Professional Documents

Culture Documents

Effect of The Size of Austenite Grains On The Capacity of Low-Carbon Martensitic Steel 12Kh2G2Nmft For Nitriding

Uploaded by

Sinhro018Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effect of The Size of Austenite Grains On The Capacity of Low-Carbon Martensitic Steel 12Kh2G2Nmft For Nitriding

Uploaded by

Sinhro018Copyright:

Available Formats

Metal Science and Heat Treatment, Vol. 52, Nos. 11 12, March, 2011 (Russian Original Nos.

. 11 12, November December, 2010)

UDC 669.15-194.55/621.785.532

EFFECT OF THE SIZE OF AUSTENITE GRAINS ON THE CAPACITY

OF LOW-CARBON MARTENSITIC STEEL 12Kh2G2NMFT FOR NITRIDING

O. V. Silina1 and S. S. Yugai1

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 11, pp. 57 61, November, 2010.

The department of metals science and heat treatment of the Perm State Engineering University actively works

on the problem of dispersion of low-carbon martensitic steels with ultrafine grains and a nanometric size of

the characteristic element of structure. It is shown that the highest efficiency of nitriding of this group of steels

is attained when the formed structure has a high density of phase boundaries and an elevated content of imperfections of the crystal structure.

Key words: low-carbon martensitic steels, refinement of austenite grains, nitriding, structure, properties.

Studies performed in the recent years [1, 2] show that

LCMS are promising structural materials for making welded

constructions and machine parts strengthened by heat and

thermochemical treatment. LCMS possess a high set of mechanical and process characteristics unattained in steels of

other classes. Specific combinations of carbon and alloying

elements provide a high stability of supercooled austenite,

which makes it possible to harden LCMS articles with cross

sections up to 1500 mm in size in air. The low stresses and

the low volume effect permit the use of LCMS in a hardened

state with strength sr of up to 1500 MPa.

The perspectives of the use of LCMS for parts subjected

to nitriding are shown in [3]. It is expedient to nitride LCMS

in a hardened condition (with structure of low-carbon

martensite). This eliminates preliminary heat treatment and

the accompanying additional thermal operations and reduces

the duration of the nitriding. The best results have been obtained for the LCMS complexly alloyed with vanadium and

titanium. However, despite the high operating characteristics

of the hardened layer, nitrided steels including LCMS ones

are inferior to carburized steels where the strength characteristics of the core are concerned. For this reason and due to

the low thickness of the nitrided layer a source of fatigue

fracture lies close to the surface, which lowers the fatigue resistance of the metal.

The results of a study of the effect of grain boundaries on

the diffusion of interstitial impurities allow us to judge on the

effect of the grain size of austenite on the processes of diffusion saturation of low-carbon martensitic steels with nitrogen.

INTRODUCTION

The processibility of structural steels determines the

method of production of parts (the number and succession of

mechanical operations) and the degree of complexity of the

hardening heat treatment for forming the final combination

of the characteristics of mechanical properties and for providing precision of the parts.

Various kinds of heat and thermochemical treatment

(TCT) are used to raise the working capacity of parts serving

under conditions of wear, corrosion, and contact and fatigue

loads.

The main kinds of TCT improving the hardness, wear resistance, and contact endurance are carburizing and nitriding.

Carburized materials are most often low-carbon structural

steels (12KhN3A, 20Kh, etc.) and nitrided materials are preferentially medium-carbon heat treatable steels of type

38Kh2MYuA.

Virtually any nitrided heat-treatable steel is characterized

by low processibility. The great number of preliminary heat

treatment and auxiliary operations, the high hardening temperatures, the large tolerances for mechanical processing,

and the durable nitriding process complicate the production

of parts and increase their cost and probability of rejection.

For this reason, it is important to develop and install new

manufacture-adaptable steels that would simplify considerably the production of parts and lower their cost. A new class

of materials, i.e., low-carbon martensitic steels (LCMS),

meets these requirements.

1

Perm State Engineering University, Perm, Russia (e-mail:

jugaj@do.pstu.ru).

