Professional Documents

Culture Documents

Isolasi 3m PDF

Uploaded by

lailiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Isolasi 3m PDF

Uploaded by

lailiCopyright:

Available Formats

Page 1 of 3

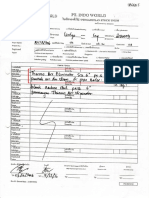

Scotch 23

All-Voltage Splicing Tape

Data Sheet

__________________________________________________________________________________

Product Description

Scotch 23 Electrical Tape is a highly conformable self-fusing

EPR (Ethylene Propylene Rubber) based, high voltage splicing

tape. It is a non-vulcanising, shelf-stable tape with excellent

electrical properties. 23 Tape can be used as an insulation for

low-voltage applications as well as an insulation for splices up to

69kV.

Tape Features

Can be used to splice and terminate cables whose emergency

overload temperatures can reach 130C.

Based on Ethylene Propylene Rubber (EPR).

Physical and electrical properties are unaffected by the

degree of stretch.

Self-fusing tape.

Excellent electrical properties.

A special polyester liner which will not stick to the tape

upon unwind.

Compatible with all solid dielectric cable insulation:Polyethylene (high and low density).

Cross-linked polyethylene (XLPE).

Polyvinyl chloride (PVC).

Butyl rubber.

Ethylene Propylene Rubber (EPR).

Oil-based rubber.

Applications

Primary electrical insulation for splicing cable from 600V to

69kV on all solid dielectric cables.

Primary insulation for building stress cones on cables up to

35kV on all solid dielectric cables.

Jacketing on high-voltage splices and terminations.

Moisture sealing electrical connections.

Bus bar insulations.

End sealing high-voltage cables.

Data Typical Properties

Physical Properties

Test Method

Typical Value*

Colour

Black

Thickness ASTM-D4325

0.76mm

Tensile Strength ASTM-D4325

1.4KN/m

Ultimate Elongation ASTM-D4325

1000%

Operating Temperature

90C (194F)

Emergency Operating Temperature

130C (266F)

Fusion, ASTM-D4388

Passes

Thermal Conductivity

0.1208 Btu

ASTM-D1518

(hr)(sq ft) (F per ft)

Modulus @ 130C

See Section 5

Ozone Resistance ASTM-D4388

Passes

Electrical Properties

Test Method

Typical Value*

Dielectric Strength ASTM-D4325

After Standard Conditioning 31.5 MV/m

After 96 hours @ 96% RH

>90% of Std

Condition Value

Insulation Resistance ASTM-1000

(Indirect method of electrolytic

>1 x 106

corrosion)

megohms

Dissipation Factor

See Section 5

Dielectric Constant

See Section 5

Dielectric Strength at elevated

temperature

See Section 5

*This data is not to be used for specification. Values listed are

for typical properties and should not be considered minimum or

maximum.

Specifications

Product

The high-voltage corona-resistant tape must be based on ethylene

propylene rubber and be capable of operation at the emergency

cable temperature of 130C (266F). The tape must be capable

of being applied in either the stretched or unstretched condition

without any resulting loss in either physical or electrical

properties.

The tape must not split, crack, slip or flag when exposed to

various environments (indoor and outdoor). The tape must be

compatible with all synthetic cable insulations. The tape must

have a dissipation factor of less than 5% at 130C (266F) and

must have a shelf life of 5 years.

Engineering/Architectural Specification

Splicing and terminating solid dielectric cables shall be done in

accordance with drawings engineered by the splice material

manufacturer such as the 2047 series available from 3M

Company. All splices and terminations shall be insulated using

Scotch Brand 23 Electrical Tape.

Characteristics and Test Data

Modulus at 130C (266F)

A high-voltage splicing tape must constantly maintain a rubberlike consistency throughout the life of a splice. One method of

determining a rubber material consistency is by measuring the

modulus of the material. The modulus of a material is the stress

required to elongate the material to a given elongation.

_________________________________________________________________________________________

3M UK PLC

Electrical Products

3M House, PO Box 1

Bracknell, Berkshire RG12 1JU

Telephone: 01344 858616

Fax: 01344 858758

3M Ireland

Sales Office

3M House, Adelphi Centre

Dun Laoghaire, Co Dublin, Ireland

Telephone: 353 1 280 3555

Fax: 353 1 280 3509

3M UK PLC

Sales Office

PO Box 393

Bedford MK41 0YE

Telephone: 01234 229462

Fax: 01234 229433

Page 2 of 3

Scotch 23

All-Voltage Splicing Tape

Data Sheet

__________________________________________________________________________________

Figure 1 shows the 100% modulus (stress required to elongate 23

Tape to 100% elongation) after heat ageing the samples at 130C

(266F) for a varying number of days. The results indicate a very

stable product with excellent body or elasticity after oven

ageing at 130C (266F).

