Professional Documents

Culture Documents

QW484

Uploaded by

Anonymous 4e7GNjzGWCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QW484

Uploaded by

Anonymous 4e7GNjzGWCopyright:

Available Formats

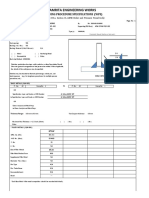

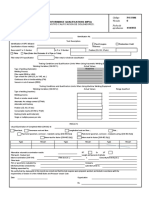

WELDER QUALIFICATION RECORD Date:

Welder's Name: SS# Stamp #:

Welding Process(es) Utilized: Type:

Welding Procedure Identification # Utlized by Welder for Qualification: .

Base Material(s) Welded: Thickness:

Manual or Semiatuomatic Variables for Each Process (QW-350) Actual Values Range Qualified

Backing (metal, weld metal, welded from both sides, flux, etc. (QW-402)

ASME P-No. to ASME P-No. (QW-403)

( ) Plate ( ) Pipe (enter diameter if pipe)

Filler metal specification (SFA): Classification (QW-404)

Filler metal F- No.:

Consumable insert for GTAW or PAW:

Weld deposit thickness for each welding process

Welding position ( 1G, 5G, etc.) (QW-405)

Welding progression (uphill/downhill)

Backing gas fro GTAW, PAW, or GMAW; fuel gas for OFW (QW-408)

GMAW transfer mode (QW-409)

GTAW welding current type/polarity

Machine Welding Variable for the Process Used (QW-360) Actual Values Range Qualified

Direct / remote visual control

Automatic voltage control (GTAW)

Automatic joint tracking

Welding position (1G, 5G, etc.)

Consumable insert

Backing (metal, weld metal, welded from both sides, flux, etc.)

Guided Bend Test Results

Guided Bend Tests Type ( ) QW-462.2 (Side) Results ( ) QW-462.3a. (Trans. R&F) Type ( ) QW-462.3b (Long, R&F) Results

Type Mandrel Dia. (mm) Bend Angel Result

Visual examination results (QW-302.4)

Radiographic test results (QW-304 and QW-305)

(For alternative qualification of groove welds by radiography)

Fillet Weld - Facture test Length & percent of defects in.

Macro Test Fusion Fillet leg size in.

Welding Test Conducted By:

Mechanical Tests Conducted By:

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and

tested in accordance with requirements of Section IX of the ASME Code.

Organization:

By:

344468605.xls WQR Blank

You might also like

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 3.5 out of 5 stars3.5/5 (7)

- Excel Construction Project Management Templates Construction Budget TemplateDocument19 pagesExcel Construction Project Management Templates Construction Budget TemplateAnonymous 4e7GNjzGW100% (3)

- Hydrostatic Test (Log) : Quality Control FormDocument22 pagesHydrostatic Test (Log) : Quality Control FormAnonymous 4e7GNjzGWNo ratings yet

- Right To Resist Unlawful ArrestDocument1 pageRight To Resist Unlawful ArrestThoth AtlanteanNo ratings yet

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Planer Vs Non Planer DefectsDocument2 pagesPlaner Vs Non Planer DefectsSavad Alwye75% (8)

- Airfix 2011 CatalogueDocument132 pagesAirfix 2011 CatalogueGordon Sorensen0% (1)

- PQR FormatDocument2 pagesPQR Formatravi0009880% (5)

- MCQs on Defence Audit Code Chapter 9 and 10Document2 pagesMCQs on Defence Audit Code Chapter 9 and 10Rustam SalamNo ratings yet

- Fireproofing Check List Quality Control and Inspection Report FormDocument1 pageFireproofing Check List Quality Control and Inspection Report FormAnonymous 4e7GNjzGWNo ratings yet

- Fireproofing Check List Quality Control and Inspection Report FormDocument1 pageFireproofing Check List Quality Control and Inspection Report FormAnonymous 4e7GNjzGWNo ratings yet

- Ab-076a Welder Qualification Record WQRDocument1 pageAb-076a Welder Qualification Record WQRAhmed Shaban KotbNo ratings yet

- 2010 SECTION IX WPS FORMATDocument5 pages2010 SECTION IX WPS FORMATAjay ChodankarNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDocument12 pagesSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWNo ratings yet

- CEMEX Global Strategy CaseDocument4 pagesCEMEX Global Strategy CaseSaif Ul Islam100% (1)

- LOGOS ENGINEERING WELDING PROCEDURE SPECIFICATIONDocument5 pagesLOGOS ENGINEERING WELDING PROCEDURE SPECIFICATIONKAMALNo ratings yet

- Hand Over Notes SampleDocument3 pagesHand Over Notes SampleRosa Amri60% (5)