568

0026-0673/11/1112-0568 2011 Springer Science + Business Media, Inc.

Effect of the Size of Austenite Grains on the Capacity of Steel 12Kh2G2NMFT for Nitriding

Since the diffusion of nitrogen atoms primarily occurs

over grain boundaries (high- and low-angle ones) and grain

bodies, we may expect that the structure of surface layers after nitriding should differ.

Thus, it would be interesting and expedient for solving

the task of raising the structural strength of nitrided low-carbon martensitic steels to study the special features of saturation of the surface of steels with nitrogen as a function of the

grain size of the austenite.

In the present work we posed a task to study the effect of

the grain size of austenite on the structure and properties of

nitrided low-carbon martensitic steel 12Kh2G2NMFT.

569

50 mm

50 mm

50 mm

METHODS OF STUDY

We studied an LCMS of grade 12Kh2G2NMFT with the

following chemical composition (in wt.%): 0.13 C, 2.24 Mn,

0.40 Si, 2.39 Cr, 1.38 Ni, 0.45 Mo, 0.10 V, 0.03 Ti.

Steel 12Kh2G2NMFT belongs to the group of LCMS

with elevated strength. The specific combination of carbon

and alloying elements provides a high stability of supercooled austenite and hence a high hardenability. Complex alloying with strong carbide-forming elements (vanadium and

titanium) makes it possible to preserve fine grains after heating and to raise the tempering resistance of the steel.

The initial preforms had the form of a hot-rolled sheet

with a thickness of 6 mm. Specimens for the study were fabricated with a size of 5 10 25 mm and 5 10 55 mm.

The volume and surface heat treatment was performed

under laboratory and industrial conditions.

In order to determine the effect of the grain size of austenite on the capacity of steel 12Kh2G2NMFT for nitriding

we used specimens treated in three modes:

(1 ) hardening from the rolling temperature (hot-rolled

condition);

(2 ) hardening from t = 1200C, t = 40 sec;

(3 ) thermocycling at t = 1030C, t = 20 sec, water cooling, 5 cycles.

Gas furnace nitriding was performed in a hardened state

at 560C, 30 h, in an atmosphere of ammonia diluted with nitrogen (20 30% NH3 ).

After the nitriding we measured the hardness of the surface and of the core of the specimens and determined the

thickness of the nitrided layer and the distribution of microhardness over the thickness of the diffusion zone. In addition,

we evaluated the brittleness of the surface of the nitrided

layer, performed x-ray phase and diffraction analyses, and

determined the characteristics of mechanical properties.

RESULTS AND DISCUSSION

After hardening from the rolling temperature, hardening

from 1200C, and thermocycling the structure of the specimens was represented by low-carbon martensite with grain

size d = 15 mm, d = 70 mm, and d = 2 mm, respectively. In

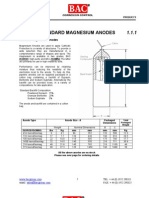

Fig. 1. Microstructure of the core of low-carbon martensitic steel

12Kh2G2NMFT after treatment by different regimes: a) hot-rolled

condition; b ) hardening from 1200C for 40 min; c) thermocycling

at 1030C, 20 sec, 5 cycles.

hardened condition (modes 1 and 2 ) the structure of the core

of the LCMS is represented by typical lath martensite with a

high dislocation density. The differences concern only the

sizes of the packets and the content of the high- and low-angle boundaries (Fig. 1a and b ). The structure of the core is

represented by a partially preserved substructure of martensite known as block one (Fig. 1c ).

Since any LCMS is nitrided with an initially martensitic

structure, the core acquires the final properties after nitriding

at 560C for 30 h.

A stable micro- and submicrostructure is preserved in

LCMS up to 500 550C. Above 550 600C the strength

characteristics decrease as a result of decrease in the density

of crystal structure defects and cell formation in the a-phase.

570

O. V. Silina and S. S. Yugai

Fig. 2. Microstructure of steel 12Kh2G2NMFT ( 40,000): a) hardening from 1200C, 40 min; b ) hardening + tempering at 560C,

30 h.

