Professional Documents

Culture Documents

2015 12 GETRAG Lecture Modular Hybrid Transmission Kit

Uploaded by

putex247Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2015 12 GETRAG Lecture Modular Hybrid Transmission Kit

Uploaded by

putex247Copyright:

Available Formats

Modular Hybrid Transmission Kit

for GETRAGs new PowerShift Generation

Uli Christian Blessing, Senior Manager & Chief Engineer Hybrid, GETRAG

GETRAG, 2015, 14th International CTI Symposium December 2015, Berlin

Ready for the CO2-Challenge

Agenda

1.

Motivation

2.

DCT Transmission Family

3.

Hybrid Transmission Kit

4.

48 V Comparison

5.

Plug-In Hybrid Solutions

6.

Conclusion and Summary

14th International CTI Symposium Germany 2015, Berlin | Senior Manager & Chief Engineer Hybrid, GETRAG | Uli Christian Blessing

Ready for the CO2-Challenge

Motivation

CO2 Improvements

High efficient powertrain

Power on demand actuation

Extended sailing functionality

Pure electric driving

Downsized engines

Customer/OEM Needs

Hybrid as must-have option

New driving functionalities

Easy scalability

Easy adaptation

No serviceability

Real world fuel savings

Automated driving

Costs

Transmission kit

Volume of scale

Reduce rare earth materials

14th International CTI Symposium Germany 2015, Berlin | Senior Manager & Chief Engineer Hybrid, GETRAG | Uli Christian Blessing

Fun 2 Drive

Increased launch performance

Boosting

Immediate reaction

Functionality

Shift-by-Wire

Park-by-Wire

In-a-box solution

Integrated hybridization

Ready for the CO2-Challenge

Looking for the Swabian CO2-Champion

Situation Today Near Future:

Various concepts (minor to medium volumes)

Various hybrid power levels:

Mild hybrid (48 V with 15 kW) with significant volume demand

Full hybrid (220 V with 50 kW)

Plug-in hybrid (>360 V with 80 kW)

Very high diversity on OEM requirements

High costs (for piece price and development) due to low overall volumes

Target: One hybrid transmission kit, that can cover most of the needs

14th International CTI Symposium Germany 2015, Berlin | Senior Manager & Chief Engineer Hybrid, GETRAG | Uli Christian Blessing

DCT Transmission Family

Ready for the CO2-Challenge

DCT Transmission Family

7DCT300

Input torque up to 320 Nm

7-speed + R with a gear ratio span of up to 8.5

Center distance of 188 mm and 197 mm

Dry weight of 67 kg

6DCT200

Input torque up to 230 Nm

6-speed + R with a gear ratio span of up to 8.0

Center distance of 183 mm

Dry weight of 61 kg

14th International CTI Symposium Germany 2015, Berlin | Senior Manager & Chief Engineer Hybrid, GETRAG | Uli Christian Blessing

Ready for the CO2-Challenge

DCT Transmission Family

Common Hardware

Wet nested double clutch

TCU mounted to housing

Electronics

Sensors

BLDC motors

Clutch actuation and clutch cooling

Others

Global manufacturing footprint

Common software architecture

14th International CTI Symposium Germany 2015, Berlin | Senior Manager & Chief Engineer Hybrid, GETRAG | Uli Christian Blessing

Hybrid Transmission Kit

Ready for the CO2-Challenge

Hybrid Transmission Kit

Key Features

Torquesplit architecture

Scalable power level:

48V hybrid up to 16 kW

Plug-in hybrid more than 80 kW

E-machine:

Integrated and high-speed

Oil-cooled

Pre-assembled as tested unit

Adjustable cooling flow (using the same electric

cooling pump as the clutch cooling)

Assembly of e-machine and inverter at GETRAG

14th International CTI Symposium Germany 2015, Berlin | Senior Manager & Chief Engineer Hybrid, GETRAG | Uli Christian Blessing

