Professional Documents

Culture Documents

A Novel Imperialist Competitive Algorithm To Solve Flexible Flow Shop Scheduling Problem in Order To Minimize Maximum Completion Time

Uploaded by

Ahmed HassanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Novel Imperialist Competitive Algorithm To Solve Flexible Flow Shop Scheduling Problem in Order To Minimize Maximum Completion Time

Uploaded by

Ahmed HassanCopyright:

Available Formats

International Journal of Computer Applications (0975 8887)

Volume 28 No.10, August 2011

A Novel Imperialist Competitive Algorithm to Solve

Flexible Flow Shop Scheduling Problem in Order to

Minimize Maximum Completion Time

S.F.Attar

M.Mohammadi

R.Tavakkoli-Moghaddam

Department of Industrial

Engineering, Faculty of

Engineering, Tarbiat Moallem

University, Karaj, Iran

Department of Industrial

Engineering, Faculty of

Engineering, Tarbiat Moallem

University, Karaj, Iran

Department of Industrial

Engineering, College of

Engineering, University of

Tehran, Tehran, Iran

ABSTRACT

This paper demonstrates solving the flexible flow shop

scheduling problem (FFSP) with considering limited waiting

time constraint, sequence dependent setup times and different

ready time to minimize maximum completion time (i.e.

makespan). Since the problem studied is NP-hard, metaheuristic

algorithms are proper to solve this class of problems. Hence, in

this paper, a novel imperialist competitive algorithm (ICA) is

proposed to tackle of addressed problem. In order to achieve the

reliable results in our proposed algorithm, a comprehensive

tuning is performed using Taguchi method. to validate this

proposed algorithm, the other popular algorithm namely

simulated annealing is developed for this goal. Simulation

results indicated that ICA is superior to SA.

General Terms

Algorithms, Scheduling.

Keywords

ICA, Flexible flow shop, Limited waiting time, Sequence

dependent setup times, Ready time

1. INTRODUCTION

In this investigation, we consider a flexible flow shop

scheduling (FFS) problem, also called flow shop with multiple

processors. A FFS consists of multiple stages with each stage

contains parallel machines. There are multiple jobs immediately

available for scheduling. Each job consists of a chain of

operations. Each job must be processed by only one machine in

each stage and it must go through all stages on this order. Each

operation takes a specific setup time and processing time on a

stage. Preemption is usually not allowed. Two types of decisions

must be made for FFS. First is assignment of each job to a

specific machine at each stage and the other is sequencing of

jobs on each machine [1]. Arthanari and Ramamurthy [2] and

Salvador [3] were among the initial whom identified this

problem. FFS is a combination of two scheduling problems: the

flow shop scheduling problem and the parallel machines

scheduling problem. In flow shop scheduling problems, a series

of different machines is arranged in multiple stages with only

one machine at each stage. In parallel machines scheduling

problems, there is a series of identical machines and they are all

at the same stage.

This kind of manufacturing environment is fairly prevalent in

the chemical processing and petroleum industries, flexible

manufacturing and assembly environments, and in packaging

industries. Salvador [3] had identified the FFS problem in the

polymer, chemical, and petrochemical industries. In these

environments, there is more than one parallel plant which can be

considered as flow shops and the jobs can be easily processed

through any one of the plants at each processing stage. A flow

shop in which parallel machines are added at one or more stages

to reduce the on bottle-neck facilities or to increase the

production capacities can be also viewed as the application of

the FFS problem. Applications of the FFS problems are also

found in computer systems and telecommunication networks [4].

Botta-Genoulaz [5] presented six heuristic algorithms to

minimize the maximum tardiness in a flexible flow-shop

problem with different due dates. Kochhar et al. [6] provide a

local search approach to a realistic flexible flow line problem

with setups, buffer capacities, blocking, breakdowns and

downtimes. Wittrock [7] developed heuristics to minimize

makespan in the k-stage hybrid flow shop (HFS) with identical

machines in each stage. Brah and Hunsucker [8] developed a

branch and bound for a k-stage hybrid flow shop to minimize

makespan. Rajendran and Chaudhuri [9] developed branch and

bound algorithms to minimize makespan and total flow time,

respectively, for a k-stage problem. Vignier et al. [10] studied a

k-stage HFS to minimize the total completion time.

Moursli and Pochet [11] presented a branch-and-bound

algorithm to minimize the objective of the makespan. Oguz et

al. [12] developed nine heuristic algorithms for solving the twostage HFS problem of minimizing makespan. Gupta et al. [13]

also proposed heuristics to minimize makespan in a two stage

HFS with parallel identical machines at the first stage. Ruiz and

Maroto [14] proposed some genetic algorithms for a HFS

problem with unrelated parallel machines per stage, sequencedependent setup times and machine eligibility. The researchers

conduct several experiments with a set of random instances as

well as with real data taken from companies of the ceramic tile

manufacturing sector. Although many realistic considerations

and constraints are addressed in several papers in literature, very

few papers considered such realistic constraints jointly.

Moreover, majority of researches in scheduling problems area

have assumed that the waiting time for each job between every

two successive stages is infinite or processing should be carry

27

International Journal of Computer Applications (0975 8887)

Volume 28 No.10, August 2011

out without waiting time (i.e. no-wait) [15-20]. However, in real

manufacturing systems, such as steelmaking process, the waiting

time in buffers are limited to keep the steel liquid hot enough for

processing [21]. Su [22] considered a hybrid two-stage flow

shop with limited waiting time constraint. This paper presented a

heuristic algorithm and a mixed integer program to minimize the

makespan. Behmanian and Zandieh [23] suggested an

imperialist competitive algorithm for minimizing summation of

earliness and quadratic tardiness in hybrid flow shop scheduling

problem. Results of their study indicated that ICA is superior

that the other algorithms which were applied. With respect to

literature, it could be seen there is not any study that mentioned

flexible flow shop scheduling problem with all of following

characteristics: Considering different ready times for jobs,

limited waiting time constraint, sequence dependent setup times

and makespan criterion. Our goal in this paper is to develop an

efficient metaheuristic to solve the flexible flow shop scheduling

problem with sequence dependent setup time ,limited waiting

time and different ready time to minimize maximum completion

time. The paper has the following structure: Framework of the

problem that is studied in this paper is presented in Section 2.

