Professional Documents

Culture Documents

CM 425 - Properties of Fresh Concrete PDF

Uploaded by

Tran Huynh NamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CM 425 - Properties of Fresh Concrete PDF

Uploaded by

Tran Huynh NamCopyright:

Available Formats

Concrete Technology

Properties of Fresh Concrete

Concrete Technology

Properties of Fresh

Concrete

CM 425

Concrete Technology

Properties of Fresh Concrete

Introduction

The potential strength and durability of

concrete of a given mix proportion is very

dependent on the degree of its

compaction.

It is vital, therefore, that the consistency

of the mix be such that the concrete can

be transported, placed, and finished

sufficiently early enough to attain the

expected strength and durability.

2

Professor Kamran M. Nemati

Winter Quarter 2015

Concrete Technology

Properties of Fresh Concrete

CM 425

Concrete Technology

Properties of Fresh Concrete

Significance

The first 48 hours are very

important for the performance of

the concrete structure.

It controls the long-term

behavior, influence f'c (ultimate

strength), Ec (elastic modulus),

creep, and durability.

3

CM 425

Concrete Technology

Elasticity and Strength of Concrete

The elastic properties of materials are a

measure of their resistance to deformation

under an applied load (but the elastic strain

is recovered when the load is removed).

Strength usually refers to the maximum

stress that a given kind of sample can carry.

Understanding these properties and how

they are measured is essential for anyone

wishing to use materials.

4

Professor Kamran M. Nemati

Winter Quarter 2015

Concrete Technology

Properties of Fresh Concrete

CM 425

Concrete Technology

Properties of Fresh Concrete

Properties at Early Ages

Workability

Slump Loss

Segregation/Bleeding

Plastic Shrinkage

Time of Set

Temperature

5

CM 425

Concrete Technology

Properties of Fresh Concrete

Workability

Definition: Effort required to

manipulate a concrete mixture

with a minimum of segregation.

It is not a fundamental property

of concrete.

6

Professor Kamran M. Nemati

Winter Quarter 2015

Concrete Technology

Properties of Fresh Concrete

CM 425

Concrete Technology

Properties of Fresh Concrete

Workability

I) consistency (slump) how

easy to flow

and

II) cohesiveness tendency

to bleed and segregate.

7

CM 425

Concrete Technology

Consistency Tests

Consistency:

Slump

Test

Professor Kamran M. Nemati

Winter Quarter 2015

Concrete Technology

Properties of Fresh Concrete

CM 425

Concrete Technology

Slump Test

CM 425

Concrete Technology

Properties of Fresh Concrete

The most important properties of

fresh concrete are thus associated

with its workability and

consistency.

Most concrete must be compacted

after it has been placed in the

forms.

10

Professor Kamran M. Nemati

Winter Quarter 2015

Concrete Technology

Properties of Fresh Concrete

CM 425

Concrete Technology

Properties of Fresh Concrete

Whether the compaction is achieved by

raming or by vibration, the process

consists essentially of the elimination

of entrapped air from the concrete until

it has achieved as dense a configuration

as possible for a given mix.

Large pockets of entrapped air seriously

weaken the concrete since they act as

powerful stress concentrators.

11

CM 425

Workability

Concrete Technology

This term is defined in ASTM C 125 as the property

determining the effort required to manipulate a freshly mixed

quantity of concrete with minimum loss of homogeneity.

The term manipulate includes the operations of placing,

compacting and finishing the concrete.

Neville and Brooks* define workability as the amount of useful

internal work necessary to produce full compaction.

They note that the useful internal work is a physical property

of the concrete alone, but they note there is additional energy

required to overcome friction between the concrete and the

formwork and the reinforcement as well as the energy

required to vibrate the formwork, the reinforcement, and the

concrete which has already been compacted.

Thus in practice, it is difficult to measure the workability as

defined.

* Neville, A.M. and Brooks, J.J., Concrete Technology, Longman Scientific & Technical

copublished with John Wiley & Sons, Inc. in the United States, 1987, p. 78.