The low content of carbon and the complex alloying with

elements hindering the recrystallization processes promote

preservation of the structure of low-carbon martensite up to

high tempering temperatures (Fig. 2).

Table 1 presents the properties of steel 12Kh2G2NMFT

after treatment by the chosen regimes and nitriding.

In the process of nitriding at 560C the hardness of the

metal decreases by about 10 HRC. This may be connected

with segregation of carbides, lowering of the dislocation density, and redistribution of dislocations. The lath structure of

martensite is preserved and provides a high resistance to brittle fracture.

It can be seen from Table 1 that as the size of the austenite grains increases, the impact toughness becomes lower; at

standard (15 mm) and large (70 mm) grain sizes it is twice

lower than in the case of ultrafine grains (2 mm). This may

imply that the LCMS with ultrafine grains are much more

advantageous than the LCMS with grain size d = 15 mm.

Thus, after nitriding of steel 12Kh2G2NMFT the core

preserves a structure of low-carbon martensite, which may

be a sign of a high tempering resistance of the LCMS.

In traditional nitrided steels formation of a nitrided layer

with a nitride net is a result of dominant diffusion of nitrogen

over boundaries of former austenite grains and of the presence of a strong carbide former, i.e., aluminum, which promotes formation of nitrides on the boundary. In steel

12Kh2G2NMFT a net is not formed, because aluminum is

not present in the composition, and the highly defective crystal structure provides a more uniform diffusion of nitrogen.

Nonbrittle layers form on steel 12Kh2NMFT (one scale division according to the VIAM scale).

Since the diffusion of nitrogen atoms develops over

boundaries (high- and low-angle ones) and over the bodies of

grains, we may expect differences in the structure of nitrided

layers after nitriding.

After nitriding of specimens hardened from the temperature of rolling (Fig. 3a ) we observe well manifested division

of the diffusion layer into two parts at a standard grain size

d = 15 mm, i.e., a thin nitride crust (about 15 mm) and a zone

of internal nitriding (ZIN) The ZIN has a homogeneous

structure, because the high degree of defectiveness of the

crystal structure of martensite results in uniform diffusion of

nitrogen from the surface to the core; the nitrides are distributed uniformly over the whole of the volume of the layer.

After nitriding of specimens hardened from 1200C

(Fig. 3b ) at grain size d = 70 mm, the nitride crust is thicker

(about 20 mm) and the diffusion layer is not so deep and homogeneous. Near the nitride crust we observe iron nitrides

(of type Fe4N) that have the form of elongated inclusions

over boundaries of packets and former austenite grains. It

can be assumed that at specific high loads these elongated nitrides can behave as a nitride net in traditional heat-treatable

nitrided steels, break, and play the role of an abrasive, which

lowers the wear resistance of the surface.

After nitriding of specimens subjected to thermocycling

(Fig. 3c ) at grain size d = 2 mm a nitride crust is also present,

but its boundary with the ZIN is more smeared than in the

metal with initially coarse grains. The dark-etching zone near

the crust is a sign of an elevated concentration of nitrogen,

which is responsible for intense formation of nitrides. The

zone of internal nitriding has a homogeneous dispersed

structure. When the thickness of the diffusion layer increases, the concentration of nitrogen decreases and the hardness becomes lower.

We judged on the presence of dispersed nitrides of alloying elements not detected by x-ray diffraction analyses using

published data [4] and indirectly, i.e., by enhanced etching

and high growth in the hardness of the nitrided layer.

