Professional Documents

Culture Documents

VCTDS 02565 en

Uploaded by

CosminOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VCTDS 02565 en

Uploaded by

CosminCopyright:

Available Formats

KTM METALTITE BALL VALVES

FLOATING AND TRUNNION TYPE

Metaltite metal seated ball valves have excellent sealing characteristics suitable

for various fluids services withawide range of operating temperatures

FEATURES

GENERAL APPLICATION

TECHNICAL DATA

Clean fluids, dirty fluids, high viscosity, scaling

fluids, corrosive, erosive, waste treatment,

sludge, saturated steam, superheated steam,

high temperature, high velocity, powder (PP.PE)

Models:

EB11M, EB12M,

E0105M,E0106M,

E0125M, E0126M,

E0108M, E0109M

Sizes:

15 mm to 500 mm ( to 20)

Pressure rating: JIS 10K, 20K ASME Class 150

to 900 (JPI available)

Face to face:

JIS B2002 / ASME B16.10

End connection: JIS B2220 / ASME B16.5

Temperature:

-29C to 500C (Up to 450C

for oxidizing conditions)

Options

Ball surface hardening process

Extension bonnet

Jacketed ball valve

Special tests

X-ray (RT)

Liquid penetrant (PT)

Positive material identification (PMI)

www.pentair.com/valves

2012 Pentair plc. All rights reserved.

High precision machining results in superior

ball and seat interfacing for tight shutoff

conforming to ANSI / FCI 70-2 Class V

(ClassVI as option)

Spring loaded seat maintains close contact

with the ball assuring tight sealing even

atlow pressures. This results in stable

opening and closing torques at high

differential pressures over a wide range

oftemperatures

The combination of metal seats and graphite

seals ensure fire-safe capabilities

Various material components are available

for a variety of service application up to 500C

Uniquely designed trunnion mounted valves

are also available for powder service

KTM can provide a complete valve

andactuator as package for special

applications including powder and

superspeed applications

Surface-hardened ball and seats allow use

in more severe applications such as slurries,

pulp stock and other abrasive media in

longlife

Ball surface hardening process can be

chosen. (For details, please refer to page 2)

Hard chrome plating

Nickel alloy overlay

Tungsten carbide

Chrome carbide

VCTDS-02565-EN 16/03

KTM METALTITE BALL VALVES

FLOATING AND TRUNNION TYPE

PIONEER IN THE METAL SEATED BALL VALVE

Experience gained from over 40 years of manufacturing metal-seated ball valves has contributed

to the development of a valve of superior quality and design Metaltite. Precision lapping of the

ball-to-seat results in superior interfacing and a tight shut-off conforming to ANSI / FCI 70-2

ClassV and Class VI as option.

KTM utilizes proprietary processes with special lapping technologies, enabling us to provide

ahigher-quality product with a superior level of performance.

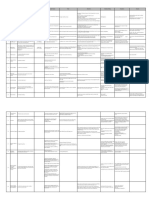

TECHNICAL SPECIFICATION

Type

Manufacturing

range[1]

Temperature

range[1]

Seat gasket /

seal ring

Class 150, 300

DN 15 to 200

(NPS to 8)

-29C to 250C

(-20F to 480F)

R-PTFE

-29C to 350C

(-20F to 662F)

Graphite

Ball: Nickel alloy overlay

Seat: Stellited

Ball: Hard chrome plated

Seat: Stellited

Graphite

Ball: Nickel alloy overlay

Seat: Stellited

Floating

Class 600

DN 15 to 40

(NPS to 1)

Class 150, 300

DN 50 to 500

(NPS 2 to 20)

Trunnion

Class 600

DN 50 to 400

(NPS 2 to 16)

Class 900

DN 40 to 300

(NPS 1 to 12)

-29C to 500C

(-20F to 932F)

[3]

-20C to 150C

(-4F to 300F)

FKM O-ring

-29C to 250C

(-20F to 480F)

PTFE seal ring

-29C to 500C[3]

(-20F to 932F)

Graphite / Metal

diaphragm

-29C to 270C

(-20F to 518F)

PTFE / PEEK

sealring

Hard-facing[4]

Ball: Hard chrome plated

Seat: Stellited

Ball: Hard chrome plated

Seat: Stellited

Ball: Nickel alloy overlay

Seat: Stellited

Ball: Hard chrome plated

Seat: Stellited

Ball: Nickel alloy overlay

Seat: Stellited

Trim

code[5]

AY[6]

BY

AG[6]

BG

BX

AY[6]

BY

AG[6]

BG

Applications

Slurries, pulp stock, solid-containing fluids,

etc.

ON-OFF or throttling.

High-temperature fluids, slurry, pulp stock,

steam, solid containing fluids, etc.

ON-OFF or throttling, fire-safe.

High-temperature, high-frequency,

high-pressure services, fire-safe.

Slurries, pulp stock, solid-containing fluids,

etc.

ON-OFF or throttling.

Slurries, pulp stock, steam, solid

containing fluids, etc.