Ready for the CO2-Challenge

Hybrid Transmission Kit Overview of Hybrid Functions

Hybrid Modes

Pure electric driving

Extended sailing

Recuperation

Boosting

Generator-mode / load-shift

Charge@standstill

Restart of internal combustion engine with torquesplit effect

Remark: Hybrid modes identical for 48 V Mild and Plug-in version

10

14th International CTI Symposium Germany 2015, Berlin | Senior Manager & Chief Engineer Hybrid, GETRAG | Uli Christian Blessing

Ready for the CO2-Challenge

Hybrid Transmission Family

7HDT300 - 48V

Based on 7DCT300

E-machine connected to sub-transmission 2

Additional weight of 21 kg

Up to 1800 Nm output torque

6HDT200 48V

Based on 7DCT300

E-machine connected to sub-transmission 2

Additional weight of 22 kg

Up to 1500 Nm output torque

11

14th International CTI Symposium Germany 2015, Berlin | Senior Manager & Chief Engineer Hybrid, GETRAG | Uli Christian Blessing

Ready for the CO2-Challenge

7HDT300 Package Comparison of DCT vs HDT

Key Features

No transmission length increase

Minimized overall hybrid package

Same interfaces as DCT

7DCT300

12

14th International CTI Symposium Germany 2015, Berlin | Senior Manager & Chief Engineer Hybrid, GETRAG | Uli Christian Blessing

7HDT300

Ready for the CO2-Challenge

7HDT300 Latest Design for 48 V

Shiftdrum 2 motor

E-machine

48 V inverter

Shiftdrum 1 motor

Clutch1/2 actuation motor

13

14th International CTI Symposium Germany 2015, Berlin | Senior Manager & Chief Engineer Hybrid, GETRAG | Uli Christian Blessing

48 V Comparison

Ready for the CO2-Challenge

48 V Comparison: Belt vs. Flanged vs. Integrated Solution

Belt Solution

Flanged Solution

Integrated Solution

Key Facts

Key Facts

Key Facts

Air-cooled claw pole EM

Belt-connection to ICE

Integrated inverter

Water-cooled EM

Flanged to transmission

Stand-alone inverter

Oil-cooled EM

Integrated in gearbox

Stand-alone inverter

Remark: For simplicity reasons, only these three main-stream examples

have been chosen

15

14th International CTI Symposium Germany 2015, Berlin | Senior Manager & Chief Engineer Hybrid, GETRAG | Uli Christian Blessing

Ready for the CO2-Challenge

48 V Comparison: Belt vs. Flanged vs. Integrated Solution

Belt Solution

Flanged Solution

Integrated Solution

Max. torque

up to 50 Nm

up to 50 Nm

up to 50 Nm

Max. power

12 - 14 kW

up to 18 kW

up to 18 kW

Cont. power

2,5 - 3,5 kW

up to 8 kW*

up to 13 kW*

up to 85%

up to 94%

up to 95%

NEDC

10 - 12%

17 - 20%

19 - 22%

WLTP

7 - 9%

12 - 14%

14 - 16%

EM-Performance

Efficiency

Fuel Efficiency

*depending on battery performance

16

14th International CTI Symposium Germany 2015, Berlin | Senior Manager & Chief Engineer Hybrid, GETRAG | Uli Christian Blessing

Ready for the CO2-Challenge

48 V Comparison: Belt vs. Flanged vs. Integrated Solution

Belt Solution

Flanged Solution

Integrated Solution

not possible

possible*

possible*

limited

possbile

possbile

Generator

possbile

diff. gears

diff. gears

Drivability

limited improvement

strong improvement

strong improvement

Package

easy

challenging

possible

Efficiency

belt-drive

efficient

very high

Hybrid Modes

El. creep/drive

Boosting

Others

17

14th International CTI Symposium Germany 2015, Berlin | Senior Manager & Chief Engineer Hybrid, GETRAG | Uli Christian Blessing

