Professional Documents

Culture Documents

MPT Health and Safety Guidelines

Uploaded by

John PajeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MPT Health and Safety Guidelines

Uploaded by

John PajeCopyright:

Available Formats

KSGM

MPT

&

KDDI Summit Global Myanmar Company Limited

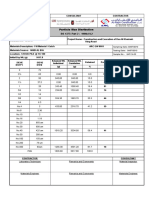

1. Health and Safety Specifications

Document type: Technical Specification for Civil Works

Concept : Daisuke Iwase & Kuniaki Shiraiwa

Designer : KSGM

Approved Date: October 25th, 2014

Function: Engineering Services/ Service Development

1|

KSGM

Table of contents

1.

PURPOSE .............................................................................................................................................................. 3

2.

SCOPE .................................................................................................................................................................... 3

3.

RESPONSIBILITIES ............................................................................................................................................ 3

4.

GENERAL ............................................................................................................................................................. 3

5.

4.1.

General safety ................................................................................................................................................. 4

ACCESS TO SITE................................................................................................................................................. 4

5.1.

Access to Greenfield sites & Roof Top Sites .................................................................................................. 4

5.1.1. Minimum criteria for ladders ..................................................................................................................... 4

5.1.2. Minimum criteria for working platforms / rest stations ............................................................................. 4

5.1.3. Hoisting / Erecting notes ............................................................................................................................ 5

5.1.4. Climbing certificates .................................................................................................................................. 6

5.2.

Access to rooftop and base station / transmission equipment ......................................................................... 6

5.2.1. Access to the site/roof................................................................................................................................. 6

5.2.2. Walkways ................................................................................................................................................... 6

5.2.3. Potential hazards ....................................................................................................................................... 7

5.2.4. Lighting ...................................................................................................................................................... 7

5.2.5. Hoisting ...................................................................................................................................................... 7

5.2.6. Access Hatch .............................................................................................................................................. 7

5.3.

Access to antennas .......................................................................................................................................... 7

5.3.1. Walkways ................................................................................................................................................... 7

5.3.2. Exclusion Zones ......................................................................................................................................... 7

5.3.3. Rooftop structure wall mounted antennas .................................................................................................. 7

5.3.4. Antennas mounted at the edge of the rooftop ............................................................................................. 8

5.3.5. Antennas mounted on the facade ................................................................................................................ 8

6.

ELECTRICAL WORK ......................................................................................................................................... 8

7.

SAFETY MEETINGS ........................................................................................................................................... 8

8.

SAFETY EQUIPMENT ........................................................................................................................................ 8

8.1.

Access to antennas .......................................................................................................................................... 8

8.2.

Caution Signs .................................................................................................................................................. 8

8.3.

Fire Protection ................................................................................................................................................ 9

9.

ENVIRONMENTAL CONDITIONS .................................................................................................................. 9

10.

DRINKING WATER AND SUN SHADE ....................................................................................................... 9

2|

KSGM

1. PURPOSE

The purpose of this document is to provide basic design specifications for Health and Safety System

and safe working Environment for Base Stations (BTS) for a new 2G and 3G network implementation

project for Rollout in Myanmar

2. SCOPE

This Health and Safety Specification is a part of the following list of Civil Works items:

1. General

2. GF Tower and Monopole

3. Rooftop Antenna Support

4. Rooftop Site Spec

5. Greenfield Site

6. Equipment Room

7. Health and Safety Specifications

8. Earthing and Lighting Protection

9. Electrical Installation work

10. DG

11. Fuel Monitoring and NMS system

12. A C

13. Rectifier

14. Power Management System

15. Battery

16. Transformer

3. RESPONSIBILITIES

Authorization

KSGM HSM

Review and amendments

KSGM HSM

Implementation

QROI Project Director/ QROI RM / Vendor Project Manager

4. GENERAL

This document covers safety aspects and KSGM on-site requirements that should be taken into

consideration at the planning stage to ensure a safe working environment for site works,

maintenance or upgrade work. It is not the intention of this document to point out the specifics for

individual health and safety in the work environment; rather an overview as to what issues may be

addressed prior to roll-out.