ON-OFF or throttling, fire-safe.

BX

High-temperature, high-frequency,

high-pressure services, fire-safe.

BG

Slurries, pulp stock, steam, solid

containing fluids, etc.

ON-OFF or throttling, fire-safe.

Ball: Nickel alloy overlay

Seat: Stellited

1. Floating type for ASME Class 900 (DN 15 to 25) are available on request.

2. Extension bonnet is required for an automated valve which fluids temperature above 300C and a manual

valve which fluids temperature above 400C.

3. Up to 450C for oxidizing conditions.

4. Tungsten carbide or chrome carbide hardenings are available.

5. For the details of the code, please refer to KTM model coding system on page 8.

6. Trim code AY and AG are not available for ASME Class 600 and 900.

BALL SURFACE HARDENING PROCESS

Varieties of surface-hardened process for balls are available

Hardening

Hard chrome plating

Nickel alloy overlay

Tungsten carbide

Chrome carbide

Hardness

HV800 or higher

HV595 or higher

HV1000 or higher

HV800 or higher

Remarks

Standard

Standard

Please consult for details

Please consult for details

Other surface hardening processes are available on request.

KTM METALTITE BALL VALVES

FLOATING AND TRUNNION TYPE

KTMS METALTITE FAMILY

Reverse pressure

Ball

Cap side

Pressure - Temperature rating of valves

are limited by sealing and stem materials.

Thecombination of body rating and trim rating

indicate the maximum valve rating at specific

pressure and temperature conditions.

Body side

Ball

Seat

Seat

Seat Gasket

Spring Holder

Spring

PRESSURE - TEMPERATURE RATING

Normal pressure

Body

cap

Seat gasket

Body

Metaltite ball valves are available in bidirectional flow. As factory recommendation however,

install valve with body cap to the downstream side when piping.

FLOATING TYPE CLASS 150, 300

7.0

SCPH2

Lower limit -5C

6.0

3.0

AY, BY type

Upper limit

DN 150, 200

2.0

1.0

0

-29

CF8M (SCS14A)

CF8 (SCS13A)

Class 150

Class 150

50

CF8M (SCS14A)

Class 300

200

250

Temperature (C)

300

350

400

450

AG, BG type Upper limit

WCB (SCPH2)

Class 150

WCB

Lower limit -29C

CF8 (SCS13A)

Class 150

50

100

200

250

100

150

200

250

Temperature (C)

300

350

400

450

500

WCB (SCPH2)

Upper limit 425C

WCB (SCPH2)

BY, BG type

300

350

400

450

6.0

SCPH2

Lower limit -5C

4.0

0

-29

500

CF8M (SCS14A)

BX type

WCB

Lower limit -29C

2.0

150

50

BG type Upper

limit

TRUNNION TYPE CLASS 600

8.0

AY, BY type Upper limit

BY type Upper limit

WCB

Lower limit -29C

10.0

WCB (SCPH2) Class 300

AY, BY, AG, BG type

CF8M (SCS14A)

Class 150

CF8 (SCS13A)

4.0

12.0

WCB (SCPH2)

Upper limit 425C

CF8 (SCS13A)

Class 300

2.0

SCPH2

Lower limit -5C

0

-29

500

BX type

4.0

0

-29

150

TRUNNION TYPE CLASS 150, 300

5.0

1.0

100

WCB (SCPH2)

Class 150

CF8M (SCS14A)

BX type

DN 40 BY, BG type

6.0

2.0

SCPH2

Lower limit -5C

6.0

3.0

AG, BG type

Upper limit

WCB

Lower limit -29C

7.0

Pressure (MPa)

Pressure (MPa)

CF8 (SCS13A)

Class 300

DN 50, 80, 25, 100, 125

WCB (SCPH2)

Upper limit 425C

8.0

Pressure (MPa)

Pressure (MPa)

DN 15, 20, 25, 40, 65

4.0

WCB (SCPH2)

DN 15, 20, 25, BY, BG type

10.0

WCB (SCPH2)

CF8M (SCS14A) Class 300

Class 300

5.0

FLOATING TYPE CLASS 600

12.0

WCB (SCPH2)

Upper limit 425C

CF8 (SCS13A)

BY type Upper limit

50

BG type Upper limit

100

150

Temperature (C)

250

300

350

400

450

500

TRUNNION TYPE CLASS 900

16.0

WCB (SCPH2)

14.0

12.0

CF8M (SCS14A)

CF8 (SCS13A)

10.0

Pressure (MPa)

Solid line

indicate trim rating.

Dashed lines indicate body ratings.