Section 3 introduces the proposed algorithm. Section 4 presents

the experimental design and computational results. Finally,

Section 5 is devoted to conclusions and future works.

starts with initial solutions which are called initial countries that

are similar to chromosome in genetic algorithm and particle in

particle swarm optimization algorithm. These countries are

divided into two groups. First group is belonged to imperialist

countries and second group is formed with membership of

colonies countries as shown in the figure 1. Imperialist countries

with applying assimilation strategy, try to decrease the gaps

between colonies and them. Imperialistic competition beside the

assimilation and revolution form the main core of ICA that make

to reach the reliable and efficient solutions. Stages of our

proposed algorithm are explained as follows: generating initial

empires, assimilation, revolution, exchange between the best

colony and imperialist, Imperialistic competition, elimination of

powerless empire.

2. Problem description

To define the hybrid flow shop scheduling problem, assume that

a set N {1, 2,.., n} of n jobs which are available in different

times (i.e. R

{r1 , r2 ,.., rn } ) must be sequentially processed on

a set of s stages S (1, 2,..., s) . Each job is processed first at

stage 1, then at stage 2,, and finally at stage s. at stage i, mi

identical parallel machines are available. Each job i N could

be only processed on one machine at a time and consists of s

operation (O1 j ,O 2 j ,..., O sj ) . An operation Oij has a processing

time pij and has to be processed without preemption on only one

of the machines at stage i. moreover, the setup times for job j

after job k at stage l is defines with sdstkjl and limited waiting

time for job j between stage i and i+1 is illustrated with

lwt i,i 1, j .

Since a relatively simple HFS, such as a two-stage HFS with

limited waiting time, is NP-hard in the strong sense [22], our

problem at least has same difficulty. So, a novel metaheuristic

algorithm is applied to solve addressed problem. The structure

of imperialist competitive algorithm is shown in next section.

3. Imperialist competitive algorithm

The optimization algorithms mainly are inspired from nature

procedures or life of animals. In these algorithms, socio-political

and cultural concepts are not considered. Recently, a new

optimization methodology namely imperialist competitive

algorithm originates the socio-political evolution. ICA has been

modeled mathematically by atashpaz-gargary [24] which is

utilizing this historical phenomenon as powerful tool for solving

the optimization problems. This algorithm recently has been

attracted to many researchers to tackle of optimization problems

such as scheduling problem [23-25-26]. Briefly, this algorithm

Fig 1: Generating the initial countries.

3.1 Generating initial empires

In ICA each solution is shown by an array. Each array be

composed of amounts of variables to be optimized. These values

are defined with characteristics of each specific problem. In GA

terminology, this array is called chromosome, while in ICA,

country plays same role. In an N dimensional optimization

problem, a country is a 1N array. This array is defined with:

(1)

country [v1 , v2 , v3 ,..., vN ]

Where vi is the variable that to be optimized (i.e. vi is similar to

gen in GA). Each variable in a country denotes a socio-political

characteristic in that country such as culture, language, business,

economical policy and etc.

In proposed ICA, each solution represents sequence of jobs

which to be assigned to earliest available machines. In order to

reach this sequence, firstly, values of variables are generated

randomly by uniform distribution function in range between

zero and one. Secondly, these values are interpreted by sorting

of them. Fig 2 indicates the initial structure (Fig 2(a)) and

decoded structure (Fig 2(b)) for a problem with five jobs.

(a) Initial

structure

0.87

0.45

0.23

0.47

0.64

(b) decoded

structure

Fig 2: The structure of one solution for a problem with five

jobs in ICA

The fitness function of each country is calculated using function

f at the variables (v1 , v2 ,..., vN ) as follow:

28

International Journal of Computer Applications (0975 8887)

Volume 28 No.10, August 2011

ci

f (countryi )

f (vi1 , vi 2 ,..., viN )

(2)

At first, algorithm generates initial countries randomly in

number of population size then the most powerful countries are

selected in number of Nimp. Remaining countries will form

colonies. The colonies are randomly distributed among

imperialists based on imperialists power. For calculating the

power of imperialists, first, the normalized cost of an imperialist

is applied based on Eq.3.

Cn

max ci c n

1, 2,..., N imp

imp

i 1

,

i 1

Ci

pi

(4)

By attention to imperialists power, the colonies are distributed

among the imperialist. In addition, the initial number of colonies

of an imperialist is calculated as follow:

(5)

NC

round P .N

n

Imperialist

New position

of colony

Colony

Fig 4: Moving colonies direction.

N imp

Cn

N

distribution. U ( , ) where is a parameter that adjusts

the deviation from the original path.

(3)

Where, cn is the cost of nth imperialist and Cn is its normalized

cost which is equal to the deviation of the maximum total

completion time from the nth imperialist cost. Then the power

of each imperialist is calculated according to Equation 4.

pn

to the direction of movement. is number with uniform

col

Where, NCn is the initial number of colonies of nth empire and

N col is the number of all colonies. We randomly select NCn of

colonies and designate them for nth imperialist. As shown in this

figure 3 empire with the bigger power has a larger number of

colonies while empire with weaker power has less. Fig 3 shows

the initial population of each empire.