Ready for the CO2-Challenge

Integrated Solution offers much better el. Driving Performance

Continuous Power of Belt vs. Integrated Solution

T in Nm

T in Nm

Integrated Solution

Belt Solution

100

100

Drag torque range of typical

combustion engines

50

50

0

0

2.000

4000

6000

n in rpm

2.000

4000

Remark: The Flanged Solution is close to the Integrated Solution

18

14th International CTI Symposium Germany 2015, Berlin | Senior Manager & Chief Engineer Hybrid, GETRAG | Uli Christian Blessing

6000

n in rpm

Easy Scalability

Ready for the CO2-Challenge

Easy Scalability: From 48 V Mild up to 360 V Plug-In Hybrid

48 V System

360 V System

Max. torque

up to 50 Nm

up to 150 Nm

Max. power

up to 21 kW

up to 110 kW

Cont. power

up to 13 kW*

up to 35 kW*

Efficiency

up to 95%

up to 96%

Max. speed

18.000 rpm

18.000 rpm

Max. phase

current

350 A

450 A

EM-Performance

20

14th International CTI Symposium Germany 2015, Berlin | Senior Manager & Chief Engineer Hybrid, GETRAG | Uli Christian Blessing

Changed stator windings

and power connectors

ensure easy scalability

Ready for the CO2-Challenge

48 V Comparison: Belt vs. Flanged vs. Integrated Solution

48 V System

360 V System

El. creep/drive

limited (20 - 30km/h)

possible (>130 km/h)

Boosting/Generator

possible (diff. gears)

possible (diff. gears)

medium

high (battery!)

NEDC

19 - 22%

26 - 80%

WLTP

14 - 16%

19 - 68%

Hybrid Modes

Cost

Fuel Efficiency

21

14th International CTI Symposium Germany 2015, Berlin | Senior Manager & Chief Engineer Hybrid, GETRAG | Uli Christian Blessing

Summary & Outlook

Modular Hybrid Transmission Kit for DCTs

Summary

23

Hybrid transmission kit established for new DCT transmission family

Easy scalabilty from 48 V up to Plug-In Hybrid

Modular integrated high-speed e-machine

Integrated 48 V system offers best ratio of cost vs. CO2 improvements

Significant fuel efficiency improvements can be achieved

Ready for the CO2-Challenge

Modular Hybrid Transmission Kit also useable for MTs

Outlook

The same hybrid transmission kit can also be used for MT

Hybrid set-up:

MT gearbox with e-clutch

Integrated high-speed e-machine

Flanged 48 V Inverter

Hybrid functionalities:

Pure el. driving

Boosting, Recuperation

Charging @ Standstill

Restart of the internal combustion engine

Fuel efficiency improvements up to 18%

24

14th International CTI Symposium Germany 2015, Berlin | Senior Manager & Chief Engineer Hybrid, GETRAG | Uli Christian Blessing

You might also like

- At Re7r01aDocument212 pagesAt Re7r01aสนั่น วิริยะเจริญกุลNo ratings yet

- SSP 300 6 Speed Automatic Transmission 09DDocument56 pagesSSP 300 6 Speed Automatic Transmission 09DKatarina UllforsNo ratings yet

- Transmission Control Module (TCM) Adaptation - 8HP45 / 845RE / 8HP50 / 8HP70 / 8HP75 / 8HP90Document6 pagesTransmission Control Module (TCM) Adaptation - 8HP45 / 845RE / 8HP50 / 8HP70 / 8HP75 / 8HP90jorge almaraz0% (1)

- CVT VB Common Warranty Complaints TsDocument9 pagesCVT VB Common Warranty Complaints TsAhmedkamal10No ratings yet

- Honda GX 630 - 660 - 690Document79 pagesHonda GX 630 - 660 - 690joao mariaNo ratings yet

- Global Service LearningDocument63 pagesGlobal Service LearningEslamAldenAbdo100% (4)