WCB

CF8

CF8M

Materials in parentheses indicate equivalent

JIS material

WCB subjected to PED certification is limited

to minimum temperature -15C

200

Temperature (C)

8.0

WCB

Lower limit -29C

BG type

PTFE Seal ring

Upper limit 250C

6.0

SCPH2

Lower limit -5C

4.0

BG type

PEEK Seal ring

Upper limit 270C

2.0

0

-29

50

100

150

200

250 270

Temperature (C)

3

KTM METALTITE BALL VALVES

FLOATING AND TRUNNION TYPE

FLOATING TYPE STRUCTURE (BIDIRECTIONAL FLOW)

7

4

8

6

9

3

12

5

1

2

10

11

a GLAND AREA

b STEM AREA

Gland flange

Gland packing

Gland packing is suitable for hightemperature service with fire-safe design

(R-PTFEpackingalso available).

c SEAT AREA (BODY-CAP SIDE)

Spring

Seat

Spring holder

Thrust

bearing

Stem with integral flange provides blow-out

proof protection if packing is loosen.

d SEAT AREA (BODY SIDE)

Seat

Seat gasket

Seat gasket

Seat spring provides flexibility to piping stress

and thermal expansion to stabilize operation.

Spring is isolated from fluid flow path,

providingstable spring load.

Seat-gaskets are press-fitted into the body

and provide stability for a wide range of

temperatures from -29C to 500C*.

*up to 450C for oxidizing conditions.

KTM METALTITE BALL VALVES

FLOATING AND TRUNNION TYPE

PARTS LIST (Floating type)

62-AY

No. Parts name

1

Body

2

Body cap

3

Ball

4

5

6

7

8

9

10

11

12

Stem

Seat

Gasket

Gland packing

Stem bearing

Spring

Stud bolt

Nut

Seat gasket

62-BY

-29C[1] to 250C

ASME Class 150 Model EB11M / ASME Class 300 Model EB12M

Body material

Carbon steel

Stainless steel[2]

Material code

62-AG

62-BG

62-BX

32-AY

32-BY

32-AG

32-BG

Temp. range

-29C[1] to 350C

Max. 425C

-29C to 250C

-29C to 350C

WCB (SCPH2)

CF8M (SCS14A)

WCB (SCPH2)

CF8M (SCS14A)

CF8

(SCS13A)

+ HCr

CF8

CF8

(SCS13A)

(SCS13A)

+ SFNi

+ HCr

329SS (SUS329J1)

316SS + Stellited

RPTFE

RPTFE

RPTFE

316SS

A193 G B7

A194 G 2H

RPTFE

CF8 (SCS13A) +SFNi

CF8M

(SCS14A)

+ HCr

Nickel alloy

Graphite

Graphite

Graphite

Nickel alloy

Graphite

CF8M

CF8M

(SCS14A)

(SCS14A)

+ SFNi

+ HCr

329SS (SUS329J1)

316SS + Stellited

RPTFE

RPTFE

RPTFE

316SS

A193 G B8

A194 G8

RPTFE

32-BX

Max. 500C[3]

CF8M (SCS14A) +SFNi

Nickel alloy

Graphite

Graphite

Graphite

Nickel alloy

Graphite

ASME Class 600 Model E0108M

Body material

Carbon steel

62-BY

No. Parts name

1

Body

2

Body cap

3

4

5

6

7

8

9

10

11

12

1.

2.

3.

-29C[1] to 250C

Ball

Stem

Seat

Gasket

Gland packing

Stem bearing

Spring

Stud bolt

Nut

Seat gasket

62-BG

-29C[1] to 350C

WCB (SCPH2)

WCB (SCPH2)

304SS (SUS304) + SFNi

329SS (SUS329J1) + ENP

316SS + Stellited

Spiral wounded gasket 316SS + Graphite

RPTFE

Graphite

RPTFE

Graphite

316SS

A193 G B7

A194 G 2H

RPTFE

Graphite

Stainless steel[2]

Material code

62-BX

32-BY

Temp. range

Max. 425C

-29C to 250C

Nickel alloy

Nickel alloy

32-BG

-29C to 350C

CF8M (SCS14A)

CF8M (SCS14A)

316 SS (SUS316) + SFNi

329SS (SUS329J1)

316SS + Stellited

Spiral wounded gasket 316SS + Graphite

RPTFE

Graphite

RPTFE

Graphite

316SS

A193 G B7 + Zn

A194 G 2H + Zn

RPTFE

Graphite

32-BX

Max. 500C[3]

Nickel alloy

Nickel alloy

Lower limit temperature depending on the material

SCPH2: -5C

WCB: -29C (PED certified: -15C)

Stainless steel body CF8 / SCS13A (Material code 31) also available.

Up to 450C for oxidizing conditions.

Materials in parentheses indicate equivalent JIS material or generic name.

Floating type for ASME Class 900 (15 mm to 25 mm) also available. Please consult for the details.

SFNi: Nickel alloy overlay

HCr: Hard chrome plated

Zn: Zn plated

ENP: Electroless nickel plating

KTM METALTITE BALL VALVES

FLOATING AND TRUNNION TYPE

TRUNNION TYPE STRUCTURE (BIDIRECTIONAL FLOW)

10

5

b

9

6

1

12

11

a GLAND AREA

b SEAT AREA

Seal ring

Gland

Spring

Gland packing

Seat

Graphite packing is suitable for fire-safe

service (RPTFE packing also available).

