Professional Documents

Culture Documents

TRONXY P802EA Installation Guide v.03

Uploaded by

Jessica RossCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TRONXY P802EA Installation Guide v.03

Uploaded by

Jessica RossCopyright:

Available Formats

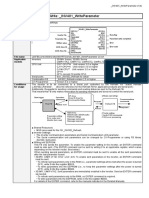

Classification Of Screws

M3 nuts 54pcs

M3*20mm Round head

screws 58pcs

M2*18mm Round head

screws & M2 Nut 2pcs

M8 nuts 12pcs

M3*10mm Round head

screws 17pcs

M3*30mm Flat-head

screws 4pcs

M8 Cushion ring

12pcs

M3*14mm Flat-head

screws 4pcs

Plastic Pillars 4pcs

Classification Of Screws

M3*25mm screws

7pcs

M4*15mm screws

12pcs

M4*8mm screws

12pcs

(Use for locking bearings on extruder)

Wing nuts*4

Compression springs*4

M3*22mm screws 4pcs

Step 1 Assemble Y-axis Motor

Fit the synchronous pulley on the motor, Locking with

M3*2mm jackscrew.

As the picture, Put Y-axis motor on <Y-axis motor support> ,

locking with Four M3*10mm screws.

Synchronous pulley

Y-axis motor

M3*2mm jackscrew

Y-axis motor

support

M3*10mm screws*4

Step 2 Assemble Y-axis Limit switch

Put the Y-axis limit switch and the holder together ,locking

with two M3*20mm screws & nuts. As picture

M3*20mm screws

Y-axis limit switch

Y-axis limit

switch holder

(Acrylic)

M3 nuts

Step 3 Assemble Base Frame Holder_Back

As the picture, put two of the Sliding rod

Restriction in front of the base frame holder

(back). locking with two M3*20mm screws &

nuts.

Put the limit switch and holder assembly on the

base frame holder, locking with one M3*20mm

screw & nut.

Sliding rod

Restriction*2

M3*20mm

screws

M3 nuts

Put Y-axis motor holder on base frame

holder ,locking with one M3*20mm screw & nut.

Put Y-axis motor assembly on base frame holder,

locking with three M3*20mm screws & nuts.

Y-axis limit

switch assembly

Y-axis motor assembly

Base frame

holder_Back

Y-axis motor

holder

Step 4 Assemble Base Frame Holder_Front

As the picture, put two of the Sliding

rod Restriction in front of the base

frame holder _front. locking with two

M3*20mm screws & nuts.

Base Frame

Holder_Front

Put Y-axis belt pulley wheel assembly

behind the base frame holder, Locking

with two M3*20mm screws & nuts.

M3*20mm Screws

& nuts

Sliding rod

Restriction*2

Y-axis belt pulley

wheel assembly

Step 5 Assemble Z-axis right motor

coupling

Put the Z-axis motor support(top) on

the Motor top, locking with M3*10mm

screws.

Put the coupling on the motor, locking

with the jackscrews.

Jackscrew

M3*10mm screws

Z-axis motor

support(top)

The Sliding Rod hole on Left as picture.

Sliding

Rod hole

Z-axis motor

Step 6 Assemble Z-axis left motor

Put the Z-axis motor support(top) on

the Motor top, locking with M3*10mm

screws.

Jackscrew

coupling

Put the coupling on the motor, locking

with the jackscrews.

Sliding

Rod hole

Z-axis motor

support(top)

The Sliding Rod hole at right as picture

M3*10mm screws

Z-axis motor

Step 7 Assemble Z-axis

As the picture, Put the two Z-axis motors assembly

on the left and right side of the Bottom plate,

locking with four M3*20mm screws & nuts.

M3*20mm

screws

Z-axis left

motor assembly

Bottom plate

Z-axis right

motor assembly

Step 8 Assemble Side plate

As the picture, Put the two Side plate on the

left and right side of the Bottom plate ,

locking with four M3*20mm screws & nuts.

Side plate

M3*20mm Round

head screws

Step 9 Assemble Top plate & Junction Plate

As the picture, Put the Top plate on Side

Plate, locking with four M3*20mm screws &

nuts.

Put the two Junction Plate on the top of the

Side plate ,locking with four M3*20 screws &

nuts.

Put two sliding rod restriction on the top of

left and right sides. Locking with one

M3*20mm screw & nut each.

