Professional Documents

Culture Documents

Slab System Assignment

Uploaded by

Sheena CherianOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Slab System Assignment

Uploaded by

Sheena CherianCopyright:

Available Formats

TOS ASSIGNMENT

Q1. EXPLAIN ONE WAY SLAB & TWO WAY SLAB.

ONE-WAY SLAB

One-way slab is supported on two opposite side only thus structural action is only at one direction.

Total load is carried in the direction perpendicular to the supporting beam.

If a slab is supported on all the four sides but the ratio of longer span (L) to shorter span (B) is

greater than 2, then the slab will be considered as one-way slab. Because due to the huge

difference in lengths, load is not transferred to the shorter beams. Main reinforcement is provided

in only one direction.

TWO-WAY SLAB

Two way slabs are the slabs that are supported on four sides and the ratio of longer span (L) to

shorter span (B) is less than 2. In two way slabs, load will be carried in both the directions. So,

main reinforcement is provided in both directions for two way slabs.

Q2. DIFFERENTIATE BETWEEN THE TWO & HOW LOADING IS DONE ON BOTH THE

SLABS?

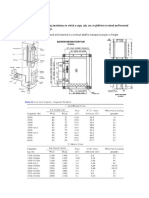

LOAD DISTRIBUTION FROM SLAB

where Ix - length of shorter side

Iy - length of longer side

a

One-way slab

B

Beam AB and

CD

lx

w = n lx / 2

C

D

ly

Two-way slab

A

B

E

ly

lx

lx/2

450

450

lx

Beam AC and BD

w = n lx / 3

lx

and CD

w = n lx / 6 {3- (lx / ly)2}

Q3. EXPLAIN BEAM & SLAB FLOOR SYSTEM IN R.C.C.

Reinforced concrete slabs are a common building system because they can be built

economically with essentially any plan geometry and supported by randomly located

beams, columns and walls.

Slabs must have sufficient strength to carry loads safely but must not deflect or crack

excessively.

This system consists of beams framing into columns and supporting slabs spanning

between the beams.

The relatively deep beams provide a stiff floor capable of long spans, and able to resist

lateral loads. However, the complications of beam formwork, co-ordination of services, and

overall depth of floor have led to a decrease in the popularity of this type of floor.

The floor loads are transferred to the beams, which are then transferred to the columns.

The traditional reinforced concrete beam-and-slab floor has an economical span L of D x

15 for a single span and D x 20 for a multi-span, where D is the depth of the slab plus

beam. The depth of slab between the beams can be initially sized using the span-to-depth

ratios for a flat plate. Pre-stressing is not normally used with this system.

Advantages:

Traditional effective solution

Long spans.

Disadvantages:

Penetrations through beams for large ducts difficult to handle

Depth of floor

Greater floor-to-floor height.

Q4. WHAT ARE SPACE FRAMES?

A space frame or space structure is a truss-like, lightweight rigid structure constructed

from interlocking struts in a geometric pattern so that they transfer moment and shear in

addition to axial forces. In comparison, space trusses are pin-jointed and as a result, their

members are in tension or compression and do not transfer moment or shear.

Space frames are either constructed from prefabricated modular units (modular system) or

individual members assembled together using different types of connectors or nodes

(nodular system). These systems are typically proprietary.

It is also possible to construct space frames by field-welding members to each other; this is

generally a costlier alternative. When field welding, the joints are considered to be rigidly

connected, capable of transferring moment and shear in addition to axial forces.

Space frames generally consist of double and multi-layer grids in flat or free forms. Flat

space frames have been typically used as roof systems, but they can also be used to

support floors.

If a force is applied to the blue node, and the red bar is not

present, the behaviour of the structure depends completely on the

bending rigidity of the blue node. If the red bar is present, and the

bending rigidity of the blue node is negligible compared to the

contributing rigidity of the red bar, the system can be calculated

using a rigidity matrix, neglecting angular factors.

The roof of this industrial

building is supported by a space

frame structure.

Simplified space frame roof

with the half-octahedron

highlighted in blue

Q5. EXPLAIN WAFFLE SLAB SYSTEM.

Ribbed floors consisting of equally spaced ribs are usually supported directly by columns.