Dissipation Factor

Figure 2 shows the dissipation of 23 Tape. This test was run

according to ASTM-D150 at a stress of 50 V/mil

(2.0 MV/m) and a frequency of 60 cycles per second.

Dielectric Strength at Elevated Temperatures

A high-voltage splice must not only have a high dielectric

strength at room temperature, but it must also have good values

at the temperature at which it is expected to operate. Figure 4

shows a plot of dielectric strength versus temperature. This test

was run according to ASTM-1000.

Dielectric Constant

Figure 3 shows the dielectric constant versus temperature of 23

Tape. This test was run according to ASTM-D150 at a stress of

50 V/mil (2.0 MV/m) and a frequency of 60 cycles per second.

_________________________________________________________________________________________

3M UK PLC

Electrical Products

3M House, PO Box 1

Bracknell, Berkshire RG12 1JU

Telephone: 01344 858616

Fax: 01344 858758

3M Ireland

Sales Office

3M House, Adelphi Centre

Dun Laoghaire, Co Dublin, Ireland

Telephone: 353 1 280 3555

Fax: 353 1 280 3509

3M UK PLC

Sales Office

PO Box 393

Bedford MK41 0YE

Telephone: 01234 229462

Fax: 01234 229433

Page 3 of 3

Scotch 23

All-Voltage Splicing Tape

Data Sheet

__________________________________________________________________________________

Dielectric Strength Versus Thickness

Figure 5 shows a plot of dielectric strength in volts per mil versus

thickness. As can be seen by the curve, the dielectric strength in

the original thickness of 0.76mm is 800 V/mil (31.5 MV/m).

However, the dielectric strength of a 0.51mm thickness of 23

Tape is 1200 V/mil

(47.2 MV/m). This test was run according to ASTM-1000.

Availability

Scotch Brand 23 Electrical Tape is available in the following

roll sizes from your local authorised 3M electrical distributor:

19mm x 9M

25mm x 9M

51mm x 9M

Other lengths and widths are available by special request.

Complete Product and Use Specifications are available through

the Electrical Products Division, 3M Company.

Installation Techniques

Scotch Brand 23 Electrical Tape should be applied in

successive half-lapped, level-wound layers until desired build-up

is reached. To eliminate voids in critical areas, highly elongate

23 Tape.

Stretch Tape in these critical areas just short of its breaking point.

Doing so will not alter its physical or electrical properties. In

less critical areas, less elongation may be used.

Normally, 23 Tape is stretched to of its original width in these

less critical areas. Always attempt to half-lap to produce a

uniform build-up. When using 23 Tape for splicing cables from

35kV to 69kV, always elongate the tape throughout the entire

splice.

Important Notice

Technical information provided by 3M is based on experience and/or tests believed

to be reliable, but their accuracy is not guaranteed and the results may not be relevant

to every users application. For this reason 3M does not accept responsibility or

liability, direct or consequential, arising from reliance upon any information provided

and the user should determine the suitability of the products for their intended use.

Nothing in this statement will be deemed to exclude or restrict 3Ms liability for

death or personal injury arising from its negligence. All questions of liability relating

to 3M products are governed by the sellers terms of sale subject where applicable to

the prevailing law. If any goods supplied or processed by or on behalf of 3M prove

on inspection to be defective in material or workmanship, 3M will (at its option)

replace the same or refund to the Buyer the price paid for the goods or services.

Except as set our above, all warranties and conditions, whether express or implied,

statutory or otherwise are excluded to the fullest extent permissible at law.

3M and Scotch are trademarks of the 3M Company. Printed in the UK.

3M United Kingdom PLC, 2001.

Maintenance

Under normal storage conditions, 23 Tape has a 5-year shelf life.

The tape is not impaired by freezing nor by overheated storage up

to the point of flow which prevents removal from the package.

