Professional Documents

Culture Documents

Garg, Aamod. 'Gantry Girders in India'

Uploaded by

Aamod GargCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Garg, Aamod. 'Gantry Girders in India'

Uploaded by

Aamod GargCopyright:

Available Formats

International Journal of Civil, Mechanical and Energy Science (IJCMES)

Infogain Publication (Infogainpublication.com)

[Vol-2, Issue-6, Nov-Dec, 2016]

ISSN : 2455-5304

Gantry Girders in India

Aamod Garg1

1

Undergraduate Student, Department of Civil Engineering, MNNIT, Allahabad, India-211004

Email: aamodgarg1994@gmail.com

Abstract In India, industries usually have quality

range of gantry girders for industrial sheds. Assisted by

skilled workers in India, companies have been able to

successfully grow towards the zenith, but there is still

minor margin remaining which can be achieved by

optimally designing the gantry girder in an economic as

well as efficient manner. For this purpose, it is essential

to implement the procedure for model, design, analyze

and validate the girder efficiently.

Keywords Automated Beam, Built-Up Section, Crane

Girder, Gantry Girder, Lateral Load, Vertical Load.

1. Introduction

Majority of the industrial buildings in India have built-in

overhead cranes for handling heavy equipment or goods.

With the help of the overhead cranes, heavy equipment or

goods can be lifted and moved from one point of work

place to another. The cranes may be hand operated

(generally they have a capacity of up to 2 tonnes) and

electrically operated (EOT). A typical EOT crane system

is shown in Fig. 1 and Fig. 2.

Since India has an expanding construction

potential, there is rising need for gantry girders with

higher capacity. For this purpose, the paper contributes

towards the modelling, analysis, design and checking of a

gantry girder with capacity of 300 kilonewtons.

1.1. Design Element of Girders

The complete design of a gantry girder consists of the

following elements:

Fig. 1: Elevation of EOT crane

www.ijcmes.com

Fig. 2: Plan of EOT crane

i)

Calculation of external loads and

estimation of self-weight

ii) Calculation of shear force and bending moment

iii) Selection of girder section by trial and error

iv) Design of girder section

v) Design of web and flange

vi) Design of connection

High quality range of composite-steel gantry girder

can be fabricated with the assistance of various IS codes

present in India. Superior quality material and latest

techniques are used to ensure that fabrication done is

accurate and up-to-the-mark. Fabrication process is

carried out in accordance with the prescribed quality

guidelines and norms. Besides, ensuring completion of

projects within the minimum possible time-period should

be targeted.

Composite girders manufactured are demanded in

ROBs and railway bridges. They are generally

manufactured in following sizes: Flange from 140mm to

1200mm, thickness 6mm to 80mm, web 180mm to

3000mm, thickness 6mm to 60mm and maximum length

20meters.

Composite steel gantry girders have following

advantages:

1) High capacity in shear, tension and compression,

2) Light weight,

3) Members are visible and thinner, factory made, which

helps us to predict the girders behavior in reasonable

manner.

Page | 1

International Journal of Civil, Mechanical and Energy Science (IJCMES)

Infogain Publication (Infogainpublication.com)

[Vol-2, Issue-6, Nov-Dec, 2016]

ISSN : 2455-5304

2. Numerical Problem

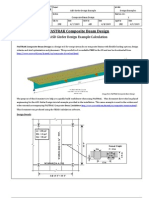

Design a Gantry Girder to be used in an industrial building carrying a Manually Operated Overhead Travelling Crane, for the

following data in Table 1:

Table 1: Data for Numerical Problem

Sr. No.

Crane Property

Magnitude

Crane Capacity

300 kN

1

Self-Weight of Crane Girder excluding Trolley

200 kN

2

Self-Weight of Trolley, Electric Motor, Hook, etc.

40 kN

3

Approximate Minimum Approach of Crane Hook to the Gantry Girder

1.20 m

4

Wheel Base

3.5 m

5

Centre-to-Centre Distance between Gantry Rails

18 m

6

Centre-to-Centre Distance between Columns (Span of Gantry Girder)

10 m

7

Self-Weight of Rail Section

300 N/m

8

Diameter of Crane Wheels

150 mm

9

Steel is of Grade Fe 410. Design also the field welded connection if required.

