Professional Documents

Culture Documents

T15u PDF

Uploaded by

joseocsilvaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

T15u PDF

Uploaded by

joseocsilvaCopyright:

Available Formats

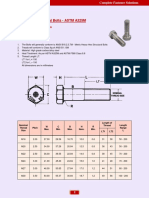

M ARYLAND METRI C S

P.O.Box 261 Owings Mills, MD 21117 USA

(410)358-3130 (800)638-1830 Faxes: (410)358-3142 (800)872-9329

http://mdmetric.com techinfo@mdmetric.com

TECHNICAL INFORMATION and DATA

Mechanical properties of bolts, screws, and studs

according DIN-ISO 898, part 1

Property class

Property (at 20 C) 3.6 4.6 4.8 5.6 5.8 6.8 8.8 1) 9.8 3) 10.9 12.9

"d >

M 16 M 16 2)

Tensile strength, nominal 300 400 500 600 800 800 900 1000 1200

Rm4), 5), N/mm2 min. 330 400 420 500 520 600 800 830 900 1040 1220

Vickers hardness min. 95 120 130 155 160 190 250 255 290 320 385

max. 220 (250 at the screw end) 250 320 335 360 380 435

HV, F $ 98 N

Brinell hardness min. 90 114 124 147 152 181 238 242 276 304 366

max. 209 (238 at the screw end) 238 304 318 342 361 414

HB, F = 30 D2

Rockwell hardness min. HRB 52 67 71 79 82 89

min. HRC 22 23 28 32 39

HR

max. HRB 95,0 (99,5 at the screw end) 99,5

max. HRC 32 34 37 39 44

Surface hardness, HV 0,3 see foot note 6)

Lower yield stress, Rel 7), N/mm2 nominal 180 240 320 300 400 480

min. 190 240 340 300 420 480

Stress at 0,2% non-proportional nominal 640 640 720 900 1080

elongation,

Rp 0,2, in N/mm2 min. 640 660 720 940 1100

Stress ratio Sp /ReL or 0,94 0,94 0,91 0,93 0,90 0,92 0,91 0,91 0,90 0,88 0,88

Sp /Rp 0,2

Stress under proof load Sp N/mm2 180 225 310 280 380 440 580 600 650 830 970

Elongation after fracture, A min. % 25 22 20 12 12 10 9 8

Reduction of area after fracture min. % 52 52 48 48 44

Strength under wedge loading 5) The values for full size bolts and screws (not studs) shall not be smaller than the minimum

values for tensile strength.

Impact strength, J min. 25 30 30 25 20 15

Head soundness no fracture

1 2 3

Minimum height of non-decarburized thread zone, E /2 H 1 /3 H 1 /4 H 1

Maximum depth of mm 0,015

complete decarburization, G

1

) For bolts of property class 8.8 in diameters d 16 mm, there is an increased risk of nut stripping in the case of inadvertent over-tightening

inducing a load in excess of proof load. Reference to ISO 898-2 is recommended..

2

) For structural bolting the limit is 12 mm.

3

) Property class 9.8 applies only to nominal thread diameters d 16 mm.

4

) Minimum tensile properties apply to products of nominal length 1 2,5 d. Minimum hardness applies to products of length 1< 2,5 and

other products which cannot be tensile-tested (e.g. due to head configuration.)

6) Surface hardness shall not be more than 30 Vickers points above the measured core hardness on the product when

readings of both surface and core are carried out at HV 0,3. For property class 10.9, any increase in hardness at the

surface which indicates that the surface hardness exceeds 390 HV is not acceptable.

7) In

cases where the lower yield stress ReL cannot be determined, it is permissible to measure the stress at 0,2% non-

proportional elongation R 0.2

ver dd11j

T 15

You might also like

- Hydrostatic Test ReportDocument1 pageHydrostatic Test ReportKashan Khan33% (3)

- 0 - Aws Welding Symbol Chart Final PDFDocument1 page0 - Aws Welding Symbol Chart Final PDFjoseocsilvaNo ratings yet

- K Value of FittingsDocument4 pagesK Value of FittingsJoydip Misra100% (6)

- tcvn1916-1995 VI enDocument16 pagestcvn1916-1995 VI enMohamad SaquibNo ratings yet

- Geomembrane HDPE Smooth Black PDFDocument1 pageGeomembrane HDPE Smooth Black PDFandriarisetiawan0% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- KNOWLEDGE FOR A BRIGHTER FUTURE: GUIDE TO NICKEL ALLOYS IN SULPHURIC ACIDDocument12 pagesKNOWLEDGE FOR A BRIGHTER FUTURE: GUIDE TO NICKEL ALLOYS IN SULPHURIC ACIDjoseocsilvaNo ratings yet