The distribution of microhardness over the thickness of

nitrided layer in specimens with different gain sizes is presented in Fig. 4. Table 2 presents the values of surface hardness and the effective thickness of nitrided layers as a func-

TABLE 1. Properties and Structure of the Core of Steel 12Kh2G2NMFT

Core hardness, HRC

Preliminary heat treatment

Size of austenite grains,

mm

prior to

nitriding

after

nitriding

Hardening from the rolling temperature (hot-rolled state)

Hardening at t = 1200C, t = 40 min

Thermocycling at t = 1030C, t = 20 sec, 5 cycles

15

70

2

40

39

40

29

27

27

KCT,

MJ/m2

0.5

0.4

0.9

Effect of the Size of Austenite Grains on the Capacity of Steel 12Kh2G2NMFT for Nitriding

571

HV, kgf/mm2

1200

1000

800

70

600

15

HVeff

400

200

0.1

0.2

0.3

0.4

0.5

0.6

0.1 mm

0.7

0.8

l, mm

Fig. 4. Microhardness distribution in depth of the diffusion layer on

steel specimen 12Kh2G2NMFT with different austenite grain size

(indicated for each curve, mm).

0.1 mm

0.1 mm

Fig. 3. Microstructure of nitrided layers on steel 12Kh2G2NMFT

after different variants of treatment: a) hot-rolled condition; b ) hardening from 1200C, 40 min; c) thermocycling at 1030C, 20 sec,

5 cycles.

tion of the regimes of preliminary (prior to nitriding) heat

treatment.

The distribution of microhardness over the thickness of

the nitrided layer in the steel with grain size d = 15 mm is

smooth and exhibits no marked change. Up to a depth of

about 0.35 mm the hardness of this layer is lower than the

hardness of the layer in the steels with grain sizes d = 70 mm

and d = 2 mm. At a distance of about 25 mm from the surface

the hardness of the metal with fine and coarse grains is

200 HV. This is a result of the difference in the concentration

of nitrogen at this depth due to the higher diffusion over

large-angle boundaries, which causes formation of a high

amount of nitrides strengthening the layer. Nitrides of type

Me4N formed near the nitride crust and nitrides of the alloying elements of the steel with grain size d = 70 mm raise the

hardness of the layer but simultaneously hinder the inflow of

nitrogen atoms into the depth of the metal. As a consequence, the layer is not so homogeneous and deep. However,

when the thickness of the layer increases, the hardness values

are leveled; at a distance of 0.4 mm from the surface the

hardness of the layer of the steel with grain size d = 15 mm

increases.

The maximum microhardness of the surface of diffusion

layer is higher in the steel with grain size d = 2 mm. At a distance of 0.4 mm from the surface the hardness of the layers

in the steels with d = 70 mm and d = 2 mm is virtually the

same.

The highest effective thickness of nitrided layer

(h = 0.5 mm) is exhibited by the LCMS with grain size

d = 15 mm, which is 0.1 mm greater than the thickness of the

layers in the steels with initially coarse and fine grains

(h = 0.4 mm).

Thus, nitriding of LCMS with initially ultrafine and initially coarse grains increases the surface hardness (which

seems to be a result of a higher nitrogen concentration) and

decreases somewhat the effective thickness of the diffusion

layer. However, the metal with initially coarse grains has a

higher brittleness (2 3 divisions of the VIAM scale).

TABLE 2. Properties of Nitrided Layer on Steel 12Kh2G2NMFT

Preliminary heat treatment

Hardening from the rolling temperature (hot-rolled state)

Hardening from t = 1200C,

t = 40 min

Thermocycling at t = 1030C,

t = 20 sec, 5 cycles

Austenite

grain size, mm

HRA

heff , mm

15

82

0.5

70

84

0.4

84

0.4

572

It is known [5] that nitriding of low-carbon martensite

causes growth in the effective thickness of the layer (as compared to traditionally nitrided steels) due to the higher density of crystal structure imperfections and more extended

boundaries of grains and packets. Large-angle boundaries are

more preferable regions for diffusion of nitrogen atoms [6].

When the grain size decreases, the extent of the grain boundaries grows. When the grain size increases, the extent of the

boundaries of former austenite grains decreases but that of

the packet boundaries grows. In the case of fine grains the

density of the grain boundaries is high; when the grains are

coarse, so is the density of the packet boundaries.

