Professional Documents

Culture Documents

Ijcsi 2015 v4 n4 p5 pp353 364

Uploaded by

mini2018Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ijcsi 2015 v4 n4 p5 pp353 364

Uploaded by

mini2018Copyright:

Available Formats

Int. J. Corros. Scale Inhib., 2015, 4, no.

4, 353364

The influence of alkalising amines on the film formation

by oleyldiamine

W. Hater,1* P. Kraft1 and C. Fort2

1

Kurita Europe APW GmbH, Giulinistrae 2, 67065 Ludwigshafen, Germany

2

Kurita France SAS, Z. I. Le Roineau, 72500 Vaas, France

E-mail: Wolfgang.Hater@Kurita.eu

Abstract

The film formation of film forming amines (FFAs), commonly used as corrosion inhibitors

in water/steam cycles, has been subject of various studies. However, less is known of the

impact of alkalising amines (AA) on the film formation. AAs have a solubilising effect on

the FFA and as a consequence might indirectly influence the properties of the film.

Therefore, the film formation of oleyldiamine, a commonly used FFA, on carbon steel

has been studied with electrochemical impedance spectroscopy (EIS) in defined test water,

containing 200 mg L1 of NaCl, with and without the presence of different AAs. The

studies have been carried out at two different pH values over an exposure time up to 5 h.

All EIS spectra of the blank show one semi-circle, whereas two distinct semi-circles

have been observed in the spectra of the test solutions with FFA. Therefore, the steel

solution interface has been described by two different equivalent circuits using resistances

and constant phase elements. All EIS spectra could be fitted with good agreement to the

experimental data. The spectra showed significant and systematic changes throughout the

exposure time.

All polarisation resistances measured with FFA at pH 9.0 are much higher compared

to the data obtained at pH 8.2. The polarisation resistance of the blank solution is strongly

decreasing over time following roughly an exponential law and almost comes to a steady

state after 5 hours. In contrast to this the solutions containing FFA show a linear increase

of the polarisation resistance over time. Obviously the film formation has not yet

completely been finished within the experimental period.

The FFA solutions containing the two different AA show a similar behaviour over

time and almost the same high polarisation resistance, reflecting the excellent corrosion

protection. Overall, the data indicate that the film obtained with oleylamine in the solutions

containing DEAE provides a slightly better protection than FFA solution with CHA. Thus,

the more toxic CHA can be replaced by DEAE.

Keywords: film formation, electrochemical impedance spectroscopy, oleyldiamine,

cyclohexylamine, diethylaminoethanol, carbon steel.

Received: September 11, 2015. Published: October 21, 2015.

doi: 10.17675/2305-6894-2015-4-4-5

Int. J. Corros. Scale Inhib., 2015, 4, no. 4, 353364

354

1. Introduction

Film forming amines (FFAs), also called fatty amines or polyamines, are used as corrosion

inhibitors in closed cooling/heating systems [1] as well as in steam generators [25]. Due

to their volatility, they are able to protect the whole water/steam cycle by the formation of

a thin film on the metal surfaces, which acts as a barrier between the corrosive agents in

the water and the metal.

In steam generators film forming amines are generally applied in combination with

alkalising amines (AAs) e.g. cyclohexylamine (CHA) or diethylaminoethanol (DEAE),

which adjust the pH to an alkaline range and minimise the solubility of iron. DEAE is

proposed as replacement for CHA, which is suspected of damaging fertility.

Although the film formation by FFA has been subject of numerous studies [610],

much less is known on the influence of AA on the film formation. There is a concern,

whether the change about the alkalising amine due to their different hydrotropy might

impact the protective properties of filming amines and thus might lead to corrosion.

Therefore, the film formation of oleyldiamine, a commonly used FFA, on carbon steel

has been studied with electrochemical impedance spectroscopy (EIS) in defined test water

with and without the presence of different AAs. The studies have been carried out at two

different pH values over an exposure time up to 5 h.

2. Experimental

Electrochemical impedance spectroscopy was used to characterize the inhibitive properties

of three different inhibitor solutions based on FFA and to compare their anticorrosion

efficiency with untreated medium (blank).