3. Solution

For Fe 410 grade of steel: fu = 410 MPa,

fy = fyw = fyf = 250 MPa

For hand-operated OT crane

Lateral loads = 5% of maximum static wheel load

Longitudinal loads = 5% of weight of crab and weight

lifted

Maximum permissible deflection = L/500

The crane will carry the self-weight as a uniformly

distributed load =

= 11.11 kN/m

Factored uniform load = 1.5 11.11 = 16.67 kN/m

For maximum reaction on the gantry girder the loads are

placed on the crane girder as shown in Fig. 2.

Taking moment about B,

RA 18 = 510 (18-1.2) +

Fig. 3: Maximum reaction on gantry girder

3.1. Partial safety factors

Load factor

crane =

= 313 kN

3.3 Maximum bending moment

m0 = 1.10

mw = 1.50 (for site welds)

m1 = 1.50

= w = y =

3.2.

or, RA = 626 kN

Similarly, RB = 184 kN

The reaction from the crane girder is distributed equally

on the two wheels at the end of the crane girder.

Therefore, maximum wheel load on each wheel of the

= 1.0

Design forces

Maximum wheel load:

Maximum concentrated load on crane=300 + 40 = 340 kN

Maximum factored load on crane = 1.5 340 = 510 kN

www.ijcmes.com

Fig. 4. Wheel configuration for max. bending

moment

Assume self weight of gantry girder as 2.2 kN/m.

For maximum bending moment, the wheel loads shall be

placed as shown in Fig. 4.

Total dead load = 2200 + 300 = 2500 N/m = 2.5 kN/m

Factored dead load = 1.5 2.5 = 3.75 kN/m

Page | 2

International Journal of Civil, Mechanical and Energy Science (IJCMES)

[Vol-2, Issue-6, Nov-Dec, 2016]

Infogain Publication (Infogainpublication.com)

ISSN : 2455-5304

Maximum reaction due to lateral forces at D by

The position of one wheel load from the midpoint of span

wheel base 3.5

proportion at C

=

=

= 0.875 m

4

4

=

Bending moment due to live load only:

Taking moment about D,

=

= 10.58 kN

RC 10 = 313 (10-2.375) + 313 4.125

RC = 367.78 kN

Horizontal reaction due to lateral force at D

= 25.50 10.58 = 14.92 kN

Taking moment about C,

Maximum bending due to lateral load by proportion

RD 10 = 313 2.375 + 313 5.875

=

1065.16 = 43.39 kNm

RC = 258.22 kN

Maximum bending moment due to live load

= 258.22 4.125

= 1065.16 kNm

Bending moment due to impact = 0.1 1065.16

= 106.52 kNm

Total bending moment due to live and impact loads

= 1065.16 + 106.52 = 1171.68 kNm

Maximum shear force due to lateral load by proportion

=

3.6

12.25 = 20.21 kN

Preliminary trial section

Approximate depth of section =

= 833.33 mm 800 mm

Bending moment due to dead load =

Approximate width of flange =

= 46.88 kNm

Therefore, maximum bending moment = 1171.68 + 46.88

= 1224.56 kNm

=1224.56 106 Nmm

= 333.33 mm 300 mm

Approximate section modulus required,

Zpz = 1.4

= 6857.5 103 mm3

We use ISMB 600 with additional plates (thickness = 20

mm and width = 320 mm) on both flanges as shown in

Fig. 6.

3.4 Maximum shear force

C

A

Fig. 5: Wheel configuration for maximum shear force

For maximum shear force, wheels are placed as shown in

Fig. 5.

