Professional Documents

Culture Documents

Bridges: The New Standard For Bridges and Bridge Reinstatement

Uploaded by

danielsu87Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bridges: The New Standard For Bridges and Bridge Reinstatement

Uploaded by

danielsu87Copyright:

Available Formats

bridges

the new standard for bridges

and bridge reinstatement

Bridges for the 21st Century

SPS, the Sandwich Plate System, is an innovative material for heavy engineering structures that

SPS Bridges

Contents

dramatically improves the economics of bridge building and bridge repair.

Save up to 70% of the weight of concrete decks without the complexity and fatigue problems inherent in orthotropic steel decks

Replace concrete bridge decks, increase load capacity, add lanes and avoid the need for girder and pier reinforcement

Erect up to 120 linear metres of deck per day with the wearing surface already factory applied

SPS is a heavy engineering material technology developed over the last ten years

SPS Technology

by Intelligent Engineering. SPS is a steel-elastomer-steel composite that delivers

SPS Bridge Decks

significant simplification, performance and safety benefits to maritime and civil

SPS Overlay Bridge Deck Repair

engineering structures. Owners and fabricators gain significant economic savings

Other SPS Bridges

during construction and throughout a structures life.

Coatings, Attachments & Maintenance

Increase architectural elegance with lighter, thinner decks

Longer spans, lighter piers, fewer piles per pier

In bridges, SPS plates are used as the deck and in other highly stiffened areas

Install decks with over a 100 year service life

such as the webs of deep girders. By incorporating SPS, bridges can be built

Reinstate bridge decks in days not weeks

using substantially lighter structures. Furthermore, SPS plates are easy to maintain

Avoid cast-in-place curing delays

and extend a bridge decks life to 100 years, eliminating the need to replace

Simple erection

concrete decks every 30 years or re-weld fatigue sensitive orthotropic steel decks.

There are now over 30,000 m2 of SPS structures in-service in demanding maritime

and civil engineering applications around the world.

This brochure outlines how to use SPS to build superior bridges, decrease

erection and repair schedules and reduce build and maintenance costs.

bridges

Tested & Proven

A Global Support Network

Improved damping

Originally developed for the maritime industry for demanding applications such as ice strengthening on Arctic drill

platforms and supertanker hulls, SPS is now bringing its significant technical, manufacturing and economic benefits to

civil engineering structures such as bridges, stadia, floors and blast walls. SPS is a strong, stiff, light construction material

with built-in vibration damping, fire insulation and security protection that requires limited through-life maintenance.

Reduced resonance

80

70

60

2

0

-2

SPS

-4

-6

-8

Transfer function

Displacement mm

SPS Technology

Steel

0

200

400 600 800 1000 1200 1400

Time, ms

50

40

30

20

10

0

20

25

Frequency, Hz

30

35

SPS Bridge Deck panel in production

Full size SPS Bridge Deck panel undergoing tests

Simple Long-lasting Structures

High Quality Production

Extensive R&D

Reduced structural complexity and maintenance

In an SPS composite, the steel faceplates act as flanges with

SPS plates are produced on dedicated production lines by local

SPS technology is supported by over ten years of research and

Improved performance and safety

the elastomer core acting as a web. The continuous support

SPS licensees. The resulting high quality, high tolerance plates are

development carried out in close cooperation with independent

Fabricated on dedicated local production lines

provided by the core eliminates local face plate buckling and

individually manufactured for each project and incorporate

institutions and regulators.

Delivered to site substantially complete

allows the SPS plate to develop its full tensile capacity. The

penetrations, attachment preparations and coatings as required.

Fully tested by independent institutions

thickness of each element can be optimised for each application.

Patented composite construction technology

Metal plates integrally bonded to solid elastomer core

The core material characteristics of SPS are well documented and

SPS plate production combines two simple and well-understood

include: static and dynamic behaviour, vibration damping, fire

Globally stiff SPS plates significantly reduce structural

processes: steel fabrication and elastomer injection. Both are

resistance, and reaction to extreme impacts and blast. Good

complexity, eliminate the majority of fatigue and corrosion prone

mature processes with decades of production quality improvements

correlation between full-scale tests and analytical models allows

details, and produce a longer life structure with reduced

and industry accepted standards.

engineers to design SPS structures with confidence.