- Flans Chen Prospekt EngDocument2 pagesFlans Chen Prospekt Englorenzinho290No ratings yet

- Flans Chen Prospekt EngDocument2 pagesFlans Chen Prospekt Englorenzinho290No ratings yet

- ISO898 For Bolts Screws&studsDocument1 pageISO898 For Bolts Screws&studskostadinovNo ratings yet

- Bolt GradeDocument1 pageBolt Grademrprabhu16No ratings yet

- Fabory Fasteners Mechanical SpecDocument10 pagesFabory Fasteners Mechanical SpecGilang Bhisma100% (1)

- Screw CharacteristicsDocument18 pagesScrew CharacteristicsJaokNo ratings yet

- 024 - Mechanical Properties of Fasteners Made of Carbon Steel and Alloy Steel PDFDocument1 page024 - Mechanical Properties of Fasteners Made of Carbon Steel and Alloy Steel PDFRonak RanaNo ratings yet

- Mechanical Properties of Fasteners Made of Carbon Steel and Alloy SteelDocument1 pageMechanical Properties of Fasteners Made of Carbon Steel and Alloy SteelVarun KumarNo ratings yet

- Mechanical and physical properties of materialsDocument1 pageMechanical and physical properties of materialspawkomNo ratings yet

- Masterseries Sample Output: Moment CapacityDocument1 pageMasterseries Sample Output: Moment CapacitysillywildfoxNo ratings yet

- ISO - 898-1-2009 - 04 Edicion - Propiedades PernoDocument1 pageISO - 898-1-2009 - 04 Edicion - Propiedades PernoCarlos PanccaNo ratings yet

- Ico PlainDocument2 pagesIco PlainHafiani HichamNo ratings yet

- General Information: 2.1. ConcreteDocument3 pagesGeneral Information: 2.1. ConcreteGeloNo ratings yet

- Cromax 280X: Hard Chrome BarDocument4 pagesCromax 280X: Hard Chrome BarpeterNo ratings yet

- Steel Bars For Concrete Reinforcement Specification: Physical PropertiesDocument1 pageSteel Bars For Concrete Reinforcement Specification: Physical PropertiesALCAV Construction Materials Testing CenterNo ratings yet

- Ficha Técnica Film Paleizador - Walter LundDocument1 pageFicha Técnica Film Paleizador - Walter LundWalter LundNo ratings yet

- TDC 09 - R1 - S690 QL & Weldox 700Document2 pagesTDC 09 - R1 - S690 QL & Weldox 700Thennarasu VelloreNo ratings yet

- Austempered Ductile Iron Offers Superior Strength, Toughness & DurabilityDocument14 pagesAustempered Ductile Iron Offers Superior Strength, Toughness & DurabilitylucianoNo ratings yet

- 07a. MR MDF TECHNICAL DATADocument2 pages07a. MR MDF TECHNICAL DATAsacdawoodNo ratings yet

- En 15048 - Iso 4014Document2 pagesEn 15048 - Iso 4014Angelo VieitoNo ratings yet

- NonPre Hex 4.6 Bolts Eurocode3 1 - 27 - 2020Document8 pagesNonPre Hex 4.6 Bolts Eurocode3 1 - 27 - 2020Alden CayagaNo ratings yet

- Etd44 PDFDocument5 pagesEtd44 PDFChAmirShokatGujjarNo ratings yet

- Ico ExDocument2 pagesIco ExHafiani HichamNo ratings yet

- Beam DesignDocument2 pagesBeam DesignBilal A BarbhuiyaNo ratings yet

- PC3 QmaxDocument1 pagePC3 QmaxCuong TranNo ratings yet

- S355J2+N Steel PlateDocument2 pagesS355J2+N Steel PlateAmanNo ratings yet

- Yemchio Transparente PDFDocument1 pageYemchio Transparente PDFSantiago López AlarcónNo ratings yet

- Yemchio Transparente PDFDocument1 pageYemchio Transparente PDFSantiago López AlarcónNo ratings yet

- Hes D3211-99a Mechnical Properties of Steel Bolts and ScreDocument12 pagesHes D3211-99a Mechnical Properties of Steel Bolts and ScrePreetam KumarNo ratings yet

- LM6 Aluminum Casting Alloy Chemical Composition Properties ApplicationsDocument3 pagesLM6 Aluminum Casting Alloy Chemical Composition Properties ApplicationsSohail ShaikhNo ratings yet