It should be noted that dislocation tubes are effective

elements of mass transfer. X-ray diffraction analysis shows

that the dislocation density decreases by an order of magnitude upon formation of coarse or ultrafine grains. This causes

lowering of the rate of diffusion of nitrogen into the depth of

the metal and explains formation of less deep layers.

Thus, the size of the austenite grains affects formation of

diffusion layer in the process of nitrogen saturation.

Nitriding of LCMS with coarse and ultrafine grains causes

decrease in the effective thickness of the layer, but at the

same time increases the surface hardness due to the higher

concentration of nitrogen.

CONCLUSIONS

1. Nitriding of steel 12Kh2G2NMFT yields hard surface

layers as a result of dispersion of the structure of low-carbon

martensite but lowers the thickness of the diffusion layer due

to reduction of the dislocation density.

O. V. Silina and S. S. Yugai

2. A coarse-grained structure in the steel also provides

formation of hard surface layers with elevated brittleness due

to the appearance of acicular nitrides but simultaneously

preserves an elevated impact toughness of the core.

3. An optimum combination of properties on the surface

and in the core of steel 12Kh2G2NMFT is provided by a

structure with a mean size of austenite grains equal to 15 mm;

in the case of such a structure the layers are deeper and the

set of mechanical properties of the core is high.

REFERENCES

1. L. M. Kleiner and A. A. Shatsov, Novel Structural Materials:

Low-Carbon Martensitic and Powder Steels. Applied Metals Science, A Study Aid [in Russian], Perm Gos. Tekh. Univ., Perm

(2004), 142 p.

2. N. N. Mitrokhovich, Yu. N. Simonov, L. M. Kleiner, et al.,

Processibility and Structural Strength of Low-Carbon Steels with

Martensitic Structure [in Russian], A Study Aid, Perm Gos.

Tekh. Univ., Perm (2004), 123 p.

3. L. M. Kleiner, S. A. Kokovyakina, N. N. Mitrokhovich, et al.,

Ecologically Pure Processes for Manufacturing Heat-Hardened

Semiproducts, Preforms, Parts, and Welded Structures [in Russian], A Study Aid, Perm Gos. Tekh. Univ., Perm (2000), 41 p.

4. Yu. M. Lakhtin and Ya. D. Kogan, Nitrided Steels [in Russian],

Mashinostroenie, Moscow (1976), 256 p.

5. S. S. Yugai, L. M. Kleiner, and A. A. Shatsov, Structure

and properties of nitrided low-carbon martensitic steel

12Kh2G2NMFT, Fiz. Met. Metalloved., 99(1), 110 115

(2005).

6. Yu. M. Lakhtin, Ya. D. Kogan, H. J. Spies, and Z. Bmer, The

Theory and Technology of Nitriding [in Russian], Metallurgiya,

Moscow (1991), 320 p.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Designing of Manual Workstation Structure With Emphasis On ErgonomicsDocument6 pagesDesigning of Manual Workstation Structure With Emphasis On ErgonomicsSinhro018No ratings yet

- HF Tools Beta200Document45 pagesHF Tools Beta200Sinhro018No ratings yet

- 207 213Document7 pages207 213Sinhro018No ratings yet

- High-strength steel composition and heat treatmentDocument1 pageHigh-strength steel composition and heat treatmentSinhro018No ratings yet

- O, O4 (O, 15,2 3.1to.141 +M.C+MC+L /+M-'C,: C TCR I Mo - !L VZNB, 0.O51O.2 L O, O 3.O O.,,, ÷Document4 pagesO, O4 (O, 15,2 3.1to.141 +M.C+MC+L /+M-'C,: C TCR I Mo - !L VZNB, 0.O51O.2 L O, O 3.O O.,,, ÷Sinhro018No ratings yet

- Stainless Steels: Corrosion-Resistant Steels For Force-Measuring Elastic MembersDocument5 pagesStainless Steels: Corrosion-Resistant Steels For Force-Measuring Elastic MembersSinhro018No ratings yet

- Theory: - (R) DR, DR I T+ I C 2 (R) T - 3)Document3 pagesTheory: - (R) DR, DR I T+ I C 2 (R) T - 3)Sinhro018No ratings yet

