Professional Documents

Culture Documents

Jurnal Inter

Uploaded by

Ikhsan Nur RohimCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jurnal Inter

Uploaded by

Ikhsan Nur RohimCopyright:

Available Formats

International Journal of Chemistry; Vol. 4, No.

6; 2012

ISSN 1916-9698

E-ISSN 1916-9701

Published by Canadian Center of Science and Education

Studies on the Gelatinization Temperature of Some Cereal Starches

S. T. Ubwa1, J. Abah1, K. Asemave1 & T. Shambe1

1

Department of Chemistry, Benue State University, Makurdi, Nigeria

Correspondence: S. T. Ubwa, Department of Chemistry, Benue State University, P. M. B. 102119 Makurdi,

Nigeria. Tel: 234-705-714-8848. E-mail: simon.ubwa@yahoo.com

Received: August 15, 2012

doi:10.5539/ijc.v4n6p22

Accepted: October 10, 2012

Online Published: October 30, 2012

URL: http://dx.doi.org/10.5539/ijc.v4n6p22

Abstract

Gelatinization temperature of starches from different varieties of cereals, deep-red sorghum, red sorghum,

white sorghum, mixed sorghum, white fonio (Digitaria exilis), black fonio (Digitaria iburua), Eleusine

coracana (tamba), proso millet (p. miliacium), brown top millet (p. ramosum) and finger millet (Eleusine

coracana) were determined by electrical conductivity (EC) method. Among the untreated starches, the

results showed that tamba recorded the least onset and peak gelatinization temperatures of 53.0oC and 63.0oC

respectively while the highest onset gelatinization temperature, 76oC was recorded with proso millet. Proso

millet and finger millet had the highest peak gelatinization temperature. deep-red sorghum and red sorghum had

the least end gelatinization temperature while proso millet recorded the highest value. The 0.1MKCl treatment of

cereals starches produced elevated onset gelatinization temperatures (62.0-78.0oC). Mixed sorghum had the least

onset gelatinization temperature while proso millet and finger millet recorded the highest gelatinization

temperature. Following the 0.1MKCl treatment, starches from tamba and proso millet recorded the least and

highest peak gelatinization temperatures respectively. Deep-red and red sorghum recorded the least end

gelatinization temperatures while proso millet, brown top millet and finger millet recorded the highest end

gelatinization temperatures. The treatment of the cereals starches with 0.10MKCl significantly (p < 0.05)

delayed the onset gelatinization temperature of the starches and narrowed the gelatinization temperature range.

The results of the conductivity of both the 0.1MKCl treated and untreated starch showed nonlinearity within

the gelatinization range. This finding has important implication on the energy and time requirement to

gelatinize the starch for specific industrial use.

Keywords: cereals starch, electrical conductivity, gelatinization temperature

1. Introduction

Starch occurs as highly organized structures, known as starch granules. Starch has unique thermal properties and

functionality that have permitted its wide use in food products and industrial applications. When heated in water,

starch undergoes a transition process, during which the granules break down into a mixture of

polymers-in-solution, known as gelatinization. Starch gelatinization is a process that breaks down the

intermolecular bonds of starch molecules in the presence of water and heat, allowing the hydrogen bonding sites

(the hydroxyl hydrogen and oxygen) to engage more water (Sobkowska, 2001). Gelatinization temperature is

regarded as the temperature at which the phase transition of starch granules from an ordered state to a disordered

state occurs. The gelatinization temperature of starch depends upon plant type and the amount of water present, pH,

types and concentrations of salt, sugar, fat and protein in the recipe, degree of cross-linking of the amylopectin, the

amount of damaged starch granules as well as derivatisation technology used (Hermansson & Svegmark, 1996;

Delcour et al., 2000). Almeida-Dominguez et al. (1997) reported that larger and more compact corn particles

required additional time and energy for hydration preceding swelling and gelatinization. Thus, a proper

understanding of starch phase transitions is extremely important in food processing (Singh et al., 2003). Native

starch is not widely used in the food industry due to its poor functional properties and hence, most starches

currently incorporated into foods are chemically modified (Coral et al., 2009).

Starch functionalities are very often decisive for rheological properties of foods. As a thickener, starch modifies

food viscosity and affects texture and structure of foods. The modifications are seen as gelatinization, thickening,

and elevated resistance to heating, shock, and ageing (Tomasik, 2000). This is particularly important for the

quality of sauces, dressings, puddings, jams, jellies (Luallen, 2000). Processing technologies and quality of

products from cereal and potato materials containing starch as a reserve substance are directly related to

22

www.ccsenet.org/ijc

International Journal of Chemistry

Vol. 4, No. 6; 2012

properties of the polysaccharide in question (Hermansson & Svegmark, 1996; Delcour et al., 2000).

