Professional Documents

Culture Documents

Water Injection

Uploaded by

Waleed El-azab0 ratings0% found this document useful (0 votes)

159 views15 pagesWater Injection

Copyright

© © All Rights Reserved

Available Formats

PPS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentWater Injection

Copyright:

© All Rights Reserved

Available Formats

Download as PPS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

159 views15 pagesWater Injection

Uploaded by

Waleed El-azabWater Injection

Copyright:

© All Rights Reserved

Available Formats

Download as PPS, PDF, TXT or read online from Scribd

You are on page 1of 15

WATER INJECTION/FLOODING

TRAINING COURSE MODULE

PRESENTED MELCHIZEDEK ENGINEERING LIMITED

MEL CONSULTING

What you will learn

Water Injection Process

Water Treatment for Injection

Water Treatment for Re-injection

Meeting Water Quality Specification

Produced Water Treatment

Produced Water Controls

Enhanced Oil Recovery

OSHA, HSE CASE

Water Flooding Training

Program

Learn Meeting water quality specifications

Learn Injection/Re-injection Essential

Learn Protecting the Permeability of the reservoir.

Learn Developing the water drive required for

enhanced oil Recovery

Learn also Subsequently the increased production

and protection of our environment.

Learn the Safety Issues and environmental Issues

Who Should Attend?

All personnel who are involved in the operation of this

equipment.

New hire engineers.

Production foreman and supervisors

Safety management personnel.

Individuals needing a Working Knowledge of a

Dehydration Systems in a Gas Plant, will find this

class extremely valuable and very interesting.

Those who already have some experience in this area

will be provided with an enlightening supplement to

their knowledge, in regards to Water Flooding Issues

Course Outline

Principles and Operations of Water

Flooding

Water Treatment

Water content of natural gas

Purpose of Water Flooding

Water Injection Process

Water Treatment for Injection

Water Treatment for Re-injection

Meeting Water Quality Specification

Produced Water Treatment

Produced Water Controls

Enhanced Oil Recovery

OSHA, HSE CASE

Course Objective

Increased employee effectiveness.

Decreased cost of operations.

Substantial financial benefits from the program can also

be realized.

The Effectively Methodology of Water Flooding Injection &

Re-Injection

Reports from our customers have indicated a cost saving

of up to 50% due the new awareness of proper startup

procedures, operating procedures, maintenance

programs and safety awareness.

System Maintenance

Water Flooding Maintenance system

Operating the flooding system

Liquid levels for Injection

Liquid levels for re-injection

Flow Rates for Permeability of the Reservoir

Effect of variables outside their recommended ranges

Continue

New unit startup in Water Injection

Shutdown for short Maintenance

Shutdown for Corrosion Controls

System Maintenance

Preventative maintenance / operation

Communication Swifter Measures

Record keeping

Mechanical Maintenance

Corrosion Control

Troubleshooting

Knowing when there is a Water

Flooding problem

Logic to troubleshooting

Re-injection Mechanism

Injection Mechanism

Excess operating cost

10

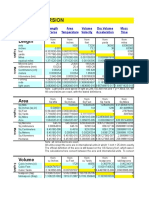

Maintaining Variable Capacity

Range

Process requirements

Treated water capacity

Suspended solids

Dissolved oxygen

Injection pressure

135,000bpd

98% removal <=2micron

<=10 ppb

126 Barg

11

Water Flooding Units

Designs formulation of a typical Water Flooding Unit Injection

Re-injection Treatment Plant.

12

Major Equipment Technique for Using

Source water solid liquid Hydro cyclones

Temporary retention pond

Surge tank

Water injection/source water manifolds at the CPF

Waterflood fine filters package

All interconnecting piping

Waterflood booster pumps

All interfaces with existing power and control

cabling

Waterflood injection pumps

Chemical injection systems

Hydrocarbon vent/flare system

Switchgear/control building

13

OUR OBJECTIVES IN PRODUCTION

TECHNIQUES

Whether you require overall project management

for complete integrated process systems or offshore

authority certification for production platforms and

floating production units, we have the engineering,

internal manufacturing JV and project management

expertise to meet your needs. And, our OEM

Partners global network of sales offices,

engineering centers and quality controlled

manufacturing facilities ensures close contact with

our us in regards to servicing Multination Oil & Gas

Companies, and expedited delivery times and

competitive pricing.