- Staircase Design RevDocument65 pagesStaircase Design RevYUVARAJ SAMPATHNo ratings yet

- Flexural Crack Width-Water Retaning StructuresDocument2 pagesFlexural Crack Width-Water Retaning StructureskkgcNo ratings yet

- Spheroidal GraphiteDocument1 pageSpheroidal GraphiteS.Mohana sundaramNo ratings yet

- P-tec Corp. PL320 Series 3mm LED Panel Mount Metal HolderDocument1 pageP-tec Corp. PL320 Series 3mm LED Panel Mount Metal HolderJajang JajaNo ratings yet

- Typical DC Bias Performance: 110 Delta Drive Pittsburgh, PA 15238 NAFTA Sales: (1) 800-245-3984 HK Sales: (852) 3102-9337Document1 pageTypical DC Bias Performance: 110 Delta Drive Pittsburgh, PA 15238 NAFTA Sales: (1) 800-245-3984 HK Sales: (852) 3102-9337JithuNo ratings yet

- Stainless Steel 1.4401 Material Data SheetDocument3 pagesStainless Steel 1.4401 Material Data SheetLuis LoayzaNo ratings yet

- CDA 84400 phosphor bronze alloy propertiesDocument4 pagesCDA 84400 phosphor bronze alloy propertiesShariq KhanNo ratings yet

- GB2 - Pump Room - 13NOV2013Document3 pagesGB2 - Pump Room - 13NOV2013Erickson MalicsiNo ratings yet

- Uk 506 - Fita GuiaDocument5 pagesUk 506 - Fita GuiaAlessandro OliveiraNo ratings yet

- Sandvik 22.8.3.L Welding Wire DatasheetDocument3 pagesSandvik 22.8.3.L Welding Wire DatasheetbhuvandesignNo ratings yet

- Heavy Hex Structural Bolts - ASTM A325M: Metric Series - DimensionsDocument2 pagesHeavy Hex Structural Bolts - ASTM A325M: Metric Series - DimensionsSuresh BabuNo ratings yet

- Astm A325 Grade 8.8 PDFDocument2 pagesAstm A325 Grade 8.8 PDFWisnu AjiNo ratings yet

- Heavy Hex Structural Bolts - ASTM A325M: Metric Series - DimensionsDocument2 pagesHeavy Hex Structural Bolts - ASTM A325M: Metric Series - Dimensionskptl6185No ratings yet

- Product Specification BS-4449Document2 pagesProduct Specification BS-4449Cyprian Cypu100% (2)

- F1SOLIDREBARDocument1 pageF1SOLIDREBARÖzgün BıçakNo ratings yet

- Raft Slab Design For Head Works of Magui Khola Irrigation Project, Madi ChitwanDocument2 pagesRaft Slab Design For Head Works of Magui Khola Irrigation Project, Madi ChitwanMohammedNo ratings yet

- Corbel Design With Angle LimitDocument2 pagesCorbel Design With Angle LimitFrederick TanNo ratings yet

- PHLAudio - Bass 20cm-8inchDocument1 pagePHLAudio - Bass 20cm-8inchRoberto richardsenNo ratings yet

- Steel Conv Belt - 1800-ST2250-8+6 FR-LRR-TKIL-NK ProjectDocument1 pageSteel Conv Belt - 1800-ST2250-8+6 FR-LRR-TKIL-NK ProjectCaspian DattaNo ratings yet

- Annealed Engineering Steel C45E / 1042 (ASTMDocument2 pagesAnnealed Engineering Steel C45E / 1042 (ASTMkazdoelahNo ratings yet

- Strands Area and Their Specifications PDFDocument2 pagesStrands Area and Their Specifications PDFLamin AungNo ratings yet

- Voestalpine Heavy Plate Datasheet Durostat en 20170904Document3 pagesVoestalpine Heavy Plate Datasheet Durostat en 20170904Kristy HillNo ratings yet

- Adi 4 (2021 - 03 - 22 20 - 48 - 50 Utc)Document2 pagesAdi 4 (2021 - 03 - 22 20 - 48 - 50 Utc)Milton Pereira JúniorNo ratings yet

- Test Parameter Comparison 29mm Thick Sparkling White Granite SR# Parameter UnitDocument3 pagesTest Parameter Comparison 29mm Thick Sparkling White Granite SR# Parameter UnitAfzal ChaudhryNo ratings yet

- 4.3 Design of Girder and Beam 4.3.1 Design of B1Document38 pages4.3 Design of Girder and Beam 4.3.1 Design of B1vijay kumar yadavNo ratings yet