3.3 Revolution

This mechanism is similar to mutation process in genetic

algorithm for creating diversification in solutions. In each

iteration, for every colony a random number which is varying

between zero and one is generated, then this value is compared

with probability of revolution (i.e. PR). If random number is

lower than PR, the procedure of revolution is performed. For

conducting the revolution procedure, at first, the number of

variables which should be changed are determined based on

revolution ratio (RR). In other words, RR multiplies in number of

jobs. After determining the number of elements for revolution,

these elements are selected randomly. Then values of selected

elements are changed randomly. The new colony will replace

with previous colony while its cost is improved.

3.4 Exchanging positions of the imperialist

and a colony

After assimilation for all colonies and revolution for a

percentage of them, the best colony in each empire is compared

with its imperialist. If the best colony is better than its

imperialist, then the position of best colony and imperialist are

exchanged.

3.5 Total power of an empire

Fig 3: Generating the initial empires.

3.2 Assimilation

Imperialists try to improve all of their colonies. The aim of

assimilation procedure is to assimilate the colonies's

characteristic toward their imperialist such as culture, social

structure, language and etc. As shown in Fig 4 each colony

moves toward the imperialist by x units. x is a random number

with uniform distribution. x U (o ,

d) ,

1 Where

is a number greater than 1 and d is distance among colony and

imperialist which is the vector of movement for colony toward

imperialist. Parameter causes the colony to get closer to

imperialist from both sides.

To intensify property of this method and to search wider area

around current solution we add a random amount of deviation

The total power of an empire is calculated to apply in the

imperialistic competition section. It is clear that the power of an

empire is including the imperialist power and their colonies.

Moreover, obviously the power of imperialist has main effect on

total power of an empire while colonies power has lower impact.

Hence, the equation of the total cost is defined as follow:

TC n

cos t (imperialist n )

(6)

mean{cos t (colonies of empire n )}

Where TCn is the total cost of the nth empire and zeta ( ) is a

positive number which is considered to be less than 1. The total

power of the empire will be determined by just the imperialist

when the value of

is small. The role of the colonies, which

determines the total power of an empire, becomes more

important as the value of increases.

29

International Journal of Computer Applications (0975 8887)

Volume 28 No.10, August 2011

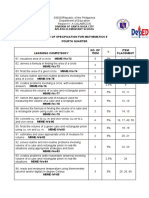

Table 1. Factors and their levels.

3.6 Imperialistic competition

Imperialists try to increase their power by possessing and

control the colonies of other empires. To apply this concept in

our proposed algorithm, in each iteration, at first the weakest

colony of weakest empire is determined. Then this colony is

given to the other empires which depend on their total power.

For this purpose we should calculate the possession probability

of each empire, first the normalized total cost is calculated as

follows:

Factors

Levels

Number of jobs

6,30,100

Number of stages

2,4,8

Machine

constant (4) , variable (U(1,10))

NTCn

Processing time

U(20,100)

SDST

U(10,40)

LWT

U(0,20)

Ready time

U(0,50)

max TCi

TCn , i 1, 2,.., Nimp

(7)

Where, NTCn is the normalized total cost of nth empire and

TCn is the total cost of nth empire. By having the normalized

total cost, the possession probability of each empire is calculated

as below:

pempn

NTC n

N

imp

i 1

(8)

4.2 Parameter tuning

NTC i

We use Roulette wheel method for assigning the mentioned

colony to the empires.

3.7 Eliminating the powerless empires

When each empire loses all of colonies this empire will collapse

and its imperialist is considered as a colony and is assigned to

other empires.

3.8 . Stopping criteria

Expiry criterion in our proposed algorithm is to get the

maximum decades which is defined by user.

4. EXPERIMENTAL EVALUATION

In this section, in order to evaluating the performance of

proposed algorithm against simulated annealing, at first some

problems are generated randomly, then the results are obtained

by these algorithms is converted to relative percentage

deviation. The formulation of this transformation is as bellow:

RPD

Method sol

Bestsol

Bestsol

100

(9)

Also, RPD is defined according to below Equation.

number of run

RPD

ARPD

RPD

i 1

(10)

number of run

For conducting of experiments, algorithms are implemented in

MATLAB 2009b and run in a personal computer with 2.66 GHz

and 4 GB of RAM memory.

4.1 Data generation

For generating the random problems five parameters are

considered. These parameters are number of jobs, number of

stage, number of machines in each stage, SDST distribution

function, processing time distribution function, LWT

distribution function and ready time distribution function. The

parameters and their levels are demonstrated in Table 1.

One of important component of metaheuristic algorithm is

calibration of parameters which impresses on performance of

algorithm. In this investigation we employed the Taguchi

method for this goal.

Taguchi [27] developed a family of FFE matrices which

eventually reduce the number of experiments, but still provide

sufficient information. In Taguchi method, orthogonal arrays are

used to study a large number of decision variables with a small

number of experiments. In Taguchi Method, the word

"optimization" implies "determination of best levels of control

factors". In turn, the best levels of control factors are those that

maximize the Signal-to-Noise ratios. The Signal-to-Noise ratios

are log functions of desired output characteristics. The

experiments that are conducted to determine the best levels, are

based on "Orthogonal Arrays", are balanced with respect to all

control factors and yet are minimum in number. This in turn

implies that the resources (materials and time) required for the

experiments are also minimum.

Taguchi has created a transformation of the repetition data to

another value which is the measure of variation. The

transformation is the signal-to-noise (S/N) ratio which explains

why this type of parameter design is called robust design [28,

29]. Here, the term signal denotes the desirable value (mean

response variable) and noise denotes the undesirable value

(standard deviation). So the S/N ratio indicates the amount of

variation presents in the response variable. The aim is to

maximize the signal-to-noise ratio.

