Professional Documents

Culture Documents

A Case Study On SCADA Implementation in 220 KV Substation

Uploaded by

malini72Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Case Study On SCADA Implementation in 220 KV Substation

Uploaded by

malini72Copyright:

Available Formats

INTERNATIONAL JOURNAL FOR RESEARCH IN EMERGING SCIENCE AND TECHNOLOGY, VOLUME-2, ISSUE-7, JULY-2015

E-ISSN: 2349-7610

A Case Study on SCADA Implementation in

220 kV Substation

Vinuta V Koluragi1

M.Tech(Power and Energy Systems)

Assisstant Professor

B.L.D.E.As V P Dr P. G. Halakatti College of Engg. & Tech., Bijapur.

ABSTRACT

Development of nation depends upon electricity energy and at present scenario there is large gap between electric generation and

load. This gap can be filled with proper control, monitoring and coordinating the distribution components at power sector. In this

view, Automation of power distribution system has increasingly been adopted by power utilities worldwide in recent years. As

part of its efforts to provide a more reliable supply to the customer and to enhance operational efficiency, the automation of the

power system can be achieved by SCADA (Supervisory Control And Data Acquisition). It is a boon to the automation concept of

dynamic technology. Karnataka Power Transmission Corporation Limited (KPTCL) has undertaken steps to automate existing

substation and new substation by use of most advanced controlling and monitoring technology ABB SCADA. Karnataka Power

Transmission Corporation Limited, presently with the help of SCADA covers major generating stations and Independent Power

Producers (IPP), receiving stations ranging from 33kV to 400kV, collects data from all feeders from 11 KV to 400 KV, upgrades

information to Load Despatch Center (LDC). Real time data acquisition from all interface points by SCADA, helps to perform

energy billing, energy audit and Availability Based Tariff (ABT) functions, and Sub-system to perform Open Access operations.

Keywords: Real Time Monitoring and Controlling, SCADA, RTU, ABT.

NOMENCLATURE

SCADA

: Supervisory Control And Data Acquisition

RTU

: Remote Terminal Unit

ABT

: Availability Based Tariff

operation

1. INTRODUCTION

are

the

major

operating

concerns.

Online

Karnataka Power Transmission Corporation Limited is a

monitoring, operation and control of the modern day power

registered company under the Companies Act, 1956 was

systems have become impossible without computer aided

incorporated on 28-7-1999 and is a company wholly owned by

monitoring & dispatching systems. The basic requirement to

the Government of Karnataka with an authorized share capital

fulfill these needs is SCADA.

of Rs. 1000 crores. KPTCL was formed on 01-08-1999 by

The ability to perform operations at an unattended location

carving out the Transmission and Distribution functions of the

from an attended station or operating center and to have a

erstwhile Karnataka Electricity Board [5].

definite indication that the operations have been successfully

Present day power systems have large interconnected

carried out can provide significant cost saving in the operation

networks. The success of the recently evolving electricity

of a system. This is exactly what is achieved through the

market structure will heavily depend on modern information

SCADA system. A formal definition of SCADA system, as

systems and online decision tools. Maintaining system

recommended by IEEE [1], is A collection of equipment that

security, reliability, quality, stability and ensuring economic

will provide an operator at a remote location with sufficient

VOLUME-2, ISSUE-7, JULY-2015

COPYRIGHT 2015 IJREST, ALL RIGHT RESERVED

57

INTERNATIONAL JOURNAL FOR RESEARCH IN EMERGING SCIENCE AND TECHNOLOGY, VOLUME-2, ISSUE-7, JULY-2015

E-ISSN: 2349-7610

information to determine the status of particular equipment or

2.1 Process Level Function: extracts the information from

a process and cause actions to take place regarding that

sensors/transducers in the substation and to send them to upper

equipment or process without being physically present.

level device, called bay level device. The other major task of

SCADA provides open architecture rather than a vendor

process level function is to receive the control command from

controlled proprietary environment. It interfaces hardware and

bay level device and execute it at the appropriate switch level.

software, and it includes functionality such as trending, alarm

handling, logging archiving, report generation, and facilitation

of automation. Thus SCADA has been used has powerful tool

for power system automation, that refers to automatic

switching, regulating, controlling, logging, protection etc. of

electric power flow without human intervention.

2.2 Bay Level Functions: acquire the data from the bay

and then mainly act on the primary (power circuit) equipment

of the bay. The different conceptual subparts of a substation

are encircled by line in figure 2.

Station Level Functions: are of two types.

2.2.1 Process Related Functions act on the data from

2. SCADA IMPLEMENTATION IN 220KV

multiple bays or substation level database. These functions are

SUBSTATION

used to submit the control commands for the primary

200/110/11kV Shivgiri substation Bijapur is newly installed

equipment (Circuit breakers) and collect the substation data

substation. Under IES project, automation of new substation is

like voltage, current, power factor etc. from the bay level

done through Substation Automation System (SAS) using IEC

devices. Each bay includes one primary equipment such as

61850. The functions performed by Substation Automation

transformers, feeders etc.