Sliding rod restriction

Junction Plate

M3*20mm

screws

Top plate

Button

hole

Side plate

Step 10 Install Base frame holder_Back

Put the Base frame holder_back back of Side plate,

locking with four M3*20mm screw

M3*20mm

screws*4

Base frame

holder_back

Step 11 Install LCD display

Put the LCD display on the top of the Top

plate ,locking with three M3*25mm screws &nuts

LCD display

assembly

M3*25mm

screws

Step 12 Install Base Frame Holder_Front

Through the Frame Holder_Front & Back by two

M8*400mm screw arbors, locking with twelve

M8 Nuts & cushion ring.

M8*400mm

screw arbors

M8 nuts &

cushion ring

Base frame

holder_front

Base frame

holder_back

Bottom plate

Step 13 Assemble Bed frame

Place three bearings under the bed frame,

locking with twelve M4*15 screws.

M4*15mm

screws *12

Bearing*3

Step 14 Assemble Bed frame

Place three bearings under the bed frame, locking with

twelve M4*15 screws.

Through the bed frame on the base by two of M8*380mm

Sliding rod. Fix both end by Sliding rod restriction

Tighten one end of the timing belt to the bed frame using a

zip-ties. the other end through the Y-axis motor and belt

pulley wheel on the base frame holder , Then tighten it to

the bed frame using zip-ties as shown in the picture .

M8*380mm

sliding rod*2

Sliding rod

Restriction

Nylon cable ties

Timing belt

Step 15 Assemble Heatbed

Place the MK3 heatbed on the bed frame use

4pcs springs between them and then through

4pcs M3-30mm screws, then top 4pcs Wing nuts

under the bed frame.

M3*30mm

screws *4

Springs*4

Wing nut*4

MK3 Heatbed

Step 16 Install Z-axis limit switch & PCBA Control Board

Install Control Board as picture , locking with Four

M3*25mm screws + 4pcs Plastic pillars + 4pcs M3 nuts

Plastic Pillars*4

M3 Nuts

Control

Board

Side plate

M3*25mm

Screws *4

Step 17 Instal the Filament Feeder

Put Filament feeder under the Junction

Plate(left), as picture ,Locking with

2pcs M3*20mm screws.

Another way is install the filament

feeder to the side plate , as shown in

the picture below.

Filament feeder

Junction Plate (Left)

M3*20mm

screw & nut

Filament feeder

Step 18 Install Power supply

Put Power supply on the right of the side plate ,

locking with three M3*14mm screws and nuts.

Side plate

Power supply

M3*14mm

screw

Step 19 Instal X-axis Motor & Pulley mount

Junction Plate (Left)

Put X-axis motor on X-axis motor mount. Locking

with three M3*10mm screws.

Through the X-axis motor mount & pulley mount

by M8*380mm sliding rod & M8*345mm screw

arbor. As picture

Limit the top of sliding rod with sliding rod

restriction, connect the bottom of screw arbors

with couplings , locking jackscrew in coupling.

X-axis Motor

Sliding rod

restriction

M8*380mm

Sliding rod

M8*345mm

screw arbor

X-axis Motor

mount

X-axis Pulley

mount

Coupling

Step 20 Assemble X-axis

Through the X-axis motor mount &

Pulley mount and Extruder assembly

using two M8*403mm sliding rods, as the

picture below

Link with Filament feeder and Extruder

Filament feeder

assembly, use the Teflon hose, as picture.

X-axis pulley

mount

Teflon hose

M8*403mm

sliding rod

X-axis motor

mount

Extruder

assembly

X-axis limit

switch

Step 21 Instal X limit switch

Place X-axis limit switch on the

Extruder acrylic, Secure it using two

M2*18mm screws & nuts

M2*18mm

screws

Step 22 Instal X-axis Timing Belt

Tighten one end of the

Timing Belt to the Belt clip

with Nylon cable ties. The

other end through the X-axis

pulley & motor ,then tighten

another end of the belt to the

another Belt clip with Nylon

cable ties . as picture

X-axis motor

mount

X-axis pulley

mount

Belt clip

X-axis

timing belt

Nylon cable ties

Step 23 Control Board Wiring Diagram

The method of connecting wire is as picture

!NOTE!: The wires connected to POWER SUPPLY and

HETBED must be AWG14 or thicker one.