They are either one-way spanning systems known as ribbed slab or a two-way ribbed

system known as a waffle slab. This form of construction is not very common because of

the formwork costs and the low fire rating. A 120-mm-thick slab with a minimum rib

thickness of 125 mm for continuous ribs is required to achieve a 2-hour fire rating.

Waffle slabs are a reinforced concrete footing and slab system. They consist of a perimeter

footing (edge beam) and a series of narrow internal beams (strip footings) at one meter

nominal centers running each way i.e., containing square grids with deep sides.

Waffle slabs tend to be deeper than the equivalent ribbed slab. Waffle slabs have a thin

topping slab and narrow ribs spanning in both directions between column heads or band

beams. The column heads or band beams are the same depth as the ribs.

Waffle slabs achieve their strength by varying their height above ground. The higher the

slab above ground the deeper the beams. The deeper the beams the more stiffness the

system has.

Slab depths typically vary from 75 to 125 mm and rib widths from 125 to 200 mm. Rib

spacing of 600 to 1500 mm can be used. The overall depth of the floor typically varies from

300 to 600 mm with overall spans of up to 15 m if reinforced, longer if post-tensioned. The

use of ribs to the soffit of the slab reduces the quantity of concrete and reinforcement and

also the weight of the floor.

For ribs at 1200-mm centers (to suit standard forms) the economical reinforced concrete

floor span L is approximately D x 15 for a single span and D x 22 for a multi-span, where D

is the overall floor depth. The one-way ribs are typically designed as T-beams, often

spanning in the long direction. A solid drop panel is required at the columns and

loadbearing walls for shear and moment resistance.

Advantages:

Savings on weight and materials

Long spans

Attractive soffit appearance if exposed

Economical when reusable formwork pans used

Vertical penetrations between ribs are easy.

Disadvantages:

Depth of slab between the ribs may control the fire rating

Requires special or proprietary formwork

Greater floor-to-floor height

Large vertical penetrations are more difficult to handle.

Q6. EXPLAIN FOLDED PLATES.

Folded plates are assemblies of flat plates rigidly connected together along their edges in such a

way that the structural system capable of carrying loads without the need for additional supporting

beams along mutual edges.

Merits:

Very light form of construction. To span 30 m shell thickness required is 60 mm only.

The use of concrete as a building material reduces both materials cost and a construction

cost.

Longer span can be provided.

Flat shapes by choosing certain arched shapes.

Esthetically it looks good over other forms of construction.

Movable form work can be employed.

Form work required is relatively simpler.

Design involves simpler calculations.

Demerits:

Shuttering is difficult.

Greater accuracy in formwork is required.

Good labor and supervision necessary.

Rise of roof may be a disadvantage.

Folded plate consumes more material than shells.

Form work may be removed after 7 days whereas in case of shells it can be little earlier.

The principle components in a folded plate structure consist of:

1) the inclined plates

2) edge plates which must be used to stiffen the wide plates

3) stiffeners to carry the loads to the supports and to hold the plates in line

4) columns to support the structure in the air.

Folded Plate Behaviors:

Each plate is assumed to act as a beam in its own plane, this assumption is justified when the

ratio of the span "length" of the plate to its height "width" is large enough. But when this ratio is

small, the plate behaves as a deep beam.

Actions of Folded plate due to loads:

1-Slab action: loads are transmitted to ridges by the bending of

plates normal to

their planes.

2-Beam action: Loads are transmitted through plates in their

planes to

diaphragms.

TYPES OF FOLDED PLATE:

FOLDED PLATE RIGID FRAME

Q7. EXPLAIN FLAT SLAB SYSTEM.

A flat slab is a one-way or two-way system with thickenings in the slab at the columns and

load bearing walls called drop panels Figure 9. Drop panels act as T-beams over the

supports. They increase the shear capacity and the stiffness of the floor system under

vertical loads, thus increasing the economical span range.

This form of construction has become less popular in recent years because of the limit on

economical spans of about 9.5 m for reinforced slabs and about 12 m for pre-stressed

slabs.

The plan dimensions of the drop panels are a minimum of 1/3 of the span in the direction

under consideration, usually rounded to the nearest 100 mm. The overall depth of the drop

panel is typically taken as 1.75 to 2 times the depth of the slab, again rounded to suit timber

sizes or the nearest 25 mm.