(SA) system are in, general, switch control, data monitoring,

2.2.2

protection etc. In IEC-61850, these functions are broken into

interface of the substation automation system to the local

low-level functions called sub-functions. Each sub-function is

station operator HMI (Human Machine Interface), to a remote

performed by the IED installed in the substation. Each IED

control centre for monitoring and maintenance.

Interface

Related Functions

enable

interactive

can perform one or many sub functions. A set of sub-functions

is integrated together to realize a substation automation

There are basically two types of equipment in a substation:

function. These communicate with each other through Local

(i) Primary equipments and (ii) Secondary equipments.

Area Network in the substation. Specific syntax and semantics

2.3.2.1 Primary Equipments Include

are defined for communication between sub-functions. All the

possible sub-functions have been standardized in IEC61850.Information produced and required by each substation

is given in the IEC-61850 standard [1].

The sub functions are assigned at three levels as shown in

figure 1: (i) Process level (ii) Bay level (iii) Station level

Fig 2: Conceptual Substation Bays [1]

transformer, switchgear etc. Secondary equipments include

protection, control and communication equipments. Further,

secondary equipments are categorized into three levels in IECFig 1: Levels defined in IEC 61850 [1]

VOLUME-2, ISSUE-7, JULY-2015

61850 standards. These are station level, bay level, and

COPYRIGHT 2015 IJREST, ALL RIGHT RESERVED

58

INTERNATIONAL JOURNAL FOR RESEARCH IN EMERGING SCIENCE AND TECHNOLOGY, VOLUME-2, ISSUE-7, JULY-2015

E-ISSN: 2349-7610

process level equipments. A conceptual substation automation

RET670-Transformer Protection IED: It is used for reliable

system based on the IEC 61850 standard is evolved and

protection & control of all types of power transformers and

depicted in figure 3.

reactors. Also it provides protection solution for any type of

transformer & shunt reactor application. It gives freedom to

select functionality according to our needs, basic functionality

is included and pre configured. A single RET670 can integrate

complete protection & control functionality for a transformer

& a connected transmission line. The distance protection

function can also be used as back up protection for faults with

in transformer & in connected lines. In all, RET670 increases

reliability and profitability of entire power system. Figure 4

shows RET670 IED.

Fig 3: Conceptual Substation Automation Topology [1]

With this conceptual view at 220kV substation Bijapur there

are 8 bays divided. Control and monitoring operation is

carried out both remotely and locally. At substation 4 IEDs are

used for collecting information and OFC is used for local

communication, for remote communication Ethernet and

Fig 4: RET670-Tansformer protection IED [8]

VSAT is used. SAS consists of Bay Control & Protection

It is designed to operate correctly over a wide frequency range

Panel and Protection Panel, they are manufactured by ABB.

in order to accommodate power system frequency variations

Control & Relay panels and Protection panel are inbuilt in

during disturbances. RET670 features also several function for

ABB panel.

local and remote apparatus control on all sides of transformer.

2.2.2.2. SCADA Equipments to Substation:

220/110/11kV substation control room is provided with Bay

Control & Protection panel and Protection panel by ABB. All

the ABB panels are equipped with 4 IEDs used for protection

It provides a large HMI for local control and instantly

accessing important data, such as settings, events and

disturbance information. 30 apparatuses can be controlled and

visualized. Large HMI provides overview of quick status of

and control. ABBs IED 670 series provides reliable, efficient

substation with position indications and service values [6].

and flexible protection, monitoring and control for all

REC670-Bay Control IED: It provides optimized control and

applications in sub-transmission and transmission systems.

reliable operation of switch yard. It provides pre configured

IED provides a common powerful hardware platform and an

control solution for any type of switch gear and different

extensive hardware-independent, modular function library.

switch gear configuration. REC670 enables the manual control

Setting, commissioning and maintenance procedures of all

of a tap-changer from a Substation Automation system. It also

IED are fast and simple. All are similar hence user can learn

integrates advanced voltage control for transformers in a

about one to know them all. These can communicate easily

substation in a single IED. This eliminates the need for

with IEC61850.

dedicated voltage control devices in cases where the

List of Intelligent Electronic Device (IED) 670:

transformer protection is not equipped with voltage control.

1.

RET670-Transformer Protection IED.

The REC670 IEDs feature a large HMI for local control and

2.

REC670-Bay Control IED.

instant access to important data, such as settings, events and

3.

REL670-Line Distance Protection IED.

disturbance information. The control is based on the select

4.