Auto level printer do not have Z-axis limit

switch , the Position sensor is for Z STOP

The red wire is

upturned

Step 24 AC Power Connector Wiring Diagram

Connect Power cable as the picture (Right)

Note: There are different voltages in different country.

Please select the appropriate voltage by switch before

power on. As the picture below.

Step 25 Assemble Filament Feeder

Separately put two Steel Pipe holder on

two Filament support frame, locking with

four M3*20mm Round head screws & nuts.

Steel Pipe

Connect the two Filament support frames

with two Fixed links , locking with four

M3*20mm Round head screws & nuts

Filament spool

Steel Pipe

holder

M3 nuts

Filament

support frame

M3*20mm Round

head screws

Fixed Link

Installation Finished

You might also like

- Schwinn Stingray OCC Chopper Bicycle Motor Kit PlansDocument38 pagesSchwinn Stingray OCC Chopper Bicycle Motor Kit PlansLiveFastMotors81% (16)

- Motors and The NECDocument10 pagesMotors and The NECMike AdvinculaNo ratings yet

- Rhino 3dDocument110 pagesRhino 3dkinglion004No ratings yet

- Photovoltaic System: From Wikipedia, The Free EncyclopediaDocument31 pagesPhotovoltaic System: From Wikipedia, The Free EncyclopediaFrederic WustNo ratings yet

- Reprap Prusa Mendel Build Manual - 2Document14 pagesReprap Prusa Mendel Build Manual - 2Laxmikanth ReddyNo ratings yet

- IEEE Guide For Array and Battery Sizing in Stand-Alone Photovoltaic (PV) SystemsDocument34 pagesIEEE Guide For Array and Battery Sizing in Stand-Alone Photovoltaic (PV) SystemsJimmy F Hernandez100% (1)

- TRONXY P802MA Installation Guide v.04Document27 pagesTRONXY P802MA Installation Guide v.04pister80% (5)

- Cambelt and Water Pump Change MultiplaDocument12 pagesCambelt and Water Pump Change Multiplaa1037699No ratings yet

- MeshMixer Tutorial For 3D Printing Beginners - All3DPDocument15 pagesMeshMixer Tutorial For 3D Printing Beginners - All3DPsferrand85050% (4)

- Clock Gear Train CalculatorDocument2 pagesClock Gear Train CalculatorDaksh Dhingra0% (1)

- Storwize V7000 Unified Problem DeterminationDocument334 pagesStorwize V7000 Unified Problem DeterminationyemeralNo ratings yet

- 4-1-Lesson PlanDocument43 pages4-1-Lesson PlanZero TwoNo ratings yet

- Ieee C57.125Document11 pagesIeee C57.125suresh kumarNo ratings yet

- 2 Gear LinkageGolf Mk1Document46 pages2 Gear LinkageGolf Mk1SteggosNo ratings yet

- Tronxy X5 Assemble English User ManualDocument16 pagesTronxy X5 Assemble English User ManualPhil Hall0% (1)

- Openscad User GuideDocument3 pagesOpenscad User GuideJose SanchezNo ratings yet

- Ultimaker 2 Assembly Manual V1.1Document69 pagesUltimaker 2 Assembly Manual V1.1petrkalousNo ratings yet

- A8 3D Printer Installation Instructions1.1Document44 pagesA8 3D Printer Installation Instructions1.1Alejandro Quiroz GraciaNo ratings yet

- Four Cylinder Air Engine Dwg.Document15 pagesFour Cylinder Air Engine Dwg.Jitendra BagalNo ratings yet

- Modular CNC Mini CNC Mill Kit Parts ListDocument1 pageModular CNC Mini CNC Mill Kit Parts ListModularCNC100% (1)

- F-15 Park Jet Plans (Parts Templates Scaled 150 Tiled)Document42 pagesF-15 Park Jet Plans (Parts Templates Scaled 150 Tiled)donlynNo ratings yet

- OpenSCAD ClassDocument33 pagesOpenSCAD Classtesla-daxNo ratings yet

- QcadCAM Tutorial enDocument12 pagesQcadCAM Tutorial enartisanicviewNo ratings yet

- MF-35 Lightning TDocument3 pagesMF-35 Lightning TAngel NietoNo ratings yet

- Board SchematicDocument1 pageBoard SchematicJOSE LENIN RIVERA VILLALOBOS0% (1)