Professor Kamran M. Nemati

Winter Quarter 2015

12

Concrete Technology

Properties of Fresh Concrete

CM 425

Concrete Technology

Stiffening and Setting

After completion of mixing,

concrete gradually stiffens until it

becomes rigid.

It is essential that it remain plastic

long enough to permit being

transported, placed, consolidated,

and finished.

13

CM 425

Concrete Technology

Setting and Hardening

The progress of setting and hardening in concrete

Initial Set: Loss of consistency, unworkable concrete (no less than

45 minutes ASTM C 150)

Final Set: Complete solidification (no more than 375 minutes)

14

Professor Kamran M. Nemati

Winter Quarter 2015

Concrete Technology

Properties of Fresh Concrete

CM 425

Concrete Technology

Compacting Factor Tests

Although there is no generally accepted method of directly

measuring workability, Neville and Brooks* point out that

probably the best test yet available uses the inverse

approach: i.e., the degree of compaction can be measured

when a standard amount of work is applied to a standard

quantity of concrete.

The degree of compaction, called the compacting factor,

is measured by the density ration which is the ratio of the

density actually achieved in the test to the density of the

same concrete fully compacted.

These tests are covered in the United States under ACI

211.3, and in the UK by BS 1881: Part 103: 1983.

*Neville, A.M. and Brooks, J.J., Concrete Technology, Longman Scientific & Technical

copublished with John Wiley & Sons, Inc. in the United States, 1987, p. 86.

15

CM 425

Concrete Technology

The Kelly Ball Test

Another method used in the field and laboratory to measure the

consistency of concrete is the ball penetration test (ASTM C360)

which is also known as the Kelly ball test*.

It is performed by measuring the penetration, in inches, of a 6-in.

diameter steel cylinder with a hemispherically shaped bottom,

weighing 30 lbs.

One of the advantages of the ball penetration test can be

performed on the concrete in a hopper, buggy, wheelbarrow, or

other suitable container.

Another advantage of this method is its simplicity and the rapidity

with which the consistency of the concrete can be determined.

It is also not dependent on a procedure of filling and rodding a

container like the slump test.

Details of the test procedure and the ball-penetration apparatus are given in ASTM C360. There

is a direct relationship between slump and ball penetration for a given mix but it varies

according to the mix. The ratio of slump to the penetration of the ball is between 1.5 and 2.

16

Professor Kamran M. Nemati

Winter Quarter 2015

Concrete Technology

Properties of Fresh Concrete

CM 425

Concrete Technology

The Kelly Ball Test

17

CM 425

Concrete Technology

Pressure Method

The most common method of measuring

the air content of freshly mixed concrete

is the pressure method (ASTM C231).

In this method, pressure is applied to a

concrete sample placed into an air meter

and the reduction in volume observed on

a gage calibrated in terms of percent air.

The observed amount of air includes both

the purposely entrained air as well as the

entrapped air (about 1% by volume of

concrete).

18

Professor Kamran M. Nemati

Winter Quarter 2015

Concrete Technology

Properties of Fresh Concrete

CM 425

Concrete Technology

Pressure Method

19

CM 425

Concrete Technology

Dont Use More Water!

What is sometimes regarded as a need for wetter concrete

may be better satisfied by more thorough vibration.

The use of adequate vibration rather than of a wetter mix

will not only insure a more thorough compaction but also the

quality of concrete will be superior by not increasing the

water content to obtain a greater slump.

The Careful attention to keeping the mix as dry as possible

and being sure that there is adequate vibration will lead to

sound concrete.

The worst combination; however, is to over vibrate

concrete which is too wet.

Excessive care must be taken to prevent this. Heavy

structural members and slabs can be satisfactorily placed

using a 2-in. slump concrete if it is properly vibrated.

20

Professor Kamran M. Nemati

Winter Quarter 2015

10

Concrete Technology

Properties of Fresh Concrete

CM 425

Concrete Technology

Consistency

Consistency or fluidity of concrete is an important

component of workability and refers in a way to the wetness

of the concrete.

However, it must not be assumed that the wetter the mix

the more workable it is. If a mix is too wet, segregation

may occur with resulting honeycomb, excessive bleeding,

and sand streaking on the formed surfaces.