REB670-Busbar Differential Protection IED.

before operate principle to ensure secure operation and to

avoid human mistakes. Control screen can be selected as

VOLUME-2, ISSUE-7, JULY-2015

COPYRIGHT 2015 IJREST, ALL RIGHT RESERVED

59

INTERNATIONAL JOURNAL FOR RESEARCH IN EMERGING SCIENCE AND TECHNOLOGY, VOLUME-2, ISSUE-7, JULY-2015

E-ISSN: 2349-7610

default screen. Control commands can be directly executed

and important measurements can be read. All measurements

are available in IED can be shown on HMI. Graphical display

can be configured as it is at substation. Figure 5 shows

REC670 IED.

Fig 6: REL670-Line distance protection IED [8]

independent, which ensures high reliability for all types of

lines. The distance and earth-fault protection functions can

communicate with remote end in any communication scheme.

It offers full control and interlocking functionality required for

Fig 5: REC670 -Bay control IED [8]

control of apparatuses in a substation. The integrated HMI

REC670 is able to handle a large number of analog signals

from CTs and VTs. The outstanding I/O capability enables

control of several bays with complete measurement with only

one IED. One REC670 IED is capable of handling control of

all apparatuses in one entire diameter in 1 breaker

allows secure and quick local control for stand-alone

applications and provides back-up control for substation

automation systems. REL670 provides efficient substation

automation solutions in terms of performance, redundancy and

cost for any high voltage application [6].

arrangement including breaker failure protection for all

REB670-Busbar Differential Protection IED: It is designed

breakers [6].

for the protection and monitoring of bus bars. REB670

REL670-Line Distance Protection IED: It provides versatile

protection,

monitoring

maximum

flexibility

and

and

control

functionality

performance

optimized

with

for

transmission overhead lines and cables. The powerful IED

provides distance protection for double circuit, parallel

operating and series compensated lines. REL670 IEDs are able

to protect and control several objects, for instance a

combination of a line and a transformer with a single IED. As

a result, this IED increases both the reliability and profitability

of entire power system. REL670 provides both customized

protects single and double bus bars with or without transfer

bus, double circuit breaker or one-and-half circuit breaker

arrangements. It provides selective, reliable and fast fault

clearance for all types of internal phase-to-phase and phase-toearth faults in solidly earthed or low-impedance earthed power

systems. At the same time, it maintains complete stability for

external faults, even when heavy CT saturation occurs. It can

also handle all internal multi-phase faults in isolated or highimpedance earthed power systems [6]. Figure 7 shows

REB670 IED.

and pre-configured protection solutions. The pre-configured

IEDs are equipped with complete functionality adapted for

four different configuration alternatives: single pole breaker or

multi-breaker arrangements with single or three phase

tripping. Figure 28 shows REL670 IED.

REL670 provides protection of power lines with high

sensitivity

and

low

requirement

on

remote

end

communication. Measurements and setting of all five zones

with six setting groups are made completely

VOLUME-2, ISSUE-7, JULY-2015

Fig 7: REB670-Bus bar differential protection IED [8]

2.2.2.3. SCADA Connections:

COPYRIGHT 2015 IJREST, ALL RIGHT RESERVED

60

INTERNATIONAL JOURNAL FOR RESEARCH IN EMERGING SCIENCE AND TECHNOLOGY, VOLUME-2, ISSUE-7, JULY-2015

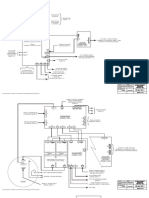

At 220/110/11kV substation, Substation Automation System

E-ISSN: 2349-7610

11kV feeder

(SAS) consists of 27 panels for protection and bay control.

Layout of panels at control room is shown in figure 8.

Feeder

Feeder

Feeder

B&P - Bay Control & Protection Panel

1&2

3&4

5&6

P - Protection Panel

B&P

B&P

B&P

BBA - Bus Bar Protection Panel

INDI 1 Indi line 1

INDI 2 Indi line 2

TRF 1 HV Transformer 1 HV side

TRF 1 LV Transformer 1 LV side

TRF 2 HV Transformer 2 HV side

TRF 2 LV Transformer 2 LV side

BGD 1 Basavan Bagewadi line 1

BGD 2 Basavan Bagewadi line 2

Fig 8: Layout of panels at Control center at 220/110/11kV

substation

IES project provides Ruzzegged com (Ethernet) Switch, 3

personal computers DRPC, SAS1 and SAS2, printer, event

list recorder and for communication VSAT, OFC. Connection

of ABB panels is shown in figure 9. There are 8 bays at

substation; at each bay have one ruzzegged com switch which

connects all bay information to main SAS through OFC.

Information from SAS can be monitored and controlled

locally and also information is sent to Master Control center

For SAS

SAS

(MCC).