The principal features of a flat slab floor are a flat soffit, simple formwork and easy

construction. The economical span L of a reinforced concrete flat slab is approximately D x

28 for simply supported, D x 32 for an end span and D x 36 for an interior span. Prestressing the slab increases the economical span to D x 35, D x 40 and D x 45 respectively,

where D is the depth of the slab excluding the drop panel.

flat slab construction

with drop panel and

column head

Uses of column heads:

increase shear strength of slab

reduce the moment in the slab by reducing the clear or effective span

Uses of drop panels:

increase shear strength of slab

increase negative moment capacity of slab

stiffen the slab and hence reduce deflection

Advantages:

Simple formwork

No beamssimplifying under-floor services outside the drops

Minimum structural depth

Usually does not require shear reinforcement at the columns.

Building height can be reduced as no beam is used.

Less construction time.

Disadvantages:

Medium spans

Generally, not suitable for supporting brittle (masonry) partitions

Drop panels may interfere with larger mechanical ducting

Vertical penetrations need to avoid area around columns

For reinforced flat slabs, deflection at the middle strip may be critical.

You might also like

- Strength Of Beams, Floor And Roofs - Including Directions For Designing And Detailing Roof Trusses, With Criticism Of Various Forms Of Timber ConstructionFrom EverandStrength Of Beams, Floor And Roofs - Including Directions For Designing And Detailing Roof Trusses, With Criticism Of Various Forms Of Timber ConstructionNo ratings yet

- SlabDocument34 pagesSlabGhazi Bahroz JumaaNo ratings yet

- Lecture 6Document5 pagesLecture 6Azher A. IsmailNo ratings yet

- Long Span Concrete StructureDocument18 pagesLong Span Concrete StructureDevvrat Chowdhary100% (1)

- Band Beam TheoryDocument26 pagesBand Beam TheoryHuzaifa zaferNo ratings yet

- Slender ColumnsDocument110 pagesSlender ColumnsvishaliNo ratings yet

- Beam and Slab Floor SystemDocument33 pagesBeam and Slab Floor SystemmuskanNo ratings yet

- Comparison Study For Various Structural Slab SystemsDocument12 pagesComparison Study For Various Structural Slab SystemsIssam SalehNo ratings yet

- Policarpio - BGT 5 - Research No.2Document21 pagesPolicarpio - BGT 5 - Research No.2Tracy PolicarpioNo ratings yet

- Ribbed and Waffle SlabsDocument5 pagesRibbed and Waffle SlabsRenzon Sison100% (1)

- Different Floor SystemsDocument25 pagesDifferent Floor Systemsfoush bashaNo ratings yet

- Voided and Ribbed SlabsDocument17 pagesVoided and Ribbed SlabsNayeeSoch100% (2)

- Structures: Name - Kavya Sharma Class 1/C Roll no-180BARCH037 Subject-Structural SystemsDocument32 pagesStructures: Name - Kavya Sharma Class 1/C Roll no-180BARCH037 Subject-Structural SystemsKavya SharmaNo ratings yet

- Chapter 6.0 Slab Design TheoryDocument19 pagesChapter 6.0 Slab Design TheoryMohd Afzal100% (1)

- Flat Plate: Advantages of SystemDocument17 pagesFlat Plate: Advantages of Systemchad quizzaganNo ratings yet

- Flat Slab1Document21 pagesFlat Slab1BGSSAP 2017No ratings yet

- Ribbed and Waffle Slabs: BenefitsDocument4 pagesRibbed and Waffle Slabs: BenefitsJoymee BicaldoNo ratings yet

- Different Type of RCC SlabsDocument4 pagesDifferent Type of RCC SlabsGirinathNo ratings yet

- Activity 1Document14 pagesActivity 1Ronan Jay DapogracionNo ratings yet

- Group 1 Report Cast in Place and Precast Slab TypesDocument55 pagesGroup 1 Report Cast in Place and Precast Slab TypesAlwyn RamosNo ratings yet

- Flat Slab: Advanced RCC RoofsDocument21 pagesFlat Slab: Advanced RCC RoofsIMRAN KHANNo ratings yet

- Advance Building ConstructionDocument14 pagesAdvance Building ConstructionashishNo ratings yet