21

CM 425

Concrete Technology

Consistency

On the other hand, if a mix is too dry it may

be difficult to place and compact, and

segregation may occur because of lack of

cohesiveness and plasticity of the paste.

22

Professor Kamran M. Nemati

Winter Quarter 2015

11

Concrete Technology

Properties of Fresh Concrete

CM 425

Concrete Technology

Workability and Consistency

In their textbook, Mehta and Monteiro*

note that workability is a composite

property, with at least two main

components:

a. Consistency which he describes as the

ease of flow of the concrete, and

b. Cohesiveness which he describes as the

tendency not to bleed or segregate.

* Mehta, P.K. and Monteiro, P.J.M., CONCRETE - Microstructure,

Properties & Materials, McGraw Hill, 3rd edition, 2006, p. 353.

CM 425

23

Concrete Technology

Workability and Consistency

Some of the important factors that affect the

workability of concrete are:

1)

2)

3)

4)

relative quantities of paste and aggregates,

plasticity of the paste itself,

maximum size and grading of aggregates, and

shape and surface characteristics of aggregate

particles.

Each of these factors effect the components

of workability, consistency and cohesiveness,

in different ways.

* Mehta, P.K. and Monteiro, P.J.M., CONCRETE - Microstructure,

Properties & Materials, McGraw Hill, 3rd edition, 2006, p. 353.

Professor Kamran M. Nemati

Winter Quarter 2015

24

12

Concrete Technology

Properties of Fresh Concrete

CM 425

Concrete Technology

Workability and Consistency

Mehta and Polivka* discuss further that:

None of the test methods proposed or in use

today simultaneously measure all of the

properties involved in workability.

In practice, the workability of a mix is judged by

several properties including consistency, ease of

conveying and placing, and lack of segregation

or of excessive bleeding.

An experienced concrete technician can readily

judge when fresh concrete has adequate

workability for use in a given situation.

* Mehta, P.K. and Polivka, M., Fresh Concrete--Materials & Properties,

Reinforced Concrete Engineering, B. Bresler, Ed., John Wiley & Sons, 1974. 25

CM 425

Concrete Technology

Workability and Consistency

Mehta and Polivka* go on to say:

A concrete mix suitable for massive

construction, e.g., of a bridge pier, would

not have the required workability for

placement in a heavily reinforced column.

Thus, a concrete mix should have the

needed workability for its intended use.

Also, it should not segregate nor bleed

excessively.

* Mehta, P.K. and Polivka, M., Fresh Concrete--Materials & Properties,

Reinforced Concrete Engineering, B. Bresler, Ed., John Wiley & Sons, 1974.

Professor Kamran M. Nemati

Winter Quarter 2015

26

13

Concrete Technology

Properties of Fresh Concrete

CM 425

Concrete Technology

Workability and Consistency

Mehta and Polivka* discuss these terms as follows:

Workability and consistency of fresh concrete are

two closely related properties. Workability is

that property of freshly mixed concrete which

determines the ease and homogeneity with

which it can be mixed, transported, placed,

compacted, and finished.

Workability is a property which depends on the

specific conditions of placement; a concrete that

is workable under some conditions may not be

workable under some other conditions.

* Mehta, P.K. and Polivka, M., Fresh Concrete--Materials & Properties,

Reinforced Concrete Engineering, B. Bresler, Ed., John Wiley & Sons, 1974. 27

Professor Kamran M. Nemati

Winter Quarter 2015

14

You might also like

- Connecticut DOT Materials Testing QA ProgramDocument236 pagesConnecticut DOT Materials Testing QA ProgramYasser AlghrafyNo ratings yet

- Prevention of Reflective Cracking in Pavements - Vanelstraete PDFDocument136 pagesPrevention of Reflective Cracking in Pavements - Vanelstraete PDFTran Huynh Nam100% (3)

- Crackwidth For Wall (Combined Bending and Tension)Document3 pagesCrackwidth For Wall (Combined Bending and Tension)mukhleshNo ratings yet