Taking moment about D,

RC 10 = 313 10 + 313 6.5

RC = 516.45 kN

Hence maximum shear force due to wheel loads = 516.45

kNm

3.5 Lateral forces

Lateral force transverse to the rails = 5% of the weight of

crab and weight lifted = 0.05 340 = 17 kN

Factored lateral force = 1.5 17 = 25.5 kN

Lateral force on each wheel =

www.ijcmes.com

= 12.75 kN

Fig. 6: Beam with additional plates on top and bottom

The relevant properties from Steel Table are as follows:

Weight per metre (w) = 248.2 kg = 2434.8 N

Sectional Area (A) = 316.21 cm2

Mean thickness of flange (tw) = 38.6 mm

Extreme fibre Distance (exx) = 32.50 mm

Ixx = 248146.3 cm4

Iyy = 16304.3 cm4

Least radius of Gyration = 7.18 cm

Modulus of section = 7635.3 cm3

Page | 3

International Journal of Civil, Mechanical and Energy Science (IJCMES)

Infogain Publication (Infogainpublication.com)

3.7 Classification of Section

[Vol-2, Issue-6, Nov-Dec, 2016]

ISSN : 2455-5304

Non-dimensional slenderness ratio,

Outstand of flange of I-section (b) = bf / 2

= 210/2 = 105 mm

b/tf of flange of I-section = 105/20.8 = 5.05 < 8.64

The entire section is plastic. (b = 1.0)

LTz

= 0.97766

= 0.5[1 + LT(LTz 0.2) + 2 LTz ] = 1.05956

= 0.21

LTz

LT

LTz

= 0.81539

3.8 Check for moment capacity

Design bending compressive stress,

fbd =

/ m0 = 0.81539 250 / 1.10

Local moment capacity:

Mdz = b Zpz fy / m0 1.2 Ze fy / m0

3

Mdz = 1.0 8793.618 10

10

fbd = 185.318 N/mm2

-6

= 1998.55 kNm

Mdz < 1.2 7635.27 103

The design bending strength,

Mdz = b Zpz fbd = 1.0 8793.618 103 185.315 10-6

= 1629.596 kNm > 1224.56 kNm

which is alright.

Therefore, the gantry girder is safe under vertical loads.

10-6

< 2082.346 kNm

Hence, moment capacity of the section,

Mdz = 1998.55 kNm > 1224.56 kNm

Therefore, the trial section is safe by sufficient margin in

the moment capacity and can be checked for combination

of loads as laterally supported beam.

Moment capacity compression flange about y-axis,

Mdy = b Zpy fy / m0 1.2 Zey fy / m0

= 1.0 1759.491 103

10-6

= 439.87 kNm

< 1.2 101946 103

10-6 = 277.9 kNm

Hence, moment capacity of flange, Mdy = 277.9 kNm

3.9 Combined check for local moment capacity

3.11 Check for shear capacity

Maximum shear force due to wheel load = 516.45 kN

Impact load = 0.1 516.45 = 51.645 kN

(10%

wheel load)

Design shear force = 516.45 + 51.645 = 568.10 kN

Shear capacity =

of

= 944.754

kN > 568.10 kN

which is safe.

Maximum shear, V = 568.10 kN

< 576.85 kN (0.6Vd = 0.6 944.75 = 576.85 kN)

Since V is less than Vd , the case obtained is of low shear

and hence no reduction will be required in the moment

capacity.

1.0

3.12 Web-buckling check

0.7688 < 1.0

which is safe. Therefore, the gantry girder is safe.

3.10 Check for buckling resistance in bending

The elastic lateral-torsional buckling moment,

Mcr = c1

(1)

Overall depth of the section, hf = h = 600+50 = 650 mm

Effective length, LLT = 10 103 mm

Radius of gyration, ry =

= 71.81 mm

Thickness of flange, tt = 38.6 mm

Coefficient from codes, c1 = 1.046

Elastic modulus of steel, E = 2 105

Therefore using Formula 1: Mcr = 2299.96 106 Nmm

www.ijcmes.com

Web should be checked for buckling under the wheel

load.

Buckling resistance = (b1 + n1) tw fcd

b1 = bearing length = mm

(wheel diameter)

n1 = 600/2 + 225 = 350 mm

Slenderness ratio of the web, w = 2.45 d1 / tw = 107.065

For w = 107.065, fy = 250 N/mm2 and buckling curve c,

the design compressive strength from Table 9(c) of IS

800:2007 = 98.32 N/mm2

Buckling resistance = (150+350)1898.3210 -3

= 884.88kN > 313kN

which is safe. Therefore, the gantry girder is safe.