- BT5Document17 pagesBT5Katkat MarasiganNo ratings yet

- Flat SlabDocument11 pagesFlat SlabMasroor Ansari100% (2)

- Types of SlabsDocument12 pagesTypes of SlabsTanyaNo ratings yet

- Voided and Ribbed SlabsDocument17 pagesVoided and Ribbed SlabsAhmadNo ratings yet

- Types of Flat Slab ConstructionDocument17 pagesTypes of Flat Slab ConstructionCharina SupenaNo ratings yet

- RESEARCHno 1 BT5Document8 pagesRESEARCHno 1 BT5Mj Cassandra Yumul SamiaNo ratings yet

- Types of Slabs 1Document14 pagesTypes of Slabs 1محمد الحمايدةNo ratings yet

- FINALDocument43 pagesFINALAnshika KhandelwalNo ratings yet

- Flat SlabDocument17 pagesFlat SlabAnushka AnandNo ratings yet

- Slab DetailDocument44 pagesSlab DetailVarunNo ratings yet

- Theory of Structures - Floor SystemsDocument31 pagesTheory of Structures - Floor SystemsLawrence Babatunde OgunsanyaNo ratings yet

- RCC Moment Framed RCC Flate Plate and Slab: Presented by Ashish, Bhavana, Hasita, Manoj and NaveedDocument22 pagesRCC Moment Framed RCC Flate Plate and Slab: Presented by Ashish, Bhavana, Hasita, Manoj and NaveedNidhi MehtaNo ratings yet

- BC6 Columns SlabsDocument47 pagesBC6 Columns SlabsHarshita SrivastavaNo ratings yet

- RE 2022 140474 - Final FileDocument7 pagesRE 2022 140474 - Final Fileersunilsingh1No ratings yet

- Theory of Structures - Floor SystemsDocument31 pagesTheory of Structures - Floor SystemsLawrence Babatunde OgunsanyaNo ratings yet

- Reviewer (Building Technology)Document27 pagesReviewer (Building Technology)Jully GonzalesNo ratings yet

- One Way Slab With BeamsDocument16 pagesOne Way Slab With BeamsSYaz WAniNo ratings yet

- Presented By:: Omkar M. Salunkhe. (132040010) M.Tech. Structure-IDocument17 pagesPresented By:: Omkar M. Salunkhe. (132040010) M.Tech. Structure-IChandra BeckNo ratings yet

- Chapter 5-1 RCDocument21 pagesChapter 5-1 RCalaa altaeeNo ratings yet

- ACI 318 14 Changes PCI JournalDocument11 pagesACI 318 14 Changes PCI Journalhakim2020No ratings yet

- Flat Slab 203Document15 pagesFlat Slab 203Osama TarekNo ratings yet

- Abcm Notes Sem 6Document18 pagesAbcm Notes Sem 6Sahil pamnani100% (1)

- Presentationprint TempDocument19 pagesPresentationprint TempMustafa AhmadNo ratings yet

- Arbt5 - Report CompilationDocument29 pagesArbt5 - Report CompilationRick SarazaNo ratings yet

- 1.1 Background of StudyDocument7 pages1.1 Background of StudyMuhamad Arief AmienNo ratings yet

- Design of SlabsDocument17 pagesDesign of SlabsAmay mishraNo ratings yet

- Chapter 6 Slab DesignDocument18 pagesChapter 6 Slab DesignZAX100% (1)

- Archi V YearDocument27 pagesArchi V YeardeepshikhaNo ratings yet

- Types of SlabsDocument15 pagesTypes of SlabsPrashant dhadukNo ratings yet

- Flat SlabsDocument11 pagesFlat SlabsSingamaneni PardhuNo ratings yet

- What Are Folded Plates?Document10 pagesWhat Are Folded Plates?Sadhana PatilNo ratings yet

- I Unit New'Document148 pagesI Unit New'sankarvk4uNo ratings yet

- Reinforced Concrete Slab PDFDocument8 pagesReinforced Concrete Slab PDFArun NesamNo ratings yet

- Waffle SlabDocument46 pagesWaffle Slabali najatNo ratings yet

- HUSANA, Thessaly Aubrey S. - BT115Research1Document27 pagesHUSANA, Thessaly Aubrey S. - BT115Research1Thessaly HusanaNo ratings yet