- Kafou Health Safety Loss Prevention ProgramDocument117 pagesKafou Health Safety Loss Prevention ProgramAnonymous 4e7GNjzGWNo ratings yet

- ASTM Reference RadiographsDocument3 pagesASTM Reference RadiographsAkbar ShaikNo ratings yet

- QW-482 (WPS) GTAW 4MM FilletDocument4 pagesQW-482 (WPS) GTAW 4MM FilletBalkishan DyavanapellyNo ratings yet

- Zaranda Finlay 684 Manual Parts CatalogDocument405 pagesZaranda Finlay 684 Manual Parts CatalogRicky Vil100% (2)

- PQRDocument2 pagesPQRSreenivas Kamachi Chettiar100% (1)

- 6 Acop v. OmbudsmanDocument1 page6 Acop v. OmbudsmanChester Santos SoniegaNo ratings yet

- Saudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-W-2026 31-Aug-11 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-W-2026 31-Aug-11 WeldAnonymous 4e7GNjzGW100% (1)

- WPQ Format - SMAWDocument3 pagesWPQ Format - SMAWBalkishan DyavanapellyNo ratings yet

- Welding Defect - MACRO PDFDocument5 pagesWelding Defect - MACRO PDFAnonymous 4e7GNjzGWNo ratings yet

- WPQ WeldCanada PDFDocument1 pageWPQ WeldCanada PDFAhmad DanielNo ratings yet

- Ey Blockchain Innovation Wealth Asset ManagementDocument16 pagesEy Blockchain Innovation Wealth Asset ManagementmichaeleslamiNo ratings yet

- Summer Training Report On HCLDocument60 pagesSummer Training Report On HCLAshwani BhallaNo ratings yet

- Qw-484B Format For Welding Operator Performance Qualifications (Wopq) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document7 pagesQw-484B Format For Welding Operator Performance Qualifications (Wopq) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Gerardo Arispe AramayoNo ratings yet

- Ab-076a Welder Qualification Record WQRDocument1 pageAb-076a Welder Qualification Record WQRvinodNo ratings yet

- Welder Certificate Sample1Document1 pageWelder Certificate Sample1Buddy EkoNo ratings yet

- Welder's Performancequalification (WPQ) FormDocument1 pageWelder's Performancequalification (WPQ) FormTegar OktoberNo ratings yet

- Welder's Performancequalification (WPQ) FormDocument1 pageWelder's Performancequalification (WPQ) FormAbhinandan BastiNo ratings yet

- Qw-483 Procedure Qualification Record (PQR) : SECTION IX, ASME Boiler and Pressure Vessel CodeDocument4 pagesQw-483 Procedure Qualification Record (PQR) : SECTION IX, ASME Boiler and Pressure Vessel Codesreejithr86No ratings yet

- WOPQ Form English1Document2 pagesWOPQ Form English1oaperuchenaNo ratings yet

- PQR FormatDocument2 pagesPQR FormatBE GNo ratings yet

- Test Description (Information Only)Document2 pagesTest Description (Information Only)dayalramNo ratings yet

- QW484BDocument1 pageQW484BMohamed Ahmed MaherNo ratings yet

- FORM QW-484B WELDING OPERATOR QUALIFICATIONSDocument1 pageFORM QW-484B WELDING OPERATOR QUALIFICATIONSKautiilaNo ratings yet

- Procedure Qualification RecordDocument6 pagesProcedure Qualification RecordGaurang PandyaNo ratings yet

- DQR Project Quality Control Form for Welder PerformanceDocument1 pageDQR Project Quality Control Form for Welder PerformanceminhnnNo ratings yet

- Standard Welding Procedure Specification Demonstration FormDocument1 pageStandard Welding Procedure Specification Demonstration FormEmma DNo ratings yet

- WPQ Format Sec IxDocument2 pagesWPQ Format Sec IxParminder SinghNo ratings yet

- ASME BPVC Sec IX 2023 - Demonstration FormDocument1 pageASME BPVC Sec IX 2023 - Demonstration Formmr.bakhtiari.mahmoudNo ratings yet

- WQT 1236Document1 pageWQT 1236mir31721No ratings yet

- FORM QW-484A WELDER PERFORMANCE QUALIFICATIONSDocument1 pageFORM QW-484A WELDER PERFORMANCE QUALIFICATIONSJose Elian Cuellar PinzónNo ratings yet

- FORM QW-484A WELDER PERFORMANCE QUALIFICATIONSDocument1 pageFORM QW-484A WELDER PERFORMANCE QUALIFICATIONSJose Elian Cuellar PinzónNo ratings yet

- Welders Performance Qualification Record (WPQ) : Welder Name Identification No. Test DescriptionDocument8 pagesWelders Performance Qualification Record (WPQ) : Welder Name Identification No. Test DescriptionGerardo Arispe AramayoNo ratings yet

