Professional Documents

Culture Documents

Nov 162845

Uploaded by

hassanaagibCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nov 162845

Uploaded by

hassanaagibCopyright:

Available Formats

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2015): 6.391

Design of Five Floors Elevator with SCADA

System Based on S7200 PLC

Abdelkarim Ahmed Eltahir Ali1 , Zhang Jiang Min2

1,2

Tianjin University of Technology and Education (TUTE), School of Electronics Engineering Tianjin, China

Professor, Tianjin University of Technology and Education (TUTE), School of Electronics Engineering Tianjin, China

Abstract: This paper explains about design of five Floors Elevator with SCADA System Based on S7200 PLC .The elevator mentioned

here is fully automated using PLC. The developed ladder logic has been implemented by Ladder diagram programming the required

inputs and outputs of the elevator for moving forward and reverse, door opening and closing and motor operation have been included in

the logic and interpreted in addition to that implementation of SCADA system Reduce waste time and improve the efficiency.

Keywords: PLC based elevator, Elevator Design, Constant speed Elevator, Ladder logic for Elevator using PLC

1. Introduction

Elevators are the important medium of vertical

transportation in both residential environment and the

industrial environment. Due to the cause of rapid population

growth at the cities and multi-stored buildings, the need of

elevators is being increased. With the rising life standards

and attention to human and with the technological

developments, elevator systems are getting better, more fast,

stronger and better quality elevators are produced.

Previously, most systems were focused on the mounting of

elevators, especially after the 1980s the need for elevator

maintenance and fault staff have been started to increase.

For instance, automatic doors have being used instead of

splash doors, microprocessor electronic cards have being

used instead of cards with relay, double-speed or speedcontrolled elevators have being used instead of one-speed

elevators. Such developments provide to improve the quality

in elevator systems, develop and diverse the used setting and

maintenance or repair tools and instruments and therefore

facilitation of the work compared to previous years and

increase the reliability of elevator.

Some of the drawbacks of the traditional system are the

control system have high failure rate that were mainly due to

numerous contacts, complexity of wiring circuit. In addition,

electrical contacts were easy to burn out, which could result

in poor contact.

Electrical controller and hardware wiring based on common

method were difficult to achieve a more complex control

function. Electromagnetic actuator and contact action were

so slow, mechanical and electromagnetic have large inertia.

Therefore; the control precision of system was difficult.

the cabinet is called to any floors the motor either runs in

forward or reverse direction and then stop at the floor

indicates. The indication of the floor position of the cabinet

is given by the limit switches which act as a sensor and gives

the signal indicating that the cabinet has reached the

required position[1].

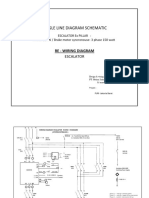

3. Block Diagram

Figure1: Elevator block diagram

Fig.1 shows the overall system block diagram of this

proposed system. The power supply is applied to both motor

drive and the plc controller. Motor of the elevator is driven

by the motor drive unit. The elevator cabin in turn driven by

the motor unit. The elevator cabins upside and downside

movement is controlled the switch operated motor. Theses

witches are controlled by the PLC controller.

4. Elevator Control System Components

2. Application of PLC for Control System

4.1 Stepper Motor

The working principle of PLC for elevator control system

functions in the similar manner as that the elevator we use in

our daily life. The motion of the elevator that people

normally use is controlled by three phases AC motors. It

consists of a pulley which helps in upward and downward

movement of the lift. The position feedback is provided by

the limit switches. The principle of this set up is; whenever

Stepper Motor is an electromagnetic device that converts

digital pulses into mechanical shaft rotation. The advantages

of step motors are low cost, high reliability, high torque at

low speeds and a simple, rugged construction that operates

in almost any environment. The disadvantages of a stepper

motor is the resonance effect often exhibited at low speeds

and decreasing torque with increasing speed. There are

Paper ID: NOV162845

Volume 5 Issue 4, April 2016

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

1309

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2015): 6.391

basically three types of stepping motors; variable reluctance,

permanent magnet and hybrid. They differ in terms of

construction based on the use of permanent magnets and

iron rotors with laminated steel stators. The motor used for

the development of the set-up is permanent magnet type.