- Atlas Copco: Stationary Air CompressorsDocument66 pagesAtlas Copco: Stationary Air CompressorsChriss Vzz100% (4)

- Piping Dead Legs: Plastic Pipe Is Particularly Susceptible To Freeze CrackingDocument3 pagesPiping Dead Legs: Plastic Pipe Is Particularly Susceptible To Freeze CrackingJithin FrancizNo ratings yet

- Designing a hose reel systemDocument6 pagesDesigning a hose reel systemSyafiqah ShahuriNo ratings yet

- Sika Solutions For Waste Water Treatment Plants - Low PDFDocument48 pagesSika Solutions For Waste Water Treatment Plants - Low PDFsaber66No ratings yet

- Pre Deployment ChecklistDocument12 pagesPre Deployment ChecklistJay ChamberlainNo ratings yet

- Building Project ReportDocument32 pagesBuilding Project ReportAssif Yousuf100% (2)

- Titanium and Titanium AlloysDocument24 pagesTitanium and Titanium AlloysGuilherme FranzoiNo ratings yet

- Rapid Techniques For Determination of Free CaO and Free MgO and Portlandite in Hydrate Cement PDFDocument10 pagesRapid Techniques For Determination of Free CaO and Free MgO and Portlandite in Hydrate Cement PDFTran Huynh NamNo ratings yet

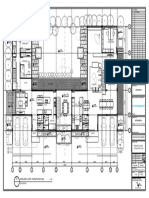

- Aic Management: Ground Floor Furniture Plan 01Document1 pageAic Management: Ground Floor Furniture Plan 01Hung NguyentheNo ratings yet

- Samsung Tv8Document65 pagesSamsung Tv8Enrile Labiano BaduaNo ratings yet

- In-Vitro Antidiabetic Activity of Swietenia Mahagoni (L) - Seeds and Its Different Fraction With Isolated CompoundsDocument10 pagesIn-Vitro Antidiabetic Activity of Swietenia Mahagoni (L) - Seeds and Its Different Fraction With Isolated CompoundsIJAR JOURNALNo ratings yet

- Emb MC 2020 28 Clarification On The Renewal and Revocation of Accreditation of Pollution Control OfficersDocument2 pagesEmb MC 2020 28 Clarification On The Renewal and Revocation of Accreditation of Pollution Control Officersvivian dimaandalNo ratings yet

- Impact of Aggregate Gradation and Type oDocument10 pagesImpact of Aggregate Gradation and Type oBank NutchanonNo ratings yet

- Customer satisfaction towards Royal Enfield bikesDocument50 pagesCustomer satisfaction towards Royal Enfield bikesPraveenkumarsingh.finnoyNo ratings yet

- RT Annual Results 2022 SlidesDocument80 pagesRT Annual Results 2022 SlidesMayank MNo ratings yet

- To What Extent Does Vivienne Westwood's Sustainable Fashion Initiatives Provide It With A Competitive Advantage Over Other Luxury Brands?Document24 pagesTo What Extent Does Vivienne Westwood's Sustainable Fashion Initiatives Provide It With A Competitive Advantage Over Other Luxury Brands?Verónica Pinacho VegaNo ratings yet

- Exosomes in Atherosclerosis: Performers, Bystanders, Biomarkers, and Therapeutic TargetsDocument15 pagesExosomes in Atherosclerosis: Performers, Bystanders, Biomarkers, and Therapeutic TargetsAlexa ReinkeNo ratings yet

- Model Contract of Apprenticeship Training For Major/Minor ApprenticesDocument3 pagesModel Contract of Apprenticeship Training For Major/Minor ApprenticesTejashree patilNo ratings yet

- Unfortunate That India's Democracy Was Questioned in London, Says PM Modi in Dig at Rahul GandhiDocument3 pagesUnfortunate That India's Democracy Was Questioned in London, Says PM Modi in Dig at Rahul Gandhisumits07No ratings yet

- Question 1Document114 pagesQuestion 1OneNo ratings yet

- American Innovation and Choice Online ActDocument22 pagesAmerican Innovation and Choice Online ActAlex KantrowitzNo ratings yet