After initial plate production, SPS plates are assembled and

Leading research institutions in North America and Europe have

erected using conventional steel processes. SPS plates can be

recently completed successful full-scale load and fatigue testing

shipped to your local fabricator for incorporating into the final

on SPS structures.

Over 30,000 m2 in-service

maintenance demands.

structure or the SPS licensee can complete your structure and work

with your chosen erectors to install the bridge.

Maximising the amount of fabrication and finishing undertaken in

a high quality factory environment is proven to reduce project

schedules, increase project quality and save costs. SPS delivers

these benefits to your bridge projects.

SPS Bridge Decks

Typical Project Savings

35% lighter girders

The weight savings, reduced maintenance and shorter erection schedules associated with SPS Bridge Decks allow designers and planners

30% fewer piers

to rethink the economic feasibility of long and short span bridge projects and thereby help to get more out of ever tightening highway budgets.

38% lighter piers

Shop fabrication enables components to be substantially finished off-site (including wearing surfaces) and assures a high quality finish, which is

Days rather than weeks of erection

proven to outperform conventional structures. Furthermore, the simplicity and lightness of SPS Bridge Decks enable the rapid replacement of

Two fewer deck replacements over the bridge's life

concrete decks with minimal disruption to daily traffic and no reinforcement of the supporting structure.

SPS Bridge Decks being erected

Lighter New Bridges

Faster Bridge Deck Replacement

SPS Bridge Decks are up to 70% lighter than concrete decks,

Increasingly countries face the problem of an ageing bridge

enabling lighter bridge designs with fewer lighter girders. SPS

inventory, with increasing traffic volumes and heavier truck loads.

Bridge Decks permit longer spans than conventional bridges,

Many bridges throughout North America and Europe are in need

with fewer lighter piers and reduced piling.

of major repair or total replacement.

SPS Bridge Deck panels are delivered to site virtually complete

Reducing the deck dead load by up to 70% allows the bridge to

with the wearing surface already applied. Erection uses light

carry significantly greater live load without needing girder or pier

conventional asphalt with a membrane protection for the steel, or more modern wearing surfaces

equipment and is mostly limited to bolting plates together. Over

strengthening. Load restrictions on bridges can be removed and

can be used which offer further weight savings.

60 linear metres at each end of the bridge can be erected in an

extra lanes added to increase traffic capacity. Deck replacement

eight hour shift.

can be completed leaving the steel or concrete girders in place

250

40

SPS Bridge Decks are up to 70% lighter than equivalent reinforced concrete decks and

create fully composite decks with either steel or concrete girders.

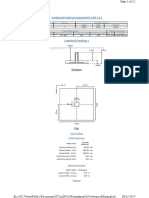

SPS 4.76-25.4-4.76

100

200

SPS Bridge Deck Panels

1"DIA ASTM A490

NUT, BOLT & WASHER

(SLIP CRITICAL CONNECTION)

W530 x 92

BRIDGE GBR

Long Life

SPS Bridge Decks offer 100 years of service life, significantly reducing the deck replacement costs

associated with the short 30 year service life of concrete. Typically, SPS Bridge Decks are made

from corrosion resistant steel although other metals can also be used. The wearing surface can be

SPS 4.7625.4-4.76

SEE

DETAIL "E"

8 THK

SIDE PL

High Quality Fabrication

SPS Bridge Deck panels are simple to produce. Firstly, an SPS plate is produced by fabricating a

All bridge geometries such as vertical and horizontal curves,

100

steel cavity from two metal plates and perimeter bars into which an elastomer core is injected.

deck camber, super-elevations and skew are possible.

Secondly, edge frames and longitudinals are attached and finally the wearing surface is applied. Deck

10

SPS Bridge Decks reduce total project costs and substantially

70

panel flatness is below L/1500. Panels are made to a +0mm -3mm tolerance, preventing oversize

Top PL

decks during erection.

SPS 4.76-25.4-4.76

Backing Bar

Elastomer

Btm PL

SPS Bridge erection is fast, uses a single trade, light equipment and standard industry practices. Once

the girders are in place and prepared, SPS Bridge Decks are bolted to them. The upper seams

between the SPS Bridge Decks are welded, crash barriers erected and asphalt laid if required.

32

Fast Erection

M20 ASTM A325M

NUT, BOLT & WASHER

(SLIP CRITICAL CONNECTION)

Cross Stringer

Cross Stringer

reduce project schedules.

or, if speed is critical, by replacing the deck and girders with preassembled longitudinal deck-girder units.