Local regulations for Health and Safety shall always be followed; both during site works and the

subsequent maintenance and upgrade work unless stated otherwise, all recommendations

contained in this document are KSGM policy, and will be considered the "minimum requirement"

unless local regulations stipulate otherwise.

3|

KSGM

4.1. General safety

When working on site, always use the following:

Safety belt, harness and helmet

ID card. All people working at site must wear ID -card with info, Company Name of person

full name and photo of person, Blood Type, Contact Number of KSGM and Vendor.

Minimum one supervisor from Vendor and two man team.

Proper working attire (coveralls, tool belts, proper climbing shoes/boots etc.)

Safety belts shall be hooked onto the rail whenever climbing ladders, or working close to

the edge of roofs

Every before starting any ascent/descent to the tower, visually inspect all safety belts,

harnesses and carriages to make sure that equipment is not damaged. Additionally, profiles

and fixed construction shall be checked during use for possible damage, corrosion, loose

bolts etc. Any faults shall be repaired immediately.

The physical condition of the site must be according to safety regulations and condition

must be reported everyday by using Accident Prediction Format

Any potential hazards shall be identified and/or neutralized (i.e., flammable, caustic and

explosive materials, electrical wiring, other hazardous material etc.) and condition must be

reported everyday by using Accident Prediction Format.

Clear working area

Turn off the transmitters when climbing tower/mast.

5. ACCESS TO SITE

These specifications are to be considered the minimum criteria if no other relevant local

requirements are specified.

5.1. Access to Greenfield sites & Roof Top Sites

This includes all installation and maintenance work involving monopole and towers.

Requirements will include, but not be limited to:

Non-skid/slip surfaces on ladders and work platforms

The safety climbing equipment for monopole and towers.

Access security; protection against vandalism and unauthorized access

General accessibility (equipment deliveries, worker mobility etc.)

Hoisting/erecting

Potential hazards (overhead cables, radio antennas etc.)

5.1.1. Minimum criteria for ladders

The monopoles and towers shall be equipped with galvanized climbing ladders including an

approved safety rail system. The width of the climbing ladder shall be at least 400 mm. The spacing

of the step rungs shall be 300mm.On sites that are not fenced (Greenfield) or where the public has

access to the roof, a climbing barrier (anti-climb device) shall be installed to prevent unauthorized

persons climbing the monopole or tower. The climbing barrier shall be equipped with a lockable

hatch. It shall be installed at the height of 3-5m from the base. On Greenfield tower a temporary

anti-climb device shall be installed until the fence around the site area is finished.

5.1.2. Minimum criteria for working platforms / rest stations

Working platforms will be used on towers at the main antenna levels. Separate rest platforms

consisting of small foldable foot rests as minimum will be installed on the towers maximum 10m

intervals. On monopoles a working platform around the trunk with width of 500 mm is recommended.

4|

KSGM

5.1.3. Hoisting / Erecting notes

Possible point of placement for a mobile crane for material lifts shall be marked on the site drawings.

When hoisting/erecting is ongoing, safety areas and exclusion zones shall be clearly indicated

Manual tower erection works;

I.

Towers members shall be arranged member by member and quantity checked according

to drawing supplied.

II.

In case any member is bent or twisted, it shall be replaced.

III.

In tower erection work erecting order shall be observed and orientation of tower shall be

accurately carried out. In assembling, members shall be successively lifted on the position

shown in the details of tower. Precautions shall be taken so that the lifted weight does not

exceed the weight limit.

IV.

The erection work of tower etc. should be carried out strictly in accordance to the schedule

specified in the manufacturers instructions. The contractor may however, adopt any other

standard procedure for erection of the tower but he shall have to submit the details of his

proposed method of erection for approval of the KSGM Engineer-in-charge.

V.

VI.

VII.

VIII.

IX.

X.

XI.

The erection of tower should be carried out during normal working hours during day time

i.e. 7am to 6 pm.

A telephone/ walky-talky may be used for communication between workers on the ground

and those on the top as the erection progresses to the upper part of the tower.

Bolts and nuts should be fitted in positions as shown in drawings. Bolts in horizontal level

shall be inserted from inside of tower with nuts applied on the outside of the tower. Bolts in

a vertical line shall be inserted from beneath with nuts applied on upside.