- 8 HP45 Hi SSWDocument37 pages8 HP45 Hi SSWВиталий ЧерненкоNo ratings yet

- Mercedes 9g-Tronic InfoDocument17 pagesMercedes 9g-Tronic InfoRob LeaneyNo ratings yet

- Dual-Clutch Transmission: Scalable HybridDocument4 pagesDual-Clutch Transmission: Scalable HybridSamadNo ratings yet

- 09a, B 1 PDFDocument72 pages09a, B 1 PDFdevfin100% (1)

- Vaccum Testing Info SonnaxDocument34 pagesVaccum Testing Info SonnaxRobert Moreau100% (3)

- Thectsc Mechatronic ReplacementDocument22 pagesThectsc Mechatronic Replacementros56100% (1)

- Presentation 7DCT300Document37 pagesPresentation 7DCT300Mauricio Exequiel Chavez100% (1)

- COLUMN DESIGN REPORTDocument13 pagesCOLUMN DESIGN REPORTdongshengNo ratings yet

- CtimagDocument40 pagesCtimagDeepak Chachra100% (1)

- 1.users Manual Dipstick Mercedes 722.6 722.7 722.8 Professional ToolsDocument2 pages1.users Manual Dipstick Mercedes 722.6 722.7 722.8 Professional ToolsLeonardo SouttoNo ratings yet

- BS en 12334-2001Document14 pagesBS en 12334-2001Udit Kumar SarkarNo ratings yet

- SM 11 PDFDocument139 pagesSM 11 PDFEnrique Arevalo LeyvaNo ratings yet

- A1083290 - MAN - CG+MP16II RevBDocument104 pagesA1083290 - MAN - CG+MP16II RevBhardev88% (8)

- 01K inDocument2 pages01K indaniel100% (1)

- 307-01 Automatic Transmission 10 Speed - Description and Operation - D ClutchDocument6 pages307-01 Automatic Transmission 10 Speed - Description and Operation - D ClutchCARLOS LIMADA100% (1)

- Repair Manual: ZF Getriebe GMBH SaarbrückenDocument104 pagesRepair Manual: ZF Getriebe GMBH SaarbrückenVIDAL ALEJANDRO GARCIAVARGASNo ratings yet

- Cmax 4aDocument13 pagesCmax 4aAlberto Morillas Puebla100% (2)

- Jatco/Nissan JF016E, JF017E: (RE0F10D) (RE0F10E)Document1 pageJatco/Nissan JF016E, JF017E: (RE0F10D) (RE0F10E)ak_adamNo ratings yet

- Aisin Aw Tr-60snDocument1 pageAisin Aw Tr-60snJesus Alejandro Miranda PalaciosNo ratings yet

- Merc 722-5 ManualDocument104 pagesMerc 722-5 ManualcarlosNo ratings yet

- 09D-TG AtsgDocument75 pages09D-TG AtsgValdir Gomiero100% (1)

- GM 5L40E Automatic Diagrams and ListDocument9 pagesGM 5L40E Automatic Diagrams and ListBrayan Aragon diego100% (1)

- Unrestrained Beam With End MomentsDocument9 pagesUnrestrained Beam With End MomentsNikos StathoulopoulosNo ratings yet

- Haltech Support CenterDocument15 pagesHaltech Support Centerkorovnikovdenis8No ratings yet

- The 8-Speed Automatic Transmission 09P: Self Study Program 850193Document37 pagesThe 8-Speed Automatic Transmission 09P: Self Study Program 850193Allan Cancino100% (1)

- Workshop Manual Checking Fluid Level PDKDocument11 pagesWorkshop Manual Checking Fluid Level PDKEderson BJJNo ratings yet

- CUTIE DSG 2 TOURAN 1.6 DIESEL - PDF Versiunea 1 PDFDocument403 pagesCUTIE DSG 2 TOURAN 1.6 DIESEL - PDF Versiunea 1 PDFMarinel TerisNo ratings yet