High corrosion-resistant PTFE seal ring or FKM

O-ring provides excellent sealing performance.

KTM METALTITE BALL VALVES

FLOATING AND TRUNNION TYPE

PARTS LIST (Trunnion type)

62-AY

-29C[1] to 150C

No. Parts name

1

Body

2

Body cap

3

Ball

4

5

Stem

Seat

6

7

8

9

10

11

12

Gasket

Gland packing

Stem bearing

Spring

Seal ring

Stud bolt

Nut

62-BY

CF8

(SCS13A)

+ HCr

ASME Class 150 Model E0105M, E0125M / ASME Class 300 Model E0106M, E0126M

Body material

Carbon steel

Stainless steel[2]

Material code

62-AG

62-BG

62-BX

32-AY

32-BY

32-AG

32-BG

Temp. range

-29C[1] to 250C

Max. 425C

-20C to 150C

-29C to 250C

WCB (SCPH2)

CF8M (SCS14A)

WCB (SCPH2)

CF8M (SCS14A)

CF8

CF8

(SCS13A)

(SCS13A)

+ SFNi

+ HCr

403SS (SUS403) + HCr

304SS + Stellited

RPTFE

RPTFE

O-ring

No. Parts name

1

Body

2

Body cap

3

Ball

4

5

6

Stem

Seat

Gasket

7

8

9

10

11

12

Gland packing

Stem bearing

Spring

Seal ring

Stud bolt

Nut

1.

2.

3.

CF8M

(SCS14A)

+ HCr

Nickel alloy

304SS

+ Stellited

Graphite

Graphite

Metal back PTFE

316SS

PTFE seal ring

A193 G B7

A194 G 2H

Carbon steel

62-BY

CF8 (SCS13A) +SFNi

62-BG

-29C[1] to 150C -29C[1] to 250C

WCB (SCPH2)

WCB (SCPH2)

O-ring

ASME Class 600 Model E0108M

Body material

Stainless steel[2]

Material code

62-BX

32-BY

32-BG

Temp. range

Max. 425C

-20C to 150C -29C to 250C

CF8M (SCS14A)

CF8M (SCS14A)

CF8 (SCS13A) + SFNi

403SS (SUS403) + HCr

Nickel alloy

304SS + Stellited

329SS + Stellited

Spiral wounded gasket 316 SS + Graphite

RPTFE

Graphite

Metal back PTFE

PEEK

Stellited

316SS

Nickel alloy

O-ring

PTFE seal ring

Graphite

A193 G B7

A194 G 2H

Max. 500C[3]

CF8M

CF8M

CF8M (SCS14A) +SFNi

(SCS14A)

(SCS14A)

+ SFNi

+ HCr

329SS (SUS329J1)

Nickel alloy

316SS + Stellited

RPTFE

RPTFE

Stellited

Nickel alloy

Graphite

32-BX

Graphite

Graphite

Metal back PTFE

316SS

PTFE seal ring

A193 G B7 + Zn

A194 G 2H + Zn

Stellited

Nickel alloy

Graphite

ASME Class 900 Model E0109M

Carbon steel

Stainless steel[2]

32-BX

62-BG

32-BG

Max. 500C[3]

-5C to 270C

WCB (SCPH2)

WCB (SCPH2)

-29C to 270C

CF8M (SCS14A)

CF8M (SCS14A)

CF8M (SCS14A) + SFNi

329SS (SUS329J1)

Nickel alloy

316SS + Stellited

Spiral wounded gasket 316 SS + Graphite

RPTFE

Graphite

Metal back PTFE

PEEK

Stellited

316SS

Nickel alloy

O-ring

PTFE seal ring

Graphite

A193 G B7 + Zn

A194 G 2H + Zn

CF8 (SCS13A)

CF8M (SCS14A)

+SFNi

+SFNi

329SS (SUS329J1)

304SS + Stellited 316SS + Stellited

Spiral wounded gasket 316 SS

+Graphite

Graphite

PEEK

316SS

PTFE / PEEK seal ring

A193 G B7

A193 G B7 + Zn

A194 G 2H

A194 G 2H + Zn

Lower limit temperature depending on the material

SCPH2: -5C

WCB: -29C (PED certified: -15C)

Stainless steel body CF8 (Material code 31) also available.

Up to 450C for oxidizing conditions.

Materials in parentheses indicate equivalent JIS material or generic name.

