Professional Documents

Culture Documents

AWS WHB Power Sources

Uploaded by

ippon_osotoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AWS WHB Power Sources

Uploaded by

ippon_osotoCopyright:

Available Formats

2 CHAPTER1

ARC WELDING POWER SOURCES

CHAPTER 1

ARC WELD1NG

POWER SOURCES

INTRODUCTION

This chapter presents a general overview of the

electrical power sources used for arc welding. It

explores the many types of welding power sources

available to meet the electrical requirements of the

various arc welding processes.

Welding has a long and rich history. Commercial arc

welding is over a hundred years old, and scores of processes and variations have been developed. Over the

years, power sources have been developed or modified

by equipment manufacturers in response to the changes

and improvements in these processes. As welding processes continue to evolve, power sources continue to

provide the means of controlling the welding current,

voltage, and power. This chapter provides updated

information on the basic electrical technologies, circuits, and functions designed into frequently used

welding power sources. Topics covered in this chapter

include the following:

1. The volt-ampere (V-A) characteristics required

for common welding processes,

2. Basic electrical technologies and terminology

used in power sources,

3. Simplified explanations of commonly used

power source circuits, and

4. An introduction to useful national and international standards.

A basic knowledge of electrical power sources will

provide the background for a more complete understanding of the welding processes presented in the other

chapters of this book.

FUNDAMENTALS

This section introduces the fundamental functions of

welding power sources and the concepts of constant-

voltage (CV) and constant-current (CC) characteristics

required for welding processes.

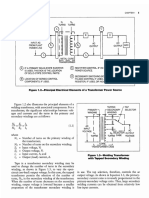

The voltage supplied by power companies for industrial purposes-120 volts (V), 230 V, 380 V, or 480 Vis too high for use in arc welding. Therefore, the first

function of an arc welding power source is to reduce the

high input or line voltage to a suitable output voltage

range, 20 V to 80 V. A transformer, a solid-state

inverter, or an electric motor-generator can be used to

reduce the utility power to terminal or open-circuit

voltage appropriate for arc welding.

Alternatively, a power source for arc welding may

derive its power from a prime mover such as an internal

combustion engine. The rotating power from an internal combustion engine is used to rotate a generator or

an alternator for the source of electrical current.

Welding transformers, inverters, or generator/

alternators provide high-amperage welding current,

generally ranging from 30 amperes (A) to 1500 A. The

output of a power source may be alternating current

(ac), direct current (dc) or both. It may be constant

current, constant voltage, or both. Welding power

sources may also provide pulsed output of voltage or

current.

Some power source configurations deliver only certain types of current. For example, transformer power

sources deliver ac only. Transformer-rectifier power

sources can deliver either alternating or direct current,

as selected by the operator. Electric motor-generator

power sources usually deliver dc output. A motoralternator delivers ac, or when equipped with rectifiers,

dc.

Power sources can also be classified into subcategories. For example, a gas tungsten arc welding power

source might be identified as transformer-rectifier,

constant-current, ac/dc. A complete description of any

power source should include welding current rating,

duty cycle rating, service classification, and input power

You might also like

- Sample Arc StrikeDocument1 pageSample Arc Strikeippon_osotoNo ratings yet

- CQI Training Certificates in QMSDocument2 pagesCQI Training Certificates in QMSippon_osotoNo ratings yet

- Continuing Professional Development: Steps of CPDDocument1 pageContinuing Professional Development: Steps of CPDippon_osoto100% (1)

- Cqi Certificate in Quality Management: Frequently Asked Questions (Faqs) ForDocument4 pagesCqi Certificate in Quality Management: Frequently Asked Questions (Faqs) Forippon_osotoNo ratings yet

- Wi Application FormDocument2 pagesWi Application Formippon_osotoNo ratings yet

- FibersparDocument2 pagesFibersparippon_osotoNo ratings yet

- Purgeye Api100 LFT A3-Web-PDocument4 pagesPurgeye Api100 LFT A3-Web-Pippon_osotoNo ratings yet

- BSI Diploma in Quality Management Systems BSI Training Sales Flyer UK enDocument2 pagesBSI Diploma in Quality Management Systems BSI Training Sales Flyer UK enippon_osotoNo ratings yet

- CQE Fact SheetDocument2 pagesCQE Fact Sheetippon_osotoNo ratings yet

- Sample API 1104 WpsDocument1 pageSample API 1104 Wpsippon_osoto100% (1)

- WI ComparisonDocument1 pageWI Comparisonippon_osotoNo ratings yet

- Completed WeldDocument1 pageCompleted Weldippon_osotoNo ratings yet

- Pages From SAES W 012Document1 pagePages From SAES W 012ippon_osotoNo ratings yet

- AIA Philam Life Policy Fund Withdrawal FormDocument2 pagesAIA Philam Life Policy Fund Withdrawal Formippon_osotoNo ratings yet

- Rev 4 January 2013 General Introduction To Welding 1-2Document1 pageRev 4 January 2013 General Introduction To Welding 1-2ippon_osotoNo ratings yet

- PEMI - Redemption Order Form (ROF)Document1 pagePEMI - Redemption Order Form (ROF)ippon_osotoNo ratings yet

- AIA Philam Life Request For Extension of Grace PeriodDocument1 pageAIA Philam Life Request For Extension of Grace Periodippon_osotoNo ratings yet