The replacement of these old decks takes days rather than

weeks and bridges can often remain partially operational

throughout the procedure.

Fast, non-intrusive steel deck strengthening

Already proven on steel ship decks

Undertaken at night to allow traffic flow during morning rush hour

Typically performed lane by lane

All other lanes remain in use during process

Can be completed from underneath with no disruption to traffic

SPS Overlay Orthotropic Bridge Deck Reinstatement

Initially developed to reinstate the strength and stiffness of vehicle decks on ships without the intrusive complexity of deck

replacement, SPS Overlay creates a stiff SPS plate over the existing degraded steel bridge deck. With traffic loads and

frequency increasing, made worse by decreasing wheel contact areas, the existing orthotropic steel bridge deck inventory

will need to be replaced or strengthened. SPS Overlay offers a fast and cost effective answer to orthotropic steel bridge

deck strengthening and reinstatement. A solution that is already well-proven in equally demanding maritime applications.

All steel

SPS Overlay

Reinstatement without Replacement

By manufacturing SPS in field, using the original degraded deck as

one side of the final plate, SPS Overlay can reinstate or strengthen

old orthotropic bridge decks. SPS Overlay creates a deck stiffer

than the original and alleviates stresses at fatigue critical welds.

The renewed stiffer deck improves the distribution of wheel loads

10 mm existing steel deck

5mm trough stiffeners

6-30-existing SPS Overlay

5 mm trough stiffeners

across the troughs which decreases deck curvatures, increasing

wearing surface life and fatigue resistance.

The process is extremely quick and since the original deck remains

in place, a bridge can be reinstated with minimal traffic disruption

and without the need to access areas underneath the bridge.

The SPS Overlay

Process

1. Remove existing wearing surfaces

2. Grit blast steel plates to white metal

3. Adhere perimeter bars to existing

bridge deck

4. Weld new top plate to perimeter

bars to form air-tight cavity

5. Inject elastomer into cavity

6. When cavity full, seal vents and

allow elastomer to cure

7. Apply new surface coating

42 MPa

16 MPa

An SPS Overlay cross-section

A Broader Range of Possibilities

Coatings, Attachments, Modification & Repair

SPS brings structural materials for heavy engineering closer to the ideal. SPS is a light, strong material that is simple to

Once completed SPS plates can be treated as any other steel plate and benefit from the ease of attachment of traditional

construct and maintain with many built-in performance and safety benefits. From landmark longspan bridges to the more

steel components. The broad range of proven coatings available for steel can be applied to SPS. Additionally, easy to coat

individual design statements of pedestrian bridges, SPS helps designers achieve affordable architectural elegance. The

flat sections with fewer fatigue sensitive joints and lower panel flexure mean coatings are easier to apply and last longer.

stiff, lightweight properties of SPS also allow it to be used in a wide range of bridge structural components such as

mobile bridge decks and the deep webs of built-up bridge and box girders.

Above images show SPS Shenley Bridge, Quebec, Canada.

Longspan Bridges

Pedestrian Bridges

Wearing Surfaces

Attachments

SPS Bridge Decks for longspan bridges offer significant

Pedestrian bridge designers can improve their current designs

SPS Bridge Decks do not suffer from the surface cracking

Given the adaptability of steel, standard attachments including

improvements in fatigue and wearing surface life over

by incorporating SPS and take advantage of its lightweight

associated with concrete decks or the high deck curvatures

crash barriers, pavements, signs and lightstands can easily be

conventional orthotropic decks. With a similar deadweight, SPS

and structural strength. Alternatively, they can develop unique

experienced with orthotropic steel decks. Engineers can now

fitted to an SPS Bridge.

removes 70% of all welds in these highly stiffened structures and

structures, such as the one below, which uses SPS to create

save significant weight by specifying thinner asphalt or more

improves the weld fatigue quality from an E1 to a B1/C1 detail.

an elegant 22m span that leaves the factory complete and is

advanced polymer wearing surfaces. Both wearing surfaces use

Furthermore, the globally stiff panels significantly reduce localized

easily erected.

a polyurethane membrane to protect the steel deck. Properly

deck curvatures, limiting wearing surface cracks and associated

maintained, these wearing surfaces allow the SPS Bridge Deck

water penetration and corrosion of the steel deck below.

to achieve a working life of up to 100 years.