Taguchi classifies objective functions into three categories: the

smaller-the-better type, the larger-the-better type, and nominal-is

best type. Since almost all objective functions in scheduling are

classified in the smaller-the-better type, their corresponding S/N

ratio [28] is:

S / N ratio

log 10 (objective function)2

(11)

The parameters in our proposed calibration of parameters and

their levels are shown in Table 2. After experimental design for

mentioned problem, the results obtained by Taguchi method

indicated that A (1), B (2), C (3) and D (1) is the best

combination of parameters values (see Fig 5).

30

International Journal of Computer Applications (0975 8887)

Volume 28 No.10, August 2011

Table 2. Parameters and their levels

Parameters

Level

2.5

C

(MaxDC,PopSize) Nimp

D

PR

(200,50)

0.1

0.2

(100,100)

0.15

0.3

(50,200)

0.2

0.4

ARPD

2

1.5

SA

ICA

0.5

0

6

30

100

Job Number

Fig 7: Interaction between job number and types of algorithms

in terms of ARPD.

ARPD

1.5

Fig 5: The mean S/N ratio plot for each level of the factors.

4.3 Performance analysis

After running the algorithms in random generated problems,

results are obtained by algorithms are converted to RPD for

analyzing the performance of algorithms. For this aim, Tuckey

95% confidence intervals of algorithms are employed. This

analyze which are illustrated in Fig 6, indicated that ICA

statistically outperformed SA. Furthermore, two sensitive

analysis for evaluating the variation of job number and machine

distribution on performance of algorithms are developed. As

seen in Fig 7 and Fig 8, both of them have not specific trend

versus variation of job numbers and machine distribution, but it

could be said, ICA in most of situations obtains better solutions

against SA. So, for the problem that has been studied in this

paper, ICA as an efficient metaheuristic algorithm is

recommended to researchers and practitioners.

Interval Plot of SA; ICA

95% CI for the Mean

1.8

1.6

1.4

RPD

1.2

1.0

0.8

0.6

0.4

0.2

SA

ICA

0.5

0

Constant= 4

Variable(1,10)

Machine distribution

Fig 8: Interaction between machine distribution and types of

algorithms in terms of ARPD.

5. CONCLUSION

RESEARCH

AND

FURTHER

Flexible flow shop scheduling problem is very important in both

fields of combinatorial optimization and engineering

management. Most literature focused on solving this problem in

unlimited waiting time or no-wait. Hence, in this paper we

considered this problem with sequence dependent setup times,

limited waiting time and different ready time. For tackle of

addressed problem, a novel metaheuristic algorithm namely

imperialist competitive algorithm is proposed. Furthermore, to

reach the more reliable and accurate results a comeprhensive

calibration methodology namely Taguchi method has been

employed for this purpose. Computational experiments

illustrated that ICA statistically outperforms SA. As a direction

for future studies, it could be interesting to work on

hybridization of ICA and SA for utilizing both capabilities. In

addition, considering some practical assumptions for this

problem could be regarded as an impressive research.

0.0

SA

Algorithms

ICA

Fig 6: Means plot and Tukey intervals (at the 95% confidence

level) for the type of algorithm factor.

31

International Journal of Computer Applications (0975 8887)

Volume 28 No.10, August 2011

6. REFERENCES

[1] Lee GC, Kim YD. 2004. A brach-and-bound algorithm for

a two-stage hybrid flow shop scheduling problem

minimizing total tardiness. International Journal of

Production Research, 42, 473143.

[2] Arthanary, T.S. and Ramamurthy, K.G. 1971. An extension

of two machines sequencing problem, Opsearch, 8, 1022.

[3] Salvador, M.S. 1973. A solution to a special case of

flowshop scheduling problems", in: S.E. Elmaghraby (ed.),

Symposium of the Theory of Scheduling and Applications,

Springer-Verlag, New York, 83-91.

[4] Brah, S.A. 1988. Scheduling in a flow shop with multiple

processors", Unpublished Ph.D. Dissertation, University of

Houston, Houston, TX.

[5] Botta-Genoulaz, V. 2000. Hybrid flow shop scheduling

with precedence constrains and time legs to minimize

maximum lateness. International Journal of Production

Economics, 64, 101111.

[6] Kochhar, S., Morris, R. and Wong, W. 1988. The local

search approach to flexible flow line scheduling.

Engineering Costs and Production Economics,14(1):2537.

[7] Wittrock, R. J. 1988. An adaptable scheduling algorithm

for flexible flow lines. Journal of Operational Research, 36,

445453.

[8] Brah, S.A. and Hunsucker, J.L. 1991. Branch and bound

algorithm for the flow shop with multiple processors.

European Journal of Operational Research, 51, 8899.

[9] Rajendran, C. and Chaudhuri, D. 1992. Scheduling in njob, m-stage flowshop with parallel processors to minimize

makespan. International Journal of Production Economics,

27, 137143.

[10] Vignier, A., Dardilrac, D., Dezalay, D., and Proust, C.

1996. A branch and bound approach to minimize the total

completion time in a k-stage hybrid flow shop. Proceedings

of the 1996 IEEE conference on emerging technologies and

factory automation. (Vol. 1) (pp. 215220).

[11] Moursli, O. and Pochet, Y. 2000. A branch-and-bound

algorithm for the hybrid flow shop. International Journal of

Production Economics, 64,113125.

[16] Kurz, M. E., & Askin, R. G. (2004). Scheduling flexible

flow lines with sequence- dependent setup times. European

Journal of Operational Research, 159, 6682.

