Professional Documents

Culture Documents

Design of Flat Head For Hydrotest

Uploaded by

SAGAROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Flat Head For Hydrotest

Uploaded by

SAGARCopyright:

Available Formats

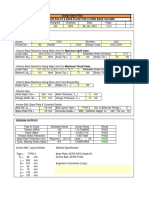

Eqpt :- C -52710

Item |:- Phenol Area Emergency Relief Scrubber

Project :- Saudi Kayan Petro Chemical complex Phenolics Facilities

Customer :- Technicas Reunidas

DESIGN OF FLAT COVER HEAD

P

Dt

t

Tt

C

Tc

N

a

b

h

St

Sc

Design Pressure

I. D Of shell

Shell Thickness

Flat Plate Thickness

Corrosion Allowance

Corroded Thickness

No. of Stiffeners

Pitch Between Stiffeners

Stiffener Width

Stiffener Height

Stiffener Thickness

Stiffener Thickness (Corroded)

( T-Tc)

(St- Sc)

Material

Yield Stress of Top Plate @ Design Temp.,

116

217

53.5

60

0

60

2

100

100

80

25

25

Mpa ( N/ mm)

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

Sy

SA 36

250

Mpa

Rho

7750.4

Kg/m3

Young's Modullus @ Design Temp.,

1.95E+05

N/mm2

Design Pressure Head

116.000

N/mm2

Density of Top Plate

Bending Stress Calculation

Allowable Bending Stress

Sb

0.6 x Sy

N/mm2

Sb

150

N/mm2

Eqpt :- C -52710

Item |:- Phenol Area Emergency Relief Scrubber

Project :- Saudi Kayan Petro Chemical complex Phenolics Facilities

Customer :- Technicas Reunidas

DESIGN OF FLAT COVER HEAD

Stiffeners are used above Top Plate as shown in Fig. 1

Spacing

a=b

100

mm

Design Calculation for Unstayed Flat heads & covers

As per ASME - Section Vii -div 1 - UG -34 (c) (3)

( Assuming that the stifener provided

at650 pitch is unstayed flat head of Square section)

Maximum allowable stress Value at given temp

Diameter or Short span

Diameter or Long span

thickness provide

Corrosion allowance

Miimum thickness ( tp - ca)

Type of unstayed Flat heads & cover

Stay factors

Joint efficiency

Factors for Non Circular Head

Thickness required

S

d

D

tp

ca

t

C

E

Z

Z

T

114.457

217

217

60

0

60

WELDED

0.33

0.7

= 3.4 - ( 2.4 d / D )

1

Mpa (N/mm)

mm

mm

mm

mm

mm

= d*Sqrt(ZCP/SE)

149.99

mm

Thickness provided is 60 more than 149.99 hence safe

REF ROARK'S FORMULA FOR STRESS & STRAIN BY WARREN C. YOUNG, TABLE 11.4, CASE 1

For Simply Supported Uniformly Distributed Load Over Entire Plate and a/b = 1

0.67

=

0.14

=

=

( x P x b2 / (Tc2)

215.9

Allowable Bending Stress

Sb

Induced Stress is Less than the Allowable Stress

150

Si < Sb

HENCE SAFE

Deflection

=

=

x P x b4 / (E x Tc3)

0.04

Induced Bending Stress

Si

As per TEMA, Eight Edition , the flat cover deflection for larger size diameter (larger than 24")

should be less than 0.125 % of Nominal diameter of flat Cover.

less than 0.125 % of Nominal diameter of flat Cover.