- Identificacion de Transmisiones Automaticas ToyotaDocument11 pagesIdentificacion de Transmisiones Automaticas Toyotaed1996No ratings yet

- Design Handbook IRC112Document111 pagesDesign Handbook IRC112zulfekharNo ratings yet

- Cat Sos 793&793b TrucksDocument7 pagesCat Sos 793&793b TrucksmkNo ratings yet

- 6HP19-19A No Fourth GearDocument1 page6HP19-19A No Fourth GearautofNo ratings yet

- Sany 230C - Sy230c8c3kDocument268 pagesSany 230C - Sy230c8c3kLS Hidráulica ManilhaNo ratings yet

- DCT450 - Clutch - Damper - Repair - Copy - Not A PDFDocument1 pageDCT450 - Clutch - Damper - Repair - Copy - Not A PDFSemen AlexandrovNo ratings yet

- Basics of Foundation Design PDFDocument433 pagesBasics of Foundation Design PDFGnkdsNo ratings yet

- New Product Announcement: Zf6Hp19A / Audi 09LDocument1 pageNew Product Announcement: Zf6Hp19A / Audi 09LFSR1407No ratings yet

- Dean Brochure High TempDocument10 pagesDean Brochure High TempAntonio VelardeNo ratings yet

- Avant Quattro (A6Q) 2016 Year Audi EUROPA 300055Document3 pagesAvant Quattro (A6Q) 2016 Year Audi EUROPA 300055eduone65No ratings yet

- Smokevent Calculation..Document2 pagesSmokevent Calculation..Karthy GanesanNo ratings yet

- 2010 08 8 Speed Automatic Gearbox PDFDocument22 pages2010 08 8 Speed Automatic Gearbox PDFJOHNNY5377No ratings yet

- 01JDocument1 page01JPedroMecanicoNo ratings yet

- Technical Service Information: BMW ZF-5HP-18Document2 pagesTechnical Service Information: BMW ZF-5HP-18Alejandro RoldanNo ratings yet

- 722.0 722.1 722.2 W3a040 W4B025 K4a040 K4C025Document2 pages722.0 722.1 722.2 W3a040 W4B025 K4a040 K4C025Gloria Fontes100% (1)

- ZF8 Zip inDocument10 pagesZF8 Zip inEdgar BolañosNo ratings yet

- 0B5 MechatronicDocument3 pages0B5 MechatronicpecirepiNo ratings yet

- Regalage AccDocument11 pagesRegalage AccJOHNNY5377No ratings yet

- AC Product Update November 2014Document1 pageAC Product Update November 2014Raca ZivkovicNo ratings yet

- ZF 9hpDocument3 pagesZF 9hpNilay Srivastava0% (1)

- LuK TecBr WDC 210x297 LowRes ENDocument28 pagesLuK TecBr WDC 210x297 LowRes ENTop AutoNo ratings yet

- Transmission NoteDocument6 pagesTransmission Notesyariza ismailNo ratings yet

- D4B80762D4F-Maintenance (06.2017) PDFDocument120 pagesD4B80762D4F-Maintenance (06.2017) PDFrobbertmdNo ratings yet

- zf5hp19 PDFDocument6 pageszf5hp19 PDFReinaldo De Oliveira SilvaNo ratings yet

- 55 50SNDocument1 page55 50SNPedroMecanicoNo ratings yet

- SonnaxDocument1 pageSonnaxJhony Fui100% (1)

- 6 HP 19Document4 pages6 HP 19JhonsonNo ratings yet

- 41TE Accumulator PositionDocument10 pages41TE Accumulator PositionLula MarquesNo ratings yet

- AL4 Pressure Regulation FaultDocument3 pagesAL4 Pressure Regulation Faultsirajmy100% (1)