Sidewalk detail

SPS Orthotropic

Bridge Deck

Weather Protection

SPS panels typically use corrosion resistant steel, however,

coated or galvanised steel, aluminium or stainless steel can also

be used for particular applications.

Weather protective coatings and modern wearing surfaces are

Conventional Orthotropic

Bridge Deck

typically applied in the factory with only finishing layers at bridge

panel joints applied on-site.

Modifications & Repair

Penetrations or other details not fitted during manufacture can

be incorporated on-site using simple steel modification

processes such as drilling or welding.

Though unusual, small repairs can be completed on-site with a

simple manual welding and injection process that produces an

as new panel. Larger repairs are best achieved by replacing a

complete SPS Bridge Deck panel.

Static load analysis on SPS Bridge Deck panels

MAX

= 13.5mm

MX

MN

MX

MN

MAX

Tested & Proven

34 tonnes

(ULS factored wheel load)

Load testing the SPS Shenley Bridge, Quebec, Canada.

Static load test on full size SPS Bridge Deck panel

A coordinated test programme on SPS Bridge Decks and bridge deck reinstatement

Excellent Results

Fatigue test on SPS Bridge Deck connection detail

has been conducted by industry experts at leading bridge research institutions in

North America and Europe.

Statics

Legal load limit of six axle truck applied (70 tons)

The tests comprised:

Deflection and strains in plate and girders as predicted

SPS Bridge: Tested for static and dynamic performance and FEA correlation

SPS Bridge Deck panel acts compositely with girders

Full-scale SPS Bridge Deck panel: Tested for plate and panel deflection

Ultimate capacity: Bottom flange of girder yields at 3.75 times the specified truck load (15,100 kN.m)

Half-scale SPS Bridge: Tested to confirm composite action in positive and negative

Actual yield moment within 1% of the moment calculated from section properties

moment areas as well as tyre load distribution

Maximum shear stresses at the steel-elastomer interface at the ultimate load is less than the factored

SPS Overlay Bridge Deck: Tested for static and fatigue performance as well as

bond resistance of 4 MPa (tests show SPS typically achieves 10 MPa bond resistance)

tyre load distribution

Fatigue tests on welded/bolted joint between SPS Bridge Deck panels

Dynamics

Full size SPS Bridge Deck tested for vibration

Mode 1: Measured 5.8Hz, Predicted: 5.7Hz

Mode 2: Measured 6.0Hz, Predicted: 5.9Hz

Welded Connection

Field welded connection across the width of the bridge above and slip critical bolted connection below

Loaded fatigue tests to 10 million cycles without failure

Estimated fatigue life of 11mm deck weld = 100 million cycles

The panel connection can be designed for the required resistance of each particular bridge

New S-N fatigue curve produced for the panel connection

= 14.2mm

A Global Support Network

Designers, constructors and authorities planning to use SPS in their bridges are supported by Intelligent

Engineering and a global network of SPS licensees, each of whom are major fabricators in their local bridge

building market.

Design & Regulatory Support

Experienced Bridge Fabricators

When designing with SPS, bridge engineers and consultants are

Local SPS licensees are industry leading steel structure

supported by an experienced team of structural engineers and

fabricators with long track records of delivering large and small

material scientists at Intelligent Engineering and BASF Elastogran.

high-quality, innovative solutions.

With over ten years of SPS design, testing and regulatory

They all have significant experience in bridge fabrication and

approval, our team will help you develop the most efficient

have their own design teams able to support you as you finalise

combination of SPS and conventional structural engineering

your SPS Bridge design.

materials for your specific projects and then support your

regulatory approval process with detailed data and analysis

based on studies with leading research institutes.

SPS Bridge Decks

High Quality

Lightweight

Fast Erection

Low Cost

SPS is now an integrated part of their production processes and

therefore comes with all the quality and production standards

you would expect of a modern fabricated steel structure.

Intelligent Engineering invented SPS and leads its continuing

development for a diverse range of maritime and civil engineering

structures. Elastogran is part of the worlds leading chemical

company, BASF and provides the elastomer core of SPS. Our joint

team includes structural engineers, material scientists, regulatory

advisors and production engineers.

Images of bridges in this brochure are intended to illustrate typical bridge structures that could incorporate SPS Technology.