Allowable Deflection

=

Dt x 0.00125

mm

0.27125

mm

Induced Deflection is within the Allowable Limit, So Provided Thickness of

60

mm is Safe

Eqpt :- C -52710

Item |:- Phenol Area Emergency Relief Scrubber

Project :- Saudi Kayan Petro Chemical complex Phenolics Facilities

Customer :- Technicas Reunidas

DESIGN OF FLAT COVER HEAD

Stiffener Design

3.142 x Dt2 x P/4

=

=

420859

N

Since 4 Nos. Stiffeners are placed as shown in drg. The Load assumed to be shared evenly

Max. Length of Stiffeners

Le

=

413

mm

Total Length of Stiffneres

L

=

826

mm

Total Load on Stiffeners

Wt

Assume that Stiffener is under Uniformly Distributed Load and Simply Supported

So Uniformly Distributed Load

We

Wt/L

509.514

N/mm

N.m

N.m

Bending Moment

=

=

We x Le2/8

10863416

Required Section Modulus,Z

Zr

M/Sb

72422.8

Provided

Section Modulus calculation

No Of Stiffener Provided

Stiffeners Provided at pitch of

2 nos

100 mm

Y

60

X

80

50

50

25

100.0

Top Plate thickness, mm =

Stiffener Thickness,mm =

Stiffener Width, mm =

Effective plate Thk , mm =

Y

60

25

80

24

Area Propertied About X-X axis

Part

1

2

A

1450.0

4000

5450

y

30

100

SAy

43501

400000

###

Neutral axis= SAy /A =

81.38

Y

51.4

100.0

SAY2

3827980.1

40000000.0

43827980

SIcg

1800000

1066667

2866667

mm

Total moment of inertia Ixx= SIcg+SAY2

= 2866667 + 43827980

= 46694647 mm4

Minimum section Modulus ,Zxx= Ixx / N.Amax

= 46694647 / MAX ( 81.38 , 60+80-81.38 )

= 46694647 / 81.38

= 573785

mm3

mm3

Eqpt :- C -52710

Item |:- Phenol Area Emergency Relief Scrubber

Project :- Saudi Kayan Petro Chemical complex Phenolics Facilities

Customer :- Technicas Reunidas

DESIGN OF FLAT COVER HEAD

Required Section Modulus,Z

Zr

M/Sb

mm3

=

72422.8

Since Provided Section Modulus 573785 Is greater than required section modulus 72422.77 hence this is safe

Item |:- Phenol Area Emergency Relief Scrubber

Eqpt :- C -52710

Project :- Saudi Kayan Petro Chemical complex Phenolics Facilities

Customer :- Technicas Reunidas

DESIGN OF FLAT COVER HEAD

DERIVATION OF WELD STRESS

Check for Fillet Size

Shell O.D

324

Shell Thk

53.5

Weld size

reqd

0.7 x shell thk

37.45

Weld size

provided

42

where

Yield Stress Sy=

250

mpa

k=

0.9

for fillet welds

=

1

=

1.2

Force acting on welds

F=

Bending Stress

S1 =

Shear Stress

P x d2 x 0.785

4287924.34

Fr *103/(*R2(0.7tw)

1768.96

N/mm2

S2 =

Fr/(*R(0.7t))

286.57

N/mm2

Resultant Shear Stress

S=

( S12 + S22)0.5

1792.02

N/mm2

Capacity of weld

Sc =

k(Sy+455)

793.125

N/mm2

(2xx)1/3

The reultant stress in fillet welds 1792.02 Mpa is less than capacity of wld stress 793.125 Mpa

Mpa ( N/ mm)

Mpa (N/mm)

N/mm2

N/mm2

N/mm2

mm

mm

mm is Safe

s 72422.77 hence this is safe

s 793.125 Mpa

You might also like

- Boiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFDocument4 pagesBoiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFAlexandru AsmarandeiNo ratings yet

- WRC-107 Nozzles (PVElite)Document5 pagesWRC-107 Nozzles (PVElite)Alvin SmithNo ratings yet

- Tailing LugDocument12 pagesTailing LuguvarajmecheriNo ratings yet

- Cover Plate CalculationDocument1 pageCover Plate CalculationSachin5586No ratings yet