We also offer treatability testing at our state-of-theart laboratories and with our on-site pilot units. With

these services, youre assured the right equipment

for the job, designed and sized to meet your specific

application.

14

Presented By

ENGINEERING CONSULTING

To TOTALFINAELF

15

You might also like

- Advanced Water Injection for Low Permeability Reservoirs: Theory and PracticeFrom EverandAdvanced Water Injection for Low Permeability Reservoirs: Theory and PracticeRating: 4 out of 5 stars4/5 (2)

- SPE 160703 Simultaneous Well Stimulation and Scale Squeeze Treatments in Sandstone and Carbonate ReservoirsDocument21 pagesSPE 160703 Simultaneous Well Stimulation and Scale Squeeze Treatments in Sandstone and Carbonate ReservoirsJose Miguel GonzalezNo ratings yet

- OLI Course IntroductionDocument7 pagesOLI Course Introductionahad_shiraziNo ratings yet

- Microbial Enhancement of Oil Recovery - Recent AdvancesFrom EverandMicrobial Enhancement of Oil Recovery - Recent AdvancesNo ratings yet

- Water InjectionDocument62 pagesWater InjectionFlowealth100% (1)

- Reusing Produced Water (SPE White Paper) PDFDocument6 pagesReusing Produced Water (SPE White Paper) PDFMubin Ashraf Sheikh100% (1)

- Water Problems On Gas/Oil WellsDocument11 pagesWater Problems On Gas/Oil WellswillyNo ratings yet

- Treatment of EmulsionDocument7 pagesTreatment of EmulsionSaurab DevanandanNo ratings yet

- Exploiting the Digital Oilfield: 15 Requirements for Business ValueFrom EverandExploiting the Digital Oilfield: 15 Requirements for Business ValueRating: 5 out of 5 stars5/5 (1)

- 25 One Year Experience With The Injection of Nitrate To Control Souring in Bonga Deepwater Development Offshore NigeriaDocument9 pages25 One Year Experience With The Injection of Nitrate To Control Souring in Bonga Deepwater Development Offshore NigeriaCatalinaManjarresNo ratings yet

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsFrom EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNo ratings yet

- EOR Final ReportDocument60 pagesEOR Final Reportvalay_k07No ratings yet

- Carbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyFrom EverandCarbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyNo ratings yet

- 4.0 Hydrates, Wax, Asphaltenes and Chemical InjectionDocument30 pages4.0 Hydrates, Wax, Asphaltenes and Chemical InjectionJair IParraNo ratings yet

- Chemical Sand Consolidation Trials (Shell)Document33 pagesChemical Sand Consolidation Trials (Shell)Nur Syaffiqa Mohamad RuzlanNo ratings yet

- Surfactant Flooding 2020MSPET103Document49 pagesSurfactant Flooding 2020MSPET103Sunny BbaNo ratings yet

- Formation DamageDocument26 pagesFormation DamagerajneeshgogoiNo ratings yet

- Water FloodingDocument94 pagesWater FloodingOlusegun OyebanjiNo ratings yet

- Flow AssuranceDocument7 pagesFlow AssuranceMubarik AliNo ratings yet

- Petroleum: Mahdi Zeinali Hasanvand, Mohammad Ali Ahmadi, Reza Mosayebi BehbahaniDocument7 pagesPetroleum: Mahdi Zeinali Hasanvand, Mohammad Ali Ahmadi, Reza Mosayebi Behbahanimarcoesteban97No ratings yet

- Enhanced Oil Recovery - EOR-1Document16 pagesEnhanced Oil Recovery - EOR-1seb359No ratings yet

- Wax RemediationDocument3 pagesWax RemediationDonna GrayNo ratings yet

- SPE-174699-MS Dalia/Camelia Polymer Injection in Deep Offshore Field Angola Learnings and in Situ Polymer Sampling ResultsDocument18 pagesSPE-174699-MS Dalia/Camelia Polymer Injection in Deep Offshore Field Angola Learnings and in Situ Polymer Sampling ResultslimbergNo ratings yet