- Lift Line TheoryDocument19 pagesLift Line TheoryMuzakkir Sharieff100% (1)

- Read MeDocument1 pageRead MeSinhro018No ratings yet

- 42 44Document3 pages42 44Sinhro018No ratings yet

- 675 676Document2 pages675 676Sinhro018No ratings yet

- CorrespondenceDocument7 pagesCorrespondenceSinhro018No ratings yet

- Cracking of Welded Joints of Cast and Deformed Titanium Alloy Vt5Document5 pagesCracking of Welded Joints of Cast and Deformed Titanium Alloy Vt5Sinhro018No ratings yet

- Litx Oo :, Al/L .V'I 1 I/Lgd "1 L - JDocument6 pagesLitx Oo :, Al/L .V'I 1 I/Lgd "1 L - JSinhro018No ratings yet

- Simulation of The Kinetics of Circulation Aluminizing of Nickel and Nickel-Base AlloysDocument3 pagesSimulation of The Kinetics of Circulation Aluminizing of Nickel and Nickel-Base AlloysSinhro018No ratings yet

- Methods of Testing: A Study of Coatings On High-Temperature Nickel Alloys by The Potentiodynamic MethodDocument5 pagesMethods of Testing: A Study of Coatings On High-Temperature Nickel Alloys by The Potentiodynamic MethodSinhro018No ratings yet

- Rapid Induction Heat Treatment of Articles From Plain and Low-Alloy Low-Carbon and Medium-Carbon SteelsDocument4 pagesRapid Induction Heat Treatment of Articles From Plain and Low-Alloy Low-Carbon and Medium-Carbon SteelsSinhro018No ratings yet

- Fatigue Curve For SCM440Document6 pagesFatigue Curve For SCM440Nagaraj RaoNo ratings yet

- Structural Steels: Structure and Properties of High-Carbon Steel Cast PelletsDocument4 pagesStructural Steels: Structure and Properties of High-Carbon Steel Cast PelletsSinhro018No ratings yet

- Corrosion-Resistant SteelsDocument5 pagesCorrosion-Resistant SteelsSinhro018No ratings yet

- Mechanohydrogen Treatment of Titanium Alloys With Rough TurningDocument4 pagesMechanohydrogen Treatment of Titanium Alloys With Rough TurningSinhro018No ratings yet

- ObituaryDocument1 pageObituarySinhro018No ratings yet

- Ductile-Brittle Transition in Steels at Near-Solidus TemperaturesDocument12 pagesDuctile-Brittle Transition in Steels at Near-Solidus TemperaturesSinhro018No ratings yet

- 280 283Document4 pages280 283Sinhro018No ratings yet

- Structure Formation in Ferrous Alloys. Nonequilibrium StructuresDocument9 pagesStructure Formation in Ferrous Alloys. Nonequilibrium StructuresSinhro018No ratings yet

- 5 8Document4 pages5 8Sinhro018No ratings yet

- Magnesium and Titanium Alloys: Special Features of The Structure and Phase Composition of Magnesium Alloy Ma20Document4 pagesMagnesium and Titanium Alloys: Special Features of The Structure and Phase Composition of Magnesium Alloy Ma20Sinhro018No ratings yet

- 143 145Document3 pages143 145Sinhro018No ratings yet

- Strain and FractureDocument6 pagesStrain and FractureSinhro018No ratings yet

- Chemicothermal Treatment: LimitDocument5 pagesChemicothermal Treatment: LimitSinhro018No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Metcon 2013 Conference Program Final 10.09.13Document4 pagesMetcon 2013 Conference Program Final 10.09.13ZeejnANo ratings yet

- Question Paper For Snr. WeldingDocument3 pagesQuestion Paper For Snr. WeldingThulasi Ram100% (1)

- Ni Energy ConsumptionDocument10 pagesNi Energy ConsumptionjokanovNo ratings yet

- Extractive Metallurgy of Nickel PDFDocument2 pagesExtractive Metallurgy of Nickel PDFJohnNo ratings yet