Long Life

For further information please contact:

Intelligent Engineering

Shire House, West Common

Gerrards Cross

Buckinghamshire SL9 7QN

United Kingdom

Tel

Fax

Web

+44 (0)1753 890 575

+44 (0)1753 899 056

enquiries@ie-sps.com

www.ie-sps.com

You might also like

- Sandwich Plate SystemDocument3 pagesSandwich Plate SystemMihai LunguNo ratings yet

- Sheet PilingDocument24 pagesSheet PilingniyatiNo ratings yet

- Stud RailsDocument3 pagesStud RailsBruno PilieciNo ratings yet

- Corrugated Steel Pipe DesignDocument588 pagesCorrugated Steel Pipe DesignEmrE GöktuĞNo ratings yet

- Applications of Sandwich Plate System For Ship StructuresDocument8 pagesApplications of Sandwich Plate System For Ship StructuresHusen ShahabNo ratings yet

- Steel SleepersDocument7 pagesSteel Sleepersapi-23179831150% (2)

- Steel SleepersDocument7 pagesSteel Sleepersapi-231798311100% (2)

- Precast Stay FormsDocument19 pagesPrecast Stay FormsJosue LewandowskiNo ratings yet

- Composite Steel Bridges - CorusDocument28 pagesComposite Steel Bridges - CorusRui OliveiraNo ratings yet

- Steel Bridges Lecture 1Document16 pagesSteel Bridges Lecture 1MohamedNo ratings yet

- Steel As A Structural MaterialDocument10 pagesSteel As A Structural MaterialFaisal ShahzadNo ratings yet

- Girder Bridges FDocument22 pagesGirder Bridges FajaymrNo ratings yet

- TriboroDocument2 pagesTriboroRavikirankv007No ratings yet

- Jacking Pipes Humes PDFDocument24 pagesJacking Pipes Humes PDFrizanindya100% (1)

- Kurilpa Bridge Case StudyDocument4 pagesKurilpa Bridge Case StudyTheomi BunburyNo ratings yet

- Composite Structure (31-38)Document48 pagesComposite Structure (31-38)Badri DadiNo ratings yet

- Precast Options For Bridge Superstructure DesignDocument18 pagesPrecast Options For Bridge Superstructure DesignrammirisNo ratings yet

- Bridges - Initial DesignDocument20 pagesBridges - Initial Design2003655300% (1)

- Manuscript Ipd 2Document87 pagesManuscript Ipd 2John Louie PimentelNo ratings yet

- Sapa Aluminum DeckDocument4 pagesSapa Aluminum DeckoiuedcNo ratings yet

- ConstructionSpecifier Studcast 07Document7 pagesConstructionSpecifier Studcast 07Roberto FernandesNo ratings yet

- Sheet Pile Design HandbookDocument368 pagesSheet Pile Design HandbookLandon Mitchell92% (12)

- Prestressed Concrete Bridge Beams (CBDG)Document2 pagesPrestressed Concrete Bridge Beams (CBDG)TaiCheong Lee100% (2)

- Chapter 5Document41 pagesChapter 5tewele brhaneNo ratings yet

- Stay Cable SSI2000Document13 pagesStay Cable SSI2000Rusandi NoorNo ratings yet

- Bridges - Steelconstruction PDFDocument16 pagesBridges - Steelconstruction PDFdik_gNo ratings yet

- Introduction To Advanced R.C.C Roofing.: Group - 1Document15 pagesIntroduction To Advanced R.C.C Roofing.: Group - 1Nidhi MehtaNo ratings yet

- MB Concrete Footbridges July2012Document8 pagesMB Concrete Footbridges July2012gorgika papand0% (1)

- Long Span Beams 2Document14 pagesLong Span Beams 2ashNo ratings yet

- Guidelines For Design of Integral AbutmentsDocument10 pagesGuidelines For Design of Integral Abutmentsc1366No ratings yet

- Construction Methods in Industrialized BuildingsDocument37 pagesConstruction Methods in Industrialized BuildingsJoseph EzekielNo ratings yet

- The Surest Way Is Steel: WWW - Steelconstruction.infoDocument12 pagesThe Surest Way Is Steel: WWW - Steelconstruction.infoMarshall BravestarNo ratings yet

- Construction and Building Materials: Christoph Czaderski, Moslem Shahverdi, Julien MichelsDocument16 pagesConstruction and Building Materials: Christoph Czaderski, Moslem Shahverdi, Julien MichelsSAMUEL ALBERTO ZAMBRANA MALDONADONo ratings yet