SFNi: Nickel alloy overlay

HCr: Hard chrome plated

Zn: Zn plated

KTM METALTITE BALL VALVES

FLOATING AND TRUNNION TYPE

FLOATING TYPE (FULL BORE)

W

W1

W2

H

Handle for valvesizeDN 65, 80

H

W3

H

W

d

H1

Handle for valvesize DN 100

L

Size DN 125 to 200

Full bore

Size DN 15 to 100

Full bore

JIS10K / ASME CLASS 150 DIMENSIONS (mm)

Valve size

(DN)

15

20

25

40

50

65

80

100

125

150

200

d

13

19

25

38

51

64

76

102

127

152

203

L

108

117

127

165

178

190

203

229

356

394

457

H

81

85

98

125

135

165

174

240

311

331

414

L

Size DN 150 to 200

Full bore

H1

348

421

W

200

200

240

350

350

600

600

1130

1740

1740

2345

Model EB11M

Bare stem*

weight (kg) Gear type

2

3

5

9

11

18

21

34

63

83

B

132

C

W1

350

420

W2

600

800

W3

115.5

171.0

Gear weight

(kg)

35

74

Model EB12M

Bare stem*

weight (kg) Gear type

W1

W2

W3

Gear weight

(kg)

350

420

600

800

115.5

171.0

35

74

* Bare stem: Valve without gear, operation parts, actuator.

JIS20K / ASME CLASS 300 DIMENSIONS (mm)

Valve size

(DN)

H1

15

20

25

40

50

65

80

100

125

150

200

13

19

25

38

51

64

76

102

127

152

203

140

152

165

190

216

241

283

305

381

403

502

81

85

98

125

135

165

174

240

311

331

414

348

421

200

200

240

350

350

600

600

1130

1740

1740

2345

3

4

6

12

17

26

33

53

77

116

187

B

C

* Bare stem: valve without gear, operation parts, actuator.

ASME CLASS 600 DIMENSIONS (mm)

Valve size

(DN)

15

20

25

40

RF

13

19

25

38

165

190

216

241

Model E0108M

L

RJ

-

163

190

216

241

Cv VALUES

H

98

105

124

134

240

240

350

350

Floating type for ASME Class 900 (DN 15 to 25) are available on request.

Floating type

Valve size (DN)

Full bore

15

26

20

50

25

94

40

260

50

480

65

750

80

1300

100

2300

125

3800

150

5400

200

10000

Trunnion type

Valve size (DN)

Full bore

50

480

80

1300

100

2300

150

5400

200

10000

250

16000

300

24000

350

31400

400

43000

450

57000

500

73000

KTM METALTITE BALL VALVES

FLOATING AND TRUNNION TYPE

TRUNNION TYPE (FULL BORE)

W

H

H1

H1

W1

d

H2

W2

Sizes DN 50 to 100

Full bore

Sizes DN 150 and larger

Full bore

JIS10K / ASME CLASS 150 DIMENSIONS (mm)

Valve size

(DN)

H1

H2

50

80

100

150

200

51

76

102

152

203

178

203

229

394

457

154

193

254

-

131

186

210

386

448

81

108

132

207

265

350

600

1065

-

L

533

610

686

762

864

914

Carbon steel

H1

H2

521

325

580

365

659

400

699

440

769

500

964

555

Valve size

(DN)

250

300

350

400

450

500

W3

H2

d

254

305

337

387

438

489

Stainless steel

H1

H2

521

335

580

385

714

430

717

470

767

520

972

590

Model E0125M

Bare stem*

weight (kg)

13

31

44

133

229

Model E0105M

Bare stem*

weight (kg)

330

490

605

891

1122

1408

Gear type

W1

W2

W3

B

C

350

420

600

800

115.5

171.0

Gear type

C

C

D

D

E

H1

W1

420

420

400

400

450

410

W2

800

800

800

800

800

800

W3

171.0

171.0

257.0

257.0

354.5

150.0

Gear weight

(kg)

35

74

Gear weight

(kg)

74

74

145

145

150

207

* Bare stem: valve without gear, operation parts, actuators.

KTM METALTITE BALL VALVES

FLOATING AND TRUNNION TYPE

JIS20K / ASME CLASS 300 DIMENSIONS (mm)

Valve size

(DN)

50

80

100

150

200

d

51

76

102

152

203

L

216

283

305

403

502

H

154

193

254

-

H1

131

186

210

386

448

L

568

648

762

838

914

991

Carbon steel

H1

H2

521

325

619

365

659

400

699

440

904

500

964

555

H2

81

108

132

207

265

W

350

600

1065

-

Model E0126M

Bare stem*

weight (kg)

20

40

73

169

286

Gear type

B

C

W1

350

420

W2

600

800

W3

115.5

171.0

Gear weight

(kg)

35

74

Gear type

C

D

E

E

H1

H1

W1

420

400

450

450

410

410

W2

800

800

800

800

800

800

W3

171.0

257.0

354.5

354.5

150.0

150.0

Gear weight

(kg)

74

145

150

150

207

207

Model E0106M

Valve size

(DN)

250

300

350

400

450

500

d

254

305

337

387

438

489

Stainless steel

H1

H2

521

335

619

385

664

430

717

470

902

520

972

590

Bare stem*

weight (kg)

402

583

814

1133

1408

1694

* Bare stem: valve without gear, operation parts, actuators.