- Clock 27 FDM DrawingsDocument2 pagesClock 27 FDM DrawingsAli Shodiqin100% (1)

- Mechanical Turing Machine in Wood PDFDocument15 pagesMechanical Turing Machine in Wood PDFJesus Flores100% (1)

- Origami-Shop SPIRAL Origami Art DesignDocument2 pagesOrigami-Shop SPIRAL Origami Art DesignCosmicBlue24No ratings yet

- CSTAR P802M Installation Guide v.04Document28 pagesCSTAR P802M Installation Guide v.04Hector GarciaNo ratings yet

- ZONESTAR P802M Installation Guide v.02Document28 pagesZONESTAR P802M Installation Guide v.02Jose Miguel Cañete HidalgoNo ratings yet

- Tronxy x1 Assembly GuideDocument26 pagesTronxy x1 Assembly GuideВайсер Евгений100% (1)

- Tronxy X3A Assemble Guide v.02Document29 pagesTronxy X3A Assemble Guide v.02ramblicasNo ratings yet

- Tronxy X3 Assemble Guide V.03Document30 pagesTronxy X3 Assemble Guide V.03everestoNo ratings yet

- How To Build A MendelMax 1.5 3D PrinterDocument124 pagesHow To Build A MendelMax 1.5 3D PrinterFr0styanNo ratings yet

- MicroCube Assembly GuideDocument22 pagesMicroCube Assembly GuideAlexandruNo ratings yet

- Sidecar Mount For Intruder 800 or Volusia 800Document2 pagesSidecar Mount For Intruder 800 or Volusia 800dneprmt1No ratings yet

- TRONXY P802EA Installation Guide V.03 PDFDocument29 pagesTRONXY P802EA Installation Guide V.03 PDFSalas Meneses JavierNo ratings yet

- ARB 3438100 FittingDocument7 pagesARB 3438100 FittingthailanNo ratings yet

- 04-11 GM Colorado / Canyon 2WD / 4WD 4" Suspension Lift Installation InstructionsDocument10 pages04-11 GM Colorado / Canyon 2WD / 4WD 4" Suspension Lift Installation Instructionstrimoca_234178616No ratings yet

- Kit WJ 639pDocument8 pagesKit WJ 639pjp_xtremNo ratings yet

- Prusa Mendel Iteration 2 Documentation: Thingdoc November 16, 2011Document13 pagesPrusa Mendel Iteration 2 Documentation: Thingdoc November 16, 2011Mr. KNo ratings yet

- FMINTPOLODocument24 pagesFMINTPOLOClaudiu PunkkNo ratings yet

- Prusa I3 Build Document by 3D Printer CzarDocument29 pagesPrusa I3 Build Document by 3D Printer CzarlasersmartNo ratings yet

- Prusa I3 Build Document by 3D Printer Czar PDFDocument29 pagesPrusa I3 Build Document by 3D Printer Czar PDFlasersmartNo ratings yet

- Compact Pet Filament MachineDocument13 pagesCompact Pet Filament Machineaex853120No ratings yet

- DMYCO3dp-001 Installation Guide v.07Document26 pagesDMYCO3dp-001 Installation Guide v.07Saed CattywampusNo ratings yet

- Contitech: Installation Tips - Changing Timing Belts: Press ReleaseDocument6 pagesContitech: Installation Tips - Changing Timing Belts: Press Releasecabral_bhNo ratings yet

- MSS404G Installation Guide Line 20161112 英文版安装说明Document12 pagesMSS404G Installation Guide Line 20161112 英文版安装说明Karen PillasaguaNo ratings yet

- Ecksbot Electronics InstructionsDocument78 pagesEcksbot Electronics InstructionsjohnNo ratings yet

- Ibiza 6l FMIC Mount InstructionsDocument18 pagesIbiza 6l FMIC Mount Instructionsvagelis vlaxopouliotisNo ratings yet

- M-Jet ManualDocument17 pagesM-Jet Manualh2oo2hNo ratings yet

- Body - Headlight Conversion, Vac To Electric Elite & EclatDocument3 pagesBody - Headlight Conversion, Vac To Electric Elite & EclatbrynerNo ratings yet

- Folgertech Prusa I3 Build Manual v1.1Document74 pagesFolgertech Prusa I3 Build Manual v1.1DonutdealerdNo ratings yet

