Professional Documents

Culture Documents

Effect of Robo Sand On Strength Characteristic of Recycled Aggregate Concrete PDF

Uploaded by

esatjournalsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effect of Robo Sand On Strength Characteristic of Recycled Aggregate Concrete PDF

Uploaded by

esatjournalsCopyright:

Available Formats

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

EFFECT OF ROBO SAND ON STRENGTH CHARACTERISTIC OF

RECYCLED AGGREGATE CONCRETE

A.Anbarasan1, M.Venkatesan2

1

M.Tech Student, Department of Civil Engineering, Prist University, Kumbakonam Campus, Tamilnadu, India

Asst. Professor, Department of Civil Engineering, Prist University, Kumbakonam Campus, Tamilnadu, India

Abstract

With increased depletion of natural construction materials, alternative means must be sought for substitution of the same.

Excessive energy consumption in the production of construction materials, environmental setbacks and debris disposal are some

of the other burning issues fuelling the need for reuse of the raw materials. With the need of natural sand, there is an urgent need

for a product that matches the properties of natural sand in concrete. Construction- Demolition waste and ROBO Sand are some

of the upcoming resources which enables effective replacement of the materials of mineral origin. In the present work, natural

coarse aggregate was replaced with recycled coarse aggregate and river sand was replaced with ROBO Sand in different

percentages in plain cement concrete. Different strength test were conducted with combination of ROBO Sand and recycled

aggregate to study the effect of these two materials on strength Concrete with a characteristic compressive strength of 30 N/mm2

(M30 grade), was used for our study. In total, 16 sets of 6 cubes each were cast and tested.

Keywords: ROBO Sand, recycled aggregate

--------------------------------------------------------------------***---------------------------------------------------------------------1. INTRODUCTION

Concrete is a major building material which is used in

construction throughout the globe. It is extremely good and

is used for all types of structures. Due to rapid growth in

construction sector, the extreme usage of concrete is rapidly

increasing every year. This results in huge extraction of

natural aggregates, which occupy 65 to 80% of the total

volume of concrete. Out of the total composition of

concrete, fine aggregate consumes 20 to 30 % of volume.

With a few local exceptions, it is expected ROBO Sand to

be a global practice. Developing countries face lot of

problems regarding exploitation of natural resources. Now a

days the availability of natural sand is a constraint .due to

the immense growth in new designs old structures are

demolished and the waste management is a problem, to

overcome these problems some innovative way of recycling

of waste should be done.

Current levels of demolition waste at UK construction sites

are in the region of 70 Mt per annum [1]. Of this only 10%

finds use as aggregate, but mainly in road construction [2],

where traditionally low grade aggregates are used. The

remaining items are disposed as landfill. This low level of

use clearly has economic and environmental implications

and given the potential benefits associated with the material,

dumping is no longer considered sustainable

1.1 Objectives

To study effect of ROBO Sand on compressive

strength,tensile strength of recycled aggregate concrete and

natural aggregate concrete. To study the cost aspects and

arrive an optimum combination

1.2 Research Study

In our study, for each composition, four combinations each

was tested. For 0% Recycled coarse aggregate (RCA), 0%,

30%,50% and 100% Robo sand (RS)was added. Likewise

for 30%, 50% and 100% RCA, RS is mixed as 0%,

30%,50% and 100%. Totally 16 mix proportions were

tested. Strength test in terms of compression and tensile

stress. Concrete mix of M30 is used for our study.

2. MATERIAL PROPERTIES & MIX DESIGN

2.1 Cement

The cement used for the investigation was Ordinary

Portland Cement with 53 grade. The specific gravity of

cement was found out by density bottle method and the

corresponding value is 3.15

2.2 Coarse Aggregate

Crushed aggregate available from local sources has been

used. To obtain a reasonably good grading, aggregate

passing through 20mm IS sieve and retained on 16mm IS

sieve was used. The properties of coarse aggregate such as

specific gravity and fineness modulus are found out as

per Indian Standard guidelines. The specific gravity of

coarse aggregate is 2.70.

2.3 Fine Aggregate

Locally available river sand of size less than 4.75 mm was

used. The specific gravity of fine aggregate is 2.65, fineness

modulus was found to be 2.7 as per IS 383:1970.