- Atra GM 6l45!50!80-90 BulletinDocument2 pagesAtra GM 6l45!50!80-90 BulletinAndrés Caleb Blanco GuzmanNo ratings yet

- SWAG Fluessigkeiten 2012 2013Document33 pagesSWAG Fluessigkeiten 2012 2013Hatem NasrNo ratings yet

- A04 12 02Document4 pagesA04 12 02Marius Babei100% (1)

- A43Document126 pagesA43Василий ДимовNo ratings yet

- Mercedes 722.9 Transmission Checkball & Small Parts LocationsDocument1 pageMercedes 722.9 Transmission Checkball & Small Parts Locationsمحمد يونسNo ratings yet

- Gearbox Adapter For DQ250 DQ200 VL381 VL300 DQ500 DL501 Read and WriteDocument4 pagesGearbox Adapter For DQ250 DQ200 VL381 VL300 DQ500 DL501 Read and WriteAla' AlqamNo ratings yet

- Esquema Elétrico 8HP45Document7 pagesEsquema Elétrico 8HP45HatusNo ratings yet

- 2008 A5 BrochureDocument52 pages2008 A5 BrochurePeter BondarNo ratings yet

- CTI Mag - 12-2018Document68 pagesCTI Mag - 12-2018王永健No ratings yet

- DimensionsDocument1 pageDimensionsputex247No ratings yet

- Properties of CastDocument1 pageProperties of Castputex247No ratings yet

- Product Redesign Based On An Axiomatic PRESENTATIONDocument20 pagesProduct Redesign Based On An Axiomatic PRESENTATIONputex247No ratings yet

- 3 Papers PHD GuideDocument4 pages3 Papers PHD GuideMiss_BayesNo ratings yet

- Chapter 3 - Basic Graphing RoutinesDocument3 pagesChapter 3 - Basic Graphing RoutinesKrishna KumarNo ratings yet

- EX-1733 TankCalDocument4 pagesEX-1733 TankCaljacquesmayolNo ratings yet

- Chapter 1 - Basic MATLAB CommandsDocument7 pagesChapter 1 - Basic MATLAB CommandsKrishna KumarNo ratings yet

- Optimized Gearbox Design ParametersDocument16 pagesOptimized Gearbox Design Parametersputex247No ratings yet

- Chapter 2 - Programming StructuresDocument5 pagesChapter 2 - Programming StructuresKrishna KumarNo ratings yet

- BR Series ERDocument16 pagesBR Series ERputex247No ratings yet

- Om Life Plan BrochureDocument2 pagesOm Life Plan Brochureputex247No ratings yet

- Monarch Steel Catalogue PDFDocument36 pagesMonarch Steel Catalogue PDFputex24774% (19)

- DFMDocument4 pagesDFMMarko BrkicNo ratings yet

- Solidworks 2015 PDFDocument226 pagesSolidworks 2015 PDFputex247No ratings yet

- Mechanical Design Data Book: Friction Clutches, Brakes, Belt Drives, Chain Drives, Bearings, GearsDocument69 pagesMechanical Design Data Book: Friction Clutches, Brakes, Belt Drives, Chain Drives, Bearings, Gearsvenugopalmanga100% (1)

- 4 Simple StressesDocument25 pages4 Simple StressesPRASAD326No ratings yet

- Code of Hygienic Practice for Canned FoodsDocument85 pagesCode of Hygienic Practice for Canned FoodsMonching AdecerNo ratings yet

- Module 2 Lesson 3Document11 pagesModule 2 Lesson 3putex247No ratings yet

- 5 Compound Stresses in Machine PartsDocument15 pages5 Compound Stresses in Machine PartsPRASAD326No ratings yet

- EIM 116 Course Outline (2015-2016)Document4 pagesEIM 116 Course Outline (2015-2016)putex247No ratings yet

- Unit 4 StructuresDocument27 pagesUnit 4 Structuresputex247No ratings yet

- Unit 1 Introduction To StaticsDocument26 pagesUnit 1 Introduction To Staticsputex247No ratings yet