- Microbial Enhanced Oil Recovery (MEOR)Document26 pagesMicrobial Enhanced Oil Recovery (MEOR)MilaNo ratings yet

- 3 Production Chemistry and Flow Assurance Monday CarnianiDocument13 pages3 Production Chemistry and Flow Assurance Monday CarnianiWael BadriNo ratings yet

- SPE 53715 Microbial Enhanced Oil Recovery Pilot Test in Piedras Coloradas Field, ArgentinaDocument29 pagesSPE 53715 Microbial Enhanced Oil Recovery Pilot Test in Piedras Coloradas Field, Argentinajpsi6No ratings yet

- Phosphonate Scale Inhibitor Adsorption/Desorption and The Potential For Formation Damage in Reconditioned Field CoreDocument14 pagesPhosphonate Scale Inhibitor Adsorption/Desorption and The Potential For Formation Damage in Reconditioned Field CoreLaura Natalia SalcedoNo ratings yet

- Methods To Calculate Fluid in PlaceDocument35 pagesMethods To Calculate Fluid in PlaceMisha Arshad100% (1)

- Section 2 Reservoir CharacterizationDocument82 pagesSection 2 Reservoir CharacterizationGerardo Zambrano PerdomoNo ratings yet

- Wax Deposition ProblemDocument2 pagesWax Deposition ProblemDhea SamanthaNo ratings yet

- Spe 123072Document13 pagesSpe 123072Jose Gregorio Fariñas GagoNo ratings yet

- SRB Test InstructionsDocument1 pageSRB Test InstructionsAbie RexoMenNo ratings yet

- Control of Paraffin Deposition in Production Operations: SPE, Conoco Inc. SPE, Conoco IncDocument6 pagesControl of Paraffin Deposition in Production Operations: SPE, Conoco Inc. SPE, Conoco IncAlesa Acosta JaraNo ratings yet

- HASIL - Bottle Test Queen FixDocument3 pagesHASIL - Bottle Test Queen Fixjannes_pratamaNo ratings yet

- Enhanced Oil Recovery NewDocument12 pagesEnhanced Oil Recovery NewArvind SinghNo ratings yet

- Spe 39437 MSDocument14 pagesSpe 39437 MSAndrés Bojacá MatizNo ratings yet

- T. Santhoshini Priya PP 9024 - Enhanced Oil RecoveryDocument13 pagesT. Santhoshini Priya PP 9024 - Enhanced Oil RecoveryTruth SeekerNo ratings yet

- Enhanced Oil RecoveryDocument3 pagesEnhanced Oil Recoverys33d_2010No ratings yet

- Lab Tests For Stimulation PDFDocument14 pagesLab Tests For Stimulation PDFizzybjNo ratings yet

- Enhanced Oil Recovery (Abbreviated EOR), Also Called Tertiary Recovery, Is The Extraction ofDocument9 pagesEnhanced Oil Recovery (Abbreviated EOR), Also Called Tertiary Recovery, Is The Extraction ofAnonymous QM0NLqZO100% (1)

- EmulsionsDocument44 pagesEmulsionsMax SinghNo ratings yet

- Chemical FloodingDocument18 pagesChemical FloodingAli AbukhzamNo ratings yet

- SPE-124799-PA-Determining Wax Type Paraffin or NaphtheneDocument6 pagesSPE-124799-PA-Determining Wax Type Paraffin or NaphtheneJohn HastingNo ratings yet

- Production Enhancement From Sand Control ManagementDocument14 pagesProduction Enhancement From Sand Control Managementabdulsalam alssafi94No ratings yet

- GEOG TI2012 Flow Assurance Aspects of Intrusive Erosion ProbesDocument10 pagesGEOG TI2012 Flow Assurance Aspects of Intrusive Erosion ProbesIsmail SayutiNo ratings yet

- An Introduction To EORDocument4 pagesAn Introduction To EORMnesNo ratings yet

- Res Eng CH 3Document16 pagesRes Eng CH 3weldsvNo ratings yet

- 3.3 Capillary PressureDocument78 pages3.3 Capillary PressureHind Lionne100% (1)