3.13 Deflection check

= WL3

Page | 4

International Journal of Civil, Mechanical and Energy Science (IJCMES)

Infogain Publication (Infogainpublication.com)

W = maximum static wheel load = 313 / 1.5 = 208.67 kN

a = (L-c)/2 = (10103 3.5103)/2 = 3250 mm

Vertical deflection = 208.67 103 (10103)3

= 14.67 mm

Permissible maximum deflection = L/500 = 20 mm

> 14.67 mm

which is safe. Therefore, the gantry girder is safe.

3.14 Design of connections

The required shear capacity of the weld, q =

V = 516.45 kN

A = 8000 mm2

(area above the section)

y1 = 325 25 = 300 mm

Iz = 248146.3 104 mm4

q=

= 500 N/mm

Let us provide a 5 mm weld size to connect plates with

flange of I-section.

Strength of weld provided =

= 552.33 N/mm

which is greater than 500 N/mm

Hence, provide 5 mm size fillet weld for making the

connection.

4. Result

Therefore, the gantry girder with crane capacity of 300

kN has been designed and has been checked as per the

codal provisions. Similar gantry girders can also be

designed with much higher capacities, with only change

in the selection of the girder cross section. Higher load

capacities can be achieved in India by selecting more

efficient girders. Such practices would lead to more

efficient operations in warehouses, industrial sheds,

shipyards and rail yards.

As a result of this, it was understood how a

complex steel structure is designed after expansive

planning. The usage of Indian Standard codes, other

codes and appropriate software was also understood.

5. Conclusion

Generally, it is argued as to how much load comes on

each bracket plate. If each plate was independent of its

neighbour, then either plate would, in turn, have to

support the entire reaction due to the crane and its load.

By using a diaphragm one side plate cannot deflect

without taking its neighbour with it. There is another

factor which is sometimes considered, and that is the

frequency of case of loading. It will be seldom that the

crane wheels will be called upon to carry the maximum

load with the crab drawn in tightly against the bracket.

The gantry girder is designed for the worst possible cases

if loading without consideration as to the laws of chance,

and to be consistent the vertical brackets should be

www.ijcmes.com

[Vol-2, Issue-6, Nov-Dec, 2016]

ISSN : 2455-5304

designed to meet the requirements of the maximum load.

Also, it is desirable to make the girders entirely selfsupporting in the adjacent aisles.

Currently research is being carried out to

ameliorate the vigor structure of overhead crane girder.

These incipient efforts avail to surmount overhead crane

girder failure. The girder is fortified on a felicitously

composed seat and it is withal connected to the column

near the top flange in each case in order to restrain it from

lateral bending and convoluting at the fortification point.

Material handling is a consequential practical

consideration in the design of incipient manufacturing and

distribution systems and research into better material

handling systems and practices is paramount. Material

handling uses different equipment and mechanisms. The

structure is designed as per Indian standard codes

Thus, gantry girders should be utilized in India on a

larger scale in order to maximize the output of industrial

operations.

6. References

[1] S K Duggal, Limit State Design of Steel Structures, 2nd ed.,

McGraw Gill Education, 2015, pp. 652-675.

[2] IS 800: 2007, Indian Standard General Construction In

Steel Code of Practice, 3rd ed., 2007.

[3] Birla Publications Pvt. Ltd., Steel Table, ISBN: 81-2560011-6, 17th ed., 2010.

[4] Chen X, Wu S and Zhou J, Compressive Strength of

Concrete Cores with Different Lengths, in Journals

Materials and Civil Engineering, 2014.

[5] Song W, Ma Z, Vadivelu J, Burdette E, Transfer Length

and Splitting Force Calculation for Pretension Concrete

Girders with High-Capacity Strands, in Journal of Bridge

Engineering, 2014.

[6] Hirol, Isami, Plate-Girder Construction, ISBN 978-0-55488802-6., 2008.