During erection bolts & nuts shall be tightened in the following order.

In the first place the first and second sections of tower shall be assembled with bolts and

nuts tightened tentatively. In the second place the second section shall be placed above

the first and tentatively tightened. The second section is tightened completely after it has

been confirmed that the section is accurately assembled. The remaining part of the tower

shall be assembled in the same manner. After completion of erection the verticality of the

tower shall be checked. Please follow the tower manufacture procedure.

Verticality of the Tower i.e. the bottom of the line joining the Centre of the tower and the

Centre of the base of the tower shall be within the prescribed limit from the Centre of the

base of the tower. The top horizontal member of the tower on all four faces shall have

Centre clearly and visibly marked for easy check of verticality. Please follow the tower

manufacture procedure.

The hoisting of feeder cables should be carried out under close supervision and

instructions of the vendor supervisor and according to manufacturers instructions. The

work will have to be planned well in advance. Cable clamps / angle adaptors should be

assembled and fixed on the cable ladders first. Then safe cable drum position should be

identified and placed over the raised axle to allow for free rotation of the drum below the

tower. Thereafter, Feeder Cable will be fastened at a point based about 1.0 m length from

one end. End of the sufficient length should be tied to wire grip for hoisting. Hoisting

should be done slowly and cautiously so as to avoid collision of the Feeder Cable with any

member of the tower. After feeder cable has reached a height of 40 m second wire grip

should be fastened to the feeder cable as added security and hoisting rope should be tied

to this wire grip also. The hoisting rope should be kept along with Feeder Cable always

and if needed feeder cable may be tied with ropes at several places. Similar action should

be taken when feeder cable reaches height of 80m.

5|

KSGM

XII.

After specified height is reached feeder cable must be fixed to the cable ladder

immediately. The hoisting rope should be released only after the feeder cable has been

properly clamped to vertical cable ladder. Thereafter, it should be taken into the

equipment room over the horizontal cable ladder and through the feeder entry

plate/glands.

5.1.4. Climbing certificates

The Vendor shall provide the needed climbing certificates for all personnel who will be working in

the towers /monopoles (medical examination, worker suitability, courses etc).

5.2. Access to rooftop and base station / transmission equipment

This includes all site works, maintenance or similar work involving rooftops and elevated working

sites. Requirements will include, but not be limited to:

Safety barriers

Non slip/trip surfaces

Working platforms

Access security; protection against vandalism and unauthorized access

General accessibility (equipment deliveries, worker mobility etc.)

Potential hazards (overhead cables, radio antennas etc.)

5.2.1. Access to the site/roof

Access to the roof and equipment room/cabinets shall, where possible, be via

Existing lift(s) and/or staircase(s). Where existing access is not available, a permanent or removable

ladder shall be installed. If existing permanent ladders are to be used to gain access to

maintenance facilities, the following items should be considered:

Compliance with safety standards (pitch, rung spacing, stringers etc.)

Vendor Engineers report in technical site survey What work is to be carried out

Where stairway installation is not practicable, the installation of new ladders may be required for

access to the container/cabinet. A permanent rung ladder fixed at a slope of preferably 70 - 75

degrees (to the

Horizontal), and satisfying the local safety requirements shall be provided. Where it is not

practicable to have a ladder fixed at 70 - 75 degrees a ladder keeper should be installed for use with

a portable ladder. Alternatively a permanent vertical ladder may be installed. When a ladder is

required to be rested against a brittle or fragile surface, the top end of the stiles is to be modified to

protect these surfaces.

5.2.2. Walkways

On sites with complex access routes, the site designer shall indicate the access route on the site

drawings, from the point of entry onto the roof to the BTS/Transmission Equipment. The safety

distance from the walkway to an unprotected roof/platform edge shall be defined in accordance with

local standards. Where personnel are required to access the site within the fall zone, protection

shall be provided by installing a handrail. Where a handrail is not practicable, a fall arrest device

shall be installed. Where personnel are required to access across sloping roofs, non-slip proprietary

walkways shall be provided, if the existing walkways are inadequate. On weak roof surfaces a safe

walking bridge/catwalk shall be installed.

