG, CHINA

ADD:A2303 WANHAO MANSION, NO.176 ZHONGHUA SOUTH STREET I TEL:+86-311-89642206 I FAX:+86-311-67906676 I WEB: WWW.METALSPIPING.COM

Inconel 601 WELD NECK FORGED FLANGE 300LB ASME B16.5

Inconel 601/UNS N06601/W. Nr. 2.4851 is a nickel-chromium alloy. It has a high mechanical strength

and good resistance to oxidation and other high temperature corrosion. It is widely used for heat-treating

equipment, such as: trays, baskets, muffles, retorts, petrochemical processing equipment, gas turbine

components.

1. Chemical Composition of Inconel 601 WN Flange.

Nickel Cr Fe Al C Mn S Si Cu

58.0-63.0 21.0-25.0 Remainder 1.0-1.7 0.10 1.0 0.015 0.50 1.0

2. Mechanical Properties for W.N Flange Inconel 601

T.S min. Y.S min. Elongation, min

ksi(Mpa) ksi(Mpa) %

80(550) 30(205) 30

3. Dimensions for Weld Neck Flange Inconel 601

METALS PIPING - HEBEI METALS INDUSTRIAL LIMITED

SHIJIAZHUANG, CHINA

ADD:A2303 WANHAO MANSION, NO.176 ZHONGHUA SOUTH STREET I TEL:+86-311-89642206 I FAX:+86-311-67906676 I WEB: WWW.METALSPIPING.COM

Nom. O.D D J b h a m g Drilling Template Kg.

Size mm. mm. mm. mm. mm. mm. mm. mm. Number l k approx.

mm. mm.

1/2 21.3 95.2 15.7 14.2 52.3 21.3 38.1 35.0 4 15.7 66.5 0.75

3/4 26.7 117.3 20.8 15.7 57.1 26.7 47.7 42.9 4 19.0 82.5 1.26

1 33.4 123.9 26.7 17.5 62.0 33.5 53.8 50.8 4 19.0 88.9 1.52

1 1/4 42.2 133.3 35.1 19.0 65.0 42.2 63.5 63.5 4 19.0 98.5 2.03

1 1/2 48.3 155.4 40.9 20.6 68.3 48.3 69.8 73.2 4 22.3 114.3 2.89

2 60.3 165.1 52.6 22.3 69.8 60.5 84.0 91.9 8 19.0 127.0 3.40

2 1/2 73.0 190.5 62.7 25.4 76.2 73.2 100.0 104.6 8 22.3 149.3 5.17

3 88.9 209.5 78.0 28.4 79.2 88.9 117.3 127.0 8 22.3 168.1 6.93

3 1/2 101.6 228.6 90.2 30.2 81.0 101.6 133.3 139.7 8 22.3 184.1 8.67

4 114.3 254.0 102.4 31.7 85.8 114.3 146.0 157.2 8 22.3 200.1 11.2

5 141.3 279.4 128.3 35.0 98.5 141.2 177.8 185.6 8 22.3 234.9 15.1

6 168.3 317.5 154.2 36.5 98.5 168.4 206.2 215.9 12 22.3 269.7 19.1

8 219.1 381.0 202.7 41.1 111.2 219.2 260.3 269.7 12 25.4 330.2 29.9

10 273 444.5 254.5 47.7 117.3 273.1 320.5 323.8 16 28.4 387.3 42.7

12 323.8 520.7 304.8 50.8 130.0 323.8 374.6 381.0 16 31.7 450.8 61.8

Nom. O.D D J b h a m g Drilling Template Pounds

Size in. in. in. in. in. in. in. in. Number l k approx.

in. in.