- Framing System (Written Report)Document14 pagesFraming System (Written Report)Wincy Sta AnaNo ratings yet

- Plunge ColumnsDocument4 pagesPlunge Columnschandar70No ratings yet

- DR Fixit Powder Waterproof 49 1 PDFDocument3 pagesDR Fixit Powder Waterproof 49 1 PDFSuraj SubhashNo ratings yet

- NOBP Schedule - EPC-Floor Wise - PackagewiseDocument18 pagesNOBP Schedule - EPC-Floor Wise - PackagewiseIndraneel MaitraNo ratings yet

- Acoustic MaterialsDocument6 pagesAcoustic MaterialsLeanne Mae Patuga0% (1)

- Easy Arch ManualDocument49 pagesEasy Arch ManualDerzsi Elthes Andras100% (1)

- BhavikattiDocument7 pagesBhavikattiRakeshKrNo ratings yet

- A-Series PanelboardsDocument1 pageA-Series PanelboardsReginald D. De GuzmanNo ratings yet

- CIDB MyCESMM Library of Standard DescriptionsDocument173 pagesCIDB MyCESMM Library of Standard DescriptionsSyazwan Abh70% (20)

- Production RatesDocument29 pagesProduction RatesSam Monte0% (1)

- Bill of Quantities For POP False Ceiling No. Area Name Punning Area Didaction Total Ground FloorDocument6 pagesBill of Quantities For POP False Ceiling No. Area Name Punning Area Didaction Total Ground FloorAvinesh KumarNo ratings yet

- The History of Developments Toward Open Building in JapanDocument8 pagesThe History of Developments Toward Open Building in JapanAfonso PortelaNo ratings yet

- Nfpa 4-7Document2 pagesNfpa 4-7mujahid1137No ratings yet

- KBC2005 EngDocument61 pagesKBC2005 EngLeo LeeNo ratings yet

- TD-esc-03-de-en-16-046 Rev000a Checklist For E-82 E3, E-82 E4 Pre-Assembly and Assembly PDFDocument7 pagesTD-esc-03-de-en-16-046 Rev000a Checklist For E-82 E3, E-82 E4 Pre-Assembly and Assembly PDFAnonymous 1GuxO3zH0% (1)

- Building A Hut - The Beginners' Guide PDFDocument19 pagesBuilding A Hut - The Beginners' Guide PDFNelio CostaNo ratings yet

- Menara Standard CharteredDocument23 pagesMenara Standard CharteredAndrew Chee Man ShingNo ratings yet

- XSXSXDocument7 pagesXSXSXShelly DavisNo ratings yet

- BMU KPF Arup PDFDocument21 pagesBMU KPF Arup PDFGaruda GarudaNo ratings yet

- Arch Bim Template Guide Revit 2016 PDFDocument39 pagesArch Bim Template Guide Revit 2016 PDFilachezhiyanNo ratings yet

- Nova Scotia Barrier Free Design ChecklistDocument25 pagesNova Scotia Barrier Free Design ChecklisttroysabeanNo ratings yet

- Plumbing NotesDocument14 pagesPlumbing NotesMrityunjoy Dutta50% (2)

- Sed300s Sed200sDocument5 pagesSed300s Sed200sdaveleyconsNo ratings yet

- Atest Eco Panel Mohammad AdilDocument8 pagesAtest Eco Panel Mohammad AdilEckyAbdulahNo ratings yet

- Lecture No. 11 Stone MasonryDocument7 pagesLecture No. 11 Stone MasonryAnmol JassalNo ratings yet

- Details of Measurement (Preliminaries)Document30 pagesDetails of Measurement (Preliminaries)Engr SwapanNo ratings yet

- Assignment ELEVATORDocument7 pagesAssignment ELEVATORRenzo LopezNo ratings yet

- 2.drilling & Demolition Chapter - 3wDocument32 pages2.drilling & Demolition Chapter - 3wincineratoriumNo ratings yet

- Swimming Pool Building Code 780 CMRDocument8 pagesSwimming Pool Building Code 780 CMRfdsfsdfrrrrrrrrrNo ratings yet

- Aisi S7Document2 pagesAisi S7123vigenNo ratings yet

- Wind Load HotelDocument45 pagesWind Load HoteljohnNo ratings yet