6|

KSGM

5.2.3. Potential hazards

On site access walkways where clear head height of 2m is not possible through openings or due to

obstacles such as existing ductwork or other services, such head obstructions when deemed

dangerous (e.g. sharp edges) shall be clearly indicated with self-adhesive hazard tape or paint and

padded where deemed necessary. Floor and wall openings shall be clearly marked, and if

practicable, will be covered or barred.

5.2.4. Lighting

Minimum criteria: Container or equipment room shall be equipped with a light mounted on the

ceiling of the room.

Outdoor cabinets shall be equipped with one permanent exterior light if sufficient lighting does not

exist.

5.2.5. Hoisting

Possible point of placement for a mobile crane for material lifts shall be marked on the site drawings

or mentioned in the access description. When hoisting/erecting is ongoing, safety areas and

exclusion zones shall be clearly indicated.

5.2.6. Access Hatch

Where access to the rooftop is arranged through a horizontal hatch via ladder, a handrail is

recommended to be installed above the hatch. In some circumstances it may be necessary to

replace the existing roof hatch. New roof hatches shall be equipped with a proper hinge system to

prevent wind from blowing the hatch open or closed during egress or ingress.

5.3. Access to antennas

5.3.1. Walkways

Only sober and trained personnel with proper certification shall access the antennas. If defined

walkways to the antenna carrier/BTS equipment must be used due to safety or other relevant

reasons, they shall be marked on the site drawings.

5.3.2. Exclusion Zones

The minimum exclusion zones have to be in accordance with Myanmar regulations. Personnel

should not work on, or remain within exclusion zones. However passing and climbing through them

should not present any hazard. If the rooftop is used by the owner for any purpose, or if the rooftop

has public access, an exclusion zone shall be clearly marked. Further, if within a public zone, the

site shall also be physically secured form unauthorized personnel. Radiation and exclusion zones

related to microwave antennas shall be according to local standards.

Note:

Electro Magnetic Radiation

Radiation exposure risk is to be done on a project specific basis where the output and frequency is

known, in accordance with local regulations. Where local regulations are unclear or nonexistent,

adherence to Japanese Union directives shall be applied.

5.3.3. Rooftop structure wall mounted antennas

Access can usually be handled safely with a portable ladder if there is no inherent fall risk. If there is

a potential fall risk, a permanent ladder with safety system shall be installed. Working in a two

person team is a general rule of thumb whereby one worker can support the ladder of access for

7|

KSGM

another worker. The ladder has to be of good quality according to local requirements, please also

refer to 5.2.1 above.

5.3.4. Antennas mounted at the edge of the rooftop

Poles with a height less than 6 m shall be equipped with step irons or a removable ladder system.

Some form of attachment point for safety belt/harness shall be installed.

5.3.5. Antennas mounted on the facade

This procedure necessitates the provision of two fall arrest anchors (one for a working line, one for a

safety line) at the rooftop location from which access down the face is required. Where antennas

are to be mounted on the face of a building and there is sufficient area to allow an elevated work

platform (i.e. cherry picker) to provide access from street level, consideration shall be given to this

form of antenna access. Approval shall be sought from the Customer prior to selecting this means

of antenna access.

6. ELECTRICAL WORK

All electrical work should be carried out by personnel who are familiar with the safety guidelines and

regulations of Myanmar. Under no circumstance shall any nonqualified project personnel attempt

any electrical repairs to the equipment and or site facilities whatsoever. Any electrical work shall be

done by personnel who have been certified Myanmar authorized party.

7. SAFETY MEETINGS

On site work, every day morning Accident Prediction Meeting must be held. In the meeting local

work condition are checked and safety equipment are checked before starting the actual work.

The detail procedure is stated on the Accident Prediction Procedure & Format.

More thoroughly meeting can be held monthly where safety issues are discussed and improvement

proposal can be shown.

All safety related, incident, close calls and accidents must be reported immediately to

management by the Incident Reporting Format.

8. SAFETY EQUIPMENT

8.1. Access to antennas

For access to towers and monopoles, the climbing ladder shall be equipped with a rail type fall

arrest system complying with relevant International safety requirements.