SUX

Station

Auxiliary

Bay

Control

Panel

2BBA1

220kV Bus

Bar

Protection

Panel

2BBA2

220kV Bus

Bar

Protection

Panel

220kV line

I

N

D

I1

P

I

N

D

I

1

B

&

P

I

N

D

I

2

P

I

N

D

I

2

B

&

P

Bus

Coupler

B&P

T

R

F

1

H

V

B

&

P

T

R

F

1

L

V

B

&

P

Fig 9: Connection of ABB panels at substation

As shown in figure 9 communication network used is StarRing topology. This topology has potential to provide time

BGD

2

P

BGD 2

B&P

BGD

1

P

BGD

1

B&P

TRF

2

HV

B&P

TRF

2

LV

B&P

delay within allowable range and also offers the better

reliability of the process bus.

2.2.2.4. SCADA Operations:

Local operator at substation control room observes and

110kV line

monitors 220kV, 110kV and 11kV lines. Single line diagram

11kV

Bank

B&P

10 MAV

TRF HV

110/11kV

IE 2

B&P

VOLUME-2, ISSUE-7, JULY-2015

monitoring screen display of 220/110/11kV, 110kV and 11kV

110kV

BGD B&P

Bijapur

B&P

110kV Bus

Coupler

IE 1

B&P

line is shown in figure 10(a), 10(b) and 10(c) respectively.

Overview of 220/110/11kV substation Bijapur is monitored by

monitored by operator at control room. Same single line

COPYRIGHT 2015 IJREST, ALL RIGHT RESERVED

61

INTERNATIONAL JOURNAL FOR RESEARCH IN EMERGING SCIENCE AND TECHNOLOGY, VOLUME-2, ISSUE-7, JULY-2015

E-ISSN: 2349-7610

diagram is displayed at remote control center. In single

diagram display of SCADA screen symbols of Lighting

Arrestor (LA), Gang or Group Operated switch (GOS) and

Circuit Breaker (CB) are used. Table 1 shows symbols used

for SCADA.

Table 1: Symbols used in SCADA Screen

Sl

Equipment

Symbols

No.

Identity

No.

Lighting

89CE

Arrestor

(LA)

grounding

Fig 10(B): Single Line Diagram Display of 110kv Line at

Control Room

Gang or

2

Group

89D

Operated

switch

(GOS)

Circuit

52

Breaker

(CB)

Fig 10(C): Single Line Diagram Display of 11kv Line at

Control Room.

At present operator at substation operates 11kV circuit

breakers at control room. He note down the measurement

values displayed on monitoring screen as shown on figure 11.

Real time values are noted at every one hour and daily load is

generated. Also SAS provides facility of event recording and

alarms for operator.

There is also facility to operate GOS remotely. With the help

of IED fault can be recorded. 100 disturbance records can be

Fig 10(A): Single Line Diagram Display of 220/110/11kv

maintained with time and date. Indication during disturbances

Line at Control Room

is displayed which helps operator to carry out precaution or

solve the problem.

VOLUME-2, ISSUE-7, JULY-2015

COPYRIGHT 2015 IJREST, ALL RIGHT RESERVED

62

INTERNATIONAL JOURNAL FOR RESEARCH IN EMERGING SCIENCE AND TECHNOLOGY, VOLUME-2, ISSUE-7, JULY-2015

E-ISSN: 2349-7610

breaker, Supervisory control is required switch off or switch

on a consumer, Supervisory control is required to control the

generation as and when control is extended.

Scenario of power system without control centers:

There was no Grid Discipline.

Due to indiscipline there was problem of low voltage

and low frequency.

There were frequent Grid failures.

Non optimum utilization of available resources.

There was no real time availability of data/ events

occurring.

Fig 11(a):220kV measurement values.

Inefficient

Power

System

Operation

&

Load

Management

Due to no regulation wide gap in Demand - Supply

position.

Low voltages at Consumer end.

To overcome all problems India undergone Grid Discipline

through SCADA. In this view all Generation station, receiving

station and distribution station were integrated in project. Thus

data from 110kV & 220/110/11kV substation Bijapur are sent

to LDC for further operation. LDCs architecture, function is

Fig 11(b):110kV measurement values.

Table 2 gives the incoming and outgoing voltage, current,

active & reactive power, power factor and frequency observed

on 220kV measurement monitoring screen on 07/07/2011 time

briefly explained in this section.

Indian Power System Load Despatch Centers is divided into

At National level

11.00.08.

2.3. Load Despatch Center:

National Load Despatch Centre (NLDC)

At Regional Level

Load Despatch Center (LDC) is the hub for load despatch and

Five Regional grids

control, it requires acquiring all data from generation and

Regional Load Despatch Centers (RLDC)

substation to match generation and load. LDC requires data

with respect to available generation and load to be attended.