ASME CLASS 600 DIMENSIONS (mm)

Valve size

(DN)

50

80

100

150

200

250

300

350

400

Model E0108M

L

d

51

76

102

152

203

254

305

337

387

RF

292

356

432

559

660

787

838

889

991

RJ

295

359

435

562

664

791

841

892

994

H

192

253

-

H1

350

454

534

632

763

806

-

H2

132

143

173

242

312

377

440

490

514

W

600

1130

-

Gear type

B

C

D

E

H1

H1

-

W1

350

420

400

450

410

410

-

W2

600

800

800

800

800

800

-

W3

115.5

171.0

257.0

354.5

150.0

150.0

-

Reduced bore are available, please consult us for details.

Trunnion type for ASME Class 900 (DN 40 to 300) are available on request.

10

KTM METALTITE BALL VALVES

FLOATING AND TRUNNION TYPE

KTM MODEL CODING SYSTEM

Example:

Valve code

EB11

62

AY

A15

SF

450

450

18

500

500

20

150

E2

Class

Description

ASME

JIS

EB11

150

10K

Full bore Floating type DN 15 to 200

EB12

300

20K

Full bore Floating type DN 15 to 200

E0105 (E1101)

150

10K

Full bore Trunnion type DN 250 to 500

E0106 (E1102)

300

20K

Full bore Trunnion type DN 250 to 500

E0125 (E1125)

150

10K

Full bore Trunnion type DN 50 to 200

E0126 (E1126)

300

20K

Full bore Trunnion type DN 50 to 200

E0108 (E1108)

600

Full bore Floating type DN 15 to 400

E0108 (E1108)

600

Full bore Trunnion type DN 50 to 400

E0109 (E1109)

900

Full bore Trunnion type DN 40 to 300

* Model in parentheses: Apply to Extension bonnet type.

Sub code

M

Description

Metal seated

Special feature

Blank

E

K

Description

Not applicable

Extension bonnet (For model code EB)

Powder service

Body code

Description

JIS

SCS13A (304SS)

SCS14A (316SS)

SCPH2

ASTM

CF8 (304SS)

CF8M (316SS)

WCB

Flange code

ASME

A15

A30

(JPI also available)

Description

ASME Class 150

ASME Class 300

ASME

A60

A90

Connection code

RF

RJ

SF

Size code 15

DN

15

NPS

Description

Raced face

Ring joint

Smooth finish 125 to 250 AARH

20

25

40

50

20

25

40

50

1

1

2

Option code

Blank

E2

E4

Description

No additional option

Extension bonnet for high temperature (For model code EB)

Extension bonnet for high temperature (For other than model code EB)

31

32

62

Trim code

See trim code table

TRIM CODE

AY[1]

BY

AG[1]

BG

BX

1.

2.

3.

4.

JIS

SCS13A / HCr[2] or SCS14A / HCr[3]

SCS13A / SFNi[2] or SCS14A / SFNi[3]

SCS13A / HCr[2] or SCS14A / HCr[3]

SCS13A / SFNi[2] or SCS14A / SFNi[3]

SCS13A / SFNi[2] or SCS14A / SFNi[3]

Description

ASME Class 600

ASME Class 900

65

65

2

80

80

3

100

100

4

125

125

5

Ball

ASTM

CF8 / HCr[2] or CF8M / HCr[3]

CF8 / SFNi[2] or CF8M / SFNi[3]

CF8 / HCr[2] or CF8M / HCr[3]

CF8 / SFNi[2] or CF8M / SFNi[3]

CF8 / SFNi[2] or CF8M / SFNi[3]

Trim code AY and AG are not available for Class 600 and 900

For body code 31 and 62

For body code 32

For the details, please refer to Parts list on page 4, 5

JIS

J10

J20

150

150

6

Description

JIS 10K

JIS 20K

200

200

8

250

250

10

300

300

12

350

350

14

400

400

16

Seat[4]

Packing

Stem[4]

SS+stellited

SS+stellited

SS+stellited

SS+stellited

SS+stellited

RPTFE

RPTFE

Graphite

Graphite

Graphite

HCr: Hard chrome plating

SFNi: Nickel alloy overlay

11

PENTAIR VALVES & CONTROLS

www.pentair.com/valves

All Pentair trademarks and logos are owned by Pentair plc. All other brand or product names are trademarks or registered marks of their respective owners.

Because we are continuously improving our products and services, Pentair reserves the right to change product designs and specifications without notice.

Pentair is an equal opportunity employer. 2014 Pentair plc. All rights reserved.