Corn starch has been considered as a valuable ingredient to the food industry, being widely used as a thickener,

gelling agent, bulking agent and water retention agent (Singh, 2003). The rising cost of sugar and the increased

availability of corn syrups have raised interest in the substitution of corn syrup for sucrose in bakery items,

especially in such high-sugar items as cakes. However, to satisfactorily replace sucrose in cakes, corn syrup must

perform most of the same functions as sucrose in the cake system. In this wise, an important function is the

proper understanding and control of starch gelatinization (Spies & Hoseney, 1982). Furthermore, starch-sugar

interactions play a significant role in delaying starch gelatinization; thus, increasing the energy required for

gelatinization and consequently, the cost.

According to Ubwa et al. (2011), the determination of gelatinization temperatures of some species of maize (Zea

mays L) and sorghum (Sorghum bicolor L) obtained from Guma local government area of Benue State revealed

the gelatinization temperature of white maize as 72-78oC, yellow maize, 66-72oC, white sorghum, 74-82oC; and

brown sorghum, 74-82oC. It was concluded that yellow maize could readily be converted into sugars because of

the least gelatinization temperatures.

Morales-Sanchez et al. (2009) carried out wet method for measuring starch gelatinization temperature using

electrical conductivity and found the gelatinization temperatures for potato, 55-66; wheat, 52-66; corn,

66.2-77; and rice, 66-82. The result so obtained was compared with the gelatinization temperatures (onset,

peak, and end) of Differential Scanning Calorimetry (DSC) method, with no significant differences. This

indicates that electrical conductivity is indeed a precise method that can have certain advantages, especially in

wet starch systems. Methods that can be used in the determination of gelatinization temperatures of starches are;

The Differential Scanning Calorimetry method, Falling Number method, Ultrasound Technique, Alkaline

Spreading Value, The Brabender Viscograph, electrical conductivity and photoelectric (Ubwa et al., 2011;

Ratnayake & Jackson, 2006).

Unmodified starch can be used in the pharmaceutical, paper, mining and building industriesit can be modified

and converted to starch derivatives, isosugar, high fructose syrup and ethanol (Interactive European Network for

Industrial Crops and their Application, 2003).

Works on gelatinization temperatures of starch have been done elsewhere particularly on improved corn varieties

but data were scanty on gelatinization temperature of local corn starches. Thus, this work determined

gelatinization temperatures of starches from different varieties of cereals, deep-red sorghum, red sorghum,

white sorghum, mixed sorghum, white Fonio (Digitaria exilis), black Fonio (Digitaria iburua) and Eleusine

coracana (tamba), proso millet (p. miliacium), brown top millet (p. ramosum) and finger millet (Eleusine

coracana) by electrical conductivity method; with a view to identifying species with lower gelatinization

temperature, which will therefore reduce the cost of food processing in the food industries and increase the rate

of digestion in animals. It also sought to know if the starch sources are suitable for use in pharmaceutical

industry as binder and in drug coating.

2. Materials and Methods

2.1 Area Description

The study areas consist of Buruku Local Government Area (Benue state), Pankshin, Barkin Ladi, Shendam, Jos

South, Langtan North and Langtan South Local Government Areas (Plateau). Some important data about the

areas are presented in Table 1.

2.2 Sample Collection and Preparation

Bulk samples of Sorghum were collected from four sampling areas (sampling stations) as follows; white

sorghum (Pankshin Local Government), mixed red and pale-yellow sorghum (mai edon toro) (Barkin Ladi Local

Government), deep-red sorghum (Langtan local government) and red sorghum (Shendam Local Government) of

Plateau State. Black and white Fonio and tamba were collected from Jos south local government of Plateau State.

Proso millet, brown top millet and finger millet were all collected from Etulo in Buruku local Government of

Benue state. In each of this Local Government, 150 g sample of each species were collected from four different

sampling stations and pooled together. Grains were carefully sorted to remove damaged kernels and debris

(Okolo, 1997). The samples were milled into flour and 0.5 g of each species was measured and labeled in a

beaker.

23

www.ccsenet.org/ijc

International Journal of Chemistry

Vol. 4, No. 6; 2012

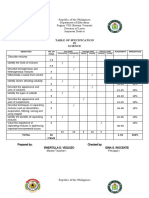

Table 1. Coordinates, total land areas and population of the study area

Study Area

Latitude

o

Longitude

o

Population NIPOST, 2009

Land Area

Buruku

7 07'7 44' N

8 45'9 36' E

203,721

1,246 km2

Pankshin

9o 14'9o 36 ' N

9o 20'9o 44' E

191,685

1, 524 km2

Barkin Ladi

9o 26'9o 46' N

8o 53'9o 14' E

175,267

1,032 km2

Shendam

8o 45'9o 15' N

9o 20'9o 45' E

208,017

2,477 km2

Jos South

9o 36'9o 55' N

8o 37'9o 07' E

306,716

510 km2

Langtan North

9o 08' N

9o 47' E

140,643

1, 188 km2

Langtan South

8o 38' N

9o 48' E

106, 305

838 km2

2.3 Procedure

The procedure used was the one reported by Li et al. (2004) with some slight modifications. 125 cm3 of distilled