All safety systems shall be installed and used only after approval from KSGM/QROI. The safety rail

system shall be installed according to the installation instruction of the safety rail supplier. The

safety belt, harness and straps, with their hooks and adjustments shall be complying with relevant

International safety requirements.

8.2. Caution Signs

The need for caution signs has to be evaluated case by case and agreed to with the QROI/KSGM

representative. Signs have to have text in Myanmar and English Language.

Minimum List of sign to be used:

High voltage warning

First Aid box

8|

KSGM

No entry

PPE and site security

Think safety slogan

Fire extinguisher

Drink Water sign

Deep excavation

Danger Construction site no entry

Low Headroom

Site code and Location

Emergency numbers

8.3. Fire Protection

Containers and equipment rooms shall be provided with a fire alarm. The fire detector submits an

alarm to the remote Network Operations Centre. The detector should be installed inside the room

and be capable of detecting unusually high levels of heat or presence of smoke. Containers and

equipment rooms shall be provided with firefighting means required by the local authorities.

9. ENVIRONMENTAL CONDITIONS

Environmental conditions at the site shall always be taken into consideration. The most vendor

supervisor on site will have the final decision on whether the environmental conditions are within

safety guidelines or not.

Environmental condition limits:

Wind:

If wind velocity is greater than 15m/sec, climbing, hoisting and erecting is prohibited

Rain:

Work on monopole/towers is prohibited in moderate or heavier continuous rain.

Snow:

Work on monopole/towers is prohibited in moderate or heavier continuous snowfall

Temperature: Local regulations shall apply as to minimum and maximum working temperatures

Lightning:

Outdoor work, especially on elevated sites is forbidden

Lighting conditions are not an environmental condition itself; however, adequate lighting shall be

available on site without compromising the safety of personnel.

10. DRINKING WATER AND SUN SHADE

Vendor is responsible to provide fresh drinking water for a workers. Water must be available at site

during construction. Drinking Water station must be marked with Drinking water sign.

Vendor is responsible to build sheltered resting area. Resting area must give protection against

sunshine and is must have seats for resting.

9|

You might also like

- 06 - Health and Safety Specifications - v1.0 - 20100617Document10 pages06 - Health and Safety Specifications - v1.0 - 20100617yoki_triwahyudiNo ratings yet

- Air-Con Installation Method StatementDocument2 pagesAir-Con Installation Method StatementMohamad Hafiz50% (2)

- MS For PD Sensor Installation For 220KV - MibDocument7 pagesMS For PD Sensor Installation For 220KV - MibSumit SawaiNo ratings yet

- 016 Procedure ScaffoldingDocument13 pages016 Procedure ScaffoldingHSE CERINo ratings yet

- Crane Tower SmsDocument16 pagesCrane Tower Smspeter morganNo ratings yet

- Section - 1 Safety: Safety, Health, and Environment Management SystemDocument13 pagesSection - 1 Safety: Safety, Health, and Environment Management SystemVasudha G. SharmaNo ratings yet

- Split Unit Installation MethodDocument2 pagesSplit Unit Installation MethodLimsreang Eang77% (26)

- Section - 1 Safety: Safety, Health, and Environment Management SystemDocument13 pagesSection - 1 Safety: Safety, Health, and Environment Management SystemDurgesh Pandey (Durgesh)No ratings yet

- Safety Rules of ContractDocument7 pagesSafety Rules of ContractArup ChatterjeeNo ratings yet

- Cable Ladder Method of Statement.Document4 pagesCable Ladder Method of Statement.Ahmad DagamsehNo ratings yet

- Method Statement For DS Installation Rev0Document15 pagesMethod Statement For DS Installation Rev0Mark DizonNo ratings yet

- Work Method Statements For Reed SelectDocument53 pagesWork Method Statements For Reed SelectInoe InaeNo ratings yet

- Installation Instructions SimoprimeDocument41 pagesInstallation Instructions SimoprimeJorge Criollo100% (1)

- Lighting and Socket Method of StatementDocument4 pagesLighting and Socket Method of StatementAhmad Dagamseh0% (1)

- Ozflux Tower Safety Guidelines: PrefaceDocument11 pagesOzflux Tower Safety Guidelines: Prefacemyn maliQueNo ratings yet