The permanent magnet motor, also referred to as a "cans

tack" motor, as the name implies, a permanent magnet rotor.

It is a relatively low speed, low torque device with large step

angles of either 45 or 90 degrees [4].

4.2 Stepper drives M542

M542 is a low cost high performance micro stepping driver

based on most advanced technology in the world today. It is

suitable for driving any 2-phase and 4-phase hybrid step

motors. By using advanced bipolar constant-current

chopping technique, it can output more speed and power

from the same motor, compared with traditional

technologies such as L/R drivers. Its 3-state current control

technology allows coil currents to be well controlled, with

relatively small current ripple and therefore less motor

heating.[10]

4.3 Inductive Proximity Sensor

Inductive proximity switches are used to detect the presence

of the elevator without actually contacting. Their high-speed

switching and small size make them indispensable in

automation applications. Inductive proximity switches

consist of a coil driven by an oscillator. The oscillator

creates an electromagnetic field which appears at the active

face of the switch. If a metal target enters this area, the

electromagnetic field is reduced and the switch turns on or

off.

4.4 Buttons

Hall buttons are on a panel on the outside of the elevator

shafts and are used by potential passengers to call an

elevator cab to the floor that the pressed summon button is

located on. Floor request buttons are particular elevator

Paper ID: NOV162845

controller will be controlling elevator cabs that are in a

building with 5 floors. Consequently, each cab has 5 floors

request buttons labeled 1 through 5 that passengers can use

to direct the elevator cabs to the floor that they would like to

go to. There is button on the interior panel of each cab. A

passenger can press this button to open the elevator doors or

keep pressing it to keep them open, but only when the

elevator cab is stopped at a floor [3].

5. Problems to be solved through ladder

diagram

Ladder diagram is used to realize the many functionalities of

the elevator control system. Some of the functionalities are,

program should be written to make the display on which

indicates the upward or downward movement, the door of

the elevator should be programmed to open and close

automatically. When the elevator has no request it remains at

its current floor with its door closed floor lamp should glow

within the lift to indicate the current position. As shown in

fig.2 The main application of PLC is in the signal control

system, all the control signals are realized using the PLC, the

input signals are operational modes, safety control signals,

car-calls, hall-calls, floor sensors, leveling sensors, door

opening and close signals.

All the functions of the elevator control systems are realized

using the PLC programs, the functions includes registration,

displaying the messages about the floors, monitoring the

safety system, monitoring the door opening and closing,

prioritizing the hall call, and car calls. Fig.1 indicates the

block diagram of the signal control system. The inputs are

given to the PLC unit where the corresponding outputs like

floor lamps, hall call lamps, direction lamps, door open and

close lamps are introduced.

As an initial move the ladder logic has to be developed for

receiving the input signal from the call buttons [5]

Volume 5 Issue 4, April 2016

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

1310

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2015): 6.391

Figure 2: Elevator flow chart

Elevator System is the system responsible for coordinating

all aspects of elevator service such as travel, speed, and

accelerating, decelerating, door opening speed and delay,

leveling and hall lantern signals. It accepts inputs (button

signals and sensors etc.) and produces outputs (elevator cars

moving, doors opening, etc.).Fig.3 shows the elevator

control system and corresponding connection to the PLC.

Table 1 show elevator ladder diagram inputs and the same is

used with the program to get the corresponding output based

on this input. Once the PLC receives the input signal the

corresponding bit will be latched to activate the desired

outputs as shows in Table 2.

Table 1: Elevator ladder diagram inputs

Table 2: Elevator ladder diagram outputs

Figure 3: Elevator PLC Connections

6. The Aim of an Elevator Control System

The main aims of the elevator control system are:

To bring the lift car to the correct floor.

To minimize travel time.