water was poured in 250 cm3 wide-mouthed flasks (reaction vessel) and suspended in a 1000 cm3 Pyrex beaker

which served as the water bath. It was then placed on a three-heat hot plate, and the conductivity meter probe

was dipped into the reaction vessel. The hot plate was adjusted to give a degree Celsius rise in temperature per

minute. When the temperature in the reaction vessel had reached 45oC, cereal flour of 0.5 g was suspended in

25cm3 of distilled water and slowly poured into the reaction vessel. The conductivities of the mixture were

recorded degree Celsius rise interval till the Gelatinization temperature was obtained.

3. Results and Discussion

3.1 Results

The gelatinization temperatures and electrical conductivities of some cereals starch and the effects of treatment

with 0.10M KCl on the gelatinization temperatures of starches of some cereals obtained from farmers in six

different Local Government Areas of plateau State and Etulo (Buruku Local Government Area) of Benue State are

presented in Tables 1 and 2. The result in Figures 1 3 present the t-test analysis of the effects of the 0.1MKCl

treatment on the onset, peak and end gelatinization temperatures respectively.

Table 2. Gelatinization temperatures and electrical conductivities of starch from different cereals starch

Variety

To(oC)

Io(S)

Tp(oC)

Ip(S)

Te(oC)

Ie(S)

Deep-red Sorghum

64.0

28.9

70.0

31.2

76.0

31.5

12

Red Sorghum

64.0

55.3

72.0

58.5

76.0

60.2

12

White Sorghum

66.0

42.7

72.0

43.7

78.0

44.7

12

Mixed Sorghum

60.0

44.4

72.0

45.8

78.0

46.0

18

White Fonio

60.0

30.0

72.0

33.6

78.0

33.5

18

Black Fonio

60.0

23.5

74.0

26.9

82.0

26.8

22

Tamba

53.0

4.8

63.0

5.8

77.0

4.1

24

Proso millet

76.0

36.7

86.0

36.6

87.3

39.3

11.3

Brown top millet

72.0

39.0

84.0

39.3

86.0

40.3

14

Finger millet

74.0

39.0

86.0

42.2

87.1

42.3

13.1

24

www.ccsenet.org/ijc

International Journal of Chemistry

Vol. 4, No. 6; 2012

Table 3. Effect of 0.1M KCl on gelatinization temperatures and electrical conductivities from different cereals

starch

Variety

To(oC)

Io(S)

Tp(oC)

Ip(S)

Te(oC)

Ie(S)

Deep-red Sorghum

70.0

1106

74.0

1192

76.0

1123

Red Sorghum

66.0

1164

72.0

1225

76.0

1325

10

White Sorghum

66.0

959

74.0

1015

78.0

1095

12

Mixed Sorghum

62.0

1034

74.0

1214

78.0

1171

16

White Fonio

64.0

1015

78.0

1132

80.0

1131

16

Black Fonio

64.0

906

80.0

1037

84.0

1140

20

Tamba

66.0

1010

70.0

1025

80.0

1023

14

Proso millet

78.0

1274

85.0

1289

86.0

1295

Brown top millet

76.0

1218

84.0

1332

86.0

1340

10

Finger millet

78.0

1042

84.0

1050

86.0

1110

10

Figure 1. Effect of 0.1M KCl on onset gelatinization temperature of some cereals starch

25

www.ccsenet.org/ijc

International Journal of Chemistry

Vol. 4, No. 6; 2012

Figure 2. Effect of 0.1M KCl on peak gelatinization temperature of some cereals starch

Figure 3. Effect of 0.1M KCl on the end gelatinization temperature of some cereals starch

Key: Results of t-test analyses with the same alphabets are statistically significant (p < 0.05).

3.2 Discussion

The results of this study showed that tamba recorded the least onset and peak gelatinization temperatures of

53.0oC and 63.0oC respectively. The highest onset gelatinization temperature (76.0oC) was recorded in Proso

millet but Proso millet and Finger millet had the highest peak gelatinization temperature (86oC). Deep-red

Sorghum and Red Sorghum at 76.0oC had the least end gelatinization temperature while Proso millet with end

gelatinization temperature of 87.3oC was the highest recorded value (Ubwa et al., 2011; Morales-Sanchez et al.,

2009).

26

www.ccsenet.org/ijc

International Journal of Chemistry

Vol. 4, No. 6; 2012

The results in Table 2 show the effect of 0.10M KCl on the gelatinization temperatures of the starches.

