Professional Documents

Culture Documents

Introduction To Valves

Uploaded by

Bagus AgungOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Introduction To Valves

Uploaded by

Bagus AgungCopyright:

Available Formats

Ch.

I Introduction to Valves

1.1. Valve

Valves are mechanical devices specifically designed to

direct, start, stop, mix, or regulate the flow, pressure,

or temperature of a process fluid.

Berdasarkan atas fungsinya, aplikasinya, dan

rancangannya, valve dapat dibedakan ke dalam

beragam kelas styles, sizes, dan ragam pressure.

Tipe yang umum ditemukan adalah plug, ball, globe,

butterfly, dan gate valves.

Valve dapat dibuat dari berbagai material seperti:

steel, iron, plastic, brass, atau sejumlah material

paduan khusus lainnya.

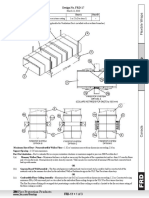

Komponen-komponen utama sebuah valve diberikan

pada Gbr. 1

Training on Valve Technology

Ch. I Introduction to Valves

The internal

elements of a valve

are collectively

referred to as a

valve's trim.

The trim typically

includes a disc,

seat, stem, and

sleeves needed to

guide the stem.

A valve's performa

nce is determined

by the disk and

seat interface and

the relation of the

disk position to the

seat.

Gbr. 1 Basic components of a valve

Training on Valve Technology

Ch. I Introduction to Valves

Gbr. 2

Manual Valve

Gbr.3

Control Valve

Training on Valve Technology

Ch. I Introduction to Valves

Gbr. 4

Ball Valve

Gbr. 5

Gate Valve

Gbr. 6

Plug Valve

Training on Valve Technology

Ch. I Introduction to Valves

Gbr. 7

Globe Valve

Gbr. 8

Butterfly Valve

Training on Valve Technology

Ch. I Introduction to Valves

Gbr. 9 Pinch Valve

open

throttling

closed

Gbr. 10 Diaphragm Valve

Training on Valve Technology

Ch. I Introduction to Valves

1.2 Klasifikasi Menurut Fungsinya

Berdasarkan atas rancangan dan fungsi valve in

handling the fluid, valve dapat dibagi ke dalam 3

kelompok: on-off valves, non-return valves, and

throttling valves.

On-off valves: handle the function of blocking the

flow or allowing it to pass.

Non-return valves: allow one direction flow only.

Throttling valve: allow for regulation of the flow at

any point between fully open to fully closed.

One confusing aspect of defining valves by function

and its specific valve-body design (plug, ball, globe,

gate, butterfly, pinch, etc.)

Training on Valve Technology

Ch. I Introduction to Valves

1. On-off Valves

Terkadang juga disebut sebagai block valve.

Kelompok valve ini yang umum dijumpai: gate, plug,

ball, pressure relief, dan tank-bottom valves.

Jenis on-off valve umumnya hand-operated, walaupun

dapat diotomasi dengan tambahan aktuator.

Pressure-relief valves adalah self-actuated on-off

valves yang dapat terbuka hanya jika preset pressure

dilampaui (mencegah over pressuration).

Pressure-relief valves dibagi menjadi 2: Relief valves,

untuk aplikasi pada fluida cair dan safety valves,

untuk aplikasi pada fluida gas.

Training on Valve Technology

Ch. I Introduction to Valves

Gbr. 11 Pengetesan pressure-relief valve

Training on Valve Technology

10

Ch. I Introduction to Valves

2. Non-return Valves

Nonreturn valves memungkinkan fluida untuk

mengalir ke suatu arah yang diinginkan (hanya satu

arah saja).

Semua check valves termasuk ke dalam kelompok

nonreturn valves.

Valve jenis ini digunakan untuk mencegah terjadinya

backflow yang tidak diinginkan.

Contoh aplikasi: untuk melindungi instalasi pompa

atau kompresor dari backflow saat shut down.

Nonreturn valves juga digunakan dalam sistem proses

dengan variasi tekanan yang harus dijaga secara

terpisah.

Training on Valve Technology

11

Ch. I Introduction to Valves

Gbr. 12 Piston check valve dalam bidang migas

Training on Valve Technology

12

Ch. I Introduction to Valves

3. Throttling Valves

Valve jenis ini digunakan untuk mengatur aliran,

temperatur, atau tekanan.