- MODEL - Project - Report (AutoRecovered)Document45 pagesMODEL - Project - Report (AutoRecovered)20EC011 P. KannanNo ratings yet

- Design Thinking in Project Management For InnovationDocument4 pagesDesign Thinking in Project Management For InnovationResearch ParkNo ratings yet

- UntitledDocument17 pagesUntitledMarlo MamarilNo ratings yet

- Analytical Techniques PDFDocument46 pagesAnalytical Techniques PDFsaber ghodbaneNo ratings yet

- Com BrochureDocument18 pagesCom BrochureBrankasNo ratings yet

- Assembling The Past and The Future of The City THRDocument14 pagesAssembling The Past and The Future of The City THRAngellicaNo ratings yet

- Articles Magazines Files 09 2016 Lighting Electronics 2 Spreads PDFDocument15 pagesArticles Magazines Files 09 2016 Lighting Electronics 2 Spreads PDFeyadNo ratings yet

- Atos 2019 Financial Report PDFDocument106 pagesAtos 2019 Financial Report PDFBustamante LisiNo ratings yet

- Curriculo LB English CompressedDocument1 pageCurriculo LB English CompressedleticiacbiazuttiNo ratings yet

- r6 - SCV - PV - 2012 June MarkB PDFDocument32 pagesr6 - SCV - PV - 2012 June MarkB PDFsanjiivNo ratings yet

- Inspection Form Harness FillableDocument1 pageInspection Form Harness FillableErica Araceli Gallegos AriasNo ratings yet

- Dye1 PDFDocument15 pagesDye1 PDFمروة فؤاد حسن شعبانNo ratings yet

- CSC 2 0 Digital Seva Connect v1.1Document41 pagesCSC 2 0 Digital Seva Connect v1.1AzImm100% (1)

- GNFCDocument249 pagesGNFCravi.youNo ratings yet

- Bank Dispute Over Forex DerivativesDocument50 pagesBank Dispute Over Forex DerivativesAnurag SharmaNo ratings yet

- Word 3E Skin Protection InstructionsDocument3 pagesWord 3E Skin Protection InstructionsPrince JuniorNo ratings yet

- Market and Pricing - Monopolistic Competition and OligopolyDocument40 pagesMarket and Pricing - Monopolistic Competition and OligopolyDaksh AnejaNo ratings yet

- Fabrication of Hydraulic Scissor LiftDocument9 pagesFabrication of Hydraulic Scissor LiftMICHEL RAJ MechNo ratings yet

- Nitesh Bhadani: ExperienceDocument2 pagesNitesh Bhadani: ExperienceChulbul PandeyNo ratings yet

- Airtel DocumentDocument6 pagesAirtel Documenttanmay100No ratings yet

- Airstream European Travel Trailers: Inspiring Adventure for Nearly 80 YearsDocument20 pagesAirstream European Travel Trailers: Inspiring Adventure for Nearly 80 Yearspeter_coleNo ratings yet

- Chapter 29 - Fabrics FibresDocument20 pagesChapter 29 - Fabrics FibresAman KeltaNo ratings yet

- Antares 6Document32 pagesAntares 6Cem AvciNo ratings yet

- The Newton2Document32 pagesThe Newton2Cynthia HtbNo ratings yet

- Madhavi Bhatt-1 PDFDocument2 pagesMadhavi Bhatt-1 PDFMadhavi BhattNo ratings yet

- Aseptic Technique.Document7 pagesAseptic Technique.Richard BidalNo ratings yet

- Clash of The TitansDocument6 pagesClash of The TitansSteven SchafersmanNo ratings yet

- Biedermann V EhrhartDocument34 pagesBiedermann V EhrhartJennifer SmithNo ratings yet

- ECR Passport Emigration Clearance Application GuideDocument13 pagesECR Passport Emigration Clearance Application GuideMohamed ShafiNo ratings yet

- ZE500KL RF Hardware Trouble Shooting GuideDocument59 pagesZE500KL RF Hardware Trouble Shooting GuideWilliam SequeraNo ratings yet