Generally, there was delay of the onset gelatinization temperatures in all the cereal starches. Thus, the

onset gelatinization temperatures recorded elevated values (62.0oC78.0oC) following the treatment. In a

similar study, Chungcharoen and Lund (1987) noted that the treatment of rice flour with sodium chloride in

the ratio of 0.04:1 increased the gelatinization temperature but decreased the enthalpy of transition in the

rice flour and isolated starch samples. It was reported that the influence of ionic and non-ionic solutes on

starch gelatinization greatly altered the gelatinization characteristics. Chinachoti et al. (1991) also reported

a shift of onset gelatinization temperatures to higher values following treatment with sucrose. Rahman (1995)

reported that starch gelatinization is affected by various electrolytes, and the effects depend on the

concentration and type of anions and cations. Also according to (Jane, 1993), neutral salts affect the onset

gelatinization temperatures and heat of transition during corn starch gelatinization, and the effects differed

by type and concentration of the salt. Mixed Sorghum had the least onset gelatinization temperature of 62.0oC

while Proso millet and Finger millet recorded the highest onset gelatinization temperature of 78.0oC after the

treatment. Tamba had the least peak gelatinization temperature of 70.0oC after addition of the salt. Proso millet

gave the highest peak gelatinization temperature value (85.0oC). Deep-red Sorghum and Red Sorghum showed

the least end gelatinization temperature of 76.0oC. Proso millet, brown top millet and Finger millet had the

highest end gelatinization temperature of 86.0oC observed in this study. In general the gelatinization

temperature ranges become smaller as result of salt addition.

The T-test analysis of the effect of the salt on the onset gelatinization temperature of the starches (Figure 1) was

statistically significant (p < 0.05) for most of the starches except sorghum and Proso millet. Peak gelatinization

temperature of White sorghum, mixed sorghum, White Fonio and Black Fonio differed significantly (p < 0.05)

for the treated and untreated starches as presented in Figure 2. Addition of the salt showed no significant effect

on the peak gelatinization temperatures of Deep - red sorghum, Red sorghum, Tamba, Proso millet, Brown top

millet and Finger millet. Only White Fonio, Black Fonio, Tamba, proso millet and Finger millet showed

significant difference in their end gelatinization temperatures (Figure 3) following the 0.1MKCl treatment.

The results of the conductivity of both the 0.1MKCl treated and untreated starch showed nonlinearity within

the gelatinization range. This agrees with the findings of (Li et al., 2004) that during ohmic heating, there was

nonlinear relationship between electrical conductivity and the gelatinization temperature range. However, the

addition of 0.1M KCl to the starch significantly increased the electrical conductivity during the gelatinization

range.

4. Conclusion

Treatment of the starches with 0.100M KCl delays the gelatinization temperatures of the starches mostly at the

onset. Consequently, the gelatinization temperature ranges become smaller and this has important implication

on the energy and time required to gelatinize the starch for specific industrial use.

References

Almeida-Dominguez, H. D., Suhendro, E. L., & Rooney, L.W. (1997). Factors affecting rapid visco analyser

curves for the determination of maize kernel hardness. J. Cereal Sci., 25, 93-102.

http://dx.doi.org/10.1006/jcrs.1996.0072

Chinachoti, P., White, V. A., Lo, L., & Stengle, T. R. (1991). Aplication of high resolution carbon-13, oxygen-17,

and sodium-23 nuclear magnetic resonance to study the influence of water, sucrose, and sodium chloride on

starch gelatinization. Cereal Chem., 68, 238-244.

Chungcharoen, A., & Lund, D. B. (1987). Inluence of solutes and water on rice starch gelatinization. Cereal Chem.,

64(4), 240-243.

Coral, D. F., Pineda-Gomez, P., Rosales-Rivera, A., & Rodriguez-Garcia, M. E. (2009). Determination of the

Gelatinization Temperature of Starch Presents in Maize Flours. J. Phys.: Conf. Ser., 167, 012057.

http://dx.doi.org/10.1088/1742-6596/167/1/012057

Delcour, J. A., Vansteelandt, J., Hythier, M. C., Abecassis, J., Sindic, M., & Deroanne, C. (2000). Fractionation

and reconstitution experiments provide insight into the role of gluten and starch interactions in pasta quality.

J. Agric. Food Chem., 48, 3767-3773.

Hermansson, A. M., & Svegmark, K. (1996). Developments in the understanding of starch functionality. Trends

Food Sci. Technol., 7, 345.

Interactive European Network for Industrial Crops and their Application. (2003). Newsletter, Number 9, 1-4.