2.1. Test solutions

Three different corrosion inhibitors were studied in the form of aqueous solutions for

corrosion protection of water/steam cycles. The inhibitor compositions are given in

Table 1. In water/steam cycles DI-water is generally used with a very low electrical

conductivity (< 1S/cm). In order to ensure the necessary electrical conductivity needed for

the measurement 200 mg/L NaCl were added.

The concentration of FFA was chosen to provide enough material to establish a

complete film on the electrode. The AA concentrations were chosen to achieve the same

pH-value in the solution, taking into account the different basicity of the two molecules.

2.2. Corrosion testing

Electrochemistry is a powerful tool to study corrosion phenomena and widely applied in

academic and industrial research [1114]. Therefore, this method was chosen for this

study.

Electrochemical measurements were carried out using an Autolab Metrohm frequency

response analyser with an electrochemical interface. The impedance diagrams were plotted

Int. J. Corros. Scale Inhib., 2015, 4, no. 4, 353364

355

Table 1. Compositions of inhibitor solutions in DI-water. All solutions additionally contained 200 mg/L

NaCl.

Oleyldiamine

Cyclohexylamine

Diethylaminoethanol

FFA [mg/L]

CHA [mg/L]

DEAE [mg/L]

Blank

FFA

FFA/CHA

14

FFA/DEAE

22

Inhibitor

at the corrosion potential after 2 hours of immersion in a frequency range of 65 kHz to a few

mHz with eight points per decade. The electrochemical results were obtained from a minimum

of five subsequent experiments. For the study of the film formation in time a maximum of 15

measurements were carried out with 20 minutes delay between the start of each one.

The corrosive medium was a 200 mg/L NaCl solution in demineralized water in

contact with air maintained at 25C. The choice of this medium was based upon the

following criteria [6]: (i) its low electrical conductivity is close to that encountered in

industrial water circuit, (ii) its corrosivity is fairly high, and (iii) it is an easily reproducible

baseline solution.

Depending on the concentration of the compounds, the pH of the inhibitive solutions

varied between 7 and 10. The pH was adjusted to the desired value by adding NaOH (for

pH increasing) or HCl (for pH decreasing).

Representing the most important material used in the water/steam cycles carbon steel

was used as sample material. For all the experiments, the sample materials were polished

in three steps with SiC paper from grade 1200 to grade 4000, cleaned in ethanol and

demineralized water and then dried in warm air.

For the test samples, the working electrode was a rotating disc consisting of a rod of

1 cm cross-sectional area to ensure uniform thickness of the diffusion layer at the

electrode surface and a heat-shrinkable sheath leaving only the tip of the cylinder in

contact with the solution. All experiments were carried out at a rotation speed of 500 rpm.

A saturated calomel electrode (SCE) was used as reference and the counter-electrode was a

platinum grid.

The carbon steel/solution interface was mathematically described in terms of an

electric equivalent circuit consisting of a resistance electrolyte in series with one or two

parallel constant phase element (CPE)/resistor combinations. The semicircular shape of the

impedance diagrams allowed the modeling with an equivalent circuit having the following

characteristic parameters: Rp, polarization resistance and CPE, double layer capacitance.

The CPE which is described by two parameters (capacity Y0 and exponent n) is generally

attributed to the roughness and inhomogeneity of the surface or to a non-uniform

distribution of the current density on the electrode undergoing corrosion [15, 16].

Int. J. Corros. Scale Inhib., 2015, 4, no. 4, 353364

356

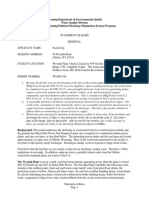

3. Results and discussion

The EIS spectra obtained were fitted with the Autolab FRA software applying three

different electric equivalent circuits EEC (Figure 1). Although single EIS spectra could

probably have been described better by different EEC, it was decided to always apply the

same model within spectra series with different exposure times.