- Technical Report On Asset Declarations Greece enDocument99 pagesTechnical Report On Asset Declarations Greece enjacobo_dopicoNo ratings yet

- Research Kyvelou Marava CNFPT OLA FINALDocument33 pagesResearch Kyvelou Marava CNFPT OLA FINALncias cdsNo ratings yet

- HSM Seminar Report Summary: High Speed Machining Applications and ParametersDocument16 pagesHSM Seminar Report Summary: High Speed Machining Applications and ParameterskdbbbNo ratings yet

- Statement For A/c XXXXXXXXX3479 For The Period 09-Nov-2022 To 08-Feb-2023Document21 pagesStatement For A/c XXXXXXXXX3479 For The Period 09-Nov-2022 To 08-Feb-2023TG HALLI-3163 PLANNING BWSSBNo ratings yet

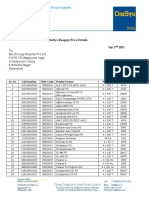

- Diasys Price Details For Bhrungi Hospital HyderabadDocument4 pagesDiasys Price Details For Bhrungi Hospital HyderabadSandeep BellapuNo ratings yet

- CR Assignment 2Document4 pagesCR Assignment 2nimraTNo ratings yet

- Circularity Indicators - Non Technical Case Studies - May2015 PDFDocument8 pagesCircularity Indicators - Non Technical Case Studies - May2015 PDFKoushik PonnuruNo ratings yet

- Airteltigo Sms Bundle Code - Google SearchDocument1 pageAirteltigo Sms Bundle Code - Google SearchAbigail BrownNo ratings yet

- B SUHENDRO HAKI WEBINAR BETON RINGAN DAN APLIKASINYA PADA PRECAST SLAB 2023 Final ShareDocument36 pagesB SUHENDRO HAKI WEBINAR BETON RINGAN DAN APLIKASINYA PADA PRECAST SLAB 2023 Final ShareHanifNo ratings yet

- NSB RulesDocument11 pagesNSB RulesSUNIL100% (1)

- CET22Document40 pagesCET22binodeNo ratings yet

- Control Deberes FormalesDocument14 pagesControl Deberes FormalesRobert AlexanderNo ratings yet

- The Big Book of Trends and Thematic InvestingDocument80 pagesThe Big Book of Trends and Thematic InvestingkiminNo ratings yet

- Dupont Nears Deals To Remake Legendary Chemicals Company: For Personal, Non-Commercial Use OnlyDocument30 pagesDupont Nears Deals To Remake Legendary Chemicals Company: For Personal, Non-Commercial Use OnlyMario LanglisNo ratings yet

- RavindraDocument3 pagesRavindraPriyanshu ChauhanNo ratings yet

- User's Manual: GB NL F E D IDocument21 pagesUser's Manual: GB NL F E D IFlorea NicolaeNo ratings yet

- Organised Versus Unorganised Retail in IndiaDocument11 pagesOrganised Versus Unorganised Retail in IndiaSharma Sumant0% (1)

- Properties of Fresh Concrete ExplainedDocument14 pagesProperties of Fresh Concrete ExplainedsuperjnrNo ratings yet

- Study On Effects of Burning Conditions and RHA Blending Amount On The Mechamical Behavior of Cement PDFDocument7 pagesStudy On Effects of Burning Conditions and RHA Blending Amount On The Mechamical Behavior of Cement PDFTran Huynh NamNo ratings yet

- Utilization of RHA in Geotechnology PDFDocument149 pagesUtilization of RHA in Geotechnology PDFTran Huynh NamNo ratings yet

- Use of RHA Blended Cement To Produce Cement Sand Blocks PDFDocument10 pagesUse of RHA Blended Cement To Produce Cement Sand Blocks PDFTran Huynh NamNo ratings yet

- Thermal Analysis Pozzolanic Index of RHA at Different Grinding Time PDFDocument9 pagesThermal Analysis Pozzolanic Index of RHA at Different Grinding Time PDFTran Huynh NamNo ratings yet

- Study On The Pozzolanic Properties of RHA by HCL Pretreatment PDFDocument6 pagesStudy On The Pozzolanic Properties of RHA by HCL Pretreatment PDFTran Huynh NamNo ratings yet