- Effect of Preheating and Stress Relief on ASTM A516 Gr. 70 SteelDocument3 pagesEffect of Preheating and Stress Relief on ASTM A516 Gr. 70 SteelLalit ModiNo ratings yet

- Metal Casting Process Types & Design GuidelinesDocument71 pagesMetal Casting Process Types & Design GuidelinesVijay Pawar100% (2)

- Analysis of Mechanical Properties of Aluminium Based Metal Matrix Composites Reinforced With SIC and Alumina A ReviewDocument5 pagesAnalysis of Mechanical Properties of Aluminium Based Metal Matrix Composites Reinforced With SIC and Alumina A ReviewInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- CMI Extractive Metallurgy ServicesDocument46 pagesCMI Extractive Metallurgy ServicesAbdullah SalemNo ratings yet

- Bas CatDocument31 pagesBas Catanwer_ahsanNo ratings yet

- 1.1.1 ISOLINE MG Anode StandardDocument2 pages1.1.1 ISOLINE MG Anode StandardJaka SembungNo ratings yet

- Crystal Structures of Solid StateDocument26 pagesCrystal Structures of Solid StaternsseturajNo ratings yet

- Periodic Table of Elements and X-Ray Energies: Innovation With IntegrityDocument2 pagesPeriodic Table of Elements and X-Ray Energies: Innovation With Integritystudentbrn100% (1)

- Kaolin Densities PDFDocument4 pagesKaolin Densities PDFalenocitoNo ratings yet

- 1.4462 Duplex PropertiesDocument2 pages1.4462 Duplex PropertiesEROL30No ratings yet

- Wire BrochureandBulletinsDocument204 pagesWire BrochureandBulletinsarturoNo ratings yet

- El Desastre de La Plataforma Alexanter KieallandDocument9 pagesEl Desastre de La Plataforma Alexanter Kieallandcarrysis2No ratings yet

- The Porphyry Copper Deposit at El Salvador Chile L.gustAFSON, J.huntDocument57 pagesThe Porphyry Copper Deposit at El Salvador Chile L.gustAFSON, J.huntDánisa Urrutia ContrerasNo ratings yet

- Aluminio BRONMETAL enDocument12 pagesAluminio BRONMETAL enPerica RakićNo ratings yet

- Chemistry Project AliDocument21 pagesChemistry Project AliWajahat AliNo ratings yet

- Dorian Tool Guide No 4Document72 pagesDorian Tool Guide No 4Arifin DzulkarnainNo ratings yet

- Classification of Mineral Deposits TypesDocument5 pagesClassification of Mineral Deposits TypesJustin HernandezNo ratings yet

- Corrosion ScienceDocument18 pagesCorrosion SciencePrem NautiyalNo ratings yet

- Design For Corrosion Resistance: Uniform AttackDocument11 pagesDesign For Corrosion Resistance: Uniform AttackIndra PradanaNo ratings yet

- 11.2 Studies On PH 13-8 Mo SteelDocument2 pages11.2 Studies On PH 13-8 Mo Steelfantasy373No ratings yet

- LateriteDocument2 pagesLateriteadinbenzNo ratings yet

- Giant Magnetic-Field-Induced Strain in NiMnGa Seven-Layered Martensitic Phase PDFDocument4 pagesGiant Magnetic-Field-Induced Strain in NiMnGa Seven-Layered Martensitic Phase PDFEclys MontenegroNo ratings yet

- Applications of Crystal DefectsDocument2 pagesApplications of Crystal Defectskrish_cvr2937No ratings yet

- Extraction Metallurgy StudentDocument132 pagesExtraction Metallurgy StudentJoaquin Jose Abarca Rodriguez100% (1)

- Tool Steels GuideDocument44 pagesTool Steels Guidesmani17083% (6)

- Key Concepts in Welding Engineering: Postweld Heat Treatment (PWHTDocument2 pagesKey Concepts in Welding Engineering: Postweld Heat Treatment (PWHTsridharchebrolu100% (2)