_________________________________________________________________________________________

3M UK PLC

Electrical Products

3M House, PO Box 1

Bracknell, Berkshire RG12 1JU

Telephone: 01344 858616

Fax: 01344 858758

3M Ireland

Sales Office

3M House, Adelphi Centre

Dun Laoghaire, Co Dublin, Ireland

Telephone: 353 1 280 3555

Fax: 353 1 280 3509

3M UK PLC

Sales Office

PO Box 393

Bedford MK41 0YE

Telephone: 01234 229462

Fax: 01234 229433

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Thermometer Indikator : Penunjukan Alat Standard Koreksi Ketidakpastian (°C) (°C) (°C) (°C)Document20 pagesThermometer Indikator : Penunjukan Alat Standard Koreksi Ketidakpastian (°C) (°C) (°C) (°C)lailiNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Sebacate (Mineral Oil)Document3 pagesSebacate (Mineral Oil)lailiNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Detect machine temperature and current using infrared thermographyDocument1 pageDetect machine temperature and current using infrared thermographylailiNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Test AnitaDocument1 pageTest AnitalailiNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Sds Silicone 500 CP PDFDocument10 pagesSds Silicone 500 CP PDFlailiNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- PTP12Document2 pagesPTP12Tung Hoang100% (3)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hanna Instruments S.R.L.: Information SheetDocument7 pagesHanna Instruments S.R.L.: Information SheetlailiNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- General Catalog2011 PDFDocument258 pagesGeneral Catalog2011 PDFlailiNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Calibration of Water Flow Rate in An Ultrasonic Flow Meter Using The MAX35101Document10 pagesCalibration of Water Flow Rate in An Ultrasonic Flow Meter Using The MAX35101lailiNo ratings yet

- Disinfection2 WebDocument200 pagesDisinfection2 WebSrijita JoarderNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Set Range and Measure with Water TesterDocument4 pagesSet Range and Measure with Water TesterlailiNo ratings yet

- Dupont Freon 22 Refrigerant: Material Safety Data SheetDocument9 pagesDupont Freon 22 Refrigerant: Material Safety Data SheetlailiNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- True Temperature Indicator Model Tti-10: User Manual/HandbookDocument12 pagesTrue Temperature Indicator Model Tti-10: User Manual/HandbooklailiNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- HI 3812 Hardness Test Kit: Instruction ManualDocument2 pagesHI 3812 Hardness Test Kit: Instruction ManualGerson SandovalNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Memmert Oilbath ONE 29 SpecsDocument3 pagesMemmert Oilbath ONE 29 SpecslailiNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Memmert Oilbath ONE 7.en PDFDocument3 pagesMemmert Oilbath ONE 7.en PDFlailiNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Phosporic Acid 85% Msds Food GradeDocument6 pagesPhosporic Acid 85% Msds Food GradelailiNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Fluke CatalogDocument164 pagesFluke CatalogrochimNo ratings yet

- Manual Refraktometer S Mill M PDFDocument2 pagesManual Refraktometer S Mill M PDFpuput1991No ratings yet

- Steam SeparatorDocument2 pagesSteam SeparatorlailiNo ratings yet

- Water Deionized PDFDocument5 pagesWater Deionized PDFDaris Putra HadimanNo ratings yet

- Safety Data Sheet Sections SummaryDocument6 pagesSafety Data Sheet Sections SummarylailiNo ratings yet

- ISO 22000 - Phosporic Acid 85% Food GradeDocument1 pageISO 22000 - Phosporic Acid 85% Food GradelailiNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Jadwal Public Training 2016 Rev0Document13 pagesJadwal Public Training 2016 Rev0lailiNo ratings yet

- Ba - DM - 146 - 03 - 07 - GB (Prominent Dulcometer) PDFDocument36 pagesBa - DM - 146 - 03 - 07 - GB (Prominent Dulcometer) PDFlailiNo ratings yet

- Method PH Calibration Procedure Optimal Measurement PrecisionDocument4 pagesMethod PH Calibration Procedure Optimal Measurement PrecisionPriyanshu GuptaNo ratings yet

- TDS Meter Calibration InstructionsDocument2 pagesTDS Meter Calibration InstructionsMartin DjaminNo ratings yet

- Instruction Manual for 2700 Series Benchtop MetersDocument60 pagesInstruction Manual for 2700 Series Benchtop MeterslailiNo ratings yet

- Disinfection2 WebDocument200 pagesDisinfection2 WebSrijita JoarderNo ratings yet

- TDS Meter Calibration InstructionsDocument2 pagesTDS Meter Calibration InstructionsMartin DjaminNo ratings yet