- Record of Welder or Welding Operator Qualification Test: Welders's Name: Stamp No.: WQT No.Document1 pageRecord of Welder or Welding Operator Qualification Test: Welders's Name: Stamp No.: WQT No.Weld Bro SandeepNo ratings yet

- FORM QW-484A WELDER PERFORMANCE QUALIFICATIONSDocument1 pageFORM QW-484A WELDER PERFORMANCE QUALIFICATIONSAlesol EquipmentNo ratings yet

- WPQ 2Document1 pageWPQ 2FirozNo ratings yet

- SWATHI PQR Procedure QualificationDocument10 pagesSWATHI PQR Procedure QualificationMustu AkolawalaNo ratings yet

- Form Qw-484B Suggested Format B For Welding Operator Performance Qualifications (Wopq) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageForm Qw-484B Suggested Format B For Welding Operator Performance Qualifications (Wopq) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)viswamanojNo ratings yet

- Welder Qualification FormatDocument1 pageWelder Qualification FormatScribdTranslationsNo ratings yet

- Wps FormatDocument2 pagesWps FormatParminder SinghNo ratings yet

- QW483Document2 pagesQW483Sc TanNo ratings yet

- FO 3310d Welding Performance Qualifications (WPQ) : Registro Calificacion de SoldadoresDocument4 pagesFO 3310d Welding Performance Qualifications (WPQ) : Registro Calificacion de SoldadoresRodolfoNo ratings yet

- Format For Manufacturer Record of Welding Operator QualificationDocument1 pageFormat For Manufacturer Record of Welding Operator QualificationRajeev KumarNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKAnonymous Ij6VfaNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- Sample WPS Format PDFDocument1 pageSample WPS Format PDFait.koufiNo ratings yet

- Base Metals (Qw-403) Postweld Heat Treatment (Qw-407)Document2 pagesBase Metals (Qw-403) Postweld Heat Treatment (Qw-407)beyNo ratings yet

- WPQ SUGGESTED FORMAT A FOR WELDER PERFORMANCE QUALIFICATIONSDocument1 pageWPQ SUGGESTED FORMAT A FOR WELDER PERFORMANCE QUALIFICATIONSMohamed Ahmed MaherNo ratings yet

- Interactive Form QW-485 PDFDocument1 pageInteractive Form QW-485 PDFRama Krishna Reddy DonthireddyNo ratings yet

- Eslam Abdelhameed Asme Ix IdDocument1 pageEslam Abdelhameed Asme Ix Idel_sharkawy2011No ratings yet

- WPQRDocument1 pageWPQRShani MalikNo ratings yet

- WPQ Welder Performance QualificationsDocument1 pageWPQ Welder Performance Qualificationsjoshrathburn1980No ratings yet

- JOINTS (QW-402) : Groove Design of Test CouponDocument2 pagesJOINTS (QW-402) : Groove Design of Test CouponbeyNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- QW-483 PQR PROCEDURE QUALIFICATION RECORDDocument6 pagesQW-483 PQR PROCEDURE QUALIFICATION RECORDZam Zam NoorNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- A-Mtl-Pro-730-38931 Rev A Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessDocument4 pagesA-Mtl-Pro-730-38931 Rev A Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessRamzi ZoghlamiNo ratings yet

- EPC Main Contract for Column Pipe Welding ProcedureDocument4 pagesEPC Main Contract for Column Pipe Welding ProcedureRamzi ZoghlamiNo ratings yet

- Welder Certificate Akilesh YadavDocument1 pageWelder Certificate Akilesh Yadavtripatipankaj023No ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- Name Name Name Name: To: CCDocument1 pageName Name Name Name: To: CCAnonymous 4e7GNjzGWNo ratings yet

- Store JDDocument2 pagesStore JDdhasdjNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWNo ratings yet

- Welder and Welder Operator Qualification Record Form PDFDocument1 pageWelder and Welder Operator Qualification Record Form PDFAnonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechDocument1 pageSaudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechAnonymous 4e7GNjzGWNo ratings yet

- Welding Procedure Specification Form PDFDocument2 pagesWelding Procedure Specification Form PDFAnonymous 4e7GNjzGWNo ratings yet

- 1234 TranslateDocument1 page1234 TranslateAnonymous 4e7GNjzGWNo ratings yet

- Weld Joint Preparation Weld Joint PreparationDocument1 pageWeld Joint Preparation Weld Joint PreparationAnonymous 4e7GNjzGWNo ratings yet

- Maintenance ManagementDocument22 pagesMaintenance ManagementMANISH_64No ratings yet