[7] Venkatesh, A., Vignesh, S., Iyappan, S., Vignesh Kumar,

P., Tamilvanan, G. and Vijaya Sarathy, R., Design of an

overhead plate gantry girder in International Journal of

Development Research, 2016.

[8] Camelia Bretotean Pinca, Gelu Ovidiu Tirian, Ana Josan,

Application of Finite Element Method to an Overhead

Crane Bridge, Issue 2, Volume 4, 2009.

[9] Dr. Pumnia, B.C. and Ashok Kumar Jain,. design of

steel structures, 1st September,1998.

[10] Euler, M. and Kuhlmann, U,.Crane runways Fatigue

evaluation of crane rail welds using local concepts", in

International Journal of Fatigue, 2011.

[11] Ozden Caglayan, Kadir Ozakgul, Ovunc Tezer, Erdogan

Uzgider, 2010. Fatigue life prediction of existing crane

runway girders", in Journal of Constructional Steel

Research, 2010.

[12] Ismail Gerdemeli, Serpil Kurt, Hasan Onur Alkan, "Main

girder beam design and finite element analysis of 2/160

gantry crane", in 14th International Research/Expert

Conference, Trends In The Development Of Machinery

and Associated Technology, 2010.

Page | 5

You might also like

- Garg, Aamod. 'Gantry Girders in India' - IJCMES PDFDocument5 pagesGarg, Aamod. 'Gantry Girders in India' - IJCMES PDFAamod GargNo ratings yet

- Gantry GirderDocument25 pagesGantry GirderYash DhabaliaNo ratings yet

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- Analytical Optimization of Chassis Frame PDFDocument9 pagesAnalytical Optimization of Chassis Frame PDFkus satria dNo ratings yet

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsFrom EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsNo ratings yet

- Gantry CraneDocument31 pagesGantry CraneWaheed Ahmad100% (1)

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- Gantry CraneDocument31 pagesGantry CraneWaheed AhmadNo ratings yet

- Gid 091 CV Cal 3070C PDFDocument9 pagesGid 091 CV Cal 3070C PDFmadhu100% (1)

- Gantry GirderDocument48 pagesGantry GirderVishnu SamyNo ratings yet

- Gantry CraneDocument18 pagesGantry Craneamirthraj7494% (16)

- Design of Gantry GirderDocument28 pagesDesign of Gantry Girders_bharathkumar75% (12)

- Unit-1 Vehicle Frame and SuspensionDocument41 pagesUnit-1 Vehicle Frame and SuspensionKrishna 1996No ratings yet

- Abutment DesignDocument10 pagesAbutment DesigndsureshcivilNo ratings yet

- Design of Through Type Plate GirderDocument9 pagesDesign of Through Type Plate GirderAnju Kl0% (1)

- Ebike Design ReportDocument15 pagesEbike Design ReportKanishka Mathur100% (1)

- Design of Gantry GirderDocument46 pagesDesign of Gantry GirderGOVINDARAJU SNo ratings yet

- Design and Development of Stair Climbing WheelchairDocument26 pagesDesign and Development of Stair Climbing WheelchairHemanthsrinivas ParasaramNo ratings yet

- Gantry GirderDocument12 pagesGantry GirderRakeshkumar T RNo ratings yet

- Bridge CH 5 Example On Slab BridgeDocument16 pagesBridge CH 5 Example On Slab BridgeHabhaile Asfaw83% (6)

- Neintitulat 1Document20 pagesNeintitulat 1Epure GabrielNo ratings yet

- Design of FlywheelDocument15 pagesDesign of FlywheelGujar SnehaNo ratings yet

- Team Screwdriver'S: Dhole Patil Collage of Engineering PuneDocument38 pagesTeam Screwdriver'S: Dhole Patil Collage of Engineering PuneAniket SankpalNo ratings yet

- Single Lane BridgesDocument55 pagesSingle Lane Bridgeshsword7No ratings yet

- Difference Beetween Is 800-2007 & Is 800-1984Document96 pagesDifference Beetween Is 800-2007 & Is 800-1984ayazmadNo ratings yet