27

www.ccsenet.org/ijc

International Journal of Chemistry

Vol. 4, No. 6; 2012

Jane, J. L. (1993). Mechanism of starch gelatinization in neutral salt solutions. Starke, 45(5), 161-166.

http://dx.doi.org/10.1002/star.19930450502

Li, F. D., Li, L. T., Li, Z., & Tatsumi, E. (2004). Determination of Gelatinization Temperature of by Ohmic

Heating. Journal of Food Engineering, 62, 113-120. http://dx.doi.org/10.1016/S0260-8774(03)00199-7

Luallen, T. (2000). Utilizing starches in product development. In A-Ch. Eliason (Ed.), Starch in food. Structure,

function and applications. Boca Raton: CRC Press.

Morales-Sanchez, E., Figueroa, J. D. C., & Gaytan-Martinez, M. (2009). Wet Method for Measuring Starch

Gelatinization Temperature Using Electrical Conductivity. Journal of Food Science, 74(7), 382-385.

http://dx.doi.org/10.1111/j.1750-3841.2009.01279.x

Okolo, B. N., Ezeogu, L. I., & Uowuaxyi, K. E. (1997). Amylolysis of Sorghum Starch as Influenced by Cultivar,

Germination time and Gelatinisation Temperature. J. Lust. Brew., 103, 371-376

Rahman, S. (1995). Phase transition in foods. In S. Rahman (Ed.), Food Properties Handbook (pp. 153156).

Boca Raton, FL: CRC press.

Singh, N., Singh, J., Kaur, L., Sodhi, N. S., & Gill, B. S. (2003). Morphological, thermal and rheological properties

of starches from different botanical sources. Food Chemistry, 81, 219-231.

Sobkowska, E. (2001). Skrobia i glikogen oraz produkty skrobiowe [Starch and glycogen and starch products]. In

J. Gawcki (Ed.), Wspczesna wiedza o wglowodanach [Contemporary knowledge on carbohydrates].

Pozna [in Polish]: Wyd. AR.

Spies, R. D & Hoseney, R. C. (1982). Effects of Sugars on Starch Gelatinization. Cereal Chem., 59, 128

Tomasik, P. (2000). Wasciwosci funkcjonalne sacharydw [Functional properties of saccharides]. In Z. Sikorski

(Ed.), Chemia ywnosci. Skad, przemiany i wasciwosci ywnosci [Food chemistry. Composition,

transformations, and properties of foods]. Warsaw [in Polish]: WNT.

Ubwa, S. T, Adie, P. A., & Wuave, R. T. (2011). Determination of Gelatinization Temperatures of some species

of Maize (Zea Mays L) and Sorgum (Sorgum bicolorI L) obtained from Guma Local Government of Benue

State. Mkar Journal of Interdisciplinary Studies, 2(1), 61-66.

Ratnayake, W. S., & Jackson, D. S. (2006). Gelatinization and Solubility of Corn Starch during Heating in

Excess Water: New Insights. Journal of Agricultural and Food Chemistry, 54(10), 3712-3716.

http://dx.doi.org/10.1021/jf0529114

28

You might also like

- Laboratory scale production of glucose syrup from maize, millet and sorghum starchDocument8 pagesLaboratory scale production of glucose syrup from maize, millet and sorghum starchRizqa FauziyahNo ratings yet

- Characterization of Starch in Relation To Flesh Colors of Sweet Potato VarietiesDocument7 pagesCharacterization of Starch in Relation To Flesh Colors of Sweet Potato Varietiesnurul khaeriaNo ratings yet

- 1 s2.0 S0733521016301011 MainDocument8 pages1 s2.0 S0733521016301011 MainhitomitsukiNo ratings yet

- Optimization of Potato Starch Gel Formulation As Green Alternative of Animal-Sourced GelatinDocument9 pagesOptimization of Potato Starch Gel Formulation As Green Alternative of Animal-Sourced GelatinMARIA FERNANDA MATTOS VILANo ratings yet

- Dietary Fiber and Β-glucan Contents of Oat Tarhana- A Turkish Fermented Cereal FoodDocument6 pagesDietary Fiber and Β-glucan Contents of Oat Tarhana- A Turkish Fermented Cereal FoodoliviaNo ratings yet

- Food Chemistry: Kaleab Baye, Claire Mouquet-Rivier, Christèle Icard-Vernière, Isabelle Rochette, Jean-Pierre GuyotDocument7 pagesFood Chemistry: Kaleab Baye, Claire Mouquet-Rivier, Christèle Icard-Vernière, Isabelle Rochette, Jean-Pierre GuyotYoseph AssefaNo ratings yet

- Properties of StarchDocument13 pagesProperties of StarchPadmavati KarthicNo ratings yet

- Wani 2012Document7 pagesWani 2012kamali dikshithaNo ratings yet

- Paper JM BfsDocument6 pagesPaper JM BfsPaula Pedrozo FavierNo ratings yet

- Characterization of Cassava Starch and Its PotentiDocument10 pagesCharacterization of Cassava Starch and Its PotentiLucky SamsonNo ratings yet