2.4 ROBO Sand and Recycled Coarse Aggregate

ROBO Sand are crusher dust which are collected from local

_______________________________________________________________________________________

Volume: 04 Issue: 03 | Mar-2015, Available @ http://www.ijret.org

353

IJRET: International Journal of Research in Engineering and Technology

eISSN: 2319-1163 | pISSN: 2321-7308

quary and aggregate from demolished building are used as

recycled coarse aggregate.Table 1 shows the Specific

gravity of RS and RCA.

Table 1 Properties of Aggregates

Aggregate

Specific gravity

Recycled

coarse 2.65

aggregate (RCA)

Robo sand (RS)

2.29

2.5 Mix Design

Property

Required

Characteristic

compressive strength

Maximum size of aggregate

Water Cement ratio

Degree of workability

Degree of quality control

Type of exposure

Mix Ratio

Water

Cement

Fine Aggregate

Coarse Aggregate

Value

30 MPa

20 mm

0.4

0.90

Good

Moderate

Weight

191 lit

478 kg

519 kg

1179 kg

Ratio

0.40

1.00

1.01

2.48

3. TESTING OF SPECIMEN

3.1 Cube Compressive Strength

Cubes of size 150 mm x 150 mm were cast and the strength

development was monitored for the ages of 7 and 28 days

for compression using digital compression testing machine

of 3000 kN capacity. This paper presents the results of

experimental investigations on concrete made with different

percentages of recycled coarse aggregate and ROBO Sand.

Specimens were designated. In all the four sets, natural sand

and coarse aggregate was replaced in increasing percentages

of 0, 30, 50&100.The first set had no replacement of

aggregate while the last set had 100%replacement of natural

aggregate with recycled coarse aggregate. The second and

third sets had 30 and 50% aggregate replacements

respectively. Totally 96 cubes were tested, for 7th and 28th

day test with 3cube per combination.

Chart 1- Compressive test

The test consists of applying compressive line loads along

the opposite generators of a concrete cylinder placed with its

axis horizontal between the platens. Due to the applied line

loading a fairly uniform tensile stress is induced over nearly

two third of the loaded diameter as obtained from an

elastic analysis. The magnitude of this tensile stress is given

by 2P/DL = 0.637P/DL.

4. RESULTS AND DISCUSSION

4.1 Cube Compressive Strength

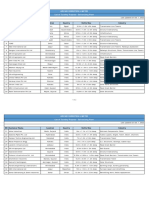

Table 2 Compressive strength in N/mm2

RCA28th

MIX

ROBO

7th Day

DAY

SAND%

Controlled 0-0

25.11

36.19

1

0-30

23.24

33.54

2

0-50

23.18

33

0-100

23.30

33.21

3.2 Split Tensile Strength Test

30-0

22.52

32.96

30-30

22.15

33.78

For split tensile strength of concrete, 150mmx300mm

cylinders were cast and cured for 7 and 28 days in water.

30-50

24.90

36.23

30-100

24.67

36.25

50-0

19.88

33.4

50-30

19.81

33.51

10

50-50

19.78

33.4

11

50-100

18.66

33.28

12

100-0

18.10

33.1

13

100-30

18.89

29.96

14

100-50

17.66

29.44

15

100-100

17.05

29.1

_______________________________________________________________________________________

Volume: 04 Issue: 03 | Mar-2015, Available @ http://www.ijret.org

354

IJRET: International Journal of Research in Engineering and Technology

The results on compressive strength of control concrete

(0-0 combination) and concrete with different percentages of

ROBO Sand are shown in table 2. Graphs plotted between

the mix and compression strength, to identify the maximum

compression strength value in 7th and 28th day. It can be seen

eISSN: 2319-1163 | pISSN: 2321-7308

from the results that, control concrete strength is 36.19

N/mm2 and RCA And ROBO Sand combination for 30-100

was found to be good when compared to other combinations

at the age of 28 days.

7th day compressive strength

Compressive strength in MPa

30.00

25.00

20.00

15.00

10.00

5.00

0.00

0 RCA

30 RCA

0 RS

30 RS

50 RCA

50 RS

100 RCA

100 RS

Chart 1 - 7th day compressive strength of the mixes

28th day compressive strength

Compressive strength in MPa

40

35

30

25

20

15

10

5

0

0 RCA

30 RCA

0 RS

30 RS

50 RCA

50 RS

100 RCA

100 RS

Chart 2 - 28th day compressive strength of the mixes

_______________________________________________________________________________________

Volume: 04 Issue: 03 | Mar-2015, Available @ http://www.ijret.org

355

IJRET: International Journal of Research in Engineering and Technology

All the different combinations shows better strength . In

7days and 28days curing 30% RCA and both 50% and

100% ROBO (Mix 5 & 6) Sand gives more strength when

compared to other combinations. When RCA percentage

increased, the results are seen decrease in strength.