- Trunnion AnalysisDocument45 pagesTrunnion AnalysisChiragJansariNo ratings yet

- Design of Circular Flat Endplate With Stiffeners - Boiler and Pressure Vessel Engineering - Eng-TipsDocument2 pagesDesign of Circular Flat Endplate With Stiffeners - Boiler and Pressure Vessel Engineering - Eng-Tipsisrar khanNo ratings yet

- Davit Arm CalculationDocument4 pagesDavit Arm Calculationjoeriji0% (1)

- Square Blind Flange With Stiffener ULDocument5 pagesSquare Blind Flange With Stiffener ULjoeriji100% (1)

- Davit CalcDocument6 pagesDavit Calcrustamriyadi100% (1)

- Flat Head Calculation (Based On Ug 34)Document2 pagesFlat Head Calculation (Based On Ug 34)rustamriyadiNo ratings yet

- Structural TrunnionDocument4 pagesStructural TrunnionecsalomNo ratings yet

- Flange Pad CalcsDocument4 pagesFlange Pad CalcstomNo ratings yet

- Blind Flange With StiffenersDocument4 pagesBlind Flange With Stiffenersshahid khan100% (1)

- Saddle Road Transportation Analysis 1Document2 pagesSaddle Road Transportation Analysis 1vpjagannaathNo ratings yet

- Vessel lifting lug design data and stress analysisDocument3 pagesVessel lifting lug design data and stress analysismiteshpatel191100% (1)

- Base Ring Fillet Size CalculationDocument4 pagesBase Ring Fillet Size Calculationmiteshpatel191No ratings yet

- Anchor Flange Design CalculationDocument6 pagesAnchor Flange Design CalculationJohakim974No ratings yet

- Saddle Stresses On Shell During Transportation: Equipment NoDocument5 pagesSaddle Stresses On Shell During Transportation: Equipment NoshazanNo ratings yet

- Round Attachment Cylindrical Shell AnalysisDocument9 pagesRound Attachment Cylindrical Shell AnalysisakisdassasNo ratings yet

- Lifting Lug CalculationsDocument1 pageLifting Lug CalculationsshazanNo ratings yet

- Saddle CalculationDocument10 pagesSaddle Calculationpharis_chrisNo ratings yet

- Engineering Design of Lifting LugsDocument1 pageEngineering Design of Lifting LugsadammzjinNo ratings yet

- Flat Plate - Roark & YoungDocument15 pagesFlat Plate - Roark & YoungPrasad Pingle0% (1)

- N-318-5 Lug Local StressDocument3 pagesN-318-5 Lug Local StresscohenfuNo ratings yet

- BlindDocument3 pagesBlindSajal KulshresthaNo ratings yet

- Manhole DavitDocument2 pagesManhole DavitgaratetaNo ratings yet

- Nozzle Reinf Calc (Rough)Document12 pagesNozzle Reinf Calc (Rough)Sajal Kulshrestha100% (1)

- Padeye Calculation LatestDocument10 pagesPadeye Calculation LatestPavan RayNo ratings yet

- Blind Flange Design Calculations - by Abdel Halim GalalaDocument6 pagesBlind Flange Design Calculations - by Abdel Halim GalalaNirmalraj Manoharan67% (3)

- WRC 297Document9 pagesWRC 297akisdassas100% (1)

- Lifting Lug TutorialDocument20 pagesLifting Lug Tutorialmontie3No ratings yet

- Horizontal Vessel Stress AnalysisDocument12 pagesHorizontal Vessel Stress AnalysissridharNo ratings yet

- Modification Thickness of A FlangeDocument3 pagesModification Thickness of A FlangePeter PerezNo ratings yet

- Lug Design (XLS)Document4 pagesLug Design (XLS)Bhartendu Patni100% (1)

- Pd5500 Flange CalculationDocument6 pagesPd5500 Flange CalculationMakrand SakpalNo ratings yet