At State Level

As such real time data is required from all Generating stations;

State Load Despatch Centre (SLDC)

real time data is required from receiving stations; real time

SLDCs at each state

data is required from Interface points from where power is

delivered to Distribution companies or Consumers. LDC also

A typical architecture of an Energy management system is

has to exercise control over the receiving stations, and

shown in figure 12.

consumers and if necessary the Generators also. As such,

Table 2: 220Kv Measurement Monitoring Values

Supervisory control is required to shed loads by opening a

VOLUME-2, ISSUE-7, JULY-2015

COPYRIGHT 2015 IJREST, ALL RIGHT RESERVED

63

INTERNATIONAL JOURNAL FOR RESEARCH IN EMERGING SCIENCE AND TECHNOLOGY, VOLUME-2, ISSUE-7, JULY-2015

DATE

TIME

INDI-1

INDI-2

07/07/2011

11.00.08

201

202

Voltage in

Vry

215.01

214.67

Vyb

217.42

Vbr

BC 203

E-ISSN: 2349-7610

TRAFO-

BGWD-

BGWD-

TRAFO-

1 204

1 206

2 207

2 208

215.02

215.16

215.05

214.48

215.18

217.59

217.76

217.37

217.63

217.21

217.37

213.46

213.22

213.45

213.13

214.17

213.67

213.75

L1

0.00

87.40

0.00

50.23

186.78

0.00

49.56

L2

0.00

89.90

0.00

51.67

192.67

0.00

51.32

L3

0.00

91.26

0.00

50.48

191.50

0.00

49.75

MW

0.00

30.55

0.00

17.97

-66.39

0.00

17.75

MVAR

0.00

13.54

0.00

5.95

-25.57

0.00

5.87

0.00

0.91

0.00

0.95

0.93

0.00

0.95

49.91

49.90

49.9

49.90

49.90

49.90

49.89

kV

Current in

Ampere

Active

power

Reactive

power

Power

factor

Frequency

Hz

Northern Regional Load Despatch Center (NRLDC)

Eastern Regional Load Despatch Center (ERLDC)

Southern Regional Load Despatch Center (SRLDC)

Western Regional Load Despatch Center (WRLDC)

Northern Eastern Regional Load Despatch Center

(NERLDC)

Southern region consists of 5 State Load Despatch Centers,

they are

Pondicherry

Fig 12: A Typical Architecture of an Energy Management

Tamilnadu

System

Kerala

Karnataka

Andhra

As shown in figure 34 data collected from all substations

through SAS or RTU is sent to Area control center (ACC) and

then same data is communicated to Regional Control Center

Central generation plants, State generation plants and

(RCC).National control center will look after the whole grid.

Independent Plant Producers (IPP) connect to common Power

There are 5 Regional Load Despatch Center, they are

Grid of India. As objective of LDC is to match generation and

VOLUME-2, ISSUE-7, JULY-2015

COPYRIGHT 2015 IJREST, ALL RIGHT RESERVED

64

INTERNATIONAL JOURNAL FOR RESEARCH IN EMERGING SCIENCE AND TECHNOLOGY, VOLUME-2, ISSUE-7, JULY-2015

E-ISSN: 2349-7610

load, there is need to continuously monitor and control.

At LDC, operator can observe generation, power flow,

Karnataka states Load Despatch Center is situated at

schedule and actual energy available etc as depicted in figure

Bangalore. At SLDC Control center, Grid connection of

13.

southern region is observed. Role of SLDC is to collect

2. Open Access Monitoring: IPP can go for open access if

information from electrical companies of Karnataka and send

they wish SCADA also provides information about open

data to SRLDC. Generation and load of state is monitored and

access monitoring screen for operator.

controlled by SLDC. SLDCs send the requisition of load to the

3. ABT monitoring Screen: At KPTCL tariff is basically

SRLDCs, against their entitlements out of available power

classified into 3 components, they are; Energy consumption,

from Central Sector Generation and the SRLDCs allocate total

Maximum demand and Unscheduled Interruption (UI).

available power to various states in the ratio of their

UI component is dependent on frequency, when load exceeds

entitlements. According to available power SLDCs schedule

generation frequency decreases depend on decrease in

power for state previous day & ESCOMs had to operate

frequency additional charges are penalized. Figure 14 shows

according to schedule. If there is any problem at generation

ABT Monitoring Screen at control center. UI charges are

then it informed to SLDCs by revising. SLDCs control state

decided by CEA.

generators according to load. Data acquired at SLDC is used

for Energy auditing, Energy billing and Availability Based

Tariff (ABT).

SRLDC collects data from SLDC and controls Central

Generation. NLDC monitors all SRLDC and communicate

with Central electricity Authority (CEA).

2.3.1. SCADA Application at LDC:

1. Network application overview: The SCADA systems

caters to the whole of Karnataka state which has five

Distribution companies and 23 major generating stations and

major IPPs and Central Generation Share. Figure 35 shows

monitoring screen at control center for Karnataka state.

Fig 14: ABT Monitoring Screen [4]

As SCADA is integration of hardware and software, care must

be taken that there exist proper synchronization between them.