Therefore it can be said that, when 30%RCA and 100% RS

is used, the strength of the concrete was similar to control

concrete. Percentage increase of strength of mix 5and 6 is

0.11% and 0.16% respectively. It will pave the way to

minimize the use of natural sand and natural aggregate and

encourage the use of waste materials like ROBO SAND and

RCA there by reducing disposal problem. It is also to be

noted that, in the above case there will be considerable

reduction in cost of construction, which in turn encourages

the use of RCA in solving environmental problem The

intermediate results depicting the various combinations of

ROBO SAND+RCA can be used according to the design

strength required considering the economical aspects.

4.2 Split Tensile Strength Test

Split tensile strength for all the mixes are tabulated in table

3. 7th day and 28th day tests were made for the mixes.

Tensile stress variation for various mixes with respect to

controlled concrete is noted in chart 3.

eISSN: 2319-1163 | pISSN: 2321-7308

Table 3 Tensile strength in N/mm2

RCAMIX

ROBO

7th Day

28th DAY

SAND%

Controlled 0-0

3.28

4.22

1

0-30

3.18

4.15

2

0-50

3.18

4.12

3

0-100

3.19

4.13

4

30-0

3.20

4.13

5

30-30

3.06

4.09

6

30-50

3.48

4.22

7

30-100

3.36

4.23

8

50-0

3.32

3.82

9

50-30

3.30

3.79

10

50-50

3.30

3.78

11

50-100

3.29

3.92

12

100-0

3.25

3.91

13

100-30

3.24

3.84

14

100-50

3.17

3.91

15

100-100

3.08

3.79

28th day Tensile strength

4

Tensile strength in MPa

2

0

-2

0 RCA

30 RCA

50 RCA

100 RCA

-4

-6

-8

-10

0 RS

30 RS

50 RS

100 RS

Chart 3- Percentage Variation in tensile strength

_______________________________________________________________________________________

Volume: 04 Issue: 03 | Mar-2015, Available @ http://www.ijret.org

356

IJRET: International Journal of Research in Engineering and Technology

It is seen from the chart 3, that there is percentage increase

in tensile strength when the RCA is added upto 30%. Above

which, gives less strength than the controlled concrete.

Maximum of 8% strength decrement is seen in mixes with

RCA added more than 30%. While seeing the increment in

tensile stress, the mix 5 ( 50% RS and 30%RCA) and mix 6

( 100% RS and 30% RCA) shows 2.48% and 2.56%

respectively. Though tensile strength is not an important

factor in concrete, it is essential to know the performance of

concrete with this new materials. Therefore these tests were

made and results are discussed.

eISSN: 2319-1163 | pISSN: 2321-7308

[9]. IS 10262 1982 Indian Standard code of practice for

recommended guidance for concrete mix design

[10]. IS: 383-1970, Indian Standard code for coarse and

fine aggregates from natural sources of concrete.

BIOGRAPHIES

A.Anbarasan is an M.Tech Student at

PRIST University, Kumbakonam Campus

and his field of interest is in concrete

technology.

5. CONCLUSION

From the detailed experimental investigations carried out for

different combinations of RCA with different percentages of

ROBO SAND, following conclusions are arrived:

1. Strength aspect of RCA and ROBO Sand based

concrete for 30-100% has shown good results both

for 7days and 28 days curing..

2. Cost aspect- to achieve reasonable strength with

reduced cost comes with the same combination of

30% RCA and 50% or 100% ROBO SAND.

3. Replacement of Natural aggregate with RCA above

30% is possible to achieve a strength reduction of

about 20% of target mean strength (without any

mineral admixture).

M.Venkatesan, is an Asst. Professor, in

PRIST University, Kumbakonam Campus

and his field of of interest is in structural

analysis, concrete technology

REFERENCES

[1]. Prof. Wakchaure M. R.1, Er. Shaikh A.P.2, Er. Gite

B.E.3,(2012), Effect of Types of Fine Aggregate on

Mechanical Properties of Cement Concrete ,International

Journal of Modern Engineering Research (IJMER), Vol.2,

Issue.5, Sep-Oct. 2012 pp-3723-3726

[2].