- EP 97-5250 Sand Management Guide (SMG) - Preface PDFDocument2 pagesEP 97-5250 Sand Management Guide (SMG) - Preface PDFKhalid ZaeemNo ratings yet

- Water Problem and Water Control PDFDocument22 pagesWater Problem and Water Control PDFwikenblessyNo ratings yet

- SPE-188174-MS Green EOR Utilizing Well-Defined Nano-Cellulose Based Nano-Fluids From Flask To FieldDocument13 pagesSPE-188174-MS Green EOR Utilizing Well-Defined Nano-Cellulose Based Nano-Fluids From Flask To FieldJosé Manuel UsuriagaNo ratings yet

- A Flow Assurance Challenge: Narve Aske, StatoilDocument28 pagesA Flow Assurance Challenge: Narve Aske, StatoilVinh PhamthanhNo ratings yet

- Mercury Contamination RisksDocument78 pagesMercury Contamination RisksguruhnurizalNo ratings yet

- Rajan 2013Document12 pagesRajan 2013TheNourEldenNo ratings yet

- Iraq ESP1Document6 pagesIraq ESP1juliocanel2009No ratings yet

- Surfactant EORDocument43 pagesSurfactant EORLê Công100% (1)

- Dsa 1183Document44 pagesDsa 1183Waleed El-azabNo ratings yet

- Rapid On-Site Analysis of Fats, Oil and Grease (FOG)Document2 pagesRapid On-Site Analysis of Fats, Oil and Grease (FOG)Waleed El-azabNo ratings yet

- Scan 0006Document1 pageScan 0006Waleed El-azabNo ratings yet

- New Iec 60296 Ed 4 From A Transformer Oil Manufactures Perspective 2013-09-01Document5 pagesNew Iec 60296 Ed 4 From A Transformer Oil Manufactures Perspective 2013-09-01Sreeram PanigrahiNo ratings yet

- 44 74453BRO LS 55andLS 45FluorescenceSpectrophotometerDocument8 pages44 74453BRO LS 55andLS 45FluorescenceSpectrophotometerumesh123patilNo ratings yet

- PRD FlexibilityDocument5 pagesPRD FlexibilityWaleed El-azabNo ratings yet

- International Biodeterioration & BiodegradationDocument8 pagesInternational Biodeterioration & BiodegradationWaleed El-azabNo ratings yet

- Gas Reinjection: Workshop on"CDM Methodology Issues Related To Gas Flaring"Document29 pagesGas Reinjection: Workshop on"CDM Methodology Issues Related To Gas Flaring"Waleed El-azabNo ratings yet

- For Further Tran: - Eeac and Devewment CommaiDocument14 pagesFor Further Tran: - Eeac and Devewment CommaiWaleed El-azabNo ratings yet

- Errors in Chemical AnalysisDocument19 pagesErrors in Chemical AnalysisWaleed El-azabNo ratings yet

- Expression of UncertaintyDocument60 pagesExpression of UncertaintyWaleed El-azab67% (3)

- Quality Control / Quality Assurance in Analytical LaboratoriesDocument110 pagesQuality Control / Quality Assurance in Analytical LaboratoriesWaleed El-azabNo ratings yet

- BRO Fluorescence SpectrosDocument24 pagesBRO Fluorescence SpectrosWaleed El-azabNo ratings yet

- Brief Review of Important Concepts For Quantitative AnalysisDocument20 pagesBrief Review of Important Concepts For Quantitative AnalysisWaleed El-azabNo ratings yet

- Calibrations and StandardizationDocument43 pagesCalibrations and StandardizationWaleed El-azabNo ratings yet

- Validation of ISO 6974 For The Measurement of The Composition of Hydrogen-Enriched Natural GasDocument8 pagesValidation of ISO 6974 For The Measurement of The Composition of Hydrogen-Enriched Natural GasWaleed El-azabNo ratings yet

- Gas FlaringDocument14 pagesGas FlaringWaleed El-azabNo ratings yet

- Oil Analysis OverviewDocument36 pagesOil Analysis OverviewWaleed El-azabNo ratings yet