To maximize passenger comfort by providing a smooth

ride.

To accelerate, decelerate and travel within safe speed

limits.

Paper ID: NOV162845

Volume 5 Issue 4, April 2016

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

1311

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2015): 6.391

7. Hall Call Request

8. Up and down control signal identification

There are two kinds of calls in the elevator they are hall call

and car call. When the passenger presses the button in the

control panel which is outside the elevator cabin that is the

hall call. When the passenger presses the button on the

control panel which is inside the elevator car that is the car

call. As shown below fig.4 .This ladder program branch

control the User from 1 to 4 floors, when the user press the

button sends out the down signal to inform the PLC to

control the elevator to run to the floor where the passenger at

Fig.6 shows ladder diagram indicates the up moving or

down of the elevator. The combination of hall call and car

calls are used to decide the elevator movement in upward or

downward direction. If the current position of the elevator is

less than the first element of the queue then the elevator will

move in the upward direction.

Figure 6: Elevator upward downward identification signal

9. Seven Segment Display Logic Design

Figure 4: Hall call signal upward ladder

The below ladder program branch control the passenger

from 2 to 5 floors, when the passenger press the button sends

out the up request signal to inform the PLC to take the

elevator for the floor where the passenger at .

The car position is displayed using seven segments display

the interior of each elevator cab has a display that indicates

to its passengers which floor the elevator cab is currently on.

This system also has floor number display on every floor

outside of the elevator doors. The controller interacts with

this display by sending a signal that tells it which floor

number to display as shown in Fig.7.

Figure 7:common cathode 7-segment display

10. Seven Segment Display Logic Equation

Figure 5: Hall call signal downward ladder

Paper ID: NOV162845

Volume 5 Issue 4, April 2016

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

1312

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2015): 6.391

Table 3: Seven segment display outputs

Figure 8: seven segment display ladder diagram

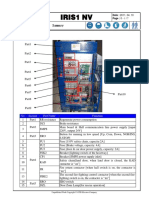

11. Supervisory control and data acquisition

systems (SCADA)

In fig.6. Shows the SCADA system of the elevator it is the

backbone of control and monitoring the systems in addition

to that SCADA allows operators to.

Monitor the elevator status.

Interact with and control the elevator which is connected

through HMI (human-machine interface) software which

is developed for this purpose.

Access history Record for maintenance and faults

checking.

This SCADA system displays the elevator in order to help

operators and other workers to reduce waste time and

improve the efficiency.

Paper ID: NOV162845

Figure 9: Elvator SCADA system

12. Results and Discussion

The interfacing between the S7200 PLC and the elevator

done successfully in addition to that the SCADA system

worked as per designed properly. When you push the button

for the first floor is pressed then the motor runs till the

cabinet reaches its required position and activates the limit

switch which enables the motor to stop and if the cabinet is

already in the required position then the motor wont get

activated again when you push the button for the second

floor is pressed then the motor runs either in forward or

reversed condition according to its position till the cabinet

reaches its required position and activates the limit switch

which enables the motor to stop and if the cabinet is already

in the required position then the motor will not get activated

and subsequently it worked successfully for other floors too.

Volume 5 Issue 4, April 2016

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

1313

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2015): 6.391

At the end using SCADA we can identify.

Elevator faults easily.

Control the elevator.

Reduce waste time and improve the efficiency [7].

[4] users Manual For M542-FL Low Cost Microstepping

Driver Version 1.0 2000 All Rights Reserved

[5] Xialoling Yang, Qunxiong Zhu, Hong Xu,, Design and

practice of an elevator control system based on PLC, In

proceedings of IEEE workshop on Power Electronics and

Intelligent Transportation System, pp.94 - 99 2008

[6] Xiaojuan Liu, Development of Elevator Monitor System

Based on the Fieldbus, February 2008

[7] KingView 6.52 Product Introduction

[8] Jie Zhang,Application of PLC in elevator control

system, Journal of Liaoning Normal University(Natural

Science Edition), 2009.