- ColmonoyNews - Properties of Colmonoy 88 Fused Thermal Spray Coatings - Dec10-SPDocument3 pagesColmonoyNews - Properties of Colmonoy 88 Fused Thermal Spray Coatings - Dec10-SPjoseocsilvaNo ratings yet

- Astm A53Document2 pagesAstm A53joseocsilvaNo ratings yet

- Wall Colmonoy - Properties of Hard Surfacing Alloy Colmonoy 88 - July 2019Document8 pagesWall Colmonoy - Properties of Hard Surfacing Alloy Colmonoy 88 - July 2019joseocsilvaNo ratings yet

- ColmonoyNews The Importance of Hardness Testing 07092020Document4 pagesColmonoyNews The Importance of Hardness Testing 07092020joseocsilvaNo ratings yet

- 20160323110402-11SMnPb30 (9SMnPb28) PDFDocument1 page20160323110402-11SMnPb30 (9SMnPb28) PDFjoseocsilvaNo ratings yet

- Tabela de Conversao de Unidades PDFDocument6 pagesTabela de Conversao de Unidades PDFjoseocsilvaNo ratings yet

- Difference between ASTM A320 L7 and L43 boltsDocument3 pagesDifference between ASTM A320 L7 and L43 boltsjoseocsilvaNo ratings yet

- Wall Colmonoy - Properties of Hard Surfacing Alloy Colmonoy 88 - July 2019Document8 pagesWall Colmonoy - Properties of Hard Surfacing Alloy Colmonoy 88 - July 2019joseocsilvaNo ratings yet

- ColmonoyNews The Importance of Hardness Testing 07092020Document4 pagesColmonoyNews The Importance of Hardness Testing 07092020joseocsilvaNo ratings yet

- Data Sheet: Mounting Kits According To DIN EN 15081Document2 pagesData Sheet: Mounting Kits According To DIN EN 15081joseocsilvaNo ratings yet

- Louvretec Design Manual Section 7 300mm AirfoilDocument10 pagesLouvretec Design Manual Section 7 300mm AirfoiljoseocsilvaNo ratings yet

- DIN3015 - PART1 - Clamps Standard Series PDFDocument29 pagesDIN3015 - PART1 - Clamps Standard Series PDFSergio SacristanNo ratings yet

- A1W6RHBS00X 1: Scale Sheet No Doc Number Title Ver NoDocument2 pagesA1W6RHBS00X 1: Scale Sheet No Doc Number Title Ver NojoseocsilvaNo ratings yet

- Understanding Welding Symbols Terms and DefinitionsDocument23 pagesUnderstanding Welding Symbols Terms and DefinitionsseymaNo ratings yet

- Pneumatic Actuators: Omal Actuator FeaturesDocument2 pagesPneumatic Actuators: Omal Actuator FeaturesjoseocsilvaNo ratings yet

- XS8C1A1MAL2 inductive sensor product data sheetDocument5 pagesXS8C1A1MAL2 inductive sensor product data sheetjoseocsilvaNo ratings yet

- Astm A 53 BDocument4 pagesAstm A 53 BLauren BowenNo ratings yet

- Deva - BM ENDocument24 pagesDeva - BM ENOscar CruzNo ratings yet

- 20160323110402-11SMnPb30 (9SMnPb28) PDFDocument1 page20160323110402-11SMnPb30 (9SMnPb28) PDFjoseocsilvaNo ratings yet

- Hazen Williams EquationDocument1 pageHazen Williams Equationanil4u29No ratings yet

- Handbok Fittings Eng Web-211217 PDFDocument72 pagesHandbok Fittings Eng Web-211217 PDFjoseocsilvaNo ratings yet

- Handbok Fittings Eng Web-211217 PDFDocument72 pagesHandbok Fittings Eng Web-211217 PDFjoseocsilvaNo ratings yet

- Garlock Compression Packing Catalog CMP4 41 PDFDocument34 pagesGarlock Compression Packing Catalog CMP4 41 PDFMartin Andrew TugadeNo ratings yet

- What Are Bolt Torque Considerations For Valve Packing That Ensure Reliable PerformanceDocument4 pagesWhat Are Bolt Torque Considerations For Valve Packing That Ensure Reliable PerformancejoseocsilvaNo ratings yet

- Tabela de LigasDocument2 pagesTabela de LigasjoseocsilvaNo ratings yet

- SameerDocument10 pagesSameerkiswah computersNo ratings yet

- PHYS 20 - Chapter 4 - Work, Energy and PowerDocument22 pagesPHYS 20 - Chapter 4 - Work, Energy and PowerbuicoandrieNo ratings yet