- 8015 BDocument28 pages8015 BAbdul Raheem U LNo ratings yet

- Degradation of AcetalDocument1 pageDegradation of AcetalWaleed El-azabNo ratings yet

- D Chesher - Troubleshooting Failed Quality Control PDFDocument34 pagesD Chesher - Troubleshooting Failed Quality Control PDFWaleed El-azabNo ratings yet

- Gpa 2261-00 2000 PDFDocument22 pagesGpa 2261-00 2000 PDFWaleed El-azabNo ratings yet

- Sample Receiving ProceduresDocument1 pageSample Receiving ProceduresWaleed El-azabNo ratings yet

- Study ProducedWaterRecyclingReuse DraftReportDocument79 pagesStudy ProducedWaterRecyclingReuse DraftReportWaleed El-azabNo ratings yet

- <html> <head> <title>DansGuardian - Access Denied</title> </head> <body bgcolor=#FFFFFF> <center> <table border=0 cellspacing=0 cellpadding=2 height=540 width=700> <tr> <td colspan=2 bgcolor=#FEA700 height=100 align=center> <font face=arial,helvetica size=6> <b>Access has been Denied!</b> </td> </tr> <tr> <td colspan=2 bgcolor=#FFFACD height=30 align=right> <font face=arial,helvetica size=3 color=black> <b>- </b> </td> </tr> <tr> <td align=center valign=bottom width=150 bgcolor=#B0C4DE> <font face=arial,helvetica size=1 color=black> Allahabad University </td> <td width=550 bgcolor=#FFFFFF align=center valign=center> <font face=arial,helvetica color=black> <font size=4> Access to the page: <br><br> <a href="http://www.scribd.com/titlecleaner?title=water+analysis.pdf" target="_blank">http://www.scribd.com/titlecleaner?title=water+analysis.pdf</a> <br><br> <font size=3> ... has been denied for the following reason: <br><br> <foDocument22 pages<html> <head> <title>DansGuardian - Access Denied</title> </head> <body bgcolor=#FFFFFF> <center> <table border=0 cellspacing=0 cellpadding=2 height=540 width=700> <tr> <td colspan=2 bgcolor=#FEA700 height=100 align=center> <font face=arial,helvetica size=6> <b>Access has been Denied!</b> </td> </tr> <tr> <td colspan=2 bgcolor=#FFFACD height=30 align=right> <font face=arial,helvetica size=3 color=black> <b>- </b> </td> </tr> <tr> <td align=center valign=bottom width=150 bgcolor=#B0C4DE> <font face=arial,helvetica size=1 color=black> Allahabad University </td> <td width=550 bgcolor=#FFFFFF align=center valign=center> <font face=arial,helvetica color=black> <font size=4> Access to the page: <br><br> <a href="http://www.scribd.com/titlecleaner?title=water+analysis.pdf" target="_blank">http://www.scribd.com/titlecleaner?title=water+analysis.pdf</a> <br><br> <font size=3> ... has been denied for the following reason: <br><br> <foyounusgulNo ratings yet

- Manual of Petroleum Measurement StandardsDocument23 pagesManual of Petroleum Measurement StandardsWaleed El-azabNo ratings yet

- 04chapter2 PDFDocument17 pages04chapter2 PDFWaleed El-azabNo ratings yet

- Unit Conversion: LengthDocument35 pagesUnit Conversion: LengthAnonymous 8aj9gk7GCLNo ratings yet

- C Elementar Vario MACRO Cube PDFDocument16 pagesC Elementar Vario MACRO Cube PDFWaleed El-azab100% (1)

- Water Sampling PDFDocument7 pagesWater Sampling PDFWaleed El-azabNo ratings yet

- 335 Model DDX-LP Dry Pipe Valve SystemDocument8 pages335 Model DDX-LP Dry Pipe Valve SystemM Kumar MarimuthuNo ratings yet

- 12auxiliary ViewsDocument22 pages12auxiliary Viewsmanishjangid9869No ratings yet

- 82 - Engineering Mechanics Refresher SetDocument6 pages82 - Engineering Mechanics Refresher Setdevilene nayazakoNo ratings yet