Operasi throttling valves: manual (handwheel or

lever) atau dengan kontrol otomatis, Gbr. 13(a).

Pressure regulators adalah throttling valve yang

memvariasikan posisi valve untuk menjaga tekanan di

hilir valve tetap konstan, Gbr. 13(b)

Automatic control valves atau control valves is a term

commonly used to describe valves that capable of

varying flow conditions to match the process

requirements dilengkapi dengan actuator.

Training on Valve Technology

13

Ch. I Introduction to Valves

(b) Pressure regulator

(a) Globe control valve

Gbr. 13 Contoh throttling valves

Training on Valve Technology

14

Ch. I Introduction to Valves

1.3 Klasifikasi Menurut Aplikasinya

Tiga klasifikasi valve menurut aplikasinya: general

service valve, special service valves, dan severe

service valves.

General service valves: valve yang dapat

digunakan pada banyak aplikasi tanpa perlu

modifikasi.

Special service valves: valve yang dirancang

khusus untuk aplikasi tertentu/spesifik.

Severe service valves: valve yang dirancang khusus

untuk mencegah efek samping pada aplikasi yang

sulit.

Training on Valve Technology

15

Ch. I Introduction to Valves

1. General Service Valves

Termasuk ke dalam kelompok ini adalah valve yang

dirancang untuk mayoritas aplikasi yang umum:

Lower-pressure: ANSI Class 150 s/d 600.

Moderate-temperature rating: -50oF s/d 650oF.

Non-corrosive fluid

Common pressure drop yang tidak menyebabkan

kavitasi atau flashing.

Dalam perancangannya, valve tipe ini dibuat dengan

level interchangeability dan flexibility yang tinggi

sehingga memiliki rentang aplikasi yang lebar.

Material body: baja karbon atau baja tahan karat.

Training on Valve Technology

16

Ch. I Introduction to Valves

Manual

Otomatis

Gbr. 14 Example of two general service valves

Training on Valve Technology

17

Ch. I Introduction to Valves

2. Special Service Valves

Special service valves is a term used for customengineered valves that are designed for a single

application that is outside normal process application.

Valve jenis ini biasanya untuk aplikasi pada

temperatur tertentu, tekanan tinggi, atau medium

yang korosif.

Gbr. 15 memperlihatkan contoh sebuah control valve

yang dirancang dengan sweep-style body dan trim

dari keramik untuk aplikasi yang erosif dengan pasir

dan tekanan yang tinggi.

Training on Valve Technology

18

Ch. I Introduction to Valves

Gbr. 15 Sweep-style globe valve used

in erosive mining application

Training on Valve Technology

19

Ch. I Introduction to Valves

3. Severe Service Valves

Severe service valves are valves equipped with

special features to handle volatile applications, such

as high pressure drops that result in severe

cavitation, flashing, choking, or high noise levels.

Pada kondisi tertentu sering dibutuhkan special

actuation untuk mengatasi gaya yang terjadi.

Gbr. 16 shows severe service valve to handle 1100oF

(593oC) liquid-sodium application with multistage trim

to handle a high pressure drop and a bonnet with

special cooling fins.

The electro-hydraulic actuator is capable of producing

almost 89 ton of thrust.

Training on Valve Technology

10

20

Ch. I Introduction to Valves

Gbr. 16 Severe service valve designed to handle highpressure drop, high temperature liquid-sodium application

Training on Valve Technology

21

Ch. I Introduction to Valves

1.4 Klasifikasi Menurut Gerakan

Some users classify valves according to the

mechanical motion of the valve: linear or rotary.

Linear valves are known for their simple design, easy

maintenance, and flexibility with more size, pressure

class, and design options than other motion

classification the most common type of valves.

Linear-motion valves (linear valves) memiliki

rancangan sliding-stem yang mendorong closure

element saat valve membuka atau menutup.

Gate, globe, pinch, diaphragm, split-body, three-way,

and angle valves semuanya masuk ke dalam

kelompok linear valves.

Training on Valve Technology

11

22

Ch. I Introduction to Valves

Rotary-motion valves (rotary valves) use a closure

element that rotates-through a quarter-turn or 90o

range-to open and close the flow.