- Thermodynamics 1 LectureDocument57 pagesThermodynamics 1 LecturefabyunaaaNo ratings yet

- Design and Analysis of Gearless Transmission Through Elbow MechanismDocument7 pagesDesign and Analysis of Gearless Transmission Through Elbow MechanismAung Khin ZawNo ratings yet

- Task of Thermodynamics EngineeringDocument10 pagesTask of Thermodynamics EngineeringDimas SetiawanNo ratings yet

- Thermal Properties and Heat Transfer of Acetamide/Expanded Graphite Composite PCMDocument9 pagesThermal Properties and Heat Transfer of Acetamide/Expanded Graphite Composite PCMAnanthesh RaoNo ratings yet

- Lec 2 Theories of Failure (Dr. M.M.abdelkader)Document13 pagesLec 2 Theories of Failure (Dr. M.M.abdelkader)Ahmed AlyNo ratings yet

- Gases and Other Properties: Lesson 5Document7 pagesGases and Other Properties: Lesson 5lucifer angelNo ratings yet

- Thermal Ratcheting of A BeamDocument33 pagesThermal Ratcheting of A Beammilan44No ratings yet

- Fanno Flow PDFDocument20 pagesFanno Flow PDFZain EejazNo ratings yet

- Design of Vertical Gas-Liquid SeparatorDocument13 pagesDesign of Vertical Gas-Liquid SeparatorAli AhsanNo ratings yet

- Thermodynamic Laws & Phase TransitionsTITLE Assignment 1: Thermodynamic ProblemsTITLE Temperature Measurement DevicesDocument2 pagesThermodynamic Laws & Phase TransitionsTITLE Assignment 1: Thermodynamic ProblemsTITLE Temperature Measurement DevicesSAUMYA MUNDRANo ratings yet

- Radiation Heat Transfer FundamentalsDocument15 pagesRadiation Heat Transfer FundamentalsJade Carlo AntonioNo ratings yet

- 00 Introduction To Geotechnical Engineering 2020Document22 pages00 Introduction To Geotechnical Engineering 2020reprano PNo ratings yet

- Manual Sy235c EscavadeiraDocument10 pagesManual Sy235c EscavadeiraSandro Frias0% (1)

- API 571 Damage MechanismsDocument16 pagesAPI 571 Damage MechanismsTahseen Jwad100% (1)

- Formation and Stabilization of Rock Cavern Roof ArchesDocument6 pagesFormation and Stabilization of Rock Cavern Roof Archesdafo407No ratings yet

- Hashemian Hashem M 201105 PHD DatatablesDocument46 pagesHashemian Hashem M 201105 PHD DatatablesSebastián CandeiasNo ratings yet

- 46 - The Thermal Efficiency Improvement of A Steam Rankine Cycle by Innovative Design of A Hybrid Cooling Tower and A Solar Chimney ConceptDocument1 page46 - The Thermal Efficiency Improvement of A Steam Rankine Cycle by Innovative Design of A Hybrid Cooling Tower and A Solar Chimney ConceptNachiket LohkareNo ratings yet

- TM.P. S.p.A. Pump Performance CurvesDocument1 pageTM.P. S.p.A. Pump Performance CurvesSiddiqui Muhammad AshfaqueNo ratings yet

- HW3 SolnDocument5 pagesHW3 SolnNaury N OliveiraNo ratings yet

- Static Calculation CWDocument64 pagesStatic Calculation CWlayaljamal2100% (1)

- Venturi MeterDocument8 pagesVenturi MeterSwati SachanNo ratings yet

- Api682 Iso21049 John Crane General CommentsDocument62 pagesApi682 Iso21049 John Crane General CommentsMixtli Garcia100% (4)

- 2 - 2020-01 - Specification - Rev I - ENDocument33 pages2 - 2020-01 - Specification - Rev I - ENiyakushev1101No ratings yet

- Refrigeration Combustion ReviewerDocument5 pagesRefrigeration Combustion ReviewerSir COCNo ratings yet

- Concrete BasementsDocument184 pagesConcrete BasementsMohan BhalmeNo ratings yet

- Friction FactorDocument6 pagesFriction Factorrajeshsapkota123No ratings yet

- Thermodynamics Applications in Chemical Engineering and the Petroleum IndustryDocument406 pagesThermodynamics Applications in Chemical Engineering and the Petroleum Industryphantanthanh100% (2)