Professional Documents

Culture Documents

Paint Troubleshooting

Uploaded by

AMIT0 ratings0% found this document useful (0 votes)

45 views6 pagesAbout paint troubleshooting

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAbout paint troubleshooting

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

45 views6 pagesPaint Troubleshooting

Uploaded by

AMITAbout paint troubleshooting

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

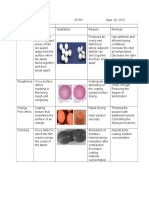

Blistering

Description: Hollow bubbles in the paint film.

Identification

Bubbles in or under the finish (0.5 to

1.5 mm)

May follow the shape of a repair spot

Most common on horizontal surfaces

May contain a vapor or a liquid

Probable Cause

Excessive moisture in air supply while

priming/topcoating

Primer not allowed to dry thoroughly

Improperly cured 2-part polyester body

Topcoat immersed in water for

extended periods of time

Remedy

Check for moisture damage

Use recommended epoxy fillers

Apply primer/sealer

Repaint

Prevention

Allow sufficient drying times

Use EP-2C Hi-Build Epoxy Primer

(waterproof at 12.0 mil) in high

moisture conditions

Cover painted articles for long term

storage with a non-airtight cover

Basecoat / Topcoat

Sealer

Primer

Substrate

Page 2

Chipping

Description: Small pieces of paint film breaking

away.

Identification

Small pieces of paint film missing

Pinhole size to thumbnail size each

May be exposing an underlying layer

Usually seen on leading edges

Probable Cause

Surface impact

Using HS-421 Primer without sealing

before applying topcoat

Exposure to harsh conditions:

- Frequent use on gravel roads

Remedy

Small chips can be filled with 2-part

Large chips or large areas with

chipping should be blended - follow

Endura's Blending Procedure

Select the most suitable coatings for

environmental conditions

Repeat all steps in application

procedure

Prevention

Avoid use of HS-421 Primer in high

impact areas

Use EP-321 Epoxy Primer or EP-521

Epoxy Primer for industrial service

(sandblasted steel, etc.)

Use EX-2C TF-2K T opcoat for severe

conditions

Basecoat / Topcoat

Sealer

Primer

Substrate

Page 3

Cracking

Description: Splitting throughout the paint film

thickness.

Identification

Topcoat splitting

Series of straight lines

Primer or substrate may be visible

Probable Cause

Substrate not at room temperature

Component A and Component B

not uniformly mixed

Coating applied over a previously

cracked finish or unstable substrate

Excessive total film thickness

Remedy

Remove finish from affected area

Apply primer/sealer

Repaint

Prevention

Remove poor quality/unstable finishes

Check current film thickness before

starting. Excessive paint should be

removed before refinishing.

Mix Component A and Component

B thoroughly

Follow recommended film thickness

Follow recommended flash-off and

drying time between coats

Basecoat / Topcoat

Sealer

Primer

Substrate

Page 4

Crawling

Description: Usually occurs with clearcoats. Wet

paint film receding, leaving some

areas uncoated.

Identification

Lack of adhesion while spraying

Coating varies from 'not hiding' to

'accumulated'

Previous coat is visible

Commonly occurs along edges or

around rivets

Probable Cause

A film of surface contamination

Re-coating a painted or clearcoated

surface already high in silicone

content

Remedy

Sand smooth

Repaint

Prevention

Proper surface preparation: use waterbased cleaning solutions

Frequently replace tack cloths and

rags used to solvent wipe

Pay special attention wiping edges

and problem areas

Reduce product for the first coat of

topcoat

Mist on the first coat of topcoat

Basecoat / Topcoat

Sealer

Primer

Substrate

Page 7

Delamination

Description: Usually occurs around edges, trim, or

hardware. Paint film not adhering to

the substrate, or, layers of paint film

separating.

Identification

Large pieces of coating peeling off

Film peels off easily

Probable Cause

Contaminated surface

Metal conditioner and/or appropriate

primer was not used

Insufficient flash-off time between

coats

Poor quality sanding

Incorrect film build-too heavy

Incorrect Spray Technique:

- Coating applied too dry or too heavy

Insufficient flash off time between coats

(and or between primer and topcoat

Remedy

Featheredge the problem areas

Use sealer as recommended

Repaint

Reduce total film thickness

Prevention

Basecoat / Topcoat

Sealer

Primer

Substrate

Follow recommended topcoat window

Follow recommended film builds,

topcoat will delaminate if applied over

an insufficient primer coat

Follow recommended viscosity

Follow recommended flash-off times

Carefully sand edges and areas

around hardware

Use recommended metal conditioner

and conversion coating

Clean thoroughly with recommended

water-based cleaners

Mix Component A and Component

B thoroughly

Page 8

Orange Peel

Description: Dry paint film has a dimpled surface.