The spectra of blank solution could be described well with the simple EEC a

(Figure 1a). The spectra of solutions containing FFA could be described only with more

complex EEC (Figure 1b, c). Since the data obtained by the fits for the EECs with two

CPE did not differ significantly (Table 2), in this paper only the data of the fit with EEC b

are shown. For the graphical presentation of the spectra the Nyquist plot has been chosen.

The comparison of measured and fitted data is shown for two examples in Figure 2.

Figure 1. Electrical equivalent circuits (EEC) used for the mathematical description of the

Electrochemical Impedance Spectra.

Table 2. Comparison of fitting data obtained for two different electrical equivalent circuits. The example

shows the data for FFA/DEAE at pH 8.2 after 20 minutes exposure time.

Parameter

Unit

EECb

EECc

Rs

[kcm]

0.205

0.206

CPEf

Y0

n

[F/cm]

1.4 E-7

0.808

1.1 E-7

0.802

Rf

[kcm]

0.707

0.813

[F/cm]

2,4 E-7

0.614

3.5 E-7

0.625

[kcm]

2.31

1.86 E-2

2,20

1.84 E-2

CPEt

Y0

n

Rt

Rel. Chisqr

Int. J. Corros. Scale Inhib., 2015, 4, no. 4, 353364

357

Figure 2. Comparison of measured and fitted data of Electrochemical Impendence Spectra

for: top: Blank fitted with electrical equivalent circuit a (EECa); bottom: FFA/CHA fitted

with electrical equivalent circuit b (EECb).

3.1. Spectra dependence on inhibitor solution

The four test solutions show very different EIS spectra: The spectra of the blank is

characterised by one asymmetrical semi-circle, whereas the spectra of the solutions

containing film forming amine show the typical two semi-circles. In the spectrum of the

solution containing only film forming amine the two semi-circles cannot be easily

distinguished. Fitting with only one CPE (EECa), however, did not provide a satisfying

result. Figure 3 shows the Nyquist plots of the EIS spectra for the four solutions at a pH of

8.2 after 300 minutes of exposure time.

Int. J. Corros. Scale Inhib., 2015, 4, no. 4, 353364

358

Figure 3. Comparison of Electrochemical Impendence Spectra for three different inhibitor

solutions based upon film forming amine (FFA) and solution without inhibitor (Blank).

It is clearly visible that the polarisation resistance for the three solutions with inhibitor

based on FFA is roughly one order of magnitude higher than the solution without inhibitor.

Both solutions containing additionally alkalising amines (AA) have a higher polarisation

resistance than the solutions containing only FFA. There is no significant difference

between the results of the two FFA + AA solutions.

3.2. Spectra dependence on time

For the solutions at pH 8.2 a series of 15 measurements over a period of totally 300

minutes have accumulated for each inhibitor solution. It can be noted that the shapes of the

EIS curves significantly change during the total measuring time of 300 minutes. Figure 4

shows as an example five EIS spectra of the series for the blank and the FFA solution with

CHA.

There is marked difference between the time dependence of the two EIS spectra

shown: the polarisation resistance decreases with time for the blank solution (top), whereas

it strongly increases for the FFA solution with CHA (bottom). The high frequency

semicircle increases in diameter, the low frequency semi-circle is more or less constant.

Apparently, the film formation process has not come to equilibrium at the end of the total

exposure time. The same is valid for the FFA/DEAE solution.

Int. J. Corros. Scale Inhib., 2015, 4, no. 4, 353364

359

Figure 4. Dependence of Electrochemical Impendence Spectra on time for the solution

without inhibitor (Blank) (top) and the solution based upon film forming amine and

cyclohexylamine (FFA/CHA) (bottom). Note that the scales of the axes are different.

For all four solutions, the solution resistance remains constant over time and is

0.30 kcm resp. 0.31 kcm for the solutions without AA and 0.20 kcm resp.

0.24 kcm for the solutions with AA. The lower resistance of the solutions containing

AA reflects their higher electrical conductivity.

Figure 5 shows the development of the polarisation resistance RP and the parameters

of the CPE with time. For the film forming amine solutions, the data of the high frequency

loop are presented.