Rotary valves are usually smaller in size and weigh

less than comparable linear valves.

The applications is limited to certain pressure drops

and are prone to cavitation and flashing problem.

As rotary-valve designs have matured, they have

overcome these inherent limitations and now being

used at an increasing rate.

Ball, plug, butterfly valves semuanya masuk ke dalam

kategori rotary-motion valves.

Training on Valve Technology

23

Ch. I Introduction to Valves

1.5 Klasifikasi Menurut Port Size

1. Full-Port Size

Valves with internal flow equal to the full area of the

inlet port.

Jenis ini utamanya digunakan sebagai on-off and

blocking service valves, dimana aliran harus distop

atau dialihkan.

Full-port valves memungkinkan penggunaan pig

dalam pipeline.

The pig is a self-driven (or flow-driven) mechanism

designed to clean the inside of the pipeline and to

remove any process buildup or scale.

Training on Valve Technology

12

24

Ch. I Introduction to Valves

2. Reduced-Port Size

Reduced-port valves are those whose closure

elements restrict the flow (area of closure element is

less then the area of the inside diameter of pipeline.)

Pembatasan aliran menyebabkan terjadinya pressure

drop saat aliran melewati closure element dan

sebagian tekanan dapat direcovery setelahnya.

The primary purpose of reduced-port valves is to

control the flow through reduced flow or throttling,

which is defined as regulating the closure element to

provide varying levels of flow at a certain opening of

the valve.

Training on Valve Technology

25

Ch. I Introduction to Valves

1.6 Common Piping Nomenclature

Valve and piping nomenclature has been heavily influenced

by imperial system (ANSI standards).

The psi is used to refer to pressure and NPS to refer to

valve and pipe size (in inches across the pipes inside

diameter.

In many countries, outside of the USA, valve and piping

nomenclature is based on the International System of Units

(metric system) from ISO.

Typically metric valve measurement are called out in

millimeter and pressure are noted in kilopascal (kPa) (or

bar).

ISO standards refer to pipe diameter as nominal diameter

(DN) and pressure rating as nominal pressure (PN).

Tables 1 and table 2 provide quick reference for both ANSI

and ISO standards.

Training on Valve Technology

13

26

Ch. I Introduction to Valves

Table 1 NPS versus DN

NPS (in.)

DN (mm)

NPS (in.)

DN (mm)

0.25

8.0

200

0.5

15

10.0

250

0.75

20

12.0

300

1.0

25

14.0

350

1.25

32

16.0

400

1.5

40

18.0

450

2.0

50

20.0

500

2.5

65

24.0

600

3.0

80

36.0

900

4.0

100

42.0

1000

6.0

150

48.0

1200

Training on Valve Technology

27

Ch. I Introduction to Valves

Table 2 ANSI Pressure Class vs. Nominal Pressure*)

ANSI Pressure Class

Nominal Pressure (PN)

(pounds of force per square

inch of surface area)

(allowable pressure in bar)

150

16

300

40

600

100

900

160

1500

250

2500

400

4500

700

Note:

PN is an approximation to the corresponding ANSI pressure class, and should

not be used as an exact correlation between two standards.

Training on Valve Technology

14

28

Ch. I Introduction to Valves

Reference

Skousen, P.L., Valve Handbook, McGraw-Hill, USA,

1998.

Fisher, Control Valve Handbook, Fisher Control

International, USA, 2001.

Training on Valve Technology

29

Training on Valve Technology

30

Ch. I Introduction to Valves

15

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- DllmeDocument1 pageDllmeBagus AgungNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Introduction To ValvesDocument15 pagesIntroduction To ValvesBagus AgungNo ratings yet