[17] Zandieh, M., Fatemi Ghomi, S. M. T., and Moattar

Husseini, S. M. 2006. An immune algorithm approach to

hybrid flowshops scheduling with sequence-dependent

setup times. Applied Mathematics and Computation, 180,

111127.

[18] Jolai, F., Sheykh, S., Torabi, A. and Karimi, B. 2009. A

genetic algorithm for solving no-wait flexible flow lines

with due window and job rejection. International Journal of

Advanced Manufacturing Technology, 42,523532.

[19] Aldowaisan, T

Allahverdi, A. 2004. A New heuristics

for m-machine no-wait flowshop to minimize total

completion time. Omega, 32, 345352.

[20] Ruiz, R. and Allahverdi, A., 2009. New heuristics for nowait flow shops with a linear combination of makespan and

maximum lateness. International Journal of Production

Research 47(20), 5717-5738.

[21] Sawik, T. 2000. Mixed integer programming for scheduling

flexible flow lines with limited intermediate buffers.

Mathematical and Computer Modeling, 31(13), 3952.

[22] Su, L-H. 2003. A hybrid two-stage flow-shop with limited

waiting time constraints. Computers and Industrial

Engineer, 44, 409424.

[23] Behnamian, J., & Zandieh, M. 2011. A discrete colonial

competitive algorithm for hybrid flowshop scheduling to

minimize earliness and quadratic tardiness penalties. Expert

Systems

with

Applications,

doi:10.1016/j.eswa.2011.04.241

[24] Atashpaz-Gargari and Lucas, E.C. 2007. Imperialist

Competitive Algorithm: An algorithm for optimization

inspired by imperialist competitive. IEEE Congress on

Evolutionary computation, Singapore.

[25] Bagher, M. Zandieh, M. Farsijani, H. 2010. Balancing of

stochastic U-type assembly lines: an imperialist

competitive algorithm. International Journal of Advanced

Manufacturing Technology. DOI 10.1007/s00170-0102937-3

[12] Oguz, C., Ercan, M., Edwin Cheng, T. C., and Fung, Y. F.

2003. Heuristic algorithms for multiprocessor task

scheduling in a two-stage hybrid flow-shop. European

Journal of Operational Research, 149, 390403.

[26] Forouharfard, S. Zandieh, M., 2010. An imperialist

competitive algorithm to schedule of receiving and

shipping trucks in cross-docking systems. International

Journal of Advanced Manufacturing Technology, 51:1179

1193.

[13] Gupta, J. N. D., Hariri, A. M. A., and Potts, C. N. 1997.

Scheduling a two-stage hybrid flow shop with parallel

machines at the first stage. Annals of Operations Research,

69, 171191.

[27] Ross, R.J., Taguchi Techniques for Quality Engineering,

McGraw-Hill, USA, 1989.

[14] Ruiz, R. and Maroto, C. 2006. A genetic algorithm for

hybrid flowshops with sequence dependent setup times and

machine eligibility. European Journal of Operational

Research, 169(3):781800.

[28] Phadke, M.S., Quality Engineering Using Robust Design,

Prentice-Hall, USA, 1989.

[29] Al-Aomar, R., 2006. Incorporating robustness into genetic

algorithm search of stochastic simulation outputs,

Simulation Modeling Practice and Theory 14 , 201223.

[15] Azizoglu, M., Cakmak, E. and Kondakci, S. 2001. A

flexible flowshop problem with total flow time

minimization. European Journal of Operational Research,

132,528538.

32

You might also like

- Hybrid Flexible Flowshop Scheduling Problem With Unrelated Parallel Machines and Limited Waiting TimesDocument17 pagesHybrid Flexible Flowshop Scheduling Problem With Unrelated Parallel Machines and Limited Waiting TimesOlivia brianneNo ratings yet

- An Improved Discrete Migrating Birds Optimization Algorithm For The No-Wait Flow Shop Scheduling ProblemDocument13 pagesAn Improved Discrete Migrating Birds Optimization Algorithm For The No-Wait Flow Shop Scheduling Problemzrdasma01No ratings yet

- A Ga-Sa Multiobjective Hybrid Search Algorithm For Integrating Lot Sizing and Sequencing in Flow-Line SchedulingDocument12 pagesA Ga-Sa Multiobjective Hybrid Search Algorithm For Integrating Lot Sizing and Sequencing in Flow-Line SchedulingASHWEENA A/P SUNDARNo ratings yet

- 10.A Branch and Bound Algorithm For Two Stage No Wait Hybrid Flow Shop SchedulingDocument26 pages10.A Branch and Bound Algorithm For Two Stage No Wait Hybrid Flow Shop SchedulingMAHİDE DOĞAN (201013161021) DOĞANNo ratings yet

- Group13 - 13000119059 - Flow Shop SchedulingDocument8 pagesGroup13 - 13000119059 - Flow Shop SchedulingKaustav DeyNo ratings yet

- A Novel Multi-Objective Particle Swarm Optimization Algorithm For No-Wait Flow Shop Scheduling ProblemsDocument21 pagesA Novel Multi-Objective Particle Swarm Optimization Algorithm For No-Wait Flow Shop Scheduling ProblemsSakthiPriyaNo ratings yet

- Minimising makespan in job-shops with deterministic machine availability constraintsDocument14 pagesMinimising makespan in job-shops with deterministic machine availability constraintsjuan ardilaNo ratings yet

- Local search metaheuristic for hybrid flow shop schedulingDocument17 pagesLocal search metaheuristic for hybrid flow shop schedulingRumah WayangNo ratings yet