Identification

Paint finish looks like the peel of an

orange

Probable Cause

Viscosity too high

Gun air pressure too low (causing lack

of atomization)

Primer or sealer applied not smooth

Wrong thinner/reducer

Incorrect spray technique:

- Holding gun too far from

surface

- Wide fan patterns

Wrong amount of thinner or reducer

used - not enough

Poor quality sanding

Remedy

Sand smooth

Repaint topcoat

Prevention

Proper surface preparation: carefully

sand smooth

Check viscosity of products

Adjust gun set up:

- Use smaller size fluid tip

- Use air cap that increases

paint atomization

Use recommended solvent

Basecoat / Topcoat

Sealer

Primer

Substrate

Page 13

You might also like

- Family Handyman HacksFrom EverandFamily Handyman HacksFamily HandymanNo ratings yet

- Your Paint GuideDocument27 pagesYour Paint Guidemanox007No ratings yet

- Paint Defect Troubleshooting Guide PDFDocument16 pagesPaint Defect Troubleshooting Guide PDFRavi KhoseNo ratings yet

- Good Painting Practic & Maintenance & Repair Painting-StandardDocument132 pagesGood Painting Practic & Maintenance & Repair Painting-StandardjasminneeNo ratings yet

- Paint DefectsDocument17 pagesPaint DefectsAshish DhimanNo ratings yet

- Kitchen ChecklistDocument48 pagesKitchen ChecklistSahil Kumar100% (11)

- Zhen Futbolka Bazovaya R XXS - 3XLDocument27 pagesZhen Futbolka Bazovaya R XXS - 3XLMauricioGuevaraNo ratings yet

- Paint DefectsDocument129 pagesPaint Defectsmohammad100% (6)

- PAINT Coating Damage and DefectsDocument70 pagesPAINT Coating Damage and DefectsAntony TomaisNo ratings yet

- Coating FailuresDocument27 pagesCoating FailuresWeld ManiacNo ratings yet

- Your Home Inspected: An Addendum for Residential Home Inspection ReportsFrom EverandYour Home Inspected: An Addendum for Residential Home Inspection ReportsNo ratings yet

- Paint Defects and RemediesDocument11 pagesPaint Defects and RemediesAldrin Ron Caina Mamaril100% (2)

- Identifying and Resolving Common Paint ProblemsDocument16 pagesIdentifying and Resolving Common Paint ProblemsNicholson Vhenz UyNo ratings yet

- Crocs SWOT AnalysisDocument15 pagesCrocs SWOT AnalysisAngel JuanNo ratings yet

- Abaris Composite Bonding OshkoshDocument51 pagesAbaris Composite Bonding Oshkoshv1alfredNo ratings yet

- Laboratory Manual of Glass-BlowingFrom EverandLaboratory Manual of Glass-BlowingRating: 5 out of 5 stars5/5 (1)

- Coating DefectsDocument13 pagesCoating DefectswahNo ratings yet

- Coating Failure DefectsDocument46 pagesCoating Failure Defectsdreamsdwan100% (3)

- Common finishing problems and solutions guideDocument16 pagesCommon finishing problems and solutions guideSyamlal Skaku100% (1)

- Coating Problem Solver: Adhesion (Blocking) : DescriptionDocument24 pagesCoating Problem Solver: Adhesion (Blocking) : DescriptionKiran Kumar JhaNo ratings yet

- Painting DefectsDocument70 pagesPainting Defectsahmed sobhy100% (1)

- Polyglass Coatings PDFDocument23 pagesPolyglass Coatings PDFr0m14rNo ratings yet

- Paint TroubleshootingDocument23 pagesPaint TroubleshootingNooruddin SheikNo ratings yet

- Common Paint ProblemsDocument5 pagesCommon Paint Problemsiimran_ahmadNo ratings yet

- Index of Coating DefectsDocument41 pagesIndex of Coating DefectsMathan76No ratings yet

- Defects in Injection MouldingDocument44 pagesDefects in Injection MouldingsatishNo ratings yet

- Coating Defects Fitz AtlasDocument73 pagesCoating Defects Fitz AtlasCiprian Iatan100% (2)