N.K.Deshpande,

Dr.S.S.Kulkarni

and

H.Pachpande,(2012), Strength Characteristics Of Concrete

With Recycled Aggregates And Artificial Sand,

International Journal of EngineeringResearch and

Applications (IJERA),Vol. 2, Issue 5, September- October

2012, pp.038-042

[3]. M. G. Shaikh, S. A. Daimi,(2011), Durability studies

of concrete made by using artificial sand with dust and

natural sand, International Journal of Earth Sciences and

Engineering 823ISSN 0974-5904, Volume 04, No 06 SPL,

October 2011, pp 823-830

[4]. Pazhani, K., and Jeyaraj, R. 2010. Study on durability

of high performance concrete with industrial wastes.ATI Applied Technologies & Innovations, 2(2), 19-28.

[5]. VenuMalagavalli and Rao, P.N. 2010. High

Performance Concrete with GGBFS and ROBO Sand.

International Journal of Engineering Science and

Technology, 2(10), 5107-5113.

[6]. IS: 383-1970, Indian Standard specification for coarse

and fine aggregates from natural sources for concrete.

[7]. IS: 456-2000, Indian standard code of practice for plain

and reinforcement concrete, Indian Standard Institution,

New Delhi.

[8]. B. B. Patil and P. D. Kumbhar Strength and Durability

Properties of High Performance Concrete incorporating

High Reactivity Powder Technology Vol 2(3), 1099-1104,

2012.

_______________________________________________________________________________________

Volume: 04 Issue: 03 | Mar-2015, Available @ http://www.ijret.org

357

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Analysis and Optimization of Electrodes For Improving The Performance of Ring Laser Gyro PDFDocument4 pagesAnalysis and Optimization of Electrodes For Improving The Performance of Ring Laser Gyro PDFesatjournalsNo ratings yet

- PTE 3 Week Study ScheduleDocument3 pagesPTE 3 Week Study ScheduleesatjournalsNo ratings yet

- Analysis and Design of A Multi Compartment Central Cone Cement Storing Silo PDFDocument7 pagesAnalysis and Design of A Multi Compartment Central Cone Cement Storing Silo PDFesatjournalsNo ratings yet

- A Review Paper On Smart Health Care System Using Internet of ThingsDocument5 pagesA Review Paper On Smart Health Care System Using Internet of ThingsesatjournalsNo ratings yet

- Analysis of Cylindrical Shell Structure With Varying Parameters PDFDocument6 pagesAnalysis of Cylindrical Shell Structure With Varying Parameters PDFesatjournalsNo ratings yet

- Analysis and Optimization of Sand Casting Defects With The Help of Artificial Neural Network PDFDocument6 pagesAnalysis and Optimization of Sand Casting Defects With The Help of Artificial Neural Network PDFesatjournalsNo ratings yet

- A Servey On Wireless Mesh Networking ModuleDocument5 pagesA Servey On Wireless Mesh Networking ModuleesatjournalsNo ratings yet

- A Three-Level Disposal Site Selection Criteria System For Toxic and Hazardous Wastes in The PhilippinesDocument9 pagesA Three-Level Disposal Site Selection Criteria System For Toxic and Hazardous Wastes in The PhilippinesesatjournalsNo ratings yet

- A Review On Fake Biometric Detection System For Various ApplicationsDocument4 pagesA Review On Fake Biometric Detection System For Various ApplicationsesatjournalsNo ratings yet

- A Study and Survey On Various Progressive Duplicate Detection MechanismsDocument3 pagesA Study and Survey On Various Progressive Duplicate Detection MechanismsesatjournalsNo ratings yet

- A Women Secure Mobile App For Emergency Usage (Go Safe App)Document3 pagesA Women Secure Mobile App For Emergency Usage (Go Safe App)esatjournalsNo ratings yet

- A Survey On Identification of Ranking Fraud For Mobile ApplicationsDocument6 pagesA Survey On Identification of Ranking Fraud For Mobile ApplicationsesatjournalsNo ratings yet

- A Research On Significance of Kalman Filter-Approach As Applied in Electrical Power SystemDocument8 pagesA Research On Significance of Kalman Filter-Approach As Applied in Electrical Power SystemesatjournalsNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Company ProfileDocument189 pagesCompany ProfileplanningNo ratings yet

- Booster Basics PresentationDocument49 pagesBooster Basics PresentationbinhjukiNo ratings yet