- Soldering: Prepared by The Welding Handbook Chapter Committee On Soldering: F. M. Hosking, ChairDocument1 pageSoldering: Prepared by The Welding Handbook Chapter Committee On Soldering: F. M. Hosking, Chairippon_osotoNo ratings yet

- Soldering: Prepared by The Welding Handbook Chapter Committee On Soldering: F. M. Hosking, ChairDocument1 pageSoldering: Prepared by The Welding Handbook Chapter Committee On Soldering: F. M. Hosking, Chairippon_osotoNo ratings yet

- Surfacing: Plasma Transferred Arc (PTA) PTADocument1 pageSurfacing: Plasma Transferred Arc (PTA) PTAippon_osotoNo ratings yet

- Single Phase Power SourceDocument1 pageSingle Phase Power Sourceippon_osotoNo ratings yet

- SS DiodesDocument1 pageSS Diodesippon_osotoNo ratings yet

- Transformer Power SourceDocument1 pageTransformer Power Sourceippon_osotoNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Bosch Rexroth - Catalog de Produse de BazăDocument38 pagesBosch Rexroth - Catalog de Produse de Bazăjo_rz_57No ratings yet

- Study On The Temperature Variation Inside The Biodigester of Modified 2 m3 GGC 2047 Biogas PlantDocument5 pagesStudy On The Temperature Variation Inside The Biodigester of Modified 2 m3 GGC 2047 Biogas PlantEr Shankar Singh DhamiNo ratings yet

- HW 1 SolutionsDocument8 pagesHW 1 SolutionsanyadamsNo ratings yet

- Biodata PT Youcom Elysia Abadi PDFDocument58 pagesBiodata PT Youcom Elysia Abadi PDFYovhy Purnama AjiNo ratings yet

- ECE 83 Revision 3 (NEDC) PDFDocument273 pagesECE 83 Revision 3 (NEDC) PDFVitaliTheGreatNo ratings yet

- Improvised Pedal Type To Light The BulbDocument38 pagesImprovised Pedal Type To Light The BulbAdrian RapsingNo ratings yet

- Komatsu 155 4 Series Workshop Manual Ab PDFDocument376 pagesKomatsu 155 4 Series Workshop Manual Ab PDFahmed100% (2)

- PSPCL Bill 3001180413 Due On 2018-FEB-09Document1 pagePSPCL Bill 3001180413 Due On 2018-FEB-09HARISHNo ratings yet

- AG Maura Healey's Energy StudyDocument83 pagesAG Maura Healey's Energy StudyMary SerrezeNo ratings yet

- 1st SeminarDocument17 pages1st SeminarNeloy BishnuNo ratings yet

- DC MOTOR - EnerconDocument19 pagesDC MOTOR - EnerconJoanna Fabricante100% (1)

- THPT2021-SGD Ha Noi OnlineDocument6 pagesTHPT2021-SGD Ha Noi Onlinetv vovoNo ratings yet

- 2021.7.6 - Strategic MGMT - LMSDocument4 pages2021.7.6 - Strategic MGMT - LMSHậu VũNo ratings yet

- Briggs StrattonDocument13 pagesBriggs StrattonRay Gomez0% (1)

- 0001 PDFDocument3 pages0001 PDFVelya Galyani Pasila GallaNo ratings yet

- BEE051 & Distributed Generation and Micro GridDocument2 pagesBEE051 & Distributed Generation and Micro GridRenga RajanNo ratings yet

- Visco PlasticityDocument18 pagesVisco PlasticitySam WilcockNo ratings yet

- Deficiency ListDocument2 pagesDeficiency Listbidyut100No ratings yet

- Governing System of Stage-1 200 MW TurbineDocument13 pagesGoverning System of Stage-1 200 MW TurbineSamNo ratings yet

- Paper 4 Final DraftDocument5 pagesPaper 4 Final Draftapi-665151630No ratings yet

- Es3003 Exam1 SolutionsDocument5 pagesEs3003 Exam1 SolutionsgiyagirlsNo ratings yet

- Penskey-Martens Flash-Point ApparatusDocument5 pagesPenskey-Martens Flash-Point ApparatusRajeesh Srikantaswamy100% (1)

- BHEL Bhopal STM Training ReportDocument20 pagesBHEL Bhopal STM Training ReportMohit Assudani50% (2)

- Renewable Energy WebDocument4 pagesRenewable Energy WebNaresh Kumar GovindanNo ratings yet

- PFD Hazira NewDocument1 pagePFD Hazira NewJagan BoseNo ratings yet

- Stirling DK EnginesDocument2 pagesStirling DK EnginesMarius-Cristian NitaNo ratings yet

- Effect of Grid Frequency On The Plant LoadDocument2 pagesEffect of Grid Frequency On The Plant LoadMr.CoolNo ratings yet

- Paper SEAS-NVE BerlinDocument9 pagesPaper SEAS-NVE BerlinNielsa100No ratings yet

- CPT4 - System Loss Analysis-6th Batch JVM EditedDocument130 pagesCPT4 - System Loss Analysis-6th Batch JVM EditedAlvin Garcia PalancaNo ratings yet

- MVDC 1 PDFDocument21 pagesMVDC 1 PDFThiaga RajanNo ratings yet