- Dump Truck PDFDocument2 pagesDump Truck PDFcityofdarwingisNo ratings yet

- How to Make Outdoor & Garden Furniture: Instructions for Tables, Chairs, Planters, Trellises & More from the Experts at American WoodworkerFrom EverandHow to Make Outdoor & Garden Furniture: Instructions for Tables, Chairs, Planters, Trellises & More from the Experts at American WoodworkerRating: 4 out of 5 stars4/5 (1)

- (English) Barad-Dûr - Free PatternDocument10 pages(English) Barad-Dûr - Free PatternRafaela SuezNo ratings yet

- Paint Problems and Solutions - BrochureDocument16 pagesPaint Problems and Solutions - BrochureBrian ArmadoNo ratings yet

- Sigma Paint GlossaryDocument6 pagesSigma Paint Glossary003086No ratings yet

- Coating FailureDocument14 pagesCoating FailureNnamdi Celestine NnamdiNo ratings yet

- Aircraft Painting and FinishingDocument29 pagesAircraft Painting and FinishingJohan Louie Rayos75% (4)

- Cotton Yarn Fabrics ExportersDocument9 pagesCotton Yarn Fabrics Exportersfayyazbhatti178No ratings yet

- 6 Plastic Part Defect - 0Document27 pages6 Plastic Part Defect - 0allrounder_mannNo ratings yet

- Paint DefectsDocument17 pagesPaint DefectsAdriana JonesNo ratings yet

- CBLM Revised.Document51 pagesCBLM Revised.Etnagorra G. Nyliam100% (1)

- DefectsDocument15 pagesDefectssupratik2401No ratings yet

- Application Guide Penguard MidcoatDocument6 pagesApplication Guide Penguard Midcoatadeoye_okunoyeNo ratings yet

- Tailift Parts List FD - fg40-50 DEC014!08!2008Document428 pagesTailift Parts List FD - fg40-50 DEC014!08!2008BudiNo ratings yet

- Conformal Coating Defects: Why They Happen & How To Prevent ThemDocument15 pagesConformal Coating Defects: Why They Happen & How To Prevent Themjav_ra993986100% (1)

- Guide To Minor Opening Bids in BridgeDocument2 pagesGuide To Minor Opening Bids in Bridgejaziblu100% (1)

- Tie-N-Dye Techniques and Tips for BeginnersDocument6 pagesTie-N-Dye Techniques and Tips for Beginnerskolarani6272No ratings yet

- Issues in Distribution - FMCGDocument71 pagesIssues in Distribution - FMCGSubhadeep ChakrabortyNo ratings yet

- Common Paint Film DefectsDocument5 pagesCommon Paint Film DefectsKevin De La CruzNo ratings yet

- Instructions and Guidelines To The Contractor For Painting of Exterior Wall of IEDocument8 pagesInstructions and Guidelines To The Contractor For Painting of Exterior Wall of IEhbgdiatmNo ratings yet

- Paint FailureDocument4 pagesPaint Failurerajiv_quantumNo ratings yet

- Problem Solving Guide 1-15Document16 pagesProblem Solving Guide 1-15Sekson LapcharoensinNo ratings yet

- Penguard Topcoat application and repair guideDocument1 pagePenguard Topcoat application and repair guideTamerTamerNo ratings yet

- ADHESIVE Coating Defects Causes Remidies Final-140101195555-Phpapp02Document21 pagesADHESIVE Coating Defects Causes Remidies Final-140101195555-Phpapp02hikmah07No ratings yet

- Two-Component Coating Problems GuideDocument4 pagesTwo-Component Coating Problems GuidePero KolevNo ratings yet

- SMT TsDocument38 pagesSMT TsGlauber AquinoNo ratings yet

- Film DefectDocument3 pagesFilm Defectamitrameshwardayal100% (2)

- Common Problems in Exterior PaintingDocument14 pagesCommon Problems in Exterior Paintingharish420No ratings yet

- Painting 1-4Document9 pagesPainting 1-4Jean Mark SilvestreNo ratings yet

- Glossary of Paint Terms-Marmoran - Co.zaDocument2 pagesGlossary of Paint Terms-Marmoran - Co.zamaliankaduNo ratings yet

- Defects in Paints: - Blistering and PeelingDocument12 pagesDefects in Paints: - Blistering and PeelingRoshanNo ratings yet

- Jotun Pioner Topcoat Application Guide - AcrylicDocument6 pagesJotun Pioner Topcoat Application Guide - AcrylicChaerul AnwarNo ratings yet