- Lifting Trunnion AnalysisDocument1 pageLifting Trunnion Analysisprajwal86No ratings yet

- Sight Glass Flange AnalysisDocument4 pagesSight Glass Flange AnalysisOmil Rastogi0% (2)

- Stress at Junction of Shell & HeadDocument13 pagesStress at Junction of Shell & HeadRey Fiedacan100% (1)

- ASME V111 Div2 APP 3 Flanges Stress Calculation in ExcelDocument16 pagesASME V111 Div2 APP 3 Flanges Stress Calculation in ExcelPanya Purahong100% (1)

- TrunnionDocument7 pagesTrunnionRUDHRA DHANASEKAR100% (1)

- Total Middle East New Bitumen Terminal in TlbuDocument25 pagesTotal Middle East New Bitumen Terminal in TlbuAnupam Jana100% (2)

- Design of anchor bolts and base plate for a fixed base columnDocument4 pagesDesign of anchor bolts and base plate for a fixed base columnSuryaSinghNo ratings yet

- SPAN Calc.Document48 pagesSPAN Calc.yoi_123No ratings yet

- Design As Per APIDocument82 pagesDesign As Per APINeeraj BhallaNo ratings yet

- Two Way Slab DesignDocument9 pagesTwo Way Slab DesignChan Kin Cheung100% (1)

- Typ-Base PlateDocument11 pagesTyp-Base PlateManoj Jaiswal100% (2)

- Premium TankDocument26 pagesPremium TankAnonymous p0iwBoNo ratings yet

- BS - FF SlabDocument7 pagesBS - FF SlabAnonymous YDwBCtsNo ratings yet

- API 650 Storage Tank Design CalculationDocument14 pagesAPI 650 Storage Tank Design CalculationMohammed EljammalNo ratings yet

- Storage Tank Design Calculation - Api 650: Close Floating RoofDocument31 pagesStorage Tank Design Calculation - Api 650: Close Floating RoofNguyễn Duy HưngNo ratings yet

- Design of Rolling Stock Maintanance Shed - Roof Final ReviewDocument29 pagesDesign of Rolling Stock Maintanance Shed - Roof Final ReviewKrishnan ChockalingamNo ratings yet

- Trafo Found DesignDocument6 pagesTrafo Found DesignIrshad Khan100% (1)

- Tank Calc - Api650Document90 pagesTank Calc - Api650kamleshyadavmoney100% (3)

- Ba Culvertf TestDocument16 pagesBa Culvertf TestsanjuktaacharyyaNo ratings yet

- 2.column Base Plate (Fixed Type)Document15 pages2.column Base Plate (Fixed Type)ZevanyaRolandTualakaNo ratings yet

- Section VIII CalDocument21 pagesSection VIII CalRuben Samoel Barros RochaNo ratings yet

- PilecapDesign-ISCODE FINALDocument3 pagesPilecapDesign-ISCODE FINALAnonymous FHmGcSA8No ratings yet

- OHSRDocument48 pagesOHSRsachingadage100% (2)

- Wind Load Calculation for 6.5m High BuildingDocument98 pagesWind Load Calculation for 6.5m High BuildingAnonymous HJ7hmihhNo ratings yet

- Japanese BeamDocument2 pagesJapanese BeamSAGARNo ratings yet

- Japanese H Sections PDFDocument2 pagesJapanese H Sections PDFSAGARNo ratings yet

- JD - Engineer Mechanical Design - 1409Document1 pageJD - Engineer Mechanical Design - 1409SAGARNo ratings yet

- Tenses TableDocument5 pagesTenses Tableapi-314670535No ratings yet

- Tenses TableDocument5 pagesTenses Tableapi-314670535No ratings yet

- VEFV1100 - Vessel S&T Heat Exchanger Standard DetailsDocument39 pagesVEFV1100 - Vessel S&T Heat Exchanger Standard DetailsYogi YuganNo ratings yet