RTU 560A at 110/11kV substation City Bijapur is digital

equipment no maintenance is required but proper cleaning of

panel has to be carried out. Minor work for adaptability of

SCADA at 110/11kV substation were improvement of

earthing, Restoration of control desk (this includes, providing

indication lamps, closing coils and TNC switches) and Wiring

of breaker position indication in 11kv.

2.4. Maintenance:

Improvement of earthing is done by providing one CI pipe

electrode as per KPTCL standard CI earthing 50 x 6 mm MS

Fig 13: Monitoring screen for Karnataka state LDC [4]

flat for connection to earth mat 50 x 6 mm GI flat for raisers

new RTU is connected to same earth with other C&R panel.

Figure 15 shows connection for improvement of earthing.

VOLUME-2, ISSUE-7, JULY-2015

COPYRIGHT 2015 IJREST, ALL RIGHT RESERVED

65

INTERNATIONAL JOURNAL FOR RESEARCH IN EMERGING SCIENCE AND TECHNOLOGY, VOLUME-2, ISSUE-7, JULY-2015

E-ISSN: 2349-7610

Real time data acquisition from all interface points by SCADA

such as voltage, current, frequency, active power, reactive

power and power factor. Operators at all substations will send

their respective load and energy required to the LDC. LDC

sends the required total load required by to SRLDC. SRLDC

according to available generation prepares load schedule and

send to LDC, this schedule must be followed by all stations.

During generation failure, availability of generation will be

Fig 15: Connection for improvement of earthing

updated to LDC; LDC will inform further it to all substations

so that proper load control can be carried out without any

When earth mat is not provided at substation, earth resistance

interruption of power.

for SCADA has to note down after installation work at

observed and controlled, thus large gap between generation

particular substation. Table 3 gives SCADA earth resistance at

and load is reduced. It also helps to perform energy billing,

110/11kV substation Atarga during visit with ABB committee

energy audit and Availability Based Tariff(ABT) functions,

on 08/07/2011. UPS for RTU 560A will under go test for

and Sub-system to perform Open Access operations at

battery back up condition.

LDC.SCADA has facilities to record data, event list,

Table 3 : Earth resistance for SCADA

Resistance in /V

Sl No.

Equipment

SCADA CI Pipe

0.28/0.6V

VSAT GI pipe

0.29/0.6V

RTU Panel

0.23/0.5V

C&R panel

0.25/0.4V

110kV TRF

0.6/0.9V

11kV TRF

1.0/0.9V

disturbance records, and trip values during fault etc., with help

of these facilities operator at substation can analyze fault, if

any mistakes in recording readings can be easily sorted out.

Thus concluding that a full fledge SCADA system is very

much necessary for monitoring, controlling, fault detection

and prevention and to make restoration power supply activities

easier and faster.

REFERENCES

[1]

KPTCL training report Remote Substation Monitoring

And Control through SCADA, 05-09 October 2009.

3. CONCLUSION

Power Systems are large complex systems covering vast areas

In this way the total grid can be

[2]

Paper presented

[3]

Martin

Chartrand,

Dual

Redundant

Controller

National grids and highly nonlinear, high order system. Many

Systems, Control Microsystems White Paper, October

process operations need to be coordinated and millions of

2004.

devices requiring harmonious interplay. The Energy flows

[4]

Chandrashekar, Mallakkappa S Integrated Extended

from various Generating stations to various Receiving Sub

SCADA project KPTCL IES Summary, October 31

stations via Transmission networks. On line monitoring,

2007.

operation and control of the modern day power systems is

[5]

Manuals and website

required for maintaining system security, reliability, quality,

[6]

ABB RTU 560A Manual.

stability and ensuring economic operation,. The basic

[7]

www.kptcl.com and www.abb.com

requirement is of power system automation which is achieved

BIOGRAPHY

by SCADA.

SCADA covers major generating stations and Independent

Ms. Vinuta V Koluragi

Power Producers (IPP), receiving stations ranging from 33kV

Bijapur, Karnataka, India. on 13th

to 400kV, collects data from all feeders from 11 KV to 400

1987.

KV, upgrades information to Load Despatch Center (LDC).

Electrical & Electronics from B.L.D.E.As

VOLUME-2, ISSUE-7, JULY-2015

COPYRIGHT 2015 IJREST, ALL RIGHT RESERVED

She

obtained

B.E

was born in

degree

July

in

66

INTERNATIONAL JOURNAL FOR RESEARCH IN EMERGING SCIENCE AND TECHNOLOGY, VOLUME-2, ISSUE-7, JULY-2015

E-ISSN: 2349-7610

Bijapur under VTU, Belgaum. She obtained M.Tech degree

in Power & Energy System from BEC Bagalkot under VTU,

Belgaum.