- Study Mechanical Behaviours RHA and Carrot Powders As Mortar For Cement Replacement PDFDocument6 pagesStudy Mechanical Behaviours RHA and Carrot Powders As Mortar For Cement Replacement PDFTran Huynh NamNo ratings yet

- The Relationship Between The Strength and Non-Destructive Parameters of RHA Concrete PDFDocument12 pagesThe Relationship Between The Strength and Non-Destructive Parameters of RHA Concrete PDFTran Huynh NamNo ratings yet

- The Relationships Between Setting Time and Early Age Strength of Concrete Contaning SF, FA & Slag PDFDocument10 pagesThe Relationships Between Setting Time and Early Age Strength of Concrete Contaning SF, FA & Slag PDFTran Huynh NamNo ratings yet

- Reaction Product of Lime and Silica From RHA PDFDocument7 pagesReaction Product of Lime and Silica From RHA PDFTran Huynh NamNo ratings yet

- Use of RHA in Concrete PDFDocument8 pagesUse of RHA in Concrete PDFTran Huynh NamNo ratings yet

- RHA Effectiveness in Cement and Concrete As A Fuction of Reactive Silica and Fineness PDFDocument8 pagesRHA Effectiveness in Cement and Concrete As A Fuction of Reactive Silica and Fineness PDFTran Huynh NamNo ratings yet

- RHA Effectiveness in Cement and Concrete As A Fuction of Reactive Silica and Fineness PDFDocument8 pagesRHA Effectiveness in Cement and Concrete As A Fuction of Reactive Silica and Fineness PDFTran Huynh NamNo ratings yet

- Study On The Pozzolanic Properties of Silica Obtained From RH by Chemical and Thermal Process PDFDocument8 pagesStudy On The Pozzolanic Properties of Silica Obtained From RH by Chemical and Thermal Process PDFTran Huynh NamNo ratings yet

- Improved Durability Performances in Mortar With Rice Husk Ash PDFDocument8 pagesImproved Durability Performances in Mortar With Rice Husk Ash PDFTran Huynh NamNo ratings yet

- Mechanical Properties of RHA Blended Cement Concrete Made With OPC 53 Cement PDFDocument6 pagesMechanical Properties of RHA Blended Cement Concrete Made With OPC 53 Cement PDFTran Huynh NamNo ratings yet

- Effects of RHA Produced From Different Temperatures On The Performances of Concrete PDFDocument65 pagesEffects of RHA Produced From Different Temperatures On The Performances of Concrete PDFTran Huynh NamNo ratings yet

- Microstructural Characterization of Rice Husk and Residual Ash For The Production of Superior Blended ConcreteDocument6 pagesMicrostructural Characterization of Rice Husk and Residual Ash For The Production of Superior Blended ConcretePriyanka Dhurvey SinghNo ratings yet

- Contribution of RHA To The Properties of Cement Mortar and Concrete PDFDocument7 pagesContribution of RHA To The Properties of Cement Mortar and Concrete PDFTran Huynh NamNo ratings yet

- Crystallite Growth of RHA Silica PDFDocument7 pagesCrystallite Growth of RHA Silica PDFTran Huynh NamNo ratings yet

- A Structural Investigation Relating To The Pozzolanic Activity of Rice Husk Ashes PDFDocument9 pagesA Structural Investigation Relating To The Pozzolanic Activity of Rice Husk Ashes PDFTran Huynh NamNo ratings yet

- Problems With Fineness Testing of Coal FA For Use in Concrete PDFDocument27 pagesProblems With Fineness Testing of Coal FA For Use in Concrete PDFTran Huynh NamNo ratings yet

- Statistical Analysis of Strength and Durability of Concrete Made With Different Cements PDFDocument11 pagesStatistical Analysis of Strength and Durability of Concrete Made With Different Cements PDFTran Huynh NamNo ratings yet

- Effect of RHA On High Strength Concrete PDFDocument6 pagesEffect of RHA On High Strength Concrete PDFTran Huynh NamNo ratings yet