Int. J. Corros. Scale Inhib., 2015, 4, no. 4, 353364

360

The polarisation resistances of the two AA containing solutions continuously increase

and have more or less the same value, both reaching a value of approx. 6 kcm at the

end of the experiment. The absolute differences should be critically viewed due to the

scattering of data. The polarisation resistances of the solution containing only film forming

amine are roughly constant (4.20.4 kcm). In contrast to this the polarisation resistance

of the blank decreases over time and finally reaches 0.6 kcm. The decay roughly

follows an exponential law. The corrosion protection achieved by the inhibitor solutions

decreases in the order: FFA/DEAE FFA/CHA > FFA > Blank.

From the time dependence of the polarisation data the conclusion can be drawn that

the layer formation has not come to equilibrium for the blank and the film forming amine

solutions containing alkalising amines (FFA/DEAE and FFA/CHA). A closer look on the

data of the constant phase elements proves that in spite of the constant polarisation

resistance the layer formation is not finished for the solution containing only FFA, as both

parameters (capacity Y0 and the exponent n) significantly and systematically change over

time (Figure 5b,c).

The continuous increase of n from 0.26 at the beginning to 0.55 at the end of the

experiment indicates an increasing homogeneity of the layer. Furthermore, the increase of

Y0 shows a change of its porosity. This could be interpreted as a reorganisation of the film.

The inhomogeneity of the layer constantly increases over time for the blank: The

exponent decreases almost linear with time from 0.64 to 0.52. The corrosion process of the

metal creates a less and less protective layer.

The constantly high exponent n between 0.82 and 0.96 of the solutions containing

FFA and alkalising amines shows almost the behaviour of an ideal capacity. The value of

the FFA/DEAE solution is a little higher. These two solutions form protective layers with

low inhomogeneity within short term.

The marked difference in the layer formation between the two solutions containing

FFA and AA and the solution containing only FFA can be plausibly explained by the

hydrotropic effect of the AA: In the solutions without AA the FFA is probably existent at

least partially as micelles. Bohnsack [17] states a critical micelle concentration (CMC) of

oleyldiamine of 3 to 4 mg/L, which is close to the concentration applied in this study.

It is evident that the film forming amine molecule shows a different adsorption and

thus protection behaviour as a micelle or as an almost dissolved molecule. The

concentration of FFA applied in practice is usually between 0.1 and 0.5 mg/L, therefore,

below the CMC. However, this concentration range would not allow the formation of a

complete film on the vessel and electrode surfaces. For the objective of this study to

compare the effect of different alkalising amines on the film formation this is of minor

relevance.

Int. J. Corros. Scale Inhib., 2015, 4, no. 4, 353364

Figure 5. Dependence of a) polarisation resistance RP and constant phase element (CPE)

parameters; b) capacity Y0 and c) exponent n derived from Electrochemical Impedance Spectra

on time for four different inhibitor solutions. For the solutions containing film forming amine

(FFA) the CPE data of the high frequency semi-circle are shown.

361

Int. J. Corros. Scale Inhib., 2015, 4, no. 4, 353364

362

3.3. pH dependence

Additionally to the studies at pH 8.2, which represent a situation of poor pH control in the

water steam cycle, e.g. due to an ingress of a pollutant, EIS spectra were measured at pH

9.0, which is in the normal range of a well-controlled system. The EIS spectra were

recorded over a period of 100 minutes. Unfortunately, the spectra of the inhibitor solution

containing only film forming amine (FFA) showed high distortion. That is why the authors

decided not to evaluate them.

The EIS spectra at pH 9.0 for the two inhibitor solutions containing alkalising amines

are dominated by the very large low frequency semi-circle (Figure 6). The EIS spectrum of

the blank can only be seen in the detail. The polarisation resistances of the film forming

amine solutions are almost two orders of magnitude higher than at a pH of 8.2, whereas the

value for the blank increases only slightly (Table 3).