- Design and Analysis of Ladder Frame Chassis Considering Support at Contact Region of Leaf Spring and Chassis FrameDocument9 pagesDesign and Analysis of Ladder Frame Chassis Considering Support at Contact Region of Leaf Spring and Chassis FrameInternational Organization of Scientific Research (IOSR)No ratings yet

- Philosophy of Limit State Design and Classification of SectionsDocument96 pagesPhilosophy of Limit State Design and Classification of Sectionsybm987100% (1)

- Customized Spring and Damper of An AtvDocument6 pagesCustomized Spring and Damper of An AtvIAEME PublicationNo ratings yet

- Crane Matress DesignDocument37 pagesCrane Matress DesignNilesh Kumar100% (1)

- AbaqusDocument9 pagesAbaqusAlfredo Soliz GamboaNo ratings yet

- k041203 7377 150114033728 Conversion Gate02 PDFDocument5 pagesk041203 7377 150114033728 Conversion Gate02 PDFdarkruseNo ratings yet

- Ijmet 08 01 016Document6 pagesIjmet 08 01 016Shri Hari .SNo ratings yet

- Suspension: ObjectivesDocument5 pagesSuspension: ObjectivesYathiraaj AmbureNo ratings yet

- 1984Document46 pages1984Praveen Kumar85% (13)

- Irjet V2i3314 PDFDocument8 pagesIrjet V2i3314 PDFVictor PeterNo ratings yet

- Gantry GirderDocument2 pagesGantry GirderSivaAgathamudiNo ratings yet

- Design of Grating For PlatformDocument5 pagesDesign of Grating For Platformvj8584100% (2)

- Quiz 6 Belt Conveyor IdlersDocument3 pagesQuiz 6 Belt Conveyor Idlersmuhammad anginNo ratings yet

- Design Verification CalculationsDocument15 pagesDesign Verification CalculationsKarthik KrNo ratings yet

- Tee Beam ProbDocument14 pagesTee Beam ProbSai GowthamNo ratings yet

- Design of Steel Structure (Chapter 2) by DR R BaskarDocument57 pagesDesign of Steel Structure (Chapter 2) by DR R Baskarelect aksNo ratings yet

- 2 Way Slab Design - 31 Jul 13Document111 pages2 Way Slab Design - 31 Jul 13Vance Kang100% (1)

- Simulation and Static Analysis of An Off-Road Vehicle Roll CageDocument8 pagesSimulation and Static Analysis of An Off-Road Vehicle Roll CageIJMERNo ratings yet

- Crane GirderDocument45 pagesCrane GirderbolarinwadeNo ratings yet

- Simulation of ATV Roll Cage TestingDocument5 pagesSimulation of ATV Roll Cage TestingIOSRjournalNo ratings yet

- Space Frame DesignDocument5 pagesSpace Frame DesignAmeer ShNo ratings yet

- Design and Analysis of Connecting Rod Using Forged Steel Report 31-08-2014 6.20 PM PDFDocument20 pagesDesign and Analysis of Connecting Rod Using Forged Steel Report 31-08-2014 6.20 PM PDFbalamech1230% (1)

- Machine Design CEPDocument8 pagesMachine Design CEPRizwan AkramNo ratings yet

- Design Example LRFD GirderDocument12 pagesDesign Example LRFD GirderEdward van Martino100% (1)

- Automech Report PDFDocument18 pagesAutomech Report PDFdheeraj choudharyNo ratings yet

- 1017 - 19.08m 9.4.14Document90 pages1017 - 19.08m 9.4.14ravi4paperNo ratings yet

- Design Example ASD GirderDocument12 pagesDesign Example ASD GirderEdward van MartinoNo ratings yet

- Design and Analysis of Transmission System For ATVDocument7 pagesDesign and Analysis of Transmission System For ATVIJRASETPublicationsNo ratings yet

- New Text DocumentDocument6 pagesNew Text DocumentsadsdNo ratings yet

- Limit State Design of Liquid Retaining SectionDocument6 pagesLimit State Design of Liquid Retaining Sectionarif_rubinNo ratings yet