- Unit 2 Force SystemsDocument46 pagesUnit 2 Force Systemsputex247No ratings yet

- Conceptual Design of A Bus Emergency Exit RampDocument4 pagesConceptual Design of A Bus Emergency Exit Rampputex247No ratings yet

- Unit 5 Distributed ForcesDocument27 pagesUnit 5 Distributed Forcesputex247100% (1)

- Adams Se 2013 Doc PidDocument4 pagesAdams Se 2013 Doc PidMahesh DevasigamaniNo ratings yet

- ThesisDocument79 pagesThesisputex247No ratings yet

- Tractor Operator AgricultureDocument9 pagesTractor Operator AgricultureConstantin CarpenNo ratings yet

- Circular Motion Week 2Document8 pagesCircular Motion Week 2Solace HusseinNo ratings yet

- Chapter 3b Fugacity and Fugacity Coefficient For MixtureDocument26 pagesChapter 3b Fugacity and Fugacity Coefficient For MixtureSeptiana AyuningtiasNo ratings yet

- B30D 4Document150 pagesB30D 4Teknik MakinaNo ratings yet

- ANSYS-CFD Analysis of Condensation Process Occurring Inside High Efficiency BoilersDocument20 pagesANSYS-CFD Analysis of Condensation Process Occurring Inside High Efficiency Boilerskulov1592No ratings yet

- Autoscan P12 04 16 enDocument12 pagesAutoscan P12 04 16 enCouscoussiere GrandgazNo ratings yet

- DIFFERENTIALDocument4 pagesDIFFERENTIALsaffrinNo ratings yet

- 0303 MEA Multi V HeatpumpDocument119 pages0303 MEA Multi V HeatpumpfatjoebirdNo ratings yet

- Atlas Copco QES RangeDocument8 pagesAtlas Copco QES RangeDave WallaceNo ratings yet

- By Amruta Pawar (4550) Bhavika Karkare (4521) Rasika Kadam (4519) Unnati Wadke (4565) Under The Guidance of Prof. MR A. K. JoshiDocument18 pagesBy Amruta Pawar (4550) Bhavika Karkare (4521) Rasika Kadam (4519) Unnati Wadke (4565) Under The Guidance of Prof. MR A. K. JoshiAmrutaNo ratings yet

- Charcoal TowerDocument9 pagesCharcoal TowerPrathmesh GujaratiNo ratings yet

- Well DiagramDocument2 pagesWell DiagramSanjay KapoorNo ratings yet

- AMP Summer Question Paper (Msbte Study Resources)Document4 pagesAMP Summer Question Paper (Msbte Study Resources)Varad DateNo ratings yet

- Tank and Vessel Trace Heating Thermon Temperature Maintenance and Frost Protection HeetSheet Spec SheetDocument2 pagesTank and Vessel Trace Heating Thermon Temperature Maintenance and Frost Protection HeetSheet Spec SheetCarlos SopasNo ratings yet

- SamSung CompreSSor SM SeriesDocument8 pagesSamSung CompreSSor SM SeriesmaisheyanNo ratings yet

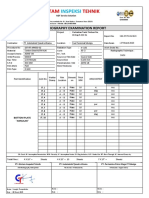

- Pt. Gintam Tehnik: InspeksiDocument5 pagesPt. Gintam Tehnik: Inspeksirizky youlandaNo ratings yet

- ASTM A153 Guide for Galvanized Hardware & FastenersDocument5 pagesASTM A153 Guide for Galvanized Hardware & FastenersMekhmanNo ratings yet

- Hazard and Operability Analysis (HAZOP) of A Plastic Manufacturing Plant at Karachi, PakistanDocument7 pagesHazard and Operability Analysis (HAZOP) of A Plastic Manufacturing Plant at Karachi, PakistanFaisal AkhterNo ratings yet