The fitting data for the EIS spectra remain almost constant for the CPEs during the

exposure time of 100 minutes. The polarisation resistances show the same dependence as

for pH 8.2: increase over time for the FFA containing solutions (117 kcm to 263 kcm

for FFA/DEAE, 92 kcm to 242 kcm for FFA/CHA); decrease for the blank

(2.40 kcm to 1.65 kcm). Generally, the polarisation resistance measured for

FFA/DEAE is a little bit higher than for FFA/CHA.

Figure 6. Comparison of Electrochemical Impendence Spectra for three different inhibitor

solutions based upon film forming amine (FFA) and solution without inhibitor (Blank).

Int. J. Corros. Scale Inhib., 2015, 4, no. 4, 353364

363

Table 3. Comparison of polarization resistances at pH 8.2 with 9.0 derived from electrochemical

impedance spectra for four inhibitor solutions. The exposure time was 100 minutes.

Polarisation resistance

[kcm]

Inhibitor

pH = 8.2

pH = 9.0

FFA/DEAE

4.01

264

FFA/CHA

3.90

242

FFA

4.90

n.d.

Blank

1.09

1.65

4. Conclusions

The corrosion protection of three inhibitor solutions based upon oleyldiamine, a frequently

used film forming amine (FFA), alone and in combination with two alkalising amines has

been studied by means of Electrochemical Impedance Spectroscopy (EIS) at two pH values

in dependence on time. FFA based formulations are applied for the conditioning of

water/steam cycle in power plant.

The main objective of this work was to investigate the impact of a substitution of

cyclohexylamine (CHA), which is labelled H361f (suspected of damaging fertility) in FFA

formulations by the non CMR labelled diethylaminoethanol (DEAE) on the film formation

and thus on the corrosion protection.

All EIS spectra obtained for FFA containing solutions showed two semi-circles

characteristic for the formation of a film on the surface. The film formation is not

spontaneous and does not come to equilibrium state within the total exposure time of 300

minutes. At pH 9.0 the low-frequency semi-circle is predominant. The EIS spectra of the

blank show a single asymmetric semi-circle.

All EIS spectra were mathematically described by mainly two different electric

equivalent circuits using constant phase elements. The evolution of the parameters was

determined over time. At both pH the polarisation resistance and thus the corrosion

protection of the FFA and AA containing solutions increased significantly over time,

whereas the blank showed a decrease. It remained almost constant for the solution only

with FFA. The difference in behaviour between the FFA solution without and with AA is

probably due to hydrotropic effect, which has a considerable influence under the conditions

of the experimental set-up.

At pH 9.0 the polarisation resistance was almost two orders of magnitude higher than

at pH 8.2. The strongly improved corrosion protection cannot be explained by the different

pH, as the polarisation resistance of the blank only slightly increased.

According to the results of this study the cyclohexylamine, which is suspected to be

toxic for reproduction can be replaced by the non CMR-labelled diethylaminoethanol

Int. J. Corros. Scale Inhib., 2015, 4, no. 4, 353364

364

without a deterioration of film formation and thus of the corrosion inhibition. The overall

data may indicate even a slight improvement of the corrosion inhibition, when DEAE is

used instead of CHA in combination with the film forming amine.

References

1. C. Fort, G. Stoianovici, P. Bleriot, W. Hater and J. Matheis, PowerPlant Chem., 2014,

16, no. 6, 361.

2. W. Hater, C. Digiaro and C. Frayne, Int. Water Conf. 2012, San Antonio, Paper IWC

1220.

3. R. van Lier, G. Janssen and J. Savelkoul, VGB PowerTech., 2012, no. 8, 84.

4. B. Kolander, A. de Bache and W. Hater, PowerPlant Chem., 2013, 15, no. 2, 137.

5. W. Hater, A. de Bache and T. Petrick, PowerPlant Chem., 2014, 16, no. 5, 284.

6. M. Duprat, M. C. Lafont, F. Moran and F. Dabosi, Electrochim. Acta, 1985, 30, 353.

7. N. Ochoa, F. Moran and N. Pbre, J. Appl. Electrochem., 2004, 34, 487.

8. N. Ochoa, F. Moran, N. Pbre and B. Tribollet, Corros. Sci., 2005, 47, 593.

9. D. Frahne and T. Blum, PowerPlant Chem., 2006, 8, no. 1, 21.

10. C. Fort, G. Stoianovici, G. Chaussec, A. de Bache, C. zum Kolk and W. Hater, Study

of efficiency and stability of film forming amines (FFA) for the corrosion protection of

the carbon steel in water circuits, EUROCORR 2008, Edinburgh, Paper no. 1404.