- Scheduling in Flexible Manufacturing Systems: Dpto. de Admon. de Empresas y Contabilidad, University of Oviedo, SpainDocument4 pagesScheduling in Flexible Manufacturing Systems: Dpto. de Admon. de Empresas y Contabilidad, University of Oviedo, SpainkcvaraNo ratings yet

- GA Job SchedullingDocument6 pagesGA Job Schedullingbudi2326No ratings yet

- Content ServerDocument13 pagesContent ServerAntoniojuarezjuarezNo ratings yet

- Flexible Flow Shop Sheduling Problem With Machine EligibilityDocument12 pagesFlexible Flow Shop Sheduling Problem With Machine EligibilityRajesh RavindranNo ratings yet

- Solving The Permutation Flow Shop Problem With Makespan Criterion Using GridsDocument12 pagesSolving The Permutation Flow Shop Problem With Makespan Criterion Using Gridsferronatto11No ratings yet

- European Journal of Operational Research: Luca Venditti, Dario Pacciarelli, Carlo MeloniDocument9 pagesEuropean Journal of Operational Research: Luca Venditti, Dario Pacciarelli, Carlo MeloniOlivia brianneNo ratings yet

- Priced Timed Automata: Algorithms and Applications: Lecture Notes in Computer Science January 2004Document23 pagesPriced Timed Automata: Algorithms and Applications: Lecture Notes in Computer Science January 2004Far ArfNo ratings yet

- A Review On Parallel Scheduling of Machines and AGV'S in An FMS EnvironmentDocument8 pagesA Review On Parallel Scheduling of Machines and AGV'S in An FMS EnvironmentInternational Journal of computational Engineering research (IJCER)No ratings yet

- An Improved Bat Algorithm For The Hybrid Flowshop Scheduling To Minimize Total Job Completion TimeDocument7 pagesAn Improved Bat Algorithm For The Hybrid Flowshop Scheduling To Minimize Total Job Completion TimeRahul SharmaNo ratings yet

- Amulti Phasecoveringpareto OptimalfrontmethodDocument28 pagesAmulti Phasecoveringpareto OptimalfrontmethodarpitdagreatNo ratings yet

- Assembly Line Balancing Literature ReviewDocument5 pagesAssembly Line Balancing Literature Reviewaflstquqx100% (1)

- Flow Shop Scheduling Genetic Algorithm in Manufacturing: Biological Database (BIT2002) Slot: G1Document5 pagesFlow Shop Scheduling Genetic Algorithm in Manufacturing: Biological Database (BIT2002) Slot: G1kumarklNo ratings yet

- Ching Ying. 2018. Improved Exact Methods For Solving No-Wait Flowshop Scheduling Problems With Due Date ConstraintsDocument12 pagesChing Ying. 2018. Improved Exact Methods For Solving No-Wait Flowshop Scheduling Problems With Due Date Constraintsmilyhya fgNo ratings yet

- A New Mathematical Model For A Competitive Vehicle Routing Problem With Time Windows Solved by Simulated AnnealingDocument10 pagesA New Mathematical Model For A Competitive Vehicle Routing Problem With Time Windows Solved by Simulated Annealingheri asbowoNo ratings yet

- Hybrid Flow Shop Scheduling With Sequence Dependent Family Setup Time and Uncertain Due DatesDocument35 pagesHybrid Flow Shop Scheduling With Sequence Dependent Family Setup Time and Uncertain Due Datesdaimon_pNo ratings yet

- Relaxations and discretizations for solving the NP-hard pooling problemDocument28 pagesRelaxations and discretizations for solving the NP-hard pooling problemkhaled_behery9934No ratings yet

- The Air Traffic Controller Work-Shift Scheduling PDocument16 pagesThe Air Traffic Controller Work-Shift Scheduling PpoljakxNo ratings yet

- Genetic algorithm for unrelated parallel machine scheduling with sequence dependent setup timesDocument11 pagesGenetic algorithm for unrelated parallel machine scheduling with sequence dependent setup timesOlivia brianneNo ratings yet

- Joie 831309203000Document11 pagesJoie 831309203000julNo ratings yet

- A Survey of Lot Sizing and Scheduling ModelsDocument10 pagesA Survey of Lot Sizing and Scheduling ModelsClebson CardosoNo ratings yet

- A Study of Cycle Time Role in Product Safety Margin in Assembly Systems (Case Study)Document8 pagesA Study of Cycle Time Role in Product Safety Margin in Assembly Systems (Case Study)Prem AnanthNo ratings yet

- (Cybernetics and Information Technologies) A Survey of Solving Approaches For Multiple Objective Flexible Job Shop Scheduling ProblemsDocument20 pages(Cybernetics and Information Technologies) A Survey of Solving Approaches For Multiple Objective Flexible Job Shop Scheduling ProblemsajaymechengineerNo ratings yet

- Simple Assembly Line Balancing Problem Type 2 by Variable Neighborhood Strategy Adaptive Search: A Case Study Garment IndustryDocument22 pagesSimple Assembly Line Balancing Problem Type 2 by Variable Neighborhood Strategy Adaptive Search: A Case Study Garment IndustryAristita OmelcoNo ratings yet

- Multi-Agent Pathfinding With Continuous TimeDocument80 pagesMulti-Agent Pathfinding With Continuous TimeDavids MarinNo ratings yet

- Distributed Shifting Bottleneck Heuristic for Complex Job ShopsDocument18 pagesDistributed Shifting Bottleneck Heuristic for Complex Job ShopsMarcelo SandovalNo ratings yet

- Lahrichi 2021Document26 pagesLahrichi 2021Youssef LahrichiNo ratings yet

- A Genetic Algorithm Approach For The Time-Cost Trade-Off in PERT NetworksDocument23 pagesA Genetic Algorithm Approach For The Time-Cost Trade-Off in PERT NetworksLeonardo BaganhaNo ratings yet