- Local Housing Market Cycle and Loss Given Default: Evidence From Sub-Prime Residential MortgagesDocument30 pagesLocal Housing Market Cycle and Loss Given Default: Evidence From Sub-Prime Residential MortgagesAamod GargNo ratings yet

- Impact of Women Portrayal in BollywoodDocument32 pagesImpact of Women Portrayal in BollywoodAamod GargNo ratings yet

- Impactof Indian Cinemaoncultureandcreationofworldview Asciological NalysisofbollywoodmoviesDocument8 pagesImpactof Indian Cinemaoncultureandcreationofworldview Asciological NalysisofbollywoodmoviesAamod GargNo ratings yet

- WBSL-Site-Plan - Warner Brothers UKDocument1 pageWBSL-Site-Plan - Warner Brothers UKAamod GargNo ratings yet

- Strategies For Successful Software Development Risk ManagementDocument16 pagesStrategies For Successful Software Development Risk ManagementAamod GargNo ratings yet

- MKTG 466 - Syllabus Fall 2012Document18 pagesMKTG 466 - Syllabus Fall 2012Aamod GargNo ratings yet

- Accenture Energy Operations BP 25 Year Relationship InfographicDocument1 pageAccenture Energy Operations BP 25 Year Relationship InfographicAamod GargNo ratings yet

- Agile Architecture and DesignDocument52 pagesAgile Architecture and DesignAamod GargNo ratings yet

- 6 Methods of Data Collection PDFDocument30 pages6 Methods of Data Collection PDFKristine Agustin100% (4)

- Homework Problems On Differential EquationsDocument29 pagesHomework Problems On Differential EquationsAamod GargNo ratings yet

- Format For A Review Paper (Attach To F204)Document1 pageFormat For A Review Paper (Attach To F204)Ankita BhardwajNo ratings yet

- Electrical Model of Thermal Power PlantDocument81 pagesElectrical Model of Thermal Power PlantMahesh KumbharNo ratings yet

- Craftsman 73754 ManualDocument24 pagesCraftsman 73754 Manualjkchromy945No ratings yet

- Rail Mechanical PropertiesDocument46 pagesRail Mechanical PropertiesAGnes Stephani MuntheNo ratings yet

- Catalogo TiboxDocument5 pagesCatalogo Tiboxfabiola100% (1)

- Deep Bar and Double Cage 010223Document20 pagesDeep Bar and Double Cage 010223Debankan ChatterjeeNo ratings yet

- Top 10 Masturbation Tips From WomenDocument3 pagesTop 10 Masturbation Tips From WomengmeadesNo ratings yet

- Paver BlockDocument16 pagesPaver BlockRavinder Singh100% (1)

- Modelsim TutorialDocument26 pagesModelsim Tutorialsachinshetty001No ratings yet

- Electric Circuits 10th Edition Nilsson Solutions ManualDocument89 pagesElectric Circuits 10th Edition Nilsson Solutions ManualKimCoffeyjndf100% (41)

- Basics of CT and PTDocument15 pagesBasics of CT and PTanamika1690% (1)

- Company Names and Number UAEDocument35 pagesCompany Names and Number UAESoju Suresh100% (1)

- 1Z0 053 PDFDocument36 pages1Z0 053 PDFOscarRamirezNo ratings yet

- RE14092021Document2 pagesRE14092021francis puthuserilNo ratings yet

- Pdca Cycle Problem SolvedDocument3 pagesPdca Cycle Problem Solvedjose luisNo ratings yet

- Catalogo. Aparatos de Maniobra y Proteccion - Sirius. Siemens PDFDocument52 pagesCatalogo. Aparatos de Maniobra y Proteccion - Sirius. Siemens PDFPedro MalpicaNo ratings yet

- Positector Calibration ProcedureDocument6 pagesPositector Calibration ProcedureluigimasterNo ratings yet

- 3.re Situation in Suez Canal - M.V EVER GIVEN SUCCESSFULLY REFLOATEDDocument9 pages3.re Situation in Suez Canal - M.V EVER GIVEN SUCCESSFULLY REFLOATEDaungyinmoeNo ratings yet