11. H. Wang, Electrochemical investigation of green film-forming corrosion inhibitors,

Master Thesis, Division of Surface and Corrosion Science School of Chemical Science

and Engineering KTH - Royal Institute of Technology Stockholm, Sweden 2011.

12. L. E. Tsygankova, V. I. Vigdorovich, N. V. Shel and E. V. Dubinskaya, Int. J. Corros.

Scale Inhib., 2013, 2, 4, 304.

13. A. Frignani, C. Monticelli, F. Zucchi and G. Trabanelli, Int. J. Corros. Scale Inhib.,

2014, 3, no. 2, 105.

14. S. Koehler and G. Reinhard, Int. J. Corros. Scale Inhib., 2014, 3, no. 4, 286.

15. C. Gabrielli, Identification of Electrochemical Processes by Frequency Response

Analysis; Technical Report 004/83 of Solartron Analytical, Paris, 1980, 93.

16. G. J. Brug, A. L. G. Van Den Eeden, M. Sluyters-Rehbach and J. H. Sluyters,

J. Electroanal. Chem., 1984, 176, 275.

17. G. Bohnsack, VGB KraftwerksTechnik, 1997, 77, no. 10, 841.

You might also like

- PDFDocument18 pagesPDFmini2018No ratings yet

- Study Material For The Certificate of Fitness Examination G-91 Supervision of Natural Gas Co-Generation SystemDocument58 pagesStudy Material For The Certificate of Fitness Examination G-91 Supervision of Natural Gas Co-Generation Systemmini2018100% (1)

- Iron TransformationDocument13 pagesIron Transformationmini2018No ratings yet

- Tao Et Al-2016-Journal of Geophysical Research AtmospheresDocument12 pagesTao Et Al-2016-Journal of Geophysical Research Atmospheresmini2018No ratings yet

- Optimization of Maputo Power Plant: Armando AbacarDocument43 pagesOptimization of Maputo Power Plant: Armando Abacarmini2018No ratings yet

- Calbiochem BuffersDocument38 pagesCalbiochem BuffersLorraine MalaspinaNo ratings yet

- Fulltext01 PDFDocument47 pagesFulltext01 PDFphotongan mhanjangNo ratings yet

- 1981096Document12 pages1981096mini2018No ratings yet

- Strategic Program - Sensors and Operations Product Id - 1023485 Date Published - May 10, 2013 Page 3 - UnlockedDocument5 pagesStrategic Program - Sensors and Operations Product Id - 1023485 Date Published - May 10, 2013 Page 3 - Unlockedmini2018No ratings yet

- The Study of Pipeline Corrosion Monitoring Using Fiber Optic Sensing Technique Liang Ren - UnlockedDocument7 pagesThe Study of Pipeline Corrosion Monitoring Using Fiber Optic Sensing Technique Liang Ren - Unlockedmini2018No ratings yet

- TheeffectofAnodamineonthecorrosionbehaviorof1018mildsteel-2 Unlocked PDFDocument8 pagesTheeffectofAnodamineonthecorrosionbehaviorof1018mildsteel-2 Unlocked PDFmini2018No ratings yet

- UnlockedDocument21 pagesUnlockedmini2018No ratings yet

- E PFbSteamateNASeries enDocument2 pagesE PFbSteamateNASeries enmini2018No ratings yet