- Build Guide - Ender 5 Exoslide Xy Motion KitDocument6 pagesBuild Guide - Ender 5 Exoslide Xy Motion KitGreg RobertsonNo ratings yet

- SKRRFrontbrake FrameDocument3 pagesSKRRFrontbrake Framesacomani_123No ratings yet

- Yosh R55 InstallDocument6 pagesYosh R55 Installsnoop43No ratings yet

- Service Manual Tandberg Td20aDocument41 pagesService Manual Tandberg Td20aangelescuo100% (1)

- 07K Manifold IEIMVB1 IEIMVB2 Install GuideDocument18 pages07K Manifold IEIMVB1 IEIMVB2 Install GuideEmmanuel HernandezNo ratings yet

- A8 3D Printer Installation Instructions PDFDocument50 pagesA8 3D Printer Installation Instructions PDFmickymausNo ratings yet

- G768 Car ModelDocument2 pagesG768 Car ModelVaibhav GaurNo ratings yet

- Build Instructions:: Download Extra 300 - 900 MM Plans Download Extra 300 - 900 MM Mazda DecalsDocument16 pagesBuild Instructions:: Download Extra 300 - 900 MM Plans Download Extra 300 - 900 MM Mazda Decalsfer freeNo ratings yet

- Wbs Pi3 Diy Mec Rev03Document20 pagesWbs Pi3 Diy Mec Rev03api-226287634No ratings yet

- 001-Component-Build: Build The Following Contraptor Components Before AssemblyDocument50 pages001-Component-Build: Build The Following Contraptor Components Before AssemblyTashi BestNo ratings yet

- 1500 Goldwing ManualDocument31 pages1500 Goldwing ManualMotorcycle ShopNo ratings yet

- A8 3D Printer Installation Instructions1.1 PDFDocument44 pagesA8 3D Printer Installation Instructions1.1 PDFNicolas Carvajal HerreraNo ratings yet

- Controller Design For Buck Converter Step-by-Step Approach: Swapna ManurkarDocument3 pagesController Design For Buck Converter Step-by-Step Approach: Swapna ManurkarJessica RossNo ratings yet

- On The Practical Design of A Sliding Mode Voltage Controlled Buck ConverterDocument13 pagesOn The Practical Design of A Sliding Mode Voltage Controlled Buck ConverterJessica RossNo ratings yet

- Implementing Sliding Mode Control For Buck Converter: Ahmed, Kuisma, Tolsa, SilventoinenDocument4 pagesImplementing Sliding Mode Control For Buck Converter: Ahmed, Kuisma, Tolsa, SilventoinenJessica RossNo ratings yet

- On DC/DC Voltage Buck Converter Control Improvement Through The QFT ApproachDocument8 pagesOn DC/DC Voltage Buck Converter Control Improvement Through The QFT ApproachJessica RossNo ratings yet

- 1999 IFAC 14th Triennial World Congn.:ss, Beijing. China: Elare Oyj, P.O.BoxDocument6 pages1999 IFAC 14th Triennial World Congn.:ss, Beijing. China: Elare Oyj, P.O.BoxJessica RossNo ratings yet

- Ug897 Vivado Sysgen UserDocument226 pagesUg897 Vivado Sysgen UserJessica RossNo ratings yet

- BW500 ManualDocument315 pagesBW500 ManualJessica RossNo ratings yet

- Implementing Ball Balancing Beam Using Digital Image Processing and Fuzzy LogicDocument4 pagesImplementing Ball Balancing Beam Using Digital Image Processing and Fuzzy LogicJessica RossNo ratings yet

- Ball and Beam: Design and ControlDocument3 pagesBall and Beam: Design and ControlJessica RossNo ratings yet

- BB01 User ManualDocument21 pagesBB01 User ManualJessica RossNo ratings yet

- Nonlinear PD Regulation For Ball and Beam System: Wen YuDocument15 pagesNonlinear PD Regulation For Ball and Beam System: Wen YuJessica RossNo ratings yet

- Mathematical Modelling of The Mass-Spring-Damper System - A Fractional Calculus ApproachDocument7 pagesMathematical Modelling of The Mass-Spring-Damper System - A Fractional Calculus ApproachJessica RossNo ratings yet

- Design and Control of Pid Controlled Ball and Beam SystemDocument6 pagesDesign and Control of Pid Controlled Ball and Beam SystemJessica RossNo ratings yet