- Catalogue Mp200Document33 pagesCatalogue Mp200Adrian TudorNo ratings yet

- Long Span Composite Beams: Steel Industry Guidance NotesDocument2 pagesLong Span Composite Beams: Steel Industry Guidance NotesJasmine SmithNo ratings yet

- Structural Steel DesignDocument27 pagesStructural Steel DesignLilyNo ratings yet

- Meyer Product Guide 2010Document20 pagesMeyer Product Guide 2010Adrian RogersNo ratings yet

- Digital Assignment 1Document4 pagesDigital Assignment 1Atul RajNo ratings yet

- Capesize Bulk Carrier: GH ResourcesDocument2 pagesCapesize Bulk Carrier: GH ResourcespothirajkalyanNo ratings yet

- Portal Frame Structure: Lect 8Document35 pagesPortal Frame Structure: Lect 8jkaliwonNo ratings yet

- Lenton TerminatorDocument8 pagesLenton Terminatordanker1988No ratings yet

- Innovative Structural Steel SystemsDocument12 pagesInnovative Structural Steel SystemsCIVILNo ratings yet

- NMBS Composite Slab Engineering CourseDocument72 pagesNMBS Composite Slab Engineering CourseDario P. YanezNo ratings yet

- Shipyard VisitDocument16 pagesShipyard VisitJagadeep TcNo ratings yet

- Deepwater Riser InstallationDocument9 pagesDeepwater Riser InstallationekhwanhakimNo ratings yet

- Long Span and High-Rise Steel ConstructionDocument89 pagesLong Span and High-Rise Steel Constructionကိုနေဝင်း100% (1)

- Sika Solutions For Concrete BridgesDocument17 pagesSika Solutions For Concrete BridgescaapromoNo ratings yet

- Advatages of Prestress ConcreteDocument44 pagesAdvatages of Prestress ConcreteVivek PremjiNo ratings yet

- 13.pole Type Structure 1Document22 pages13.pole Type Structure 1Hariprasad gantyalaNo ratings yet

- Sps HullDocument3 pagesSps HullshineabcNo ratings yet

- Esdep WG 14Document23 pagesEsdep WG 14Marites DelaraNo ratings yet

- 25 AsmitaS Long Span BeamsDocument9 pages25 AsmitaS Long Span BeamsAsmita SutarNo ratings yet

- The First L555 (X80) Pipeline in JapanDocument11 pagesThe First L555 (X80) Pipeline in JapanMarcelo Varejão CasarinNo ratings yet

- Steel Frame InnovationDocument6 pagesSteel Frame InnovationKeanu Joseph VelascoNo ratings yet

- Aisc InnovativestructuralsteelDocument12 pagesAisc InnovativestructuralsteelJorge perezNo ratings yet

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesFrom EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesRating: 4.5 out of 5 stars4.5/5 (16)

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesFrom EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesNo ratings yet

- Sexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicFrom EverandSexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicNo ratings yet

- Triangulation - Applied to Sheet Metal Pattern Cutting - A Comprehensive Treatise for Cutters, Draftsmen, Foremen and Students: Progressing from the Simplest Phases of the Subject to the Most Complex Problems Employed in the Development of Sheet Metal Patterns with Practical Solutions of Numerous Problems of Frequent Occurrence in Sheet Metal ShopsFrom EverandTriangulation - Applied to Sheet Metal Pattern Cutting - A Comprehensive Treatise for Cutters, Draftsmen, Foremen and Students: Progressing from the Simplest Phases of the Subject to the Most Complex Problems Employed in the Development of Sheet Metal Patterns with Practical Solutions of Numerous Problems of Frequent Occurrence in Sheet Metal ShopsRating: 5 out of 5 stars5/5 (1)

- Unrestrained BeamDocument40 pagesUnrestrained Beamdanielsu87100% (1)

- Sdre14-6 Vig 1-8-May 2019Document9 pagesSdre14-6 Vig 1-8-May 2019danielsu87No ratings yet

- Chemical 18 Sep 14Document4 pagesChemical 18 Sep 14danielsu87No ratings yet

- SpecificationDocument1 pageSpecificationdanielsu87No ratings yet

- Sabarigiri HEP 11 - Chapter 7 PDFDocument81 pagesSabarigiri HEP 11 - Chapter 7 PDFPremkumar Vasudevan100% (1)