- GESPRO Harmonie Discrete SearchDocument10 pagesGESPRO Harmonie Discrete Searchzrdasma01No ratings yet

- Accepted Manuscript: Swarm and Evolutionary Computation BASE DATADocument44 pagesAccepted Manuscript: Swarm and Evolutionary Computation BASE DATANasir SayyedNo ratings yet

- A H A F J S S W M C: N Efficient Euristic Lgorithm For Lexible OB HOP Cheduling ITH Aintenance OnstraintsDocument13 pagesA H A F J S S W M C: N Efficient Euristic Lgorithm For Lexible OB HOP Cheduling ITH Aintenance OnstraintsRaj PawarNo ratings yet

- Project Work (Uniben) RetouchedDocument26 pagesProject Work (Uniben) RetouchedClement Ofoluwanyo100% (1)

- Discrete-Time Control System Implementation Techniques: Advances in Theory and ApplicationsFrom EverandDiscrete-Time Control System Implementation Techniques: Advances in Theory and ApplicationsNo ratings yet

- A Variable Capacity Parallel Machine Scheduling ProblemDocument7 pagesA Variable Capacity Parallel Machine Scheduling Problemieom2012No ratings yet

- Operations Scheduling For Manufacturing Systems With Parallel ComputingDocument6 pagesOperations Scheduling For Manufacturing Systems With Parallel ComputingSakshi SaxenaNo ratings yet

- Minimizing mean completion time in hybrid flowshopsDocument12 pagesMinimizing mean completion time in hybrid flowshopsOlivia brianneNo ratings yet

- Scheduling Unrelated Parallel Machines with Sequence-Dependent Setup TimesDocument10 pagesScheduling Unrelated Parallel Machines with Sequence-Dependent Setup TimesOlivia brianneNo ratings yet

- Production Control of a Flexible Manufacturing System in a Job Shop EnvironmentDocument21 pagesProduction Control of a Flexible Manufacturing System in a Job Shop Environmentharshgupta2988No ratings yet

- Two MachineDocument5 pagesTwo MachineIAEME PublicationNo ratings yet

- On The Development of A Mixed-Integer Linear Programming Model For The Flowshop Sequencing ProblemDocument12 pagesOn The Development of A Mixed-Integer Linear Programming Model For The Flowshop Sequencing ProblemMuhammad Arif DarmawanNo ratings yet

- Applied Sciences: Hybrid Flow Shop Scheduling Problems Using Improved Fireworks Algorithm For PermutationDocument16 pagesApplied Sciences: Hybrid Flow Shop Scheduling Problems Using Improved Fireworks Algorithm For PermutationOlivia brianneNo ratings yet

- Assembly Line Balancing in A Clothing Company: S. H.Eryuruk, F. Kalaoglu, M. BaskakDocument6 pagesAssembly Line Balancing in A Clothing Company: S. H.Eryuruk, F. Kalaoglu, M. BaskakAbouSalsabilNo ratings yet

- A Branch-And-Bound Algorithm For The Hybrid #Owshop: O. Moursli !,, Y. Pochet!,"Document13 pagesA Branch-And-Bound Algorithm For The Hybrid #Owshop: O. Moursli !,, Y. Pochet!,"Ketut Edy SetiawanNo ratings yet

- Computers and Operations Research: Chunlong Yu, Quirico Semeraro, Andrea MattaDocument19 pagesComputers and Operations Research: Chunlong Yu, Quirico Semeraro, Andrea MattaOlivia brianneNo ratings yet

- Genetic Algorithm For Vehicle Routing Problem With BackhaulsDocument8 pagesGenetic Algorithm For Vehicle Routing Problem With BackhaulsYuri Adixs Ucux'saeNo ratings yet

- A23-Article 1680438103Document9 pagesA23-Article 1680438103Safiye SencerNo ratings yet

- Unrelated parallel machine scheduling with SADocument9 pagesUnrelated parallel machine scheduling with SAOlivia brianneNo ratings yet

- New Calculation of Thetray Numbers For Debutanizer Tower in BIPCDocument8 pagesNew Calculation of Thetray Numbers For Debutanizer Tower in BIPCinventionjournalsNo ratings yet

- Mixed-Integer Programming Models For Flowshop Scheduling Problems Minimizing The Total Earliness and TardinessDocument14 pagesMixed-Integer Programming Models For Flowshop Scheduling Problems Minimizing The Total Earliness and TardinessPugazhenthi RajagopalNo ratings yet

- Production and Delivery Scheduling Problem With Time WindowsDocument10 pagesProduction and Delivery Scheduling Problem With Time WindowsJose GarciaNo ratings yet

- A Dynamic Programming Algorithm For The Buffer Allocation Problem in Homogeneous Asymptotically Reliable Serial Production LinesDocument16 pagesA Dynamic Programming Algorithm For The Buffer Allocation Problem in Homogeneous Asymptotically Reliable Serial Production LinesDocente Fede TecnologicoNo ratings yet

- Aydillek. 2020. No-Wait Flowshop Scheduling Problem With Separate Setup Times To Minimize Total Tradiness Subject To MakespanDocument16 pagesAydillek. 2020. No-Wait Flowshop Scheduling Problem With Separate Setup Times To Minimize Total Tradiness Subject To Makespanmilyhya fgNo ratings yet

- Solar Energy: S. Daud, A.F.A. Kadir, C.K. Gan, A. Mohamed, Tamer KhatibDocument8 pagesSolar Energy: S. Daud, A.F.A. Kadir, C.K. Gan, A. Mohamed, Tamer KhatibAhmed HassanNo ratings yet