- 1 s2.0 S0733521020305701 MainDocument9 pages1 s2.0 S0733521020305701 MainLUIS EDUARDO CIRO PARRANo ratings yet

- Bakare Et Al, 2016 - Rheological, Baking, and Sensory Properties of Composite Bread Dough With Breadfruit and Wheat FlourDocument15 pagesBakare Et Al, 2016 - Rheological, Baking, and Sensory Properties of Composite Bread Dough With Breadfruit and Wheat FlourArinamelia PsNo ratings yet

- Vida de AnaquelDocument8 pagesVida de AnaquelDANIELA AVILA HERNANDEZNo ratings yet

- Lu 2006Document7 pagesLu 2006Willian QuinteroNo ratings yet

- Process Optimization and Characterization of Popped Brown RiceDocument12 pagesProcess Optimization and Characterization of Popped Brown Ricea4558305No ratings yet

- Effect of High-Pressure Treatment On Rheological, Thermal and Structural Changes in Basmati Rice Our SlurryDocument9 pagesEffect of High-Pressure Treatment On Rheological, Thermal and Structural Changes in Basmati Rice Our SlurryPenina TariganNo ratings yet

- tmpD928 TMPDocument9 pagestmpD928 TMPFrontiersNo ratings yet

- Kaur 2007Document11 pagesKaur 2007kamali dikshithaNo ratings yet

- Effect of Soaking and Roasting On The Physicochemical and Pasting Properties of Soybean FlourDocument11 pagesEffect of Soaking and Roasting On The Physicochemical and Pasting Properties of Soybean Flourdesy ratna purwantiNo ratings yet

- Potravinarstvo Slovak Journal of Food Sciences: Diah Susetyo Retnowati, Andri Cahyo Kumoro, Ratnawati RatnawatiDocument7 pagesPotravinarstvo Slovak Journal of Food Sciences: Diah Susetyo Retnowati, Andri Cahyo Kumoro, Ratnawati RatnawatiNur Arif MajidNo ratings yet

- Physical-Chemical Characteristics Determination of Potato (Solanum Phureja Juz. & Bukasov) StarchDocument8 pagesPhysical-Chemical Characteristics Determination of Potato (Solanum Phureja Juz. & Bukasov) StarchCamilo MartinezNo ratings yet

- Rice Flour PropertiesDocument7 pagesRice Flour PropertiesJorge GKNo ratings yet

- Chapter-2-RELATED LITERATUREDocument10 pagesChapter-2-RELATED LITERATURENizeth Jane Macion CuajotorNo ratings yet

- Cereal Chem - 1998 - Wehrle - Rheological Changes in Wheat Sourdough During Controlled and Spontaneous FermentationDocument5 pagesCereal Chem - 1998 - Wehrle - Rheological Changes in Wheat Sourdough During Controlled and Spontaneous Fermentationmohamed.alkadour96No ratings yet

- Effect of Salinity On Proteins in Some Wheat CultivarsDocument9 pagesEffect of Salinity On Proteins in Some Wheat Cultivarsray m deraniaNo ratings yet

- Evaluating The Effects of Sweet Potato Varieties On Flour QualityDocument28 pagesEvaluating The Effects of Sweet Potato Varieties On Flour QualityInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- FNS20120300006 90511490Document7 pagesFNS20120300006 90511490Olga Diokta FerinnandaNo ratings yet

- Cereal Chem - 2002 - Clarke - Effect of Single Strain and Traditional Mixed Strain Starter Cultures On RheologicalDocument8 pagesCereal Chem - 2002 - Clarke - Effect of Single Strain and Traditional Mixed Strain Starter Cultures On Rheologicalmohamed.alkadour96No ratings yet

- 3 - Examination of Freshness Degradation of Sourdough Bread Made With Kefir Through PDFDocument7 pages3 - Examination of Freshness Degradation of Sourdough Bread Made With Kefir Through PDFDuyệt LêNo ratings yet

- Tarobiscend PDFDocument12 pagesTarobiscend PDFGina AshfihaniNo ratings yet

- Studies On The Gelatinization Temperature of Some Cereal StarchesDocument8 pagesStudies On The Gelatinization Temperature of Some Cereal StarchesMochammad ilhan naafiNo ratings yet

- 1 s2.0 S0268005X11001688 MainDocument8 pages1 s2.0 S0268005X11001688 MainAlejandro RamirezNo ratings yet

- Original Article Properties of Extruded Whole Grain Cereals and Pseudocereals FloursDocument8 pagesOriginal Article Properties of Extruded Whole Grain Cereals and Pseudocereals FloursRONEL JOEL BAZAN COLQUENo ratings yet

- New - Hab.1 (Repaired)Document42 pagesNew - Hab.1 (Repaired)Thiago leonardNo ratings yet