- Evaluation Methods for Corrosion Damage of Components in Cooling Systems of Nuclear Power Plants by Coupling Analysis of Corrosion and Flow Dynamics (v) Flow-Accelerated Corrosion Under Single- And Two-phase Flow Conditions_unlockedDocument15 pagesEvaluation Methods for Corrosion Damage of Components in Cooling Systems of Nuclear Power Plants by Coupling Analysis of Corrosion and Flow Dynamics (v) Flow-Accelerated Corrosion Under Single- And Two-phase Flow Conditions_unlockedmini2018No ratings yet

- Solubility of Inorganic Compounds PDFDocument6 pagesSolubility of Inorganic Compounds PDFPablo Ignacio Santiagos HeviaNo ratings yet

- Chemistry of Salts in Aqueous Solutions: Applications, Experiments, and TheoryDocument16 pagesChemistry of Salts in Aqueous Solutions: Applications, Experiments, and Theorymini2018No ratings yet

- Electrical Conductivity of Aqueous SolutionsDocument1 pageElectrical Conductivity of Aqueous SolutionslaughingalirezaNo ratings yet

- Minutes 2015Document100 pagesMinutes 2015mini2018No ratings yet

- Evaluation of Solution and Rheological Properties For Hydro 2017 Egyptian JoDocument7 pagesEvaluation of Solution and Rheological Properties For Hydro 2017 Egyptian Jomini2018No ratings yet

- Atomic Properties of The Elements TableDocument1 pageAtomic Properties of The Elements TableMaahiNo ratings yet

- Bankiewicz DorotaDocument73 pagesBankiewicz Dorotamini2018No ratings yet

- 7.5 Reactions of Carboxylic Acids and AminesDocument3 pages7.5 Reactions of Carboxylic Acids and Aminesmini2018No ratings yet

- NPCDocument29 pagesNPCMarcTimNo ratings yet

- Investigations On The Influence of Phosphonates in Dispersing Iron Oxide (Rust) by Polymeric Additives For Industrial Water ApplicationsDocument12 pagesInvestigations On The Influence of Phosphonates in Dispersing Iron Oxide (Rust) by Polymeric Additives For Industrial Water Applicationsmini2018No ratings yet

- Oxygen - Problems and Solutions in ElectrochemistryDocument85 pagesOxygen - Problems and Solutions in Electrochemistrymini2018No ratings yet

- Effect of Oxygenated Treatment To Oxide Growth and Exfoliation of Superheater TubesDocument3 pagesEffect of Oxygenated Treatment To Oxide Growth and Exfoliation of Superheater Tubesmini2018No ratings yet

- Superheater Tube From Boiler - Metallurgical Technologies, Inc.Document9 pagesSuperheater Tube From Boiler - Metallurgical Technologies, Inc.mini2018No ratings yet

- Wyoming Department of Environmental Quality Water Quality Division WYPDES (Wyoming Pollutant Discharge Elimination System) PrograDocument32 pagesWyoming Department of Environmental Quality Water Quality Division WYPDES (Wyoming Pollutant Discharge Elimination System) Programini2018No ratings yet

- Oiler Chemical Cleaning TechniquesDocument135 pagesOiler Chemical Cleaning Techniquesmini2018No ratings yet

- Predicting and Preventing Flow Accelerated Corrosion in Nuclear Power PlantDocument18 pagesPredicting and Preventing Flow Accelerated Corrosion in Nuclear Power Plantmini2018No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- NRF Nano EthicsDocument18 pagesNRF Nano Ethicsfelipe de jesus juarez torresNo ratings yet

- Gender, Slum Poverty and Climate Change in Flooded River Lines in Metro ManilaDocument53 pagesGender, Slum Poverty and Climate Change in Flooded River Lines in Metro ManilaADBGADNo ratings yet

- Penilaian Akhir TahunDocument4 pagesPenilaian Akhir TahunRestu Suci UtamiNo ratings yet

- Registration Statement (For Single Proprietor)Document2 pagesRegistration Statement (For Single Proprietor)Sherwin SalanayNo ratings yet

- Turning Risk Into ResultsDocument14 pagesTurning Risk Into Resultsririschristin_171952No ratings yet

- EXP 2 - Plug Flow Tubular ReactorDocument18 pagesEXP 2 - Plug Flow Tubular ReactorOng Jia YeeNo ratings yet