- Forklift Risk AssessmentDocument5 pagesForklift Risk AssessmentPajserchina100% (4)

- Preparation of Giemsa Working SolutionDocument4 pagesPreparation of Giemsa Working SolutionMUHAMMAD DIMAS YUSUF 1903031No ratings yet

- Intelligent Building FacadeDocument32 pagesIntelligent Building FacadeVeè Vêk JåyswãlNo ratings yet

- ARCO ANDI Wayne PIB Installation and Start Up GuideDocument39 pagesARCO ANDI Wayne PIB Installation and Start Up GuidejotazunigaNo ratings yet

- What Is Situational Coaching and When To Use ItDocument3 pagesWhat Is Situational Coaching and When To Use ItBrian KamoedNo ratings yet

- Ball Valves PDFDocument34 pagesBall Valves PDFThomasFrenchNo ratings yet

- EER Model: Enhance Entity Relationship ModelDocument12 pagesEER Model: Enhance Entity Relationship ModelHaroon KhalidNo ratings yet

- Assessment of Spinach Seedling Health Status and Chlorophyll Content by Multivariate Data Analysis and Multiple Linear Regression of Leaf Image FeaturesDocument9 pagesAssessment of Spinach Seedling Health Status and Chlorophyll Content by Multivariate Data Analysis and Multiple Linear Regression of Leaf Image FeaturesYugal KumarNo ratings yet

- (ANSI - AWS A5.31-92R) AWS A5 Committee On Filler Metal-SpecificationDocument18 pages(ANSI - AWS A5.31-92R) AWS A5 Committee On Filler Metal-SpecificationSivaram KottaliNo ratings yet

- Philosophical Warfare and The Shadow of IdeasDocument5 pagesPhilosophical Warfare and The Shadow of IdeasDavid MetcalfeNo ratings yet

- Real-World Data Is Dirty: Data Cleansing and The Merge/Purge ProblemDocument29 pagesReal-World Data Is Dirty: Data Cleansing and The Merge/Purge Problemapi-19731161No ratings yet

- Features and ApplicationsDocument36 pagesFeatures and ApplicationsFWEFWEFWNo ratings yet

- X20PS9600-en V1.20Document10 pagesX20PS9600-en V1.20PREVENCIONISTA HUAQUIANNo ratings yet

- Principles of MicroeconomicsDocument41 pagesPrinciples of MicroeconomicsHoàng LýNo ratings yet

- MgF2 SolGelDocument8 pagesMgF2 SolGelumut bayNo ratings yet

- Final Model Paper Computer Science HSSC-IIDocument9 pagesFinal Model Paper Computer Science HSSC-IIMUhammad Milad AwanNo ratings yet

- Questionnaire Supply ChainDocument4 pagesQuestionnaire Supply ChainKshatriy'as ThigalaNo ratings yet

- Airsprings - TroubleshootingDocument4 pagesAirsprings - TroubleshootingCihan CantaşNo ratings yet

- V Packing SealDocument10 pagesV Packing SealBobby ArbianugrohoNo ratings yet

- Biology Taxonomy Worksheet ANSWERSDocument3 pagesBiology Taxonomy Worksheet ANSWERSPsudopodNo ratings yet

- Lac CultureDocument7 pagesLac CultureDhruboNo ratings yet

- Materi 2 - Obligation, Prohibition, and Suggestion - AdviceDocument12 pagesMateri 2 - Obligation, Prohibition, and Suggestion - AdviceShadrina ChaerunissaNo ratings yet

- English Vs Romanian SyntaxDocument7 pagesEnglish Vs Romanian SyntaxAna Maria Chirea-Stoica100% (1)

- Uvm UnderstandingDocument8 pagesUvm UnderstandingLokesh KumarNo ratings yet

- The Standard Model Theory - Kreon Papathanasiou - ph4884Document30 pagesThe Standard Model Theory - Kreon Papathanasiou - ph4884Haigh RudeNo ratings yet

- TOC - Question AnswerDocument41 pagesTOC - Question AnsweretgegrgrgesNo ratings yet

- Hypersizer For Composite Bicycle AnalysisDocument29 pagesHypersizer For Composite Bicycle AnalysislawrenceNo ratings yet