- Theoretical Evaluation of RC Deep Beam With Web Opening by Using Nonlinear Finite Element Software AbaqusDocument10 pagesTheoretical Evaluation of RC Deep Beam With Web Opening by Using Nonlinear Finite Element Software AbaqusOrhan YanyatmazNo ratings yet

- Material Consumption RateDocument13 pagesMaterial Consumption RateMillion Gemechu100% (2)

- Design Speculations: M-25 Mix Design (By Mass) For Ips-5 (Shastri Nagar), MeerutDocument3 pagesDesign Speculations: M-25 Mix Design (By Mass) For Ips-5 (Shastri Nagar), MeerutMuneer HaiderNo ratings yet

- Dekguard Primer WBDocument2 pagesDekguard Primer WBmohamedbossilyNo ratings yet

- Circular Section Crack Width Under Pure TensionDocument1 pageCircular Section Crack Width Under Pure TensionAbinash ModakNo ratings yet

- Aci Structural Journal Jan.-Feb. 2015 v. 112 No. 01Document122 pagesAci Structural Journal Jan.-Feb. 2015 v. 112 No. 01Professor Dr. Nabeel Al-Bayati-Consultant Engineer100% (3)

- Air Entrained ConcreteDocument3 pagesAir Entrained Concrete7vortex9No ratings yet

- A Critical Analysis of The Design and Construction of Boyne Bridge, IrelandDocument10 pagesA Critical Analysis of The Design and Construction of Boyne Bridge, Irelandahmed55No ratings yet

- DO - 147 - s2017 - Item 706 - Concrete, Clay, Plastic & Fiber PipeDocument5 pagesDO - 147 - s2017 - Item 706 - Concrete, Clay, Plastic & Fiber PipeFaustino AbadNo ratings yet

- Auroville ReportDocument35 pagesAuroville ReportIshani50% (2)

- Dry Stack Manual & Reference Tek 14-22Document6 pagesDry Stack Manual & Reference Tek 14-22rickbmayNo ratings yet

- 277 SpecDocument86 pages277 Specmanil_5No ratings yet

- Transmission - Line Foundation DesignDocument53 pagesTransmission - Line Foundation DesignKalyan100% (2)

- Road MaintenanceDocument64 pagesRoad MaintenanceWira PutrantoNo ratings yet

- Method Statement FOR Concreting Work: ProjectDocument6 pagesMethod Statement FOR Concreting Work: ProjectKelvin LauNo ratings yet

- 7804 Idrocretekr1000 GBDocument4 pages7804 Idrocretekr1000 GByaw shuNo ratings yet

- Ph7A - Oustanding Submissions (Overall)Document20 pagesPh7A - Oustanding Submissions (Overall)Cheap TrickNo ratings yet

- Firm Analysis - ACC Cements: Project Report - Competition and StrategyDocument17 pagesFirm Analysis - ACC Cements: Project Report - Competition and StrategySanju VisuNo ratings yet

- 01 Lowcosthousing 181224175137Document42 pages01 Lowcosthousing 181224175137Damanpreet DandiwalNo ratings yet

- Praveen SinghDocument24 pagesPraveen SinghAbhay Kumar PandeyNo ratings yet

- BP QuoteExampleDocument80 pagesBP QuoteExampleNur IrawanNo ratings yet

- DR - MAJID AL-BANA KARADA Structural-1 - 221108 - 213032Document16 pagesDR - MAJID AL-BANA KARADA Structural-1 - 221108 - 213032Bahaa AldeenNo ratings yet

- Isolated Footing Design (ACI 318-11) : ElevationDocument12 pagesIsolated Footing Design (ACI 318-11) : ElevationAhmed Ben HmidaNo ratings yet

- Calculate Bags of Concrete Mix - Round + Square Footing Holes and Small Slabs - InchDocument1 pageCalculate Bags of Concrete Mix - Round + Square Footing Holes and Small Slabs - InchAlan MatzdorfNo ratings yet

- Cement MENADocument60 pagesCement MENAazizelam11No ratings yet

- Hydraulic Design of Small Hydro PlantsDocument63 pagesHydraulic Design of Small Hydro Plantsmassi99100% (3)

- NCHRP RPT 673 PDFDocument285 pagesNCHRP RPT 673 PDFRenugopalNo ratings yet

- Sample Pages Build SourceDocument29 pagesSample Pages Build SourceArunKumarVermaNo ratings yet