- ImjjDocument1 pageImjjBagus AgungNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Air Coolers Excerpt From Rules of Thumb For Chemical EngineersDocument3 pagesAir Coolers Excerpt From Rules of Thumb For Chemical Engineershalder_kalyan9216No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Belajar Menggambar 3d Dengan Autocad 2007Document200 pagesBelajar Menggambar 3d Dengan Autocad 2007Iswant MacanNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- FRD17Document3 pagesFRD17Raul FloresNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- California Plumbing CodeDocument7 pagesCalifornia Plumbing CodeMOHAMMAD ASIFNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- TCC15 Resistance of Retaining Members XLDocument8 pagesTCC15 Resistance of Retaining Members XLalexanderNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Secondary Composite ExampleDocument12 pagesSecondary Composite Examplef2662961No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Comparative Analysis of Green Building Rating Systems and Codes - 1Document46 pagesComparative Analysis of Green Building Rating Systems and Codes - 1Rohit TirkeyNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Cost in House ConstructionDocument32 pagesCost in House ConstructionSj interiorNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Casting Fundamentals and Basics ConceptsDocument68 pagesCasting Fundamentals and Basics Conceptsquiron2010No ratings yet

- The History of Investment Foundry ProcessDocument11 pagesThe History of Investment Foundry ProcessVrinda NilotpalNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Zhao - Lee - Post Weld Heat Treatment For High Strength Steel Welded ConnectionsDocument11 pagesZhao - Lee - Post Weld Heat Treatment For High Strength Steel Welded Connectionsbob8c5No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- ADM Masonry M1Document26 pagesADM Masonry M1Ronel ConstantinoNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Subject: Redevelopment of The Society Buildings An UpdateDocument11 pagesSubject: Redevelopment of The Society Buildings An Updatekkundan52No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Lifting Lug CalculationDocument2 pagesLifting Lug Calculationrustamriyadi100% (2)

- Activity - 01&02 - Capitalizable Costs and Modes of Acquisition of PPEDocument2 pagesActivity - 01&02 - Capitalizable Costs and Modes of Acquisition of PPEFrankie AsidoNo ratings yet

- My Dream HouseDocument2 pagesMy Dream HouseDannish JayabalaNo ratings yet

- Selection and Application of Piping System Materials: Standard Practice ForDocument23 pagesSelection and Application of Piping System Materials: Standard Practice ForRoberto Omar Morante VillarrealNo ratings yet

- 2011 UK Waste WoodDocument31 pages2011 UK Waste WoodStuart JonesNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Engineering Interview QuestionDocument174 pagesEngineering Interview QuestionKharisma Jayatra100% (1)

- Case Study Structure Building Collapse - CompressDocument9 pagesCase Study Structure Building Collapse - CompressnaserNo ratings yet

- Ashrae Pubcatalog 2019winter PDFDocument16 pagesAshrae Pubcatalog 2019winter PDFkunkzNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Foundation Design For A High Bay Warehouse With A Steel Fibre Reinforced Concrete SlabDocument13 pagesFoundation Design For A High Bay Warehouse With A Steel Fibre Reinforced Concrete SlabEstetika chinta PertiwiNo ratings yet

- Catalogo Interroll PDFDocument3 pagesCatalogo Interroll PDFIgorXavierNo ratings yet

- 2006 Navistar DT466 Engine Torque ValuesDocument5 pages2006 Navistar DT466 Engine Torque ValuesMeadows TruckNo ratings yet

- DIN Low Pressure Fittings and AccessoriesDocument184 pagesDIN Low Pressure Fittings and AccessoriesImtiaz NusratNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- 02 Bituseal e enDocument2 pages02 Bituseal e enYoussef ElgendyNo ratings yet

- Colosseum ResearchDocument3 pagesColosseum ResearchUnmasked kidNo ratings yet

- IABSE-JSCE Bridge Conference August 2015 Bridge Collapses - FinalDocument27 pagesIABSE-JSCE Bridge Conference August 2015 Bridge Collapses - FinalJamilur Reza ChoudhuryNo ratings yet

- SPAN Part H - Particular Construction...Document8 pagesSPAN Part H - Particular Construction...ang.xicongNo ratings yet

- Registration CRDocument5 pagesRegistration CRnandha gopalNo ratings yet

- Hvac Boq - R0 - 2914Document46 pagesHvac Boq - R0 - 2914Vikash TiwariNo ratings yet

- Microsoft Word - Plumbing & Fire Fighting Design & Construction - IPC & NFPA - Online Training CourseDocument4 pagesMicrosoft Word - Plumbing & Fire Fighting Design & Construction - IPC & NFPA - Online Training CourseShaik Bepari JakeerNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)