- Controller Setting Kit Software (ACT Controller) : Product NameDocument33 pagesController Setting Kit Software (ACT Controller) : Product NameCesar ChaconNo ratings yet

- Work at Height StandardDocument15 pagesWork at Height StandardabhishekjhaypNo ratings yet

- NSC-400-CE-3110-MOS-01-A-Method Statement For 69kV Transmission Line ConstructionDocument28 pagesNSC-400-CE-3110-MOS-01-A-Method Statement For 69kV Transmission Line ConstructionElisco Pher SalmasanNo ratings yet

- OHS PROC 113 BarricadesDocument9 pagesOHS PROC 113 BarricadesPhillip L100% (1)

- Working at HeightDocument9 pagesWorking at Heightsixejo100% (6)

- Ap25 Plant Fencing ProcessDocument14 pagesAp25 Plant Fencing Processabsriva00No ratings yet

- AG04M 2.66 İnstallation Instruction ENGDocument13 pagesAG04M 2.66 İnstallation Instruction ENGINFRASTRUKTURANo ratings yet

- RAMS Risk AssessmentDocument36 pagesRAMS Risk AssessmentAkshay DeepNo ratings yet

- Proline Promass F Heating Jacket Operation InstructionsDocument20 pagesProline Promass F Heating Jacket Operation InstructionsPrasanna KumarNo ratings yet

- Channelers Diesel Gasoline Engines: (C) What Are The Hazardous Area Classification?Document43 pagesChannelers Diesel Gasoline Engines: (C) What Are The Hazardous Area Classification?vikasNo ratings yet

- ScaffoldingDocument7 pagesScaffoldingFreshop SurabayaNo ratings yet

- Job Safety Procedure SummaryDocument13 pagesJob Safety Procedure SummaryRavi thokalNo ratings yet

- Ad723 Parts & Service ManualsDocument58 pagesAd723 Parts & Service Manualsminoltaep4050No ratings yet

- MS of Hoarding WorkDocument5 pagesMS of Hoarding WorkLOURLINE TANGZONo ratings yet

- DEHN IndiaDocument6 pagesDEHN IndialoganathanNo ratings yet

- Installation Manual: Handling and Storage Installation Start-Up Test Maintenance Test ReportsDocument33 pagesInstallation Manual: Handling and Storage Installation Start-Up Test Maintenance Test ReportsJAIRO EDUARDO RAMIREZ ACERONo ratings yet

- Site Safety InstructionDocument6 pagesSite Safety InstructionSathish Kumar TRNo ratings yet

- Manual MR Configurator 2Document13 pagesManual MR Configurator 2Juan Antonio Galvez RozasNo ratings yet

- CCTV O&M ManualDocument64 pagesCCTV O&M ManualDilan ThilangaNo ratings yet

- Shutdown Book 2007Document184 pagesShutdown Book 2007api-380385875% (8)

- Sicam TM Io Module EngDocument139 pagesSicam TM Io Module EngGokhan MertNo ratings yet

- SS 559-1-2022 PreviewDocument6 pagesSS 559-1-2022 Previewalvinhay11.11No ratings yet

- Gujarat Energy Transmission Corporation Limited Safety ManualDocument82 pagesGujarat Energy Transmission Corporation Limited Safety ManualPiyush BorkarNo ratings yet

- Barricading and Signage ProcedureDocument10 pagesBarricading and Signage ProcedureAristotel C. Cabais, RN50% (2)

- An17808a PDFDocument8 pagesAn17808a PDFtatingoNo ratings yet

- Use and Refuelling of Portable GeneratorDocument4 pagesUse and Refuelling of Portable GeneratorJonasNo ratings yet

- GI Cable Tray & Trunking MethodDocument9 pagesGI Cable Tray & Trunking Methodrkss100% (1)

- BGS-MOS Redevelopment of BHS at T2-R2Document33 pagesBGS-MOS Redevelopment of BHS at T2-R2LOURLINE TANGZONo ratings yet

- 501 2012 6 28 27 39 561Document26 pages501 2012 6 28 27 39 561MITHILESH KUMARNo ratings yet