[9] http://researchtrend.net/ijet61/7%20NCRIET.pdf.[10]Da

e-Woong Chung, Hyung-Min Ryu, Young-Min Lee, LoWon Kang, Seung-Ki Sul, Seok-Joo Kang, Jun-Ho Song,

Joong-Seok Yoon, Kil-Haeng Lee and Jong-Ho Suh

(2001) Drive systems for high-speed gearless elevators,

IEEE Industry Applications Magazine, vol. 7, pp 52-56.

Figure 10: Passenger ordering on 5th floor

Figure 11: Elevator at 5th floor

13. Conclusion

This paper describes implementation for five floors elevator

with SCADA system using S7200 PLC also used sensors,

buttons, actuators connection and their configuration at

different floors.

The developed ladder logic has been implemented by Ladder

diagram programming the required inputs and outputs of

elevator for moving forward and reverse, door opening and

closing and motor operation have been included in the logic

and interpreted.

References

[1] Jack H., Programmable Logic Controller

[2] Yang X., Zhu Q., 1, Xu H., Design and Practice of an

Elevator Control System Based on PLC

[3] http://www.electrical-knowhow.com/2012/04/elevatorcontrol-system.html

Paper ID: NOV162845

Volume 5 Issue 4, April 2016

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

1314

You might also like

- Control of A Four-Level Elevator System Using A Programmable Logic Controller Experiment No. 4Document16 pagesControl of A Four-Level Elevator System Using A Programmable Logic Controller Experiment No. 4Varun Hknz100% (1)

- Four Elevator COntrollerDocument26 pagesFour Elevator COntrollerMehul Garg100% (1)

- PLC Based Elevator Control System-1Document26 pagesPLC Based Elevator Control System-1Belete GetachewNo ratings yet

- PLCDocument21 pagesPLCThiagoLiraNo ratings yet

- 229-Feedback 34 150-Feedback 34 150 ElevatorDocument2 pages229-Feedback 34 150-Feedback 34 150 Elevatorrajabcomp2No ratings yet

- Elevator Block DiagramDocument3 pagesElevator Block Diagramangelie220% (1)

- Elevator Control Circuit DiagramDocument7 pagesElevator Control Circuit DiagramNanotech NilsiNo ratings yet

- B00VOG9GSGDocument58 pagesB00VOG9GSGklm0% (1)

- PLC Based Elevator (Group-1) n2Document25 pagesPLC Based Elevator (Group-1) n2Juliano RicardoNo ratings yet

- Basic Module MasterKDocument230 pagesBasic Module MasterKjalves_712355100% (1)

- Mitsubishi V3F Advance PDFDocument4 pagesMitsubishi V3F Advance PDFFERNSNo ratings yet

- CP1 eDocument326 pagesCP1 eFelipe Leiro AbalNo ratings yet

- Vacon NXL Lift ALFIFF28 Application Manual UD00973Document44 pagesVacon NXL Lift ALFIFF28 Application Manual UD00973TanuTiganuNo ratings yet

- Induction Motor DrivesDocument70 pagesInduction Motor DrivesAshwin Gopinath80% (5)

- FRENIC LiftDocument8 pagesFRENIC LiftSamih AlraghbanNo ratings yet

- Modified Graduation ProjectDocument37 pagesModified Graduation ProjectSagar G ReddyNo ratings yet

- PLC Technology TrainerDocument15 pagesPLC Technology Trainerladabd2No ratings yet

- Lab 5 Transistor Characteristic 1Document14 pagesLab 5 Transistor Characteristic 1Ratnadewi SerbiniNo ratings yet

- 1S9H52 27-4-09 AVRy ENDocument190 pages1S9H52 27-4-09 AVRy ENMoran MartinesNo ratings yet

- Car Parking SP SystemDocument4 pagesCar Parking SP System61engineer61No ratings yet

- 6 Timer 2Document86 pages6 Timer 2Silver LeoNo ratings yet

- Lift 1Document27 pagesLift 1shelmi100% (1)