You might also like

- Public Media PDF PDF BALLDocument64 pagesPublic Media PDF PDF BALLCarlos LópezNo ratings yet

- A - General Bray InternationalDocument16 pagesA - General Bray InternationalNestor QuevedoNo ratings yet

- Valves - PresentationDocument119 pagesValves - Presentationkrahul100% (15)

- Catalogo Valvula Compuerta NewcoDocument92 pagesCatalogo Valvula Compuerta NewcoAlfredo Medina100% (1)

- DeZURIK KCG Knife Gate ValvesDocument12 pagesDeZURIK KCG Knife Gate ValvesKithkarnonNo ratings yet

- OneSteel Valve Product CatalogueDocument40 pagesOneSteel Valve Product CatalogueEr Pupone de Naza100% (1)

- BallValve Body Trim MaterialDocument3 pagesBallValve Body Trim Materialsabes26No ratings yet

- Flanged Standard Bore Ball Valves: ANSI CLASS 150 & 300Document8 pagesFlanged Standard Bore Ball Valves: ANSI CLASS 150 & 300marpadanNo ratings yet

- KTMMC 0550 UsDocument84 pagesKTMMC 0550 UsmaungmaunglattNo ratings yet

- Ball Valve GuideDocument22 pagesBall Valve GuideBalakrishna BisoyiNo ratings yet

- Material SpecificationDocument50 pagesMaterial SpecificationSangyt Karna0% (2)

- Steel UserguideDocument50 pagesSteel UserguideBhanu Pratap ChoudhuryNo ratings yet

- High Performance Butterfly ValvesDocument8 pagesHigh Performance Butterfly ValvesTejas JasaniNo ratings yet

- SteelDocument38 pagesSteelArdeela IlezNo ratings yet

- ZD Company PresentationDocument38 pagesZD Company Presentationcheng xinxianNo ratings yet

- Kitz Stainless Steel Catalog NewDocument58 pagesKitz Stainless Steel Catalog NewFerri HermawanNo ratings yet

- Userguide For SSDocument26 pagesUserguide For SSehsan4uNo ratings yet

- Válvulas Bola SegmentadaDocument12 pagesVálvulas Bola SegmentadarehynaldoNo ratings yet

- Gasket Documents PDFDocument66 pagesGasket Documents PDFramnadh803181No ratings yet

- Ball ValveDocument12 pagesBall ValveIdabaNo ratings yet

- WKM HP Butterfly BrochureDocument28 pagesWKM HP Butterfly BrochureAarthi PadmanabhanNo ratings yet

- Flow ServeDocument8 pagesFlow ServeSagarKBLNo ratings yet

- Metal Seated Ball ValvesDocument14 pagesMetal Seated Ball ValvesUday GokhaleNo ratings yet

- Industeel Tableau Nuances Special Carbon and Low AlloyDocument1 pageIndusteel Tableau Nuances Special Carbon and Low AlloyPravin VisputeNo ratings yet

- Ball Valve SeatDocument4 pagesBall Valve SeatRobin HillsonNo ratings yet

- KITZ Ball Valve SeatDocument4 pagesKITZ Ball Valve Seatarachman297988No ratings yet

- Ball Valves: DN-300 (12) To DN-400 (16 Class-150 & 300 DN-150 (6) To DN-300Document52 pagesBall Valves: DN-300 (12) To DN-400 (16 Class-150 & 300 DN-150 (6) To DN-300dchosgo2639No ratings yet

- KGV Bi MDocument3 pagesKGV Bi MArmando Palacios EscuderoNo ratings yet

- m10 BWDocument2 pagesm10 BWMiguel CallataNo ratings yet

- Ball Valve KnowledgeDocument40 pagesBall Valve KnowledgeMeanRat100% (1)

- TRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFDocument8 pagesTRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFjdietz4No ratings yet

- Navco b2 BrochureDocument16 pagesNavco b2 Brochurejorge28csNo ratings yet

- NLMK in Hot Rolled ProductsDocument7 pagesNLMK in Hot Rolled Productsafraz_xecNo ratings yet

- ASME Class 150 and 300Document12 pagesASME Class 150 and 300pca97No ratings yet

- 2WS21ENDocument8 pages2WS21ENcibocrisNo ratings yet

- Ball Valves - Metal SeatedDocument6 pagesBall Valves - Metal Seatedmetasoniko2014No ratings yet

- Catálogo Válvula DirecionalDocument20 pagesCatálogo Válvula DirecionalcristianoclemNo ratings yet

- A 447Document27 pagesA 447superman3kNo ratings yet

- GasketDocument45 pagesGasketSathish RajanNo ratings yet

- AMRI ISORIA 10 Type Series Booklet Data PDFDocument20 pagesAMRI ISORIA 10 Type Series Booklet Data PDFMurrali Raj Jeyagapal50% (2)

- CIRCOR D-Series Technical BrochureDocument12 pagesCIRCOR D-Series Technical BrochureJAYNo ratings yet

- Score GCDocument41 pagesScore GCJim PengNo ratings yet

- Valvula Bola Sarco m40Document3 pagesValvula Bola Sarco m40radacoNo ratings yet

- V9271 Fivalco 2902eDocument6 pagesV9271 Fivalco 2902eharenas7No ratings yet

- C1e 010Document9 pagesC1e 010Agung SumargoNo ratings yet

- MK15-BW: Semi-Welded Plate Heat ExchangerDocument2 pagesMK15-BW: Semi-Welded Plate Heat ExchangerAli NorouziNo ratings yet