- CPCCCA3005 Learner Guide V1.0Document67 pagesCPCCCA3005 Learner Guide V1.0hurairamughal666No ratings yet

- M05 CommissioningDocument47 pagesM05 CommissioningTariku TesfayeNo ratings yet

- Safety Inspection Checklist for Substation ConstructionDocument6 pagesSafety Inspection Checklist for Substation ConstructionJENNNo ratings yet

- Electrical Method StatementDocument7 pagesElectrical Method StatementDylanNo ratings yet

- Service Bulletin (ECB) Priority - Ii - Iii - : Rebuilding Kit - Parking Brake SwitchDocument2 pagesService Bulletin (ECB) Priority - Ii - Iii - : Rebuilding Kit - Parking Brake SwitchAlexander LopezNo ratings yet

- UntitledDocument18 pagesUntitledPramod SinghNo ratings yet

- MS-45R1 For Filter Skid Molition (Electrical)Document4 pagesMS-45R1 For Filter Skid Molition (Electrical)Mahaboob PashaNo ratings yet

- CSD 819 CDocument182 pagesCSD 819 CJulián MorelosNo ratings yet

- METHOD STATEMENT Transmission Line PDFDocument8 pagesMETHOD STATEMENT Transmission Line PDFSyed Mohiuddin PashaNo ratings yet

- MST-AFC-AC565-000118 .Rev01Document5 pagesMST-AFC-AC565-000118 .Rev01Jacob PriyadharshanNo ratings yet

- Cable Installation MethodDocument7 pagesCable Installation MethodAhmad Dagamseh100% (1)

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsFrom EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Methodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsFrom EverandMethodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsNo ratings yet

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- Atx31026ft-Allie TelesisDocument116 pagesAtx31026ft-Allie TelesisJohn PajeNo ratings yet

- WLAN SW Troubleshoot GuideDocument239 pagesWLAN SW Troubleshoot GuidecuongdoducNo ratings yet

- The Constitutions of The Freemasons - 1734 Anderson, Franklin & RoysterDocument51 pagesThe Constitutions of The Freemasons - 1734 Anderson, Franklin & Roystertodayperhaps100% (1)

- Gantt Chart Excel TemplateDocument3 pagesGantt Chart Excel TemplateJohn PajeNo ratings yet

- dt800 IpDocument3 pagesdt800 IpJohn PajeNo ratings yet

- AVDocument122 pagesAVJohn PajeNo ratings yet

- HJC CL-16 Us ManualDocument7 pagesHJC CL-16 Us ManualJohn PajeNo ratings yet

- Jazz 2014 BrochureDocument21 pagesJazz 2014 BrochureRoseAnn Jose Dela FuenteNo ratings yet

- Userguides - NEC - SV9100 System Maintenance Manual v1.0Document105 pagesUserguides - NEC - SV9100 System Maintenance Manual v1.0John PajeNo ratings yet

- Tracer 2Document2 pagesTracer 2John PajeNo ratings yet

- x3100 m5 Type 5457Document688 pagesx3100 m5 Type 5457John PajeNo ratings yet

- 200-120CCNA Cisco Certified Network Associate CCNA (803) 2014-06-02Document8 pages200-120CCNA Cisco Certified Network Associate CCNA (803) 2014-06-02Christine Wood100% (1)

- Sv9100 In-Mail User GuideDocument416 pagesSv9100 In-Mail User GuideJohn PajeNo ratings yet

- SW T1-E1Document16 pagesSW T1-E1John PajeNo ratings yet

- IP Address Into Your IE's Trust Host List As FollowsDocument1 pageIP Address Into Your IE's Trust Host List As FollowsJohn PajeNo ratings yet

- HotelDocument27 pagesHotelJohn PajeNo ratings yet

- SV8100 PCPro ManualDocument140 pagesSV8100 PCPro ManualJohn PajeNo ratings yet

- SV8100 Brochure PDFDocument3 pagesSV8100 Brochure PDFJohn PajeNo ratings yet

- SL1000 Hardware Manual 1.1 GEDocument144 pagesSL1000 Hardware Manual 1.1 GEJohn Paje0% (1)