- MathematicsDocument13 pagesMathematicsJeevan ReddyNo ratings yet

- An Efficient Microgrid Management System For Rural Area Using ArduinoDocument7 pagesAn Efficient Microgrid Management System For Rural Area Using ArduinoRicha SharmaNo ratings yet

- Perkins 1104DDocument158 pagesPerkins 1104Dsj1202100% (17)

- Lyceum of The Philippines University Cavite: Iredalei (Crassotrea: Ostreidae) ) As An Exhaust Filter For Selected PublicDocument42 pagesLyceum of The Philippines University Cavite: Iredalei (Crassotrea: Ostreidae) ) As An Exhaust Filter For Selected PublicCj Lucero50% (2)

- SC Physics FormulasDocument2 pagesSC Physics Formulashassan75% (4)

- Energies 14 04876 v2Document15 pagesEnergies 14 04876 v2FlogamagNo ratings yet

- N42EH Grade Neodymium Magnets DataDocument1 pageN42EH Grade Neodymium Magnets DataSteve HsuNo ratings yet

- Thermodynamic Analysis of Zinc Ferrite ZnFe2O4 Formation InsideDocument16 pagesThermodynamic Analysis of Zinc Ferrite ZnFe2O4 Formation InsideFatemeh RezaeiNo ratings yet

- Name .. Tutor .: Carbohydrate & Water Test (/50)Document4 pagesName .. Tutor .: Carbohydrate & Water Test (/50)NecrOtic ObsessionNo ratings yet

- Primer On Wood Biomass For Energy PDFDocument10 pagesPrimer On Wood Biomass For Energy PDFSTEFANIANo ratings yet

- Ultra Series Boom LiftsDocument16 pagesUltra Series Boom Liftsmcuentas1984No ratings yet

- Unit ConversionDocument2 pagesUnit ConversionharoldNo ratings yet

- 6.1 Mastering IELTS Writing Task 1 (PDFeBook) PDFDocument228 pages6.1 Mastering IELTS Writing Task 1 (PDFeBook) PDFHarsh Patel100% (6)

- Data Sheet 6ES7231-4HF32-0XB0: General InformationDocument3 pagesData Sheet 6ES7231-4HF32-0XB0: General InformationRoberto cafeNo ratings yet

- ME 503 DomDocument9 pagesME 503 Domsuneel kumar rathoreNo ratings yet

- Theoretical Approaches Regarding The VENTURI EffectDocument4 pagesTheoretical Approaches Regarding The VENTURI EffectJose A AbrahamNo ratings yet

- Client List - Arvind Corrotech Ltd.Document2 pagesClient List - Arvind Corrotech Ltd.Ricardo Javier Cotamo De la espriellaNo ratings yet

- Continuously Variable Transmission - CVTDocument18 pagesContinuously Variable Transmission - CVTPratheep Srinivas100% (3)

- MIM WinGD X52DF-S2-0Document259 pagesMIM WinGD X52DF-S2-0Κώστας ΧατζηδάκηςNo ratings yet

- In and Ex System DescDocument5 pagesIn and Ex System DescAli KuncoroNo ratings yet

- Tubing Thread Type, External Upset Tubing, Yaosheng Non Upset Tubing ManufacturerDocument2 pagesTubing Thread Type, External Upset Tubing, Yaosheng Non Upset Tubing ManufacturerEDWIN M.PNo ratings yet

- Solution of The Graetz-Brinkman Problem With The Laplace Transform Galerkin MethodDocument9 pagesSolution of The Graetz-Brinkman Problem With The Laplace Transform Galerkin MethodDeny Arief RusamsiNo ratings yet

- 1.1.1.2 The Four-Stroke-Cycle Spark-Ignition (Petrol) EngineDocument1 page1.1.1.2 The Four-Stroke-Cycle Spark-Ignition (Petrol) EngineFuad AnwarNo ratings yet

- Heat Transfer: Thermal EmissivityDocument5 pagesHeat Transfer: Thermal EmissivityvjtiitNo ratings yet

- HYDRODocument122 pagesHYDROAnonymous K48TgviNo ratings yet

- Yonos 1Document20 pagesYonos 1Dim VatNo ratings yet

- Foot MouswitchDocument11 pagesFoot MouswitchnewbeatleeNo ratings yet

- Heavy Equipment Tooling, Test & MeasurementDocument26 pagesHeavy Equipment Tooling, Test & MeasurementA A Napis TeaNo ratings yet