- Switching Theory and Logic Design PDFDocument159 pagesSwitching Theory and Logic Design PDFSai TejaswiniNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- PML Rev-I Preferred Manufacturer List for PT Pertamina EPDocument12 pagesPML Rev-I Preferred Manufacturer List for PT Pertamina EPAndreas Schlager100% (1)

- Parts List 8198417 RevCDocument12 pagesParts List 8198417 RevCSonaina KhanNo ratings yet

- Ea80 Series PDFDocument82 pagesEa80 Series PDFAnca MunteanuNo ratings yet

- Friction Factor For Turbulent Pipe Flow: January 2006Document17 pagesFriction Factor For Turbulent Pipe Flow: January 2006John AnthoniNo ratings yet

- Stokes' theorem simplifies integration of differential formsDocument6 pagesStokes' theorem simplifies integration of differential formssiriusgrNo ratings yet

- Lesson 7: Cylinders: Basic Hydraulic SystemsDocument12 pagesLesson 7: Cylinders: Basic Hydraulic Systemsoscar el carevergaNo ratings yet

- VisiLogic Software Manual-LadderDocument158 pagesVisiLogic Software Manual-LadderEduardo Vasquez CastroNo ratings yet

- Epc of Well Pad D For Sorik Marapi Geothermal Project Recovery ScheduleDocument1 pageEpc of Well Pad D For Sorik Marapi Geothermal Project Recovery ScheduleGema SuryaNo ratings yet

- Caterpillar 914GDocument28 pagesCaterpillar 914GForomaquinas100% (3)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Staircase Preliminary Design Based On NBC and IS CodeDocument10 pagesStaircase Preliminary Design Based On NBC and IS CodeEducation. HubNo ratings yet

- 5TH Week EnergyDocument6 pages5TH Week EnergyMira VeranoNo ratings yet

- Apache Oozie - A workflow scheduler to manage Hadoop jobsDocument5 pagesApache Oozie - A workflow scheduler to manage Hadoop jobsarjuncchaudharyNo ratings yet

- Experion Scada PinDocument7 pagesExperion Scada PinKhalid AliNo ratings yet

- Ceramic Terminal BlocksDocument1 pageCeramic Terminal BlockselijbbNo ratings yet

- Dow Corning (R) 200 Fluid, 50 Cst.Document11 pagesDow Corning (R) 200 Fluid, 50 Cst.Sergio Gonzalez GuzmanNo ratings yet

- Seminar ReportDocument30 pagesSeminar Reportshashank_gowda_7No ratings yet

- Smart Structural Protective Packaging Design Approach For Handicrafts ProductsDocument12 pagesSmart Structural Protective Packaging Design Approach For Handicrafts ProductsNohaNo ratings yet

- Motion ReportDocument2 pagesMotion Reportmikeb-erau100% (2)

- Sallyport MBI Bifold BrochureDocument6 pagesSallyport MBI Bifold BrochureameraldaherNo ratings yet

- 2 Interference in Spur GearsDocument2 pages2 Interference in Spur Gearschris100% (1)

- Technical Presentation - Arik Ethan Kinajil (25231)Document5 pagesTechnical Presentation - Arik Ethan Kinajil (25231)Arik EthanNo ratings yet

- ESD Protection in CMOS: Characterization and Failure AnalysisDocument113 pagesESD Protection in CMOS: Characterization and Failure AnalysisElisavNirolfNo ratings yet

- Civil 3 8sem PDFDocument43 pagesCivil 3 8sem PDFG0utham100% (1)

- Advanced Data Structures and ImplementationDocument56 pagesAdvanced Data Structures and ImplementationSyam Prasad Reddy BattulaNo ratings yet

- Challenges in PavementsDocument23 pagesChallenges in PavementsSomeshwar Rao ThakkallapallyNo ratings yet

- VGS 8.1.2 Rev.20 - UTDocument29 pagesVGS 8.1.2 Rev.20 - UTPaul-Petrus MogosNo ratings yet

- Cotta Transfer Case Lube PlanDocument3 pagesCotta Transfer Case Lube PlanMatias Alfredo Contreras KöbrichNo ratings yet

- Central GeothermalDocument48 pagesCentral GeothermalНиколай ШипочкиNo ratings yet

- 2014-6-2 PCED South Hill Coalition Proposed Elements MatrixDocument2 pages2014-6-2 PCED South Hill Coalition Proposed Elements MatrixSpokane City CouncilNo ratings yet