- Paint DefectsDocument45 pagesPaint Defectsningsarinya73No ratings yet

- Tablet DefectsDocument3 pagesTablet Defectsjeniccax17No ratings yet

- Mascoat Sound Control DB Application InstructionsDocument5 pagesMascoat Sound Control DB Application InstructionsSkylarNo ratings yet

- Shield CreteDocument2 pagesShield Cretechris77779No ratings yet

- Application-0 1603076965Document9 pagesApplication-0 1603076965Ahmed AllamNo ratings yet

- Keys For WB LaminationDocument24 pagesKeys For WB LaminationTahsin SungurNo ratings yet

- Clay Pattern Styling and Rigid Surface Casting in Today's Composite IndustryDocument3 pagesClay Pattern Styling and Rigid Surface Casting in Today's Composite Industrybugsy77No ratings yet

- Glossary of Paint Defect TermsDocument7 pagesGlossary of Paint Defect Terms4romi89No ratings yet

- The Paint System: Primer Intermediate CoatsDocument5 pagesThe Paint System: Primer Intermediate CoatsJerome ChuaNo ratings yet

- Vocab First 200 PDFDocument4 pagesVocab First 200 PDFAMITNo ratings yet

- 16 - Environmental ScienceDocument2 pages16 - Environmental ScienceAMITNo ratings yet

- SIMULATION LaminarPipeFlow Geometry 030716 1947 17154Document4 pagesSIMULATION LaminarPipeFlow Geometry 030716 1947 17154setiawanayNo ratings yet

- Laminar Pipe Flow - Verification & ValidationDocument7 pagesLaminar Pipe Flow - Verification & ValidationAMITNo ratings yet

- Modelling A ProcessDocument4 pagesModelling A ProcessarpitkshrNo ratings yet

- OCS-B1010-SP Book-V1.2-601-17275Document103 pagesOCS-B1010-SP Book-V1.2-601-17275Rodolfo Barrón López100% (1)

- Nivea OsDocument17 pagesNivea OsNikhil AggarwalNo ratings yet

- Perfect Prints - PLAIN & PRINTED Plastic Cups, Paper Cups, BowlsDocument8 pagesPerfect Prints - PLAIN & PRINTED Plastic Cups, Paper Cups, BowlsJoe LimNo ratings yet

- Employee Motivation at Bata India LTDDocument68 pagesEmployee Motivation at Bata India LTDmeetsweetpari22100% (1)

- Manly Junior Rugby Union Tour Booklet 2015Document20 pagesManly Junior Rugby Union Tour Booklet 2015api-259806728No ratings yet

- Bara Bazar, KolkataDocument13 pagesBara Bazar, Kolkataharini0% (1)

- 20170322190836toms CaseDocument9 pages20170322190836toms CaseJay SadNo ratings yet

- Float Type Level Gauge Using Spring MotorDocument13 pagesFloat Type Level Gauge Using Spring MotorravishanNo ratings yet

- Operation Joining Collar Panels Location Ie Asin Factory Operator - Charted by - Date 21 May 2020 L/H Process R/H ProcessDocument1 pageOperation Joining Collar Panels Location Ie Asin Factory Operator - Charted by - Date 21 May 2020 L/H Process R/H Processsanchit gumberNo ratings yet

- HRR216VKA Lawn Mower Owner's ManualDocument24 pagesHRR216VKA Lawn Mower Owner's Manualkpilota2No ratings yet

- KTS 840-960-1080 spare parts catalogDocument16 pagesKTS 840-960-1080 spare parts catalogBrano JovicicNo ratings yet

- Managerial Economics: Theory and ApplicationsDocument17 pagesManagerial Economics: Theory and ApplicationsAzlan Psp100% (1)

- Week Five:: Reporting andDocument38 pagesWeek Five:: Reporting andIzham ShabdeanNo ratings yet

- Basic Concepts of Supply Chain and Logistics Management - Session3Document20 pagesBasic Concepts of Supply Chain and Logistics Management - Session3Aulie CamayaNo ratings yet

- Reading Activity - FeijoadaDocument1 pageReading Activity - FeijoadajanainalunaNo ratings yet

- MathDocument7 pagesMathroseNo ratings yet

- Pav BahjiDocument7 pagesPav BahjiJyotsana SinghNo ratings yet

- Reclaiming The Identity of A BrandDocument6 pagesReclaiming The Identity of A BrandjjogrovankaNo ratings yet

- ITC - History and EvolutionDocument2 pagesITC - History and EvolutionSiddhartha NeogNo ratings yet