1/2 0.84 3.75 0.62 0.56 2.06 0.84 1.50 1.38 4 0.62 2.62 1.7

3/4 1.05 4.62 0.82 0.62 2.25 1.05 1.88 1.69 4 0.75 3.25 2.8

1 1.315 4.88 1.05 0.69 2.44 1.32 2.12 2.00 4 0.75 3.50 3.5

1 1/4 1.66 5.25 1.38 0.75 2.56 1.66 2.50 2.50 4 0.75 3.88 4.5

1 1/2 1.90 6.12 1.61 0.81 2.69 1.90 2.75 2.88 4 0.88 4.50 6.4

2 2.375 6.50 2.07 0.88 2.75 2.38 3.31 3.62 8 0.75 5.00 7.5

2 1/2 2.875 7.50 2.47 1.00 3.00 2.88 3.94 4.12 8 0.88 5.88 11.4

3 3.50 8.25 3.07 1.12 3.12 3.50 4.62 5.00 8 0.88 6.62 15.3

3 1/2 4.00 9.00 3.55 1.19 3.19 4.00 5.25 5.50 8 0.88 7.25 19.1

4 4.50 10.00 4.03 1.25 3.38 4.50 5.75 6.19 8 0.88 7.88 24.7

5 5.563 11.00 5.05 1.38 3.88 5.56 7.00 7.31 8 0.88 9.25 33.3

6 6.625 12.50 6.07 1.44 3.88 6.63 8.12 8.50 12 0.88 10.62 42.4

8 8.625 15.00 7.98 1.62 4.38 8.63 10.25 10.62 12 1.00 13.00 65.9

10 10.75 17.50 10.02 1.88 4.62 10.75 12.62 12.75 16 1.12 15.25 94.1

12 12.75 20.50 12.00 2.00 5.12 12.75 14.75 15.00 16 1.25 17.75 136

4. Our Informations:

Sales@metalspiping.com

Contact Person: Yilia Wang

Website: www.metalspiping.com

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- A516A516M-17 Standard Specification Pressure Vessel PlatesDocument2 pagesA516A516M-17 Standard Specification Pressure Vessel PlatesYilia Wang100% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- A350A350M-2018 Grade LF1, LF2, LF3, LF5, LF6, LF9, LF787Document6 pagesA350A350M-2018 Grade LF1, LF2, LF3, LF5, LF6, LF9, LF787Yilia WangNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- ASTM A105 Material Properties Asme b16.5 - Shijiazhuang Metalsin Pipeline Tech Co., LTDDocument5 pagesASTM A105 Material Properties Asme b16.5 - Shijiazhuang Metalsin Pipeline Tech Co., LTDYilia WangNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Incoloy 800 Thread Flange 300LB 300# ASME B16.5Document2 pagesIncoloy 800 Thread Flange 300LB 300# ASME B16.5Yilia WangNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hastelloy C276 Lap Joint Flange 900LB 900# CLASS900Document2 pagesHastelloy C276 Lap Joint Flange 900LB 900# CLASS900Yilia WangNo ratings yet

- Inconel 600 Blind Flange BF 600LB 600# CLASS600Document2 pagesInconel 600 Blind Flange BF 600LB 600# CLASS600Yilia WangNo ratings yet

- Nickel 201 Slip On Forged Flange SO Flange 300LB Class300Document2 pagesNickel 201 Slip On Forged Flange SO Flange 300LB Class300Yilia WangNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

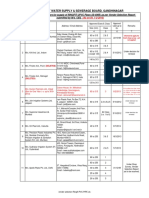

- GWSSB Vendor List 19.11.2013Document18 pagesGWSSB Vendor List 19.11.2013sivesh_rathiNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Marine Lubricants Equivalents List: Sae 50 TBN 57 Sae 50 TBN 55 Sae 40 TBN 60 Sae 50 TBN 50 Sae 50 TBN 55Document3 pagesMarine Lubricants Equivalents List: Sae 50 TBN 57 Sae 50 TBN 55 Sae 40 TBN 60 Sae 50 TBN 50 Sae 50 TBN 55spyros_peiraiasNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Comparative Tracking Index of Electrical Insulating MaterialsDocument6 pagesComparative Tracking Index of Electrical Insulating MaterialsAbu Anas M.SalaheldinNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Opc PDFDocument20 pagesOpc PDFnirajNo ratings yet

- Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282 Subcontract N°: JI-2045/07-002BDocument15 pagesAin Tsila Development Main EPC Contract A-CNT-CON-000-00282 Subcontract N°: JI-2045/07-002BAslaouiNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Engine Maintenance PartsDocument13 pagesEngine Maintenance PartsSerkanAl100% (1)

- Concept of Circulation in A Free Vortex FlowDocument55 pagesConcept of Circulation in A Free Vortex FlowAnil KumarNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Braun KF40 - CDocument17 pagesBraun KF40 - CAgung UtoyoNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- 85GDocument4 pages85GBeny StephenNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Ball Mill SizingDocument10 pagesBall Mill Sizingvvananth100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Feasibility Study of Solar Photovoltaic (PV) Energy Systems For Rural Villages of Ethiopian Somali Region (A Case Study of Jigjiga Zone)Document7 pagesFeasibility Study of Solar Photovoltaic (PV) Energy Systems For Rural Villages of Ethiopian Somali Region (A Case Study of Jigjiga Zone)ollata kalanoNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- SemDocument31 pagesSemkaushik4208No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 2 Coagulation FlocculationDocument26 pages2 Coagulation FlocculationNurSyuhada ANo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- VLE Lactic Acid Ethyl Lactate Esterification PDFDocument7 pagesVLE Lactic Acid Ethyl Lactate Esterification PDFAseem Kashyap0% (1)

- Online Order Processing SystemDocument34 pagesOnline Order Processing SystemMuhammad ShujaNo ratings yet

- AI in RobotsDocument75 pagesAI in RobotsIslam SehsahNo ratings yet

- Efficia Infant WarmingDocument8 pagesEfficia Infant WarmingNurhidayat MursalinNo ratings yet

- Selenium-75 Sources and Source Holders: ApplicationsDocument2 pagesSelenium-75 Sources and Source Holders: ApplicationsTanpreet SinghNo ratings yet

- The Difference Between The Internet and World Wide WebDocument3 pagesThe Difference Between The Internet and World Wide WebSonal Jain100% (1)

- Structured ProgrammingDocument31 pagesStructured ProgrammingkakaboomNo ratings yet

- Skytrain Avia Services: Emergency Procedures ManualDocument32 pagesSkytrain Avia Services: Emergency Procedures ManualEndro RastadiNo ratings yet

- Materials Today: Proceedings: Avula Suresh, T. Nancharaiah, Ravikumar Dumpala, B. Ratna SunilDocument5 pagesMaterials Today: Proceedings: Avula Suresh, T. Nancharaiah, Ravikumar Dumpala, B. Ratna SunilBart MaxNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- IBM System Storage DS8000 - A QuickDocument10 pagesIBM System Storage DS8000 - A Quickmuruggan_aNo ratings yet

- Riscv SpecDocument32 pagesRiscv SpeckartimidNo ratings yet

- PG 511 B 1 B 1: Ordering Code Series PGP/PGM511Document7 pagesPG 511 B 1 B 1: Ordering Code Series PGP/PGM511Four SticksNo ratings yet

- 2013 11 DUPLEX EasyDocument21 pages2013 11 DUPLEX EasyAnonymous HC0tWeNo ratings yet

- 8J Summary SheetDocument2 pages8J Summary Sheet박찬우No ratings yet

- Elevator Traffic Analysis - Passanger Elevators Option-1Document5 pagesElevator Traffic Analysis - Passanger Elevators Option-1Amit GuptaNo ratings yet

- HighpuritysealsDocument6 pagesHighpuritysealstuannhocutNo ratings yet

- HARGA REFERENSI B2S PapuaDocument6 pagesHARGA REFERENSI B2S PapuaAbiyoga AdhityaNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)