- PLC ElevatorDocument8 pagesPLC ElevatorkindaNo ratings yet

- Prog 4534543Document559 pagesProg 4534543Vasile TroianNo ratings yet

- Tekel Incremental Encoder User ManualDocument8 pagesTekel Incremental Encoder User ManualAyman ElotaifyNo ratings yet

- Lift Inverter Series L A: For Modernization and New InstallationDocument12 pagesLift Inverter Series L A: For Modernization and New InstallationTroubleshootingNo ratings yet

- PLC Based ElevatorDocument10 pagesPLC Based ElevatorShisir KandelNo ratings yet

- Hướng dẫn sử dụng phần mềm PLC Mitsubishi GX DeveloperDocument6 pagesHướng dẫn sử dụng phần mềm PLC Mitsubishi GX DeveloperTan Phat NguyenNo ratings yet

- Elevator Programming CodeDocument178 pagesElevator Programming Code100mphNo ratings yet

- Lifts-Opeartion Maintenance PDFDocument40 pagesLifts-Opeartion Maintenance PDFaung kokoNo ratings yet

- Elevator SystemDocument6 pagesElevator SystemEdna Moreno100% (1)

- Icontrol DC Aug 08 Rel 42-02-7222 B7Document788 pagesIcontrol DC Aug 08 Rel 42-02-7222 B7ElputoAmo XDNo ratings yet

- Otis Fact Sheet Milestones 2011Document6 pagesOtis Fact Sheet Milestones 2011Siti Salwani binti Ab RahimNo ratings yet

- Low Voltage Drive - SJ 700i (415V) (30 KW To 450 KW) CatalogueDocument12 pagesLow Voltage Drive - SJ 700i (415V) (30 KW To 450 KW) Cataloguemani_208ee100% (1)

- AC DrivesDocument120 pagesAC DrivesVenkata GanesanNo ratings yet

- MUSE ED Elevator: Installation ManualDocument25 pagesMUSE ED Elevator: Installation ManualMoises PerelloNo ratings yet

- Light Curtain Guide For ElevatorsDocument10 pagesLight Curtain Guide For ElevatorsFERNSNo ratings yet

- Siemens PLC Programming Example1 PDFDocument12 pagesSiemens PLC Programming Example1 PDFHani ErrachidNo ratings yet

- Manuale IV5 (Inglese)Document223 pagesManuale IV5 (Inglese)bmonaandaNo ratings yet

- 02.mahfuzar Rahman, Savar DOHS, 9stop 8perDocument7 pages02.mahfuzar Rahman, Savar DOHS, 9stop 8perHomeland Energy LtdNo ratings yet

- Eee334 Lab#1 Ltspice and Lab Orientation - Instruments and MeasurementsDocument9 pagesEee334 Lab#1 Ltspice and Lab Orientation - Instruments and Measurementsplaystation0% (1)

- PLC Project ReportDocument18 pagesPLC Project ReportMayowaNo ratings yet

- Tricon 42-02-2T00 F4Document301 pagesTricon 42-02-2T00 F4ElputoAmo XDNo ratings yet

- AdemCo Contact IdDocument6 pagesAdemCo Contact IdRafael RicciNo ratings yet

- Spec. of Escalator Amdt. 5Document38 pagesSpec. of Escalator Amdt. 5Pasam Venkat SridharNo ratings yet

- Lifts and Escalators 3: Third Year B.Arch, Building Services Sulakshana BhanushaliDocument20 pagesLifts and Escalators 3: Third Year B.Arch, Building Services Sulakshana BhanushaliVenkat MuraliNo ratings yet

- Binder Wiring Puri Ex Pillar RewiringDocument10 pagesBinder Wiring Puri Ex Pillar RewiringWiratama MudaNo ratings yet

- Selection of Drives and Control Systems For LiftsDocument4 pagesSelection of Drives and Control Systems For LiftsSaikat ChakrabortyNo ratings yet