- Salary Increase ModelDocument1 pageSalary Increase ModelJasmineVeenaNo ratings yet

- English tenses past perfect guideDocument3 pagesEnglish tenses past perfect guidepura2030No ratings yet

- Lug Support DesignDocument3 pagesLug Support DesignSajal KulshresthaNo ratings yet

- Leave Report of Sakir PDFDocument1 pageLeave Report of Sakir PDFSAGARNo ratings yet

- Field Joint Samples ProvidedDocument11 pagesField Joint Samples ProvidedSAGARNo ratings yet

- Leave Report of Sakir PDFDocument1 pageLeave Report of Sakir PDFSAGARNo ratings yet

- FMS - Materials (1008,1009)Document157 pagesFMS - Materials (1008,1009)SAGARNo ratings yet

- Memorator MatematicaDocument1 pageMemorator MatematicaȘtefan LefterNo ratings yet

- Lug Support DesignDocument3 pagesLug Support DesignSajal KulshresthaNo ratings yet

- Lug Support DesignDocument3 pagesLug Support DesignSajal KulshresthaNo ratings yet

- Category of RadiographyDocument9 pagesCategory of RadiographySAGARNo ratings yet

- Inlet Flow For Out Breathing: Total Pump in m3/hr 20Document9 pagesInlet Flow For Out Breathing: Total Pump in m3/hr 20sonaldivNo ratings yet

- VEFV1100 - Vessel S&T Heat Exchanger Standard DetailsDocument39 pagesVEFV1100 - Vessel S&T Heat Exchanger Standard DetailsYogi YuganNo ratings yet

- Reducer Spool PDFDocument13 pagesReducer Spool PDFSAGARNo ratings yet

- Design of Flat Head For HydrotestDocument12 pagesDesign of Flat Head For HydrotestSAGAR100% (1)

- Anchore Bolt Root AreaDocument1 pageAnchore Bolt Root AreaSAGARNo ratings yet

- Comparison of API-650 To AWWA D-100Document1 pageComparison of API-650 To AWWA D-100SAGARNo ratings yet

- EC1-4 Wind Actions OverviewDocument78 pagesEC1-4 Wind Actions OverviewLeutrim AvdiuNo ratings yet

- Frangible Roof To Shell JointDocument1 pageFrangible Roof To Shell JointSAGARNo ratings yet

- Allowable Nozzle Load Calculation PDFDocument5 pagesAllowable Nozzle Load Calculation PDFSAGARNo ratings yet

- 13 Venting Requirements PDFDocument4 pages13 Venting Requirements PDFAngel LugoNo ratings yet

- Inlet Flow For Out Breathing: Total Pump in m3/hr 20Document9 pagesInlet Flow For Out Breathing: Total Pump in m3/hr 20sonaldivNo ratings yet

- VEFV3100Document19 pagesVEFV3100adolfocienfuegosNo ratings yet

- Reducer Spool PDFDocument13 pagesReducer Spool PDFSAGARNo ratings yet

- 07 SurfaceTension 2022 2023 v1Document28 pages07 SurfaceTension 2022 2023 v1Sema KurdNo ratings yet

- Iron Carbon Equilibrum DiagramDocument11 pagesIron Carbon Equilibrum DiagramtaravindnagarajNo ratings yet

- (Springer Series in Materials Science 50) F. Ernst, W. Sigle (auth.), Prof. Dr. Frank Ernst, Prof. Dr.Dr.h.c. Manfred Rühle (eds.)-High-Resolution Imaging and Spectrometry of Materials-Springer-Verlag.pdfDocument453 pages(Springer Series in Materials Science 50) F. Ernst, W. Sigle (auth.), Prof. Dr. Frank Ernst, Prof. Dr.Dr.h.c. Manfred Rühle (eds.)-High-Resolution Imaging and Spectrometry of Materials-Springer-Verlag.pdframakrishna nagunuriNo ratings yet