- DPA Fact Sheet Women Prison and Drug War Jan2015 PDFDocument2 pagesDPA Fact Sheet Women Prison and Drug War Jan2015 PDFwebmaster@drugpolicy.orgNo ratings yet

- S ELITE Nina Authors Certain Ivey This Reproduce Western Material Management Gupta Names Do OntarioDocument15 pagesS ELITE Nina Authors Certain Ivey This Reproduce Western Material Management Gupta Names Do Ontariocarlos menaNo ratings yet

- Paper Specific Instructions:: GATE Chemical Engineering MSQ Paper - 1Document11 pagesPaper Specific Instructions:: GATE Chemical Engineering MSQ Paper - 1Mayank ShelarNo ratings yet

- Senior Project RiceberryDocument76 pagesSenior Project RiceberryIttisak PrommaNo ratings yet

- DEIR Appendix LDocument224 pagesDEIR Appendix LL. A. PatersonNo ratings yet

- Village Survey Form For Project Gaon-Setu (Village Questionnaire)Document4 pagesVillage Survey Form For Project Gaon-Setu (Village Questionnaire)Yash Kotadiya100% (2)

- Inducement of Rapid Analysis For Determination of Reactive Silica and Available Alumina in BauxiteDocument11 pagesInducement of Rapid Analysis For Determination of Reactive Silica and Available Alumina in BauxiteJAFAR MUHAMMADNo ratings yet

- A Project Report On A Study On Amul Taste of India: Vikash Degree College Sambalpur University, OdishaDocument32 pagesA Project Report On A Study On Amul Taste of India: Vikash Degree College Sambalpur University, OdishaSonu PradhanNo ratings yet

- Drug-Nutrient Interaction in Prescriptions ForDocument7 pagesDrug-Nutrient Interaction in Prescriptions ForRafika DitaNo ratings yet

- HVAC (Heating, Ventilation and Air Conditioning) : SRS PrecautionsDocument1 pageHVAC (Heating, Ventilation and Air Conditioning) : SRS PrecautionssoftallNo ratings yet

- Aldehydes, Ketones, Carboxylic Acids, and EstersDocument11 pagesAldehydes, Ketones, Carboxylic Acids, and EstersNATURE COMPUTERNo ratings yet

- Comparison and Contrast Essay FormatDocument5 pagesComparison and Contrast Essay Formattxmvblaeg100% (2)

- Psychoanalysis AND History: Freud: Dreaming, Creativity and TherapyDocument2 pagesPsychoanalysis AND History: Freud: Dreaming, Creativity and TherapyJuan David Millán MendozaNo ratings yet

- Mid Day Meal Scheme-Case Study of BiharDocument4 pagesMid Day Meal Scheme-Case Study of BiharKaran singh RautelaNo ratings yet

- Covid-19 Mitigation PlanDocument8 pagesCovid-19 Mitigation PlanEkum EdunghuNo ratings yet

- EV Hammer Impact Crusher - ENDocument8 pagesEV Hammer Impact Crusher - ENKeshav NandaNo ratings yet

- Plica PDFDocument7 pagesPlica PDFIVAN VERGARANo ratings yet

- Marine Trans Owners Manual 1016313 RevH 0116 CDDocument200 pagesMarine Trans Owners Manual 1016313 RevH 0116 CDMarco Aurelio BarbosaNo ratings yet

- Outlook 2Document188 pagesOutlook 2Mafer Garces NeuhausNo ratings yet

- Reaction Paper-RprDocument6 pagesReaction Paper-Rprapi-543457981No ratings yet

- 6Document2 pages6Min Hsuan HsianNo ratings yet

- Scope: Procter and GambleDocument30 pagesScope: Procter and GambleIrshad AhamedNo ratings yet

- High Speed DoorsDocument64 pagesHigh Speed DoorsVadimMedooffNo ratings yet

- HUM110 Gilgamesh EssayDocument4 pagesHUM110 Gilgamesh EssaynsmeganNo ratings yet