- Study On Selection of Intelligent Waterdrop Algorithm For Solving Multiple Problems: A ReviewDocument4 pagesStudy On Selection of Intelligent Waterdrop Algorithm For Solving Multiple Problems: A ReviewAhmed HassanNo ratings yet

- Et 24Document6 pagesEt 24Ahmed HassanNo ratings yet

- Genetik12 PDFDocument7 pagesGenetik12 PDFAhmed HassanNo ratings yet

- Nguyen ATDocument30 pagesNguyen ATAhmed HassanNo ratings yet

- 1 s2.0 S0005109816303041 MainDocument16 pages1 s2.0 S0005109816303041 MainAhmed HassanNo ratings yet

- Presentation 1Document1 pagePresentation 1Ahmed HassanNo ratings yet

- Samaa E-Learning System For Deaf Arab StudentsDocument5 pagesSamaa E-Learning System For Deaf Arab StudentsAhmed HassanNo ratings yet

- Determination of Hospital Waste Composition and Disposal Methods: A Case StudyDocument5 pagesDetermination of Hospital Waste Composition and Disposal Methods: A Case StudyAhmed HassanNo ratings yet

- First Steps With Embedded SystemsDocument228 pagesFirst Steps With Embedded SystemsAlex Granizo100% (1)

- 2002 TreeDocument2 pages2002 TreeAhmed HassanNo ratings yet

- Math 9Document8 pagesMath 9Erich GallardoNo ratings yet

- Brent Kung AdderDocument60 pagesBrent Kung AdderAnonymous gLVMeN2hNo ratings yet

- Design of Predictive Magic Cards.Document26 pagesDesign of Predictive Magic Cards.aries25th3No ratings yet

- 1 Percent For Grouped DataDocument9 pages1 Percent For Grouped DataRyan Cris FranciscoNo ratings yet

- On The Static Solutions in Gravity With Massive Scalar Field in Three DimensionsDocument11 pagesOn The Static Solutions in Gravity With Massive Scalar Field in Three DimensionsMojeime Igor NowakNo ratings yet

- Governor System (Electrical Part)Document142 pagesGovernor System (Electrical Part)የፐፐፐ ነገርNo ratings yet

- K Means QuestionsDocument2 pagesK Means QuestionsShakeeb ParwezNo ratings yet

- Sajc 2010 Prelim Math p2Document6 pagesSajc 2010 Prelim Math p2lauyongyiNo ratings yet

- Database Systems COMP-213: By: Shahid M HmoodDocument46 pagesDatabase Systems COMP-213: By: Shahid M HmoodTranceNo ratings yet

- Rr10302 Applied MechanicsDocument12 pagesRr10302 Applied MechanicsSRINIVASA RAO GANTANo ratings yet

- Understandable Statistics Concepts and Methods 12th EditionDocument61 pagesUnderstandable Statistics Concepts and Methods 12th Editionherbert.porter697100% (36)

- Design of a Rotary Wankel Compressor for Portable Power GenerationDocument6 pagesDesign of a Rotary Wankel Compressor for Portable Power GenerationSenthil KumarNo ratings yet

- FMEA Scope AnalysisDocument14 pagesFMEA Scope AnalysisAnkurNo ratings yet

- Powershape: Training CourseDocument18 pagesPowershape: Training CourseZulhendriNo ratings yet

- Evolutionary Computation:: Genetic AlgorithmsDocument49 pagesEvolutionary Computation:: Genetic AlgorithmsShobanraj LetchumananNo ratings yet

- Design and Analysis of Tension MemberDocument29 pagesDesign and Analysis of Tension MemberJhianne Dulpina RoqueNo ratings yet

- SRB Session1 RofsDocument4 pagesSRB Session1 RofsFullo Flores MarviloneNo ratings yet

- Fundamentals of Csec Mathematics: Section I Answer All Questions in This Section All Working Must Be Clearly ShownDocument18 pagesFundamentals of Csec Mathematics: Section I Answer All Questions in This Section All Working Must Be Clearly ShownSamantha JohnsonNo ratings yet

- Chapter 1ADocument35 pagesChapter 1ASandip GaikwadNo ratings yet

- The Relationship Between Capital Structure and Firm Performance - New Evidence From PakistanDocument12 pagesThe Relationship Between Capital Structure and Firm Performance - New Evidence From Pakistanhammadshah786No ratings yet

- Ee361 Mid2 Sp2021-3Document6 pagesEe361 Mid2 Sp2021-3Seb SebNo ratings yet

- Fugacity, Activity, Thermo GraphsDocument24 pagesFugacity, Activity, Thermo Graphs1MS19CH049100% (2)

- Calculus SyllabusDocument7 pagesCalculus SyllabusRumarie de la CruzNo ratings yet

- 23 Response OptimizationDocument30 pages23 Response OptimizationafonsopilarNo ratings yet

- What Is KnowledgeDocument7 pagesWhat Is KnowledgeRaunakMishraNo ratings yet

- HIMA - WhitePaper - Hybrid Systems For Smart Pipeline Management - finalEUDocument6 pagesHIMA - WhitePaper - Hybrid Systems For Smart Pipeline Management - finalEUAndrew XuguomingNo ratings yet

- DLL Mathematics-5 Q3 W5Document7 pagesDLL Mathematics-5 Q3 W5Charlota PelNo ratings yet

- HAL An Approach Attack To Goldbach ConjectureDocument23 pagesHAL An Approach Attack To Goldbach ConjectureEMMANUEL AUDIGÉNo ratings yet

- 4th Periodical Test in Math 5-NewDocument9 pages4th Periodical Test in Math 5-NewMitchz Trinos100% (2)