- Strain TransformationDocument81 pagesStrain TransformationDevout PrakosoNo ratings yet

- Concrete TestsDocument2 pagesConcrete TestsdaraweereNo ratings yet

- Me185 Midterm2 Spring04Document3 pagesMe185 Midterm2 Spring04Behnam RahimiNo ratings yet

- SOM-Skill Course-1Document81 pagesSOM-Skill Course-1Rohit RanjanNo ratings yet

- Machine Design 1st Partial Equation SheetDocument2 pagesMachine Design 1st Partial Equation SheetRoberto Adrian Martinez ValverdeNo ratings yet

- Normen Englisch Stand 09 2013Document9 pagesNormen Englisch Stand 09 2013jmunjaNo ratings yet

- Deflection of Curved BarsDocument12 pagesDeflection of Curved Barsfahmie722140% (5)

- Mechanical Specifications For Fiberbond ProductDocument8 pagesMechanical Specifications For Fiberbond ProducthasnizaNo ratings yet

- Wetting and SpreadingDocument67 pagesWetting and SpreadingJorge PerezNo ratings yet

- Implementation of The Strain Gradient Plasticity With Linear Finite Elements and Reduced IntegrationDocument2 pagesImplementation of The Strain Gradient Plasticity With Linear Finite Elements and Reduced IntegrationMonir SamirNo ratings yet

- CH 3Document30 pagesCH 3dhanya1995No ratings yet

- Al321 PDFDocument10 pagesAl321 PDFJean-Noël LerouxNo ratings yet

- Contoh Second Law of ThermodynamicsDocument34 pagesContoh Second Law of ThermodynamicsBaihaqi Bahrin100% (2)

- Mechanical Properties of Metals ChapterDocument25 pagesMechanical Properties of Metals ChapterJesse McClure100% (9)

- Directions: Define The Following Terms Below. Write Your Answer Inside The BoxDocument5 pagesDirections: Define The Following Terms Below. Write Your Answer Inside The BoxLaika LaiNo ratings yet

- Design of Steel BeamsDocument4 pagesDesign of Steel BeamsSankalp LamaNo ratings yet

- Fundamentals of Friction - Macroscopic and Microscopic ProcessesDocument637 pagesFundamentals of Friction - Macroscopic and Microscopic ProcessesAditi Sen100% (1)

- Adhesive Product Guide 2017Document3 pagesAdhesive Product Guide 2017SalsabilaAzisNo ratings yet

- Journal of FerrocementDocument130 pagesJournal of FerrocementValentina Roncancio GuizaNo ratings yet

- Surfactants Emulsion PolymersDocument2 pagesSurfactants Emulsion Polymers8612106535100% (2)

- Shear Force and Bending Moment Diagrams ExplainedDocument5 pagesShear Force and Bending Moment Diagrams ExplainedravilalgeNo ratings yet

- CaC03 in HM FilmDocument4 pagesCaC03 in HM FilmgarapatiNo ratings yet

- CSWIP Question Answers PDFDocument32 pagesCSWIP Question Answers PDFAnonymous SA40GK6100% (2)

- Somaloy-3p Material-Data June 2018 2273hog PDFDocument11 pagesSomaloy-3p Material-Data June 2018 2273hog PDFvineethaNo ratings yet

- Σ = P A P Π R R Π Mm Τ = Tρ J Tρ Π D D Π Mm: = − = 168,000 N 140 − 125 = 13.5 MpaDocument2 pagesΣ = P A P Π R R Π Mm Τ = Tρ J Tρ Π D D Π Mm: = − = 168,000 N 140 − 125 = 13.5 MpaEdmil Jhon AriquesNo ratings yet

- 3.2 DeformationDocument8 pages3.2 DeformationSalmanNo ratings yet

- NDT Notes1 PDFDocument48 pagesNDT Notes1 PDFnagarajan224No ratings yet