- BrochureDocument2 pagesBrochureAnonymous 4e7GNjzGWNo ratings yet

- SA STD - SpecificationDocument10 pagesSA STD - SpecificationAnonymous 4e7GNjzGWNo ratings yet

- Warrior Tech Spare Parts List 2 PDFDocument1 pageWarrior Tech Spare Parts List 2 PDFAnonymous 4e7GNjzGWNo ratings yet

- Shielded Metal Arc Welding (Smaw / "Stick") Shielded Metal Arc Welding (Smaw / Â Œstickâ )Document2 pagesShielded Metal Arc Welding (Smaw / "Stick") Shielded Metal Arc Welding (Smaw / Â Œstickâ )Anonymous 4e7GNjzGWNo ratings yet

- Change in B31.3 2016 PDFDocument2 pagesChange in B31.3 2016 PDFAnonymous 4e7GNjzGWNo ratings yet

- First We InvestigatedDocument1 pageFirst We InvestigatedAnonymous 4e7GNjzGWNo ratings yet

- Warrior Tech Spare Parts List 2Document1 pageWarrior Tech Spare Parts List 2Anonymous 4e7GNjzGWNo ratings yet

- Organisation ChartDocument1 pageOrganisation ChartAnonymous 4e7GNjzGWNo ratings yet

- Bio Data-01.07.13Document2 pagesBio Data-01.07.13Anonymous 4e7GNjzGWNo ratings yet

- Numbering Format: Project DocumentationDocument1 pageNumbering Format: Project DocumentationAnonymous 4e7GNjzGWNo ratings yet

- Fac Contracts Pre-Q - Quest Attachments - 2!8!2017 V002Document28 pagesFac Contracts Pre-Q - Quest Attachments - 2!8!2017 V002Anonymous 4e7GNjzGWNo ratings yet

- UE Capability Information (UL-DCCH) - Part2Document51 pagesUE Capability Information (UL-DCCH) - Part2AhmedNo ratings yet

- VectorsDocument9 pagesVectorsdam_allen85No ratings yet

- SM 2021 MBA Assignment Forecasting InstructionsDocument3 pagesSM 2021 MBA Assignment Forecasting InstructionsAmit Anand KumarNo ratings yet

- Makerere University: Office of The Academic RegistrarDocument2 pagesMakerere University: Office of The Academic RegistrarOPETO ISAACNo ratings yet

- Chilled Beam SystemsDocument3 pagesChilled Beam SystemsIppiNo ratings yet

- National Income Practice QuestionsDocument29 pagesNational Income Practice QuestionsSujalNo ratings yet

- BS 00011-2015Document24 pagesBS 00011-2015fazyroshan100% (1)

- Payment Solutions For Travel Platform: SabreDocument2 pagesPayment Solutions For Travel Platform: Sabrehell nahNo ratings yet

- QA InspectionDocument4 pagesQA Inspectionapi-77180770No ratings yet

- Mom Luby and The Social WorkerDocument1 pageMom Luby and The Social WorkerqtissskrazyNo ratings yet

- Offer Letter - Kunal Saxena (Gurgaon)Document5 pagesOffer Letter - Kunal Saxena (Gurgaon)Neelesh PandeyNo ratings yet

- COA (Odoo Egypt)Document8 pagesCOA (Odoo Egypt)menams2010No ratings yet

- 22 Caltex Philippines, Inc. vs. Commission On Audit, 208 SCRA 726, May 08, 1992Document36 pages22 Caltex Philippines, Inc. vs. Commission On Audit, 208 SCRA 726, May 08, 1992milkteaNo ratings yet

- Thesis Submission Certificate FormatDocument6 pagesThesis Submission Certificate Formatmichellespragueplano100% (3)

- Offer Letter For Marketing ExecutivesDocument2 pagesOffer Letter For Marketing ExecutivesRahul SinghNo ratings yet

- Engineering Ethics in Practice ShorterDocument79 pagesEngineering Ethics in Practice ShorterPrashanta NaikNo ratings yet

- Sierra Wireless firmware versions for cellular modulesDocument20 pagesSierra Wireless firmware versions for cellular modulesjacobbowserNo ratings yet

- Assignment # 4 26 CH 22Document6 pagesAssignment # 4 26 CH 22Ibrahim AbdallahNo ratings yet

- Superelement Modeling-Based Dynamic Analysis of Vehicle Body StructuresDocument7 pagesSuperelement Modeling-Based Dynamic Analysis of Vehicle Body StructuresDavid C HouserNo ratings yet

- Restaurant P&L ReportDocument4 pagesRestaurant P&L Reportnqobizitha giyaniNo ratings yet

- CSCE 3110 Data Structures and Algorithms NotesDocument19 pagesCSCE 3110 Data Structures and Algorithms NotesAbdul SattarNo ratings yet