She is currently working as Assisstant Professor at

B.L.D.E.As V P Dr P. G. Halakatti College of Engg. &

Tech., Bijapur. Her areas of interest are Renewable Energy

Systems, PLC and SCADA,Control Systems, Power systems.

VOLUME-2, ISSUE-7, JULY-2015

COPYRIGHT 2015 IJREST, ALL RIGHT RESERVED

67

You might also like

- The First Handheld Sound Camera For Everyone: Product DataDocument2 pagesThe First Handheld Sound Camera For Everyone: Product Datamalini72No ratings yet

- A Novel Open-Circuit Fault Detection and Location For Open-End Winding PMSM Based On Differential-Mode ComponentsDocument11 pagesA Novel Open-Circuit Fault Detection and Location For Open-End Winding PMSM Based On Differential-Mode Componentsmalini72No ratings yet

- Analysis and Design of EMI Filters For DC-DC Converters Using Chain ParametersDocument11 pagesAnalysis and Design of EMI Filters For DC-DC Converters Using Chain Parameterstinhmaixatoi2006No ratings yet

- Two-Terminal Device: Peter Mathys ECEN 1400Document3 pagesTwo-Terminal Device: Peter Mathys ECEN 1400malini72No ratings yet

- Nonisolated High Gain DC-DC Converter For DC MicrogridsDocument8 pagesNonisolated High Gain DC-DC Converter For DC Microgridsmalini72No ratings yet

- Design of EMI Filters For DC-DC Converter: September 2010Document7 pagesDesign of EMI Filters For DC-DC Converter: September 2010anilNo ratings yet

- Electric Vehicles UnpluggedDocument2 pagesElectric Vehicles Unpluggedmalini72No ratings yet

- Laboratory Experiment 4 EE348L Spring 2005Document19 pagesLaboratory Experiment 4 EE348L Spring 2005malini72No ratings yet

- Electric Vehicle Battery Management Algorithm Development-2016Document12 pagesElectric Vehicle Battery Management Algorithm Development-2016malini72No ratings yet

- Resource Schedulling of A Renewable Energy Based Virtual Power PlantDocument17 pagesResource Schedulling of A Renewable Energy Based Virtual Power PlantAlfi NgrNo ratings yet

- Chapter2 SMDocument412 pagesChapter2 SMtazeb AbebeNo ratings yet

- Energy Saving Tips for Labs Under 40 CharactersDocument1 pageEnergy Saving Tips for Labs Under 40 Charactersmalini72No ratings yet

- Iot-Based Acoustic Monitoring in A Three Phase Induction MotorDocument9 pagesIot-Based Acoustic Monitoring in A Three Phase Induction Motormalini72No ratings yet

- Electronics1 Laboratory Manual PDFDocument61 pagesElectronics1 Laboratory Manual PDFmalini72No ratings yet

- Pedagogy and Practice Teaching and Learning in Secondary Schools en PDFDocument579 pagesPedagogy and Practice Teaching and Learning in Secondary Schools en PDFCindy VargasNo ratings yet

- Dyadic Wavelet Transform-Based AcousticDocument9 pagesDyadic Wavelet Transform-Based Acousticmalini72No ratings yet

- Pres WollenbergDocument18 pagesPres WollenbergDanielAlejandroRamosQueroNo ratings yet

- 0.multi-Objective Optimal Operation of Hybrid AC - DC Microgrid Considering Source-Network-Load CoordinationDocument12 pages0.multi-Objective Optimal Operation of Hybrid AC - DC Microgrid Considering Source-Network-Load Coordinationmalini72No ratings yet

- Energy Audit Finds Savings in Lighting, ComputersDocument144 pagesEnergy Audit Finds Savings in Lighting, Computersmalini72No ratings yet

- Analysis of Permanent Magnet Synchronous MotorDocument15 pagesAnalysis of Permanent Magnet Synchronous Motormalini72No ratings yet

- Guide To Energy Saving in The Lab PDFDocument3 pagesGuide To Energy Saving in The Lab PDFmalini72No ratings yet

- Parameter Estimation For Condition MonitoringDocument12 pagesParameter Estimation For Condition Monitoringmalini72No ratings yet

- A Dual Control Regenerative Braking Strategy For TwoWheeler Application2017Energy ProcediaDocument7 pagesA Dual Control Regenerative Braking Strategy For TwoWheeler Application2017Energy Procediamalini72No ratings yet

- Pserc Grid Integration White Paper April 2010 PDFDocument7 pagesPserc Grid Integration White Paper April 2010 PDFmalini72No ratings yet

- APPROACH PAPER Transmission Pricing 150509Document63 pagesAPPROACH PAPER Transmission Pricing 150509nike_zapNo ratings yet

- 0.stochastic Optimal Operation of Microgrid BasedDocument8 pages0.stochastic Optimal Operation of Microgrid Basedmalini72No ratings yet