- HRTEMDocument5 pagesHRTEMRajathi YadavNo ratings yet

- Relationship of EN 954-1 and IEC 61508 Standards PDFDocument2 pagesRelationship of EN 954-1 and IEC 61508 Standards PDFfitasmounirNo ratings yet

- Company ProfileDocument6 pagesCompany ProfileFaidzil ChabibNo ratings yet

- QC of Continuous Flight Auger PilesDocument1 pageQC of Continuous Flight Auger Pilesnischal_babuNo ratings yet

- Honda Gx200 Engine ManualDocument2 pagesHonda Gx200 Engine Manualgomes_marina930% (1)

- Actividad 1 Lorena GuerreroDocument4 pagesActividad 1 Lorena GuerreroAlfonso GutierrezNo ratings yet

- 82 To 88 CompleteDocument6 pages82 To 88 CompleteUmer KhanNo ratings yet

- Pacom S72724+PDR32-RMT-HYB+ManualDocument130 pagesPacom S72724+PDR32-RMT-HYB+ManualDavidChisholmNo ratings yet

- Histogram PorositasDocument2 pagesHistogram PorositasajnmboNo ratings yet

- Seismic Strengthening of Reinforced Concrete Columns With Straight Carbon Fibre Reinforced Polymer (CFRP) AnchorsDocument15 pagesSeismic Strengthening of Reinforced Concrete Columns With Straight Carbon Fibre Reinforced Polymer (CFRP) AnchorsKevin Paul Arca RojasNo ratings yet

- Using CHEMCAD For Piping Network Design and AnalysisDocument51 pagesUsing CHEMCAD For Piping Network Design and AnalysisRawlinsonNo ratings yet

- V33500 TVDocument2 pagesV33500 TVgoriath-fxNo ratings yet

- Summary of Neil Postman's Amusing Ourselves to DeathFrom EverandSummary of Neil Postman's Amusing Ourselves to DeathRating: 4 out of 5 stars4/5 (2)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNo ratings yet

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (138)

- Cable Supported Bridges: Concept and DesignFrom EverandCable Supported Bridges: Concept and DesignRating: 5 out of 5 stars5/5 (1)

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetFrom EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetRating: 4.5 out of 5 stars4.5/5 (10)

- Troubleshooting and Repair of Diesel EnginesFrom EverandTroubleshooting and Repair of Diesel EnginesRating: 1.5 out of 5 stars1.5/5 (2)

- The Finite Element Method: Linear Static and Dynamic Finite Element AnalysisFrom EverandThe Finite Element Method: Linear Static and Dynamic Finite Element AnalysisRating: 5 out of 5 stars5/5 (3)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansRating: 4.5 out of 5 stars4.5/5 (21)

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeFrom EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeRating: 4.5 out of 5 stars4.5/5 (59)

- CAREC Road Safety Engineering Manual 3: Roadside Hazard ManagementFrom EverandCAREC Road Safety Engineering Manual 3: Roadside Hazard ManagementNo ratings yet

- Structural Cross Sections: Analysis and DesignFrom EverandStructural Cross Sections: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (19)

- Pile Design and Construction Rules of ThumbFrom EverandPile Design and Construction Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (15)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Construction Innovation and Process ImprovementFrom EverandConstruction Innovation and Process ImprovementAkintola AkintoyeNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesFrom EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesNo ratings yet

- Rocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyFrom EverandRocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyRating: 4.5 out of 5 stars4.5/5 (5)

- Engineering Rock Mass Classification: Tunnelling, Foundations and LandslidesFrom EverandEngineering Rock Mass Classification: Tunnelling, Foundations and LandslidesRating: 4 out of 5 stars4/5 (5)

- Skyway: The True Story of Tampa Bay's Signature Bridge and the Man Who Brought It DownFrom EverandSkyway: The True Story of Tampa Bay's Signature Bridge and the Man Who Brought It DownNo ratings yet

- Transportation Decision Making: Principles of Project Evaluation and ProgrammingFrom EverandTransportation Decision Making: Principles of Project Evaluation and ProgrammingNo ratings yet