- Two BallDocument5 pagesTwo Ballchartwithsam0041653No ratings yet

- AGS Gaskets TrainingDocument31 pagesAGS Gaskets TrainingMee WinNo ratings yet

- Selection Guide EmersonDocument16 pagesSelection Guide Emersonmmrjbi9412No ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Proceedings of the 8th International Symposium on Superalloy 718 and DerivativesFrom EverandProceedings of the 8th International Symposium on Superalloy 718 and DerivativesNo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesFrom EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- Fundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationFrom EverandFundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- (B) Mechanical Properties of Matter: Hooke's LawDocument57 pages(B) Mechanical Properties of Matter: Hooke's LawOwani JimmyNo ratings yet

- Iron Carbon Phase DiagramDocument4 pagesIron Carbon Phase DiagramFuhad HasanNo ratings yet

- A Study On Employee Satisfaction in Avatar Gold and Diamonds, EdappalDocument74 pagesA Study On Employee Satisfaction in Avatar Gold and Diamonds, EdappalAkNo ratings yet

- THS 2001 - Brochur of All Articles PresentedDocument239 pagesTHS 2001 - Brochur of All Articles Presentedramkumar31No ratings yet

- Chlorimet 2 (N-7M) and Chlorimet 3 (CW-6M)Document6 pagesChlorimet 2 (N-7M) and Chlorimet 3 (CW-6M)gullenariNo ratings yet

- Company Profile for Globaltech EnterprisesDocument9 pagesCompany Profile for Globaltech EnterprisesDEOGRATIUSNo ratings yet

- Super Alloys (Ni-Base) and Dislocations, An IntroductionDocument26 pagesSuper Alloys (Ni-Base) and Dislocations, An IntroductionHassanNo ratings yet

- PHY4207 - Chap 2 - Solidification PDFDocument49 pagesPHY4207 - Chap 2 - Solidification PDFshuhazllyNo ratings yet

- EMAM PHASE DIAGRAMS AND ALLOY CONSTITUTIONDocument159 pagesEMAM PHASE DIAGRAMS AND ALLOY CONSTITUTIONDaniel DasNo ratings yet

- BS en 00612-2005 (2006)Document18 pagesBS en 00612-2005 (2006)Binh Hung OngNo ratings yet

- Chapter-3 Metals and Non-Metals MCQsDocument13 pagesChapter-3 Metals and Non-Metals MCQsfagstdjdNo ratings yet

- Ferrous Alloys: Printed: September Author: R. KattusDocument34 pagesFerrous Alloys: Printed: September Author: R. KattussunsirNo ratings yet

- Ductile Iron Documents 1Document277 pagesDuctile Iron Documents 1emir_osman5940No ratings yet

- SP14Document13 pagesSP14Sumit Thakur100% (1)

- L3 - Connectors-in-Fpd 1Document47 pagesL3 - Connectors-in-Fpd 1ALAA IBRAHIM IBRAHIMNo ratings yet

- 15CrMo Alloy Steel Tube Resource GuideDocument5 pages15CrMo Alloy Steel Tube Resource GuideIbnu KhusnaNo ratings yet

- Material For Automobile Chassis and BodyDocument17 pagesMaterial For Automobile Chassis and BodyRinu SathyanNo ratings yet

- Casting Lost Wax ProcessDocument13 pagesCasting Lost Wax ProcessNaveen S YadavNo ratings yet

- Smarajit Sarkar Department of Metallurgical and Materials Engineering NIT RourkelaDocument251 pagesSmarajit Sarkar Department of Metallurgical and Materials Engineering NIT RourkelaAvinash SiwachNo ratings yet

- Manufactured Substances in Industry: By: Nur Adriana Filzah BT Muhd Khar MunzakarDocument14 pagesManufactured Substances in Industry: By: Nur Adriana Filzah BT Muhd Khar MunzakarHafiy SiddqiNo ratings yet

- Aero4syll PDFDocument28 pagesAero4syll PDFLokeshNo ratings yet

- Api 571-1Document11 pagesApi 571-1Raghavan100% (1)

- Module 06 B1 NotesDocument276 pagesModule 06 B1 Notesmechanomano100% (2)

- Engg - Materials - Effect of Alloying ElementDocument22 pagesEngg - Materials - Effect of Alloying ElementSmruthi SuvarnaNo ratings yet

- Aalco Catalogue PDFDocument72 pagesAalco Catalogue PDFdisasterdazNo ratings yet

- Welding Base MetalsDocument9 pagesWelding Base MetalsBaluNo ratings yet

- Airframe Design Chapter Explains Wings, Fuselage, Tail Unit and UndercarriageDocument104 pagesAirframe Design Chapter Explains Wings, Fuselage, Tail Unit and UndercarriageBen NimmoNo ratings yet

- Engineering MaterialDocument2 pagesEngineering Materialultimatestatus2279No ratings yet

- SMT BrochureDocument8 pagesSMT BrochureLucas LobãoNo ratings yet

- High Strength Low Alloy Structural SteelsDocument16 pagesHigh Strength Low Alloy Structural SteelsTuan DangNo ratings yet