- Noodle Quality As Related To Sorghum Starch Properties: Cereal Chemistry July 2001Document5 pagesNoodle Quality As Related To Sorghum Starch Properties: Cereal Chemistry July 2001Starla CintaNo ratings yet

- Food HydrocolloidsDocument11 pagesFood HydrocolloidsLauraGómezPamiesNo ratings yet

- Chemical Composition and Nutritional Value of Composite Wheat Flours (Triticumaestivum) and Two Varieties of Taro Corms (Colocasiaesculenta) Cultivar Fouê and Cultivar YatanDocument5 pagesChemical Composition and Nutritional Value of Composite Wheat Flours (Triticumaestivum) and Two Varieties of Taro Corms (Colocasiaesculenta) Cultivar Fouê and Cultivar Yatanamir ShehzadNo ratings yet

- Noodle SorghumDocument4 pagesNoodle SorghumSukmiyati AgustinNo ratings yet

- 09.review On The Physicochemical Properties, Modifications, and Applications of Starches and Its Common Modified Forms Used in Noodle ProductsDocument25 pages09.review On The Physicochemical Properties, Modifications, and Applications of Starches and Its Common Modified Forms Used in Noodle ProductsKiefer YuNo ratings yet

- LWT - Food Science and TechnologyDocument6 pagesLWT - Food Science and TechnologyAnderson Widmer Morales VillarrealNo ratings yet

- The_Effect_of_Ultrasonic_Water_Treatment_on_the_ChDocument11 pagesThe_Effect_of_Ultrasonic_Water_Treatment_on_the_ChBianca LeyvaNo ratings yet

- Preparation of Freeze-Dried Yoghurt As A Space FoodDocument6 pagesPreparation of Freeze-Dried Yoghurt As A Space FoodNhan NguyenNo ratings yet

- IFRJ 19 (03) 2012 BalaDocument5 pagesIFRJ 19 (03) 2012 BalaAmbalavanan ChockalingamNo ratings yet

- Durum WheatDocument9 pagesDurum WheatwondimuNo ratings yet

- Extraction, Denaturation and Hydrophobic Properties of Rice Flour ProteinsDocument12 pagesExtraction, Denaturation and Hydrophobic Properties of Rice Flour ProteinsKishore SakhileNo ratings yet

- 121116-Article Text-333127-1-10-20150819Document10 pages121116-Article Text-333127-1-10-20150819Lima CostaNo ratings yet

- Physicochemical Properties of Starches from Quality Protein MaizeDocument10 pagesPhysicochemical Properties of Starches from Quality Protein MaizeMatache GabrielaNo ratings yet

- StructuralDocument10 pagesStructuralGabrielaPilarNo ratings yet

- Foods: The Physicochemical Characterization of Unconventional Starches and Flours Used in AsiaDocument12 pagesFoods: The Physicochemical Characterization of Unconventional Starches and Flours Used in AsiaWalter Chisholm SánchezNo ratings yet

- Effects of Phosphate Modified and PregelatinizedDocument5 pagesEffects of Phosphate Modified and Pregelatinizedderi arisandiNo ratings yet

- Effect of Feed Composition, Moisture Content and Extrusion Temperature On Extrudate Characteristics of Yam-Corn-Rice Based Snack FoodDocument9 pagesEffect of Feed Composition, Moisture Content and Extrusion Temperature On Extrudate Characteristics of Yam-Corn-Rice Based Snack FoodRomaric OuetchehouNo ratings yet

- Modelling of Glucose Syrup Production ProcessDocument8 pagesModelling of Glucose Syrup Production ProcessMuhammadAbdulHadiNo ratings yet

- Farine de MaisDocument7 pagesFarine de Maisimene boulaalouaNo ratings yet

- Physicochemical Properties of Thermal Alkaline Treated Pigeonpea (Cajanus Cajan L.) FlourDocument8 pagesPhysicochemical Properties of Thermal Alkaline Treated Pigeonpea (Cajanus Cajan L.) FlourAnonymous daxVUxCkYNo ratings yet

- Effect of Blending Selected Tropical Starches On Pasting Properties of Rice FlourDocument12 pagesEffect of Blending Selected Tropical Starches On Pasting Properties of Rice FlourBrianNo ratings yet

- Influence of Different Growth Conditions On The Kefir Grains Production, Used in The Kefiran SynthesisDocument7 pagesInfluence of Different Growth Conditions On The Kefir Grains Production, Used in The Kefiran Synthesispascaru_alinNo ratings yet

- Extraction and Characterization of Sorghum (Sorghum Bicolor L. Moench) StarchDocument6 pagesExtraction and Characterization of Sorghum (Sorghum Bicolor L. Moench) StarchJohn Georvin DuranNo ratings yet

- Microbiological Changes During The Production of Maize-Acha Masa Fortified With SoybeanDocument9 pagesMicrobiological Changes During The Production of Maize-Acha Masa Fortified With SoybeanAdekunbi MalomoNo ratings yet