- Application of RHA Pozzolanic Properties in The Making of CEB PDFDocument5 pagesApplication of RHA Pozzolanic Properties in The Making of CEB PDFTran Huynh NamNo ratings yet

- 21 2167 Review Am0603 157 165Document9 pages21 2167 Review Am0603 157 165Bart Lucena Jr.No ratings yet

- Role of aggregate type in determining concrete durability when reducing cement contentDocument14 pagesRole of aggregate type in determining concrete durability when reducing cement contentTran Huynh NamNo ratings yet

- Fresh Concrete - Workability PDFDocument31 pagesFresh Concrete - Workability PDFTran Huynh Nam100% (1)

- Role of Cement Content in Specification For Concrete Durability - Cement Type Influence PDFDocument15 pagesRole of Cement Content in Specification For Concrete Durability - Cement Type Influence PDFTran Huynh NamNo ratings yet

- Ds FlowserveDocument5 pagesDs FlowservejmeleNo ratings yet

- Name of Project: Structure Parcel OfficeDocument31 pagesName of Project: Structure Parcel Officemohan sundarNo ratings yet

- 4ftbsys Professional BrochureDocument12 pages4ftbsys Professional Brochure4ftbsysNo ratings yet

- SOPs To Work Maunal 2019 20 March 2019 PDFDocument274 pagesSOPs To Work Maunal 2019 20 March 2019 PDFAbhishek Choudhary100% (5)

- Illium Alloy 8 For Non-Galling, Corosion-Resistant Alloy SolutionsDocument2 pagesIllium Alloy 8 For Non-Galling, Corosion-Resistant Alloy Solutionsdouglas guedezNo ratings yet

- Effect of Floating Column On RCC Building With and Without Infill Wall Subjected Seismic ForceDocument7 pagesEffect of Floating Column On RCC Building With and Without Infill Wall Subjected Seismic ForceChime MornNo ratings yet

- Biax For Ms Windows: Strength Analysis of Reinforced Concrete SectionsDocument51 pagesBiax For Ms Windows: Strength Analysis of Reinforced Concrete SectionsEdisson Alberto Moscoso AlcantaraNo ratings yet

- 3152-3162 Draper HeaderDocument1,027 pages3152-3162 Draper HeaderBifehNo ratings yet

- Shear and Moment Diagrams for Structural FramesDocument2 pagesShear and Moment Diagrams for Structural FramesAndrei AlidoNo ratings yet

- Astm D3163 01 2023Document2 pagesAstm D3163 01 2023Georgiy MakedonovNo ratings yet

- Áfico de Correlación Del Martillo Schmidt Miller 1965 PDFDocument1 pageÁfico de Correlación Del Martillo Schmidt Miller 1965 PDFalexanderNo ratings yet

- Remanufactured Air Compressors 1-1Document48 pagesRemanufactured Air Compressors 1-1J Alberto P ArrazateNo ratings yet

- Boq FormatDocument9 pagesBoq FormatRoshan KaluarachchiNo ratings yet

- NBC ChecklistDocument24 pagesNBC ChecklistagarNo ratings yet

- Guide To Low Voltage Panel SeparationDocument6 pagesGuide To Low Voltage Panel SeparationMarkNo ratings yet

- Resume of Coolb215Document1 pageResume of Coolb215api-25059817No ratings yet

- Finned Tube Heat ExchangerDocument1 pageFinned Tube Heat ExchangerDinesh ScientificNo ratings yet

- A-Civl Foundation For 1 Compressor Package DWG#18337-FSL, 18337-FD1/2/3/4Document3 pagesA-Civl Foundation For 1 Compressor Package DWG#18337-FSL, 18337-FD1/2/3/4Current AffairsNo ratings yet

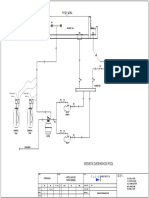

- Kids pool diagram schematic overviewDocument1 pageKids pool diagram schematic overviewHarta Dwi AsmanaNo ratings yet

- CIVL372 Lecture1Document47 pagesCIVL372 Lecture1M MNo ratings yet