- Procionix - El6 Inverter: Programming ManualDocument56 pagesProcionix - El6 Inverter: Programming ManualRuben MondejarNo ratings yet

- Selection Guide: Low Voltage Frequency Inverters by Fuji Electric EuropeDocument28 pagesSelection Guide: Low Voltage Frequency Inverters by Fuji Electric EuropeWatu Gîlang KencanåNo ratings yet

- Hyundai-Cat 4390037 PDFDocument24 pagesHyundai-Cat 4390037 PDFbagus fauziNo ratings yet

- Blank - Gold Maintenance Contract India PDFDocument5 pagesBlank - Gold Maintenance Contract India PDFJaganath PaniNo ratings yet

- Freniclift SeriesDocument107 pagesFreniclift Seriesadzkia StoreNo ratings yet

- S3 Control Unit User GuideDocument80 pagesS3 Control Unit User GuideMartynas KarkauskasNo ratings yet

- Electrically Heated Utility Table With Boiler and Suction UnitDocument1 pageElectrically Heated Utility Table With Boiler and Suction UnitSami Moqbel100% (1)

- 7096Document8 pages7096Ema RahamanNo ratings yet

- Design of Five Floors Elevator With SCADA System Based On S7200 PLCDocument6 pagesDesign of Five Floors Elevator With SCADA System Based On S7200 PLCothmanNo ratings yet

- PLC Controlled Elevator System: Gurmeet Singh, Anshul Agarwal, Member, IEEE, R.K. Jarial, Member, IEEE, Vineeta AgarwalDocument5 pagesPLC Controlled Elevator System: Gurmeet Singh, Anshul Agarwal, Member, IEEE, R.K. Jarial, Member, IEEE, Vineeta AgarwalDatarSinghChauhanNo ratings yet

- 224plc Based Railway Level Crossing Gate Control PDFDocument5 pages224plc Based Railway Level Crossing Gate Control PDFS.m. Salahuddin100% (1)

- Annex C Metering Standards Procedures Opt PDFDocument218 pagesAnnex C Metering Standards Procedures Opt PDFhassanaagibNo ratings yet

- PLC23 001B Introduction S7-200Document18 pagesPLC23 001B Introduction S7-200hassanaagib100% (1)

- Gfs-384 m12 Maxon Rx3iDocument35 pagesGfs-384 m12 Maxon Rx3ihassanaagibNo ratings yet

- Testing and Debugging: Simatic S7Document6 pagesTesting and Debugging: Simatic S7hassanaagibNo ratings yet

- Ba00065sen 0516Document190 pagesBa00065sen 0516hassanaagibNo ratings yet

- INST231 Sec1plcDocument122 pagesINST231 Sec1plchassanaagib100% (1)

- Siemens Install GuideDocument4 pagesSiemens Install GuidehassanaagibNo ratings yet

- PassMC EngDocument3 pagesPassMC EnghassanaagibNo ratings yet

- Cos PreDocument25 pagesCos PrehassanaagibNo ratings yet

- Êóðñ ST 7serv1Document349 pagesÊóðñ ST 7serv1hassanaagibNo ratings yet

- Commissioning and Configuring A High-Availability S7 ConnectionDocument23 pagesCommissioning and Configuring A High-Availability S7 ConnectionhassanaagibNo ratings yet

- Rsview32 PDFDocument2 pagesRsview32 PDFhassanaagibNo ratings yet

- 2d HV Generators Megger Test Procedure 5Document5 pages2d HV Generators Megger Test Procedure 5Mertoiu Gabriel100% (1)

- Fire-Fighting Pump Units: TO UNI EN 12845Document74 pagesFire-Fighting Pump Units: TO UNI EN 12845FILID MADNo ratings yet

- PP520E-IX - OM ManualDocument113 pagesPP520E-IX - OM ManualNoor RahmanNo ratings yet

- Closed Circuit TelevisionDocument5 pagesClosed Circuit TelevisionAlfie LariosaNo ratings yet