- Brushbond FLXIII PDFDocument2 pagesBrushbond FLXIII PDFdejanmicic972No ratings yet

- Types of BoltsDocument7 pagesTypes of BoltsPranshu JainNo ratings yet

- 0.1 Introduction PDFDocument14 pages0.1 Introduction PDFB VarunNo ratings yet

- Krone 4 Category 6Document18 pagesKrone 4 Category 6jose carlosNo ratings yet

- En 1053 3Document18 pagesEn 1053 3Alper ÇelikNo ratings yet

- Shaikh ZaheerDocument4 pagesShaikh ZaheerMonika ShindeNo ratings yet

- Sanitary installation materials for university classroomDocument37 pagesSanitary installation materials for university classroomMikuNo ratings yet

- WBS-Engineering Project PlanDocument3 pagesWBS-Engineering Project PlanM iqbalNo ratings yet

- KitchenDocument39 pagesKitchenSajeshKumarNo ratings yet

- HYDRAULIC BRIDGE DETAILSDocument4 pagesHYDRAULIC BRIDGE DETAILSPurdiansyah100% (1)

- GFRG Construction Schedule and RatesDocument50 pagesGFRG Construction Schedule and Ratessri projectssNo ratings yet

- The Effects of Coarse Sand On Sandcrete BlocksDocument14 pagesThe Effects of Coarse Sand On Sandcrete BlocksInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Calculate dry density of soil from specific gravity, void ratio and degree of saturationDocument6 pagesCalculate dry density of soil from specific gravity, void ratio and degree of saturationAiman Padilla AbreuNo ratings yet

- Modelos de Análisis de Estabilidad 34 PDFDocument1 pageModelos de Análisis de Estabilidad 34 PDFRosanna EaNo ratings yet

- 20160215052429-En 10025 en PDFDocument5 pages20160215052429-En 10025 en PDFShirish GosaviNo ratings yet

- Construction and Execution of Ras Al Khaimah Ring Road Fill Material Particle Size and Compaction Test ResultsDocument7 pagesConstruction and Execution of Ras Al Khaimah Ring Road Fill Material Particle Size and Compaction Test ResultsamesbNo ratings yet

- Research GiuDocument4 pagesResearch GiugiuNo ratings yet

- COST ESTIMATE FOR CROSS DRAINAGEDocument12 pagesCOST ESTIMATE FOR CROSS DRAINAGEManish PatelNo ratings yet

- Sumit DSR MicroprojectDocument13 pagesSumit DSR MicroprojectOnkar Vyawhare75% (12)

- Building Design OptionsDocument91 pagesBuilding Design OptionsmaheshbandhamNo ratings yet

- Flexible Pavements Development and ConstructionDocument21 pagesFlexible Pavements Development and ConstructionstefpanNo ratings yet

- Compressor Manual P 251511 Om Ssp1 GBR 3-A4Document82 pagesCompressor Manual P 251511 Om Ssp1 GBR 3-A4PRKrauseNo ratings yet

- Conduits Electrical LatviaDocument13 pagesConduits Electrical LatviaÖmer Faruk GÜLNo ratings yet

- Stabilising the Leaning Tower of PisaDocument9 pagesStabilising the Leaning Tower of Pisalomas3No ratings yet

- Plant Commissioning and StartupDocument31 pagesPlant Commissioning and StartupEric Fisher100% (5)

- 1GR-FE CoolingDocument18 pages1GR-FE CoolingJorge Miguel Couto Cabral100% (1)

- Brosur Pompa KSB Type CLTDocument20 pagesBrosur Pompa KSB Type CLThenryhh111No ratings yet

- THESIS DOCTOR OF PHILOSOPHY GEORGE Jerin Mathew 2022Document187 pagesTHESIS DOCTOR OF PHILOSOPHY GEORGE Jerin Mathew 2022Amel RADJEFNo ratings yet

- Thesis Outline 2Document13 pagesThesis Outline 2Ronald PanaliganNo ratings yet

- Investigation of Bearing Capacity and Failure Pattern in Shell Foundations by FELA MethodDocument15 pagesInvestigation of Bearing Capacity and Failure Pattern in Shell Foundations by FELA Methodسجى EngNo ratings yet