- P802 Automatic Leveling Debug Guide V2Document5 pagesP802 Automatic Leveling Debug Guide V2Jessica Ross100% (1)

- F C F N A B S: Uzzy Ontrol OR Onlinearball ND EAM YstemDocument8 pagesF C F N A B S: Uzzy Ontrol OR Onlinearball ND EAM YstemJessica RossNo ratings yet

- Experiment: 3: Metal Bar L (2) LDocument6 pagesExperiment: 3: Metal Bar L (2) LJessica RossNo ratings yet

- Total Station RObotic Topcon GT 501 With Automatic Control - TRANSSURVEYDocument4 pagesTotal Station RObotic Topcon GT 501 With Automatic Control - TRANSSURVEYTRANS SURVEYNo ratings yet

- Ic21 Sect 10 Pilot DevicesDocument222 pagesIc21 Sect 10 Pilot DevicesFawzi AlzubairyNo ratings yet

- Rancang Bangun Prototipe Sistem Kendali Iron Removal Filter (Irf) Pada Unit Pengolahan Air Bersih Berbasis PLCDocument8 pagesRancang Bangun Prototipe Sistem Kendali Iron Removal Filter (Irf) Pada Unit Pengolahan Air Bersih Berbasis PLCaulyaakmala24No ratings yet

- Lenovo SL400Document94 pagesLenovo SL400Abhilash VamanNo ratings yet

- 6204 Parts Lists PDFDocument51 pages6204 Parts Lists PDFMirzaNo ratings yet

- Huawei bm626Document3 pagesHuawei bm626florent_goueNo ratings yet

- Ofc LedDocument6 pagesOfc LedVignesh DevanNo ratings yet

- Service Manual T24PE EN 30251845A - 06192015Document54 pagesService Manual T24PE EN 30251845A - 06192015DaniloSripNo ratings yet

- Voice Over IP (VoIP)Document54 pagesVoice Over IP (VoIP)Peter R. Egli100% (1)

- Zetta - 8GB eMMC and 8Gb 2 X 4Gb LPDDR3 MCP - DatasheetDocument9 pagesZetta - 8GB eMMC and 8Gb 2 X 4Gb LPDDR3 MCP - DatasheetAmzil Emmc UfsNo ratings yet

- Vacon NX Inverters FI9 14 User Manual DPD00909A enDocument106 pagesVacon NX Inverters FI9 14 User Manual DPD00909A enTanuTiganuNo ratings yet

- D N F ElementsDocument21 pagesD N F ElementsJatinChadhaNo ratings yet

- User Friendly Smart Energy System Using IOTDocument4 pagesUser Friendly Smart Energy System Using IOTInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Microchannel Heat Exchanger: Prepared byDocument18 pagesMicrochannel Heat Exchanger: Prepared byPritam GoleNo ratings yet

- SpaceTrack 4000 CaprockDocument2 pagesSpaceTrack 4000 CaprockVanessa ChingNo ratings yet

- Lab 7 Power Electronics by Muhammad Husnain AliDocument6 pagesLab 7 Power Electronics by Muhammad Husnain AliMuhammad HusnainNo ratings yet

- Tutorial StellaDocument19 pagesTutorial StellaCaioGomesNo ratings yet

- Continental Directional-Proportional Valves PDFDocument98 pagesContinental Directional-Proportional Valves PDFhebert perezNo ratings yet

- CH 2 - Electrostatic Potential - MCQDocument2 pagesCH 2 - Electrostatic Potential - MCQDeepali MalhotraNo ratings yet

- Parameter Write: - Inv401 - Writeparameter: This FBDocument4 pagesParameter Write: - Inv401 - Writeparameter: This FBJosephNo ratings yet

- Molecular Orbital TutorialDocument28 pagesMolecular Orbital TutorialehmedNo ratings yet

- Clamp Meters: Quick Reference GuideDocument2 pagesClamp Meters: Quick Reference GuideRaul InzunzaNo ratings yet

- Fonte 12v Bivolt TNY278PNDocument37 pagesFonte 12v Bivolt TNY278PNRodolfo Arantes GonçalvesNo ratings yet

- Latch UpDocument4 pagesLatch UpSaurabh MishraNo ratings yet

- Magnetic FieldsDocument14 pagesMagnetic FieldsKid KaitoNo ratings yet