- Maintenance of Electromagnetic Contactor On Electric LocomotiveDocument42 pagesMaintenance of Electromagnetic Contactor On Electric LocomotiveAryavart DiplomaNo ratings yet

- LD Lab 2Document6 pagesLD Lab 2Nicoll Méndez ChicaNo ratings yet

- Apcy-P Series: Screw ChillersDocument48 pagesApcy-P Series: Screw ChillersThe Ka1serNo ratings yet

- Mobilefeed 301 Avs: Instruction ManualDocument34 pagesMobilefeed 301 Avs: Instruction ManualsimoriNo ratings yet

- Government Polytechnic, Muzaffarpur: Name of The Lab: Electrical Workshop LabDocument15 pagesGovernment Polytechnic, Muzaffarpur: Name of The Lab: Electrical Workshop LabTapobroto Chatterjee100% (1)

- Extractor Helicocentrifugo TT Pro 150 Vents ManualDocument20 pagesExtractor Helicocentrifugo TT Pro 150 Vents ManualHumberto LamusNo ratings yet

- How Selector Switches WorkDocument2 pagesHow Selector Switches WorkGalco IndustrialNo ratings yet

- Manual Maintenance Intervals Caterpillar Ad40 Ae40 II Underground Articulated TrucksDocument97 pagesManual Maintenance Intervals Caterpillar Ad40 Ae40 II Underground Articulated Truckssuwarjitechnic100% (2)

- Analog IO Module 1746 Installation ManualDocument28 pagesAnalog IO Module 1746 Installation ManualWilBert Alcántara MatosNo ratings yet

- MkII Connection Instructions Grove EKS4Document5 pagesMkII Connection Instructions Grove EKS4leoNo ratings yet

- Section 55 - Electrical System Chapter 9 - Wiring DiagramsDocument324 pagesSection 55 - Electrical System Chapter 9 - Wiring DiagramsCristian SterieNo ratings yet

- Iris nv2Document7 pagesIris nv2AndiosoNo ratings yet

- Ac & DC Uninterruptible Power Supply Systems and D.C. Back-Up Power Supply SystemsDocument31 pagesAc & DC Uninterruptible Power Supply Systems and D.C. Back-Up Power Supply SystemsKthiri WaelNo ratings yet

- Electrical Estimation ADDCDocument22 pagesElectrical Estimation ADDCFaisal Ozair100% (2)

- Range Rover P38 MY99 - Owner's Handbook Export (VDH100680X 2nd Edition)Document208 pagesRange Rover P38 MY99 - Owner's Handbook Export (VDH100680X 2nd Edition)Riahi RezegNo ratings yet

- Alpha 160ai AFMDocument116 pagesAlpha 160ai AFM韩超No ratings yet

- SIRIUS IC10 Chap12 English 2017Document118 pagesSIRIUS IC10 Chap12 English 2017LUIS PAULO HAUSCHILDNo ratings yet

- Switch Lateral de NivelDocument2 pagesSwitch Lateral de NivelpmmparanaNo ratings yet

- Manual Usuario Regal Raptot Daytona 350Document48 pagesManual Usuario Regal Raptot Daytona 350cain985100% (1)

- Discontinued: Miniature General Purpose RelayDocument8 pagesDiscontinued: Miniature General Purpose RelayJaydi ZambranoNo ratings yet

- Electrical Safety Rules-2016+FINAL+PUBLISHEDDocument77 pagesElectrical Safety Rules-2016+FINAL+PUBLISHEDSARyanNo ratings yet

- User Manual EngDocument12 pagesUser Manual Engjimmyfty328No ratings yet

- 7.08 ElectrDocument188 pages7.08 ElectrZeljko Pekic100% (4)

- Base Panther 6x6 Stinger SpecificationDocument61 pagesBase Panther 6x6 Stinger Specificationфранки штэинNo ratings yet

- Retro 420D PDFDocument4 pagesRetro 420D PDFelmerNo ratings yet