Professional Documents

Culture Documents

CAST386820 (168 3mmX11mmX65)

Uploaded by

suparna0 ratings0% found this document useful (0 votes)

10 views5 pagesthanks

Original Title

CAST386820(168.3mmX11mmX65)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentthanks

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views5 pagesCAST386820 (168 3mmX11mmX65)

Uploaded by

suparnathanks

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 5

i

|

H

i

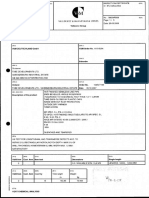

[VaM DEUTSCHLAND GmbH

Work sate

[Schiteenstasce 124

YALLOUREE 8 MasnesMann vUBIS

Vallouree Group

INSPECTION CERTIFICATE a2

3.1 EN to204-2004

No. 1002eNN07 ‘a

Page:1/ 5

Date: 01.08.2007

[Gerticat n° 1802aM? , 24.07.2007 is replaced by tvs updated version n ¥S022MuO7

oer 089

]Vatl DEUTSCHLAND GmblH ]VaM-Ordor-No. 81514577

002

[Suborder

aca

[Customer

}TUBE DEVELOPMENTS LTO,

JQUEENZIEBURN INDUSTRIAL ESTATE

cor nee

lOrdoror Jorder-lo. —taz4sier46

[TUBE DEVELOPMENTS LTD. / QUEENZIESURN INDUSTRIALESTATE [Date _ 91 08.2005

Description of

HOT FINISHED SEAMLESS LINE PIPE

x60

JENDS BEVELLED, ANGLE 20 DEGREES

TOLERANCE +5,-0 DEGREES), ROOT FACE 1.6 +-0.8 MN

[TUBE ENDS CLOSED BY PLASTIC PLUGS

INSIDE WTHOUT RUST PROTECTION

JOUTSIDE DRY VARNISH

BUNDLES OF MAX. 4000 KG

JAPI SPEC. 6 L, PSL2. 03,2004

NACE MR 0175180 15186-2:2000 / EN ISO 15156-2:2008,

|SPECIFICATION

x65

JQUENCHED AND TEMPERED

IN ACC. TO SPEC. "HOT FINISHED MLS TUBLLARS TO.

API SL X60IX85, PSL 2, NACE MR O17"

far Jao [ise on fare

aM tem [Cust tom {Item text Dimensions Single length

4 [om Tea SAI x WTH, 11 MM [LENGTHS 10000-12000 M1

vam tem [Cust tem | Quanity Total tength

4 © 526,98 22.807 i

em See

HEAT CHEMICAL ANALYSIS

VAM DEUTSCHLAND GmbH

Werk Malnoim

Schitzenstasce 124

D-45476 Mulneim an der Fuhr

HEAT CHEMICAL ANALYSIS.

an

¢'

VALLOUREC & MANNESMANN TUBES

Vallouree Group

INSPECTION CERTIFICATE a

3.1 EN 10204:2008

No, 190228U07 708

Page: 2 6

Date: 01.08.2007

fit foes fc J fm | re fs fw | aw | ow fw |v

Sa EA

om 210 su | 002s | osteo soon

Teen [orm beh | ono [oa [ie [oom Lomo [orm [ome [om [om [ms

on 1 [wo | 2 | coos | erve

ead arse || yf

mm _| 200 Ls [oe

wees [oes [omer | se Don

PRODUCT CHEMICAL ANALYSIS

feaoe ‘CAE = C + MING + (CREMOAVIS + (NFOUVIS

fEFon EFaVeTIONB

eas tal kilos

be

worn gee

Hat Test Pie si | ttn P s a | o wo te v

% % % % % % % % %

max. 140 | 0025 | 00150 1.000

936820 cost [ oat | 135 | oor | coos | ora | ooo | ore | coe [ 000s

386820 oo | ozis | 193 | 0013 | coves | oro | coe | oro | cow | ooo

Hoot Tost Pisce ri | spice | 8 | coos | eFo2

% % % % %

max 0.040 aa | ons.

386820 10.003 | ooze | oon | a7 | 00s

356820 003 | coz | ooo | a5 | 00s

feaos, (CAE = 0 + MNIG + (CREMOAViS + (NACUVIS

fEFo2 EF=VT/sNB

TENSILE TEST RESULTS

[Vaid DEUTSCHLAND GmbH ‘100 INSPECTION CERTIFICATE, 8

Weck Maho 3.1 EN 10208-2008

[Schutzansiasse 124 I

D-45476 Mathoim an det Fuh M

\ No. ro02enuo7 ma

VALLOURFC & MANNESMANK TUBES — [Pade 9’ §

Date: 01.08.2007

Valine rep

oloue Test nEsuLTS

thon veda

fe toe |i

Pe

ec gina

HARDNESS TEST RESULTS:

eaten ODE CRCERINSWALL

Heat [tentrace | vane | vave

ve [ we

ie seas | eos

waa [ae | wo [wo I

OTHER TESTS ON PIPE

i

3

i

Va DEUTSCHLAND GmbH a0 INSPECTION CERTIFICATE va

Wier Mei 3.1 EN 10208:2000

Schitesnstasse 128 ‘

1D-45476 Malheim an der Pur ‘ML

x No. = 19022Mu07 oe

VALLOURFC & MANNESMANN TUBES — |Page:4/ S

ate: 01.08.2007

Vallouree Group,

(05

(OTHER TESTS ON PIPE

Test Conditions rack ale esut

HEAT TREATMENT [22a 940 DEGREES O WATER

HEAT TREATMENT [20 MIN 630 DEGREES AIR

HEAT TREATMENT WATER QUENCHED AND

[TEMPERED

HYDROSTATIO TEST [207_BAR (1BAR=100KPA) EACH PIPE! TUBE NO LEAKAGE:

‘APPEARANCE AND DIMENSIONS [EACH PIPE! TUBE [SATISFACTORY

(Do)

MATERIAL ENTIFICATION | SPECTROGRAPHIC ANALYSIS | EACH PIPE TUBE. [SATISFACTORY

Tes

PIPE PRODUCTIONMETHOD | SEAMLESS, HOTROLLED

BECAUSE THE HARDNESS IS

TOO LOW THE HARONESS TEST

AGC, TO ROCKWELL CIS NOT

POSSIBLE, SO THE TEST

METHOD WILL BE ROCKWELL B

ULTRASONIC TEST ACO. TO ASTM E 213 FOR LONGITUDINAL

DEFECTS, INSIDE AND OUTSIDE, NOTCH DEPTH Ste: SATISFACTORY

US-TEST FOR LAMINATIONS ACC, TO BS 5996 CL4 : SATISFACTORY

UNINSPECTED ENDS CUT OFF

aos, 208)

MARKING, IDENTIFICATION

(COLOUR MARKING:

vane

APLMONOGRAM

st0302.4 pe.

DATE {

168,3X 11 HEAT.NO,

x62 PSL2$ HO

LENGTH

TUBE-NO. WA

STAMPING:

HEAT.NO.

Enclosures

TALLY LIST SEE APPENDIX

[The supped products are in compliance with the requirements ofthe order

[VaM OEUTSCHLAND GmbH

Werk Mules

Schitzonsbasse 128

D-48476 Mulheim aa der ube

You might also like

- Ingles NarrativaDocument22 pagesIngles NarrativaPercy DpNo ratings yet

- 13 - PMP PreparePM - Mock1Document18 pages13 - PMP PreparePM - Mock1suparnaNo ratings yet

- Kel. Bimb '15 (JABAR) PDFDocument51 pagesKel. Bimb '15 (JABAR) PDFsuparnaNo ratings yet

- Example of An Expository Paragraph - Definitions and Examples of Different KiDocument4 pagesExample of An Expository Paragraph - Definitions and Examples of Different KisuparnaNo ratings yet

- HRSGDocument8 pagesHRSGAsad Iqbal SiddiquiNo ratings yet

- QualityPediaDocument2 pagesQualityPediasuparnaNo ratings yet

- 01 Guidance On Iso 9001 2008 Sub-Clause 1.2 ApplicationDocument9 pages01 Guidance On Iso 9001 2008 Sub-Clause 1.2 ApplicationSathishkumar SrinivasanNo ratings yet

- Auditing The Auditors PDFDocument2 pagesAuditing The Auditors PDFsuparnaNo ratings yet

- 01 Guidance On Iso 9001 2008 Sub-Clause 1.2 ApplicationDocument9 pages01 Guidance On Iso 9001 2008 Sub-Clause 1.2 ApplicationSathishkumar SrinivasanNo ratings yet

- MLA-SPM-206-C 3D Execution StrategyDocument8 pagesMLA-SPM-206-C 3D Execution StrategysuparnaNo ratings yet

- 1 Opportunities LogDocument1 page1 Opportunities LogsuparnaNo ratings yet

- SGP90103Document28 pagesSGP90103suparnaNo ratings yet

- 1 Opportunities Log InstructionsDocument1 page1 Opportunities Log InstructionssuparnaNo ratings yet

- 01 Guidance On Iso 9001 2008 Sub-Clause 1.2 ApplicationDocument9 pages01 Guidance On Iso 9001 2008 Sub-Clause 1.2 ApplicationSathishkumar SrinivasanNo ratings yet

- PMC-PR-101 REV.E Drawing & Document Numbering SystemDocument15 pagesPMC-PR-101 REV.E Drawing & Document Numbering SystemsuparnaNo ratings yet

- PMC-PR-001-C Drawing and Document Numbering SystemDocument13 pagesPMC-PR-001-C Drawing and Document Numbering SystemsuparnaNo ratings yet

- CAST386820 (168 3mmX11mmX65)Document5 pagesCAST386820 (168 3mmX11mmX65)suparnaNo ratings yet

- Singapore ACPE Assessment Statement - (ACPECC 1)Document23 pagesSingapore ACPE Assessment Statement - (ACPECC 1)AAAANo ratings yet

- CAST973872 (323 9mmX12 7mmX65)Document3 pagesCAST973872 (323 9mmX12 7mmX65)suparnaNo ratings yet

- CAST270406 (323 9mmX15 9mmX65)Document5 pagesCAST270406 (323 9mmX15 9mmX65)suparnaNo ratings yet

- Treasures of The McDonald Collection - Special Collections & Archives Research CenterDocument2 pagesTreasures of The McDonald Collection - Special Collections & Archives Research CentersuparnaNo ratings yet

- Key Smadδv Pro 9Document3 pagesKey Smadδv Pro 9suparnaNo ratings yet

- CAST221447 (406 4mmX21 4mmX65)Document5 pagesCAST221447 (406 4mmX21 4mmX65)suparnaNo ratings yet

- CAST81887 (168 3mmX7 1mmX65)Document3 pagesCAST81887 (168 3mmX7 1mmX65)suparnaNo ratings yet

- Bechtel SaisfactionDocument2 pagesBechtel SaisfactionsuparnaNo ratings yet

- Winning Cover Letters Showcase Your StrengthsDocument11 pagesWinning Cover Letters Showcase Your StrengthssuparnaNo ratings yet

- Comparators V1 27-07-01Document1 pageComparators V1 27-07-01suparnaNo ratings yet

- Surface PrepareDocument7 pagesSurface PreparesuparnaNo ratings yet

- Metal CoatDocument4 pagesMetal CoatsuparnaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)