- Power WheelingDocument2 pagesPower Wheelingmalini72No ratings yet

- Automatic Generation Control Using Artificial Neural Networks - HarkiratDocument47 pagesAutomatic Generation Control Using Artificial Neural Networks - Harkiratmalini72No ratings yet

- Sparsity OptimizationDocument27 pagesSparsity OptimizationJoão BatistaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Case Expansion Measurements: Configuration and Verification ManualDocument44 pagesCase Expansion Measurements: Configuration and Verification ManualRabah AmidiNo ratings yet

- ET Quiz3Document11 pagesET Quiz3Pradeep Kumar BowmarajuNo ratings yet

- 13 KW Mitsubishi Generator T16K IiDocument5 pages13 KW Mitsubishi Generator T16K IiYasir JamilNo ratings yet

- Starter Feeder DetailDocument4 pagesStarter Feeder DetailAshutosh KumarNo ratings yet

- Owner's Manual: AVR-E200Document64 pagesOwner's Manual: AVR-E200SteveNo ratings yet

- DC Bus Diagram for Dual Speed Starter InverterDocument63 pagesDC Bus Diagram for Dual Speed Starter InverterВладимир МалининNo ratings yet

- Vol06 Tab021Document274 pagesVol06 Tab021ajrojas1359No ratings yet

- Biomed Presentation Jellies & Creams-2Document15 pagesBiomed Presentation Jellies & Creams-2Raghav Gupta100% (1)

- How to Use a Tester Screwdriver to Check Electrical Equipment SafetyDocument2 pagesHow to Use a Tester Screwdriver to Check Electrical Equipment SafetyrkhayrenNo ratings yet

- Network TopologyDocument47 pagesNetwork TopologySagar S Poojary50% (2)

- NikolsddDocument1 pageNikolsddMaissyNo ratings yet

- Battery Chargers Data Sheet enUS 1895966475Document3 pagesBattery Chargers Data Sheet enUS 1895966475Ahmed ShawkyNo ratings yet

- 16BT70408 - Low Power Cmos Vlsi DesignDocument1 page16BT70408 - Low Power Cmos Vlsi DesignS KkNo ratings yet

- Lektrafuse HF Generator GN200 Version 1.8Document238 pagesLektrafuse HF Generator GN200 Version 1.8ouyangxin1991No ratings yet

- EEE 101 - Lect23Document12 pagesEEE 101 - Lect23Basim AlthafNo ratings yet

- WEG w22 Three Phase Motor Technical Nema Market 50029265 Brochure EnglishDocument44 pagesWEG w22 Three Phase Motor Technical Nema Market 50029265 Brochure EnglishDerwaish JeeNo ratings yet

- EX215028 Busbar CatalogueDocument164 pagesEX215028 Busbar Cataloguewarmaster81No ratings yet

- L&T Make RelayDocument31 pagesL&T Make RelayKishore KrishnaNo ratings yet

- Install & Maintain Pressure Regulator GuideDocument4 pagesInstall & Maintain Pressure Regulator GuideBrandon TrocNo ratings yet

- Diode Rectifiers Circuits GuideDocument17 pagesDiode Rectifiers Circuits GuideKeyboardMan1960No ratings yet

- Active Barrier RN221NDocument8 pagesActive Barrier RN221NOleg SidNo ratings yet

- Electrode IDentificationDocument3 pagesElectrode IDentificationAmit AgarwalNo ratings yet

- Miniature MV Series SwitchDocument6 pagesMiniature MV Series SwitchChrist Rodney MAKANANo ratings yet

- J95 P DOC VE 027824 000 - 1 Protection Calculation Settings Report - 13!05!2020Document75 pagesJ95 P DOC VE 027824 000 - 1 Protection Calculation Settings Report - 13!05!2020Geetha BirudalaNo ratings yet

- Circuit breaker operating sequence and pre-insertion resistor (PIRDocument2 pagesCircuit breaker operating sequence and pre-insertion resistor (PIRabhi_akNo ratings yet

- MP40 Service Manual PDFDocument92 pagesMP40 Service Manual PDFShovan AdhikaryNo ratings yet

- Buchholz RelayDocument2 pagesBuchholz RelayHamayoun MurtazaNo ratings yet

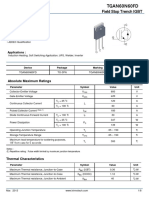

- Field Stop Trench IGBT: Absolute Maximum RatingsDocument8 pagesField Stop Trench IGBT: Absolute Maximum RatingsHeru susantoNo ratings yet

- Electrical Machines: by Dr. Krishna Roy Dr. Krishna Roy Assistant Professor Electrical Engineering Department NitrDocument214 pagesElectrical Machines: by Dr. Krishna Roy Dr. Krishna Roy Assistant Professor Electrical Engineering Department NitrManjitNo ratings yet

- TPB 10en101 PDFDocument5 pagesTPB 10en101 PDFJoseph BoshehNo ratings yet