- Changes in SPF Characteristics With DryingDocument7 pagesChanges in SPF Characteristics With DryingjairoagogoNo ratings yet

- A Compilation of Ligno-Cellulose Feedstock and Related Research for Feed, Food and EnergyFrom EverandA Compilation of Ligno-Cellulose Feedstock and Related Research for Feed, Food and EnergyNo ratings yet

- Aashto t305Document3 pagesAashto t305SyahrulRamadhanNo ratings yet

- Ecosurf SA 9Document2 pagesEcosurf SA 9ketchitoNo ratings yet

- File: Company: Jotun India PVT - Ltd. Site: A1 Fence PCO Process: Powder Coating Product: I BeamDocument1 pageFile: Company: Jotun India PVT - Ltd. Site: A1 Fence PCO Process: Powder Coating Product: I BeamEidrish ShaikhNo ratings yet

- Form 5-06 PDFDocument1 pageForm 5-06 PDFAlma PustaNo ratings yet

- Cement kiln heat balance and energy auditDocument9 pagesCement kiln heat balance and energy auditZia Khan100% (3)

- Periodical Test in SCIENCE Melc BasedDocument6 pagesPeriodical Test in SCIENCE Melc Basedaiko idioNo ratings yet

- Junior Science Talent Search Exam. (2014-2015) Subject: Chemistry Time: - M.M. 40 General InstructionsDocument6 pagesJunior Science Talent Search Exam. (2014-2015) Subject: Chemistry Time: - M.M. 40 General InstructionsKushagraNo ratings yet

- AP Biology Pea Germination LabDocument3 pagesAP Biology Pea Germination Labg2gusc38No ratings yet

- Cpre 288 Project Day1Document6 pagesCpre 288 Project Day1api-381302027No ratings yet

- Cold AsphaltDocument440 pagesCold AsphaltDem Hasi100% (1)

- Sika Poxitar MyDocument3 pagesSika Poxitar Myhijur ChenNo ratings yet

- CBSE Class 9 Science Notes Atoms and MoleculesDocument43 pagesCBSE Class 9 Science Notes Atoms and MoleculesArjunNo ratings yet

- Descriptions: PEG-4000 Is A Water-Soluble, Waxy Solid That Is Used Extensively in The Several Industries Such AsDocument1 pageDescriptions: PEG-4000 Is A Water-Soluble, Waxy Solid That Is Used Extensively in The Several Industries Such AsKeremNo ratings yet

- THERMODYNAMICSDocument12 pagesTHERMODYNAMICSVaibhav Vithoba NaikNo ratings yet

- PDF DocumentDocument5 pagesPDF DocumentMargaret Lawrence100% (1)

- Abdos Catlog 2013 - 14Document63 pagesAbdos Catlog 2013 - 14nirmalpharmaNo ratings yet

- Chemlok Adhesive: Rubber To Metal Metal To Metal Rubber To RubberDocument10 pagesChemlok Adhesive: Rubber To Metal Metal To Metal Rubber To RubberInChy Rencarnation PoseidonNo ratings yet

- BS 7371-1-2009 General RequirementsDocument24 pagesBS 7371-1-2009 General RequirementsmoorthyxNo ratings yet

- He Islamic University of Gaza Civil Engineering Department Soil Mechanics Second Semester Instructor: Dr. Jehad Hamad T.A: Eng. Waseem YounisDocument8 pagesHe Islamic University of Gaza Civil Engineering Department Soil Mechanics Second Semester Instructor: Dr. Jehad Hamad T.A: Eng. Waseem YounisIfiokobong AkpanNo ratings yet

- Mole Funsheet 2Document1 pageMole Funsheet 2Sk Aul DherNo ratings yet

- Commercial Main Stub-Out Assembly Product Component Submittal 2010Document53 pagesCommercial Main Stub-Out Assembly Product Component Submittal 2010Jose Andre Flores ChiaNo ratings yet

- Flange Torque RecommendationsDocument2 pagesFlange Torque RecommendationsTulioLopezJNo ratings yet

- Manual SC30TDocument60 pagesManual SC30Tdetrusitol73% (15)

- ME2151E Tut 1 PDFDocument21 pagesME2151E Tut 1 PDFchenshicatherineNo ratings yet

- Physical and Chemical Changes WorksheetDocument4 pagesPhysical and Chemical Changes WorksheetAndrew ChenNo ratings yet

- Performance Chemical Products GuideDocument4 pagesPerformance Chemical Products GuideA MahmoodNo ratings yet

- UST-IACUC Animal Care ReviewDocument8 pagesUST-IACUC Animal Care ReviewKate Montenegro0% (1)

- 2 Agrostudies Temperature ManagementDocument62 pages2 Agrostudies Temperature ManagementYolaina EdwarNo ratings yet