Professional Documents

Culture Documents

2004v10 in The Beginning PDF

Uploaded by

amachmouchiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2004v10 in The Beginning PDF

Uploaded by

amachmouchiCopyright:

Available Formats

another look

In the Beginning

The Origins of the One-Third Stress Increase

By Charles J. Carter, P.E., S.E.

Current ASCE 7 provisions have significantly altered the familiar one-third stress increase

but where did it come from in the first place?

n article by Keith Mueller

and Charlie Carter in the

October 2003 issue of Modern

Steel Construction magazine

titled The One-Third Stress

Increase: Where Is It Now? has

renewed interest in the history of this

topic. The article focused on what is and

is not permissible in ASCE 7, as well as

the various current and recent major

model-building codes in the U.S. It did

not, however, attempt to address the history of the one-third stress increase or

the rationale behind it in any great

detail. Fortunately, these aspects are

well covered in a paper published in the

4th Quarter 1977 AISC Engineering Journal. The paper, by Duane Ellifritt, entitled The Mysterious One-Third Stress

Increase, is paraphrased in abbreviated

form in this article. The full paper is

available at www.aisc.org/epubs.

What was it for?

Ellifritt wrote about the confusion

that stirs over the one-third stress

increase and exactly for what types of

conditions it is supposed to account.

Some believe it represents a low probability that maximum live load and maximum wind load would ever occur

simultaneously and apply it as a fourthirds factor on the strength side. Others

believe it is to account for wind load

phenomena that reduce the actual load

used in design and apply it as a threequarter load reduction. Although these

operations appear to accomplish the

same thing, Ellifritt contends that the

three-quarter factor is not the inverse of

the four-thirds factorthat isthe

allowable stress increase for wind is not

the same as the probability factor when

accounting for simultaneous application

of maximum live load and maximum

wind load.

The Survey Says

Ellifritt surveyed colleagues and

determined a great many of them used

the one-third increase merely because

AISC permitted it. Most other replies fell

into one of three categories:

1. The action of wind on a structure is

highly localized and of very short

duration. Therefore, it is not necessary

to have as high a safety factor when

designing for wind loads.

2. The properties of some materials

change with the rate of loading. Steel,

when loaded rapidly, will show

higher yield strength than when it is

loaded slowly. The one-third stress

increase merely reflects the increase in

properties due to rapid loading and

does not diminish the safety factor.

3. The one-third stress increase reflects

the low probability of maximum live

and wind loads occurring simultaneously. Therefore, when checking D +

W only, it should not be used.

From the Literature

Many references included some coverage of this principle (see the original

paper for the full bibliography of references below):

The oldest reference, found in

Theodore Coopers 1896 General Specifications for Steel Railroad Bridges and

Viaducts, permitted a 1/4 increase but

gave no reason for this measurement.

A.J. DuBoiss article entitled The

Stresses in Framed Structures (also in

1896) recommended an allowable

stress for beams of 10,000 psi and an

allowable for lateral bracing of 15,000

psi. Although no statement is made

regarding the reason for a higher

allowable stress for bracing, it could

be interpreted as a 50% increase

because of wind forces.

Milo Ketchum, in his 1903 General

Specifications for Mill Buildings, said:

When combined direct and flexural

stress due to wind is considered, add

25% to the above allowable tensile

and compressive stresses. Like

Cooper, he does not offer any explanation as to why this should be permitted.

The New York City Building Code of

1904 contained this statement: In calculations for wind bracing the working stresses set forth in this code may

be increased by 50%. Again, no reason is given.

In 1923, AISC published its first specification. In it were these words: Combined StressesFor combined stresses

due to wind and other loads, the permissible working stress may be

increased 33%, provided the section

thus found is not less than that

required by the dead and live loads

alone. Members Carrying Wind Only

For members carrying wind stresses

only, the permissible wind stresses

may be increased 33%. This provision in AISCs specification remained

October 2004 Modern Steel Construction

virtually unchanged for 51 years,

except for the inclusion of seismic

stresses.

Supplement No. 3 added a qualifying paragraph in 1974: and provided

that stresses are not otherwise*

required to be calculated on the basis

of reduction factors applied to design

loads in combinations. The footnote

read: *For example, see ANSI A58.1,

Section 4.2.

Robins Fleming wrote a comprehensive text in 1930 on wind stresses in

buildings. He put forth the first logical

explanation of the mysterious increase

that Ellifritt was able to find: Because

wind loads are intermittent and seldom

reach their maximum, greater working

stresses are permissible for them than

for live and dead loads.

He continued, This is recognized

generally by engineers and has found

a place in most building codes. In the

New York City code, where at present

(1929) a working stress of 16,000 psi is

specified for tension in rolled steel, an

excess of 50% of stresses prescribed

elsewhere in the code is allowed for

combined wind, dead, and live loads,

provided that the sections thus found

are not less than those required by the

dead and live loads alone. In Chicago,

where 18,000 psi is the basic unit

stress for tension, an excess of 33% is

allowed for combined stress, thus permitting in both New York and

Chicago a working stress of 24,000-psi

tension for combined loads. This same

unit stress is followed in the code recommended by the National Board of

Fire Underwriters. The Recommended

Building Code Requirements for Working

Stresses in Building Materials, 1926, of

the U.S. Bureau of Standards, favor an

increase of 25% based on 18,000 psi in

tension.

After listing the requirements of

several codes, Fleming recommended

the use of 24,000-psi tension on the net

section for stresses due to wind loads

combined with live and dead loads, or

for members taking wind stress

alone.

In 1940, an ASCE subcommittee

produced a report entitled Wind Bracing in Steel Buildings. The report created the first departure from the allinclusiveness of the one-third stress

increase and possible support for

answer no. 3 (previous page).

For members or details subject to

wind stress only, except rivets and

Modern Steel Construction October 2004

bolts, the permissible stress should be

the same as that allowed for dead load

or for dead and live load. For members

subjected to stresses arising from the

combined similar action of wind and

other loads, and for rivets and bolts

subject to wind stress, the wind stress

up to 33% of the other stresses may be

neglected, the excess wind stress being

considered as equivalent to an added

live load stress, provision being made

for it at the basic working stress for

dead load and live load only. Note

that rivets and bolts were permitted a

stress increase for wind only.

In 1947, the American Iron and Steel

Institute published the first edition of

the Light Gage Cold-Formed Steel Design

Manual. The pertinent provisions followed the AISC specifications in permitting a one-third increase for combined stresses and for wind or

earthquake only.

A quartet of British authors stated that

a 25% increase is allowed and made a

good argument for answer no. 1 (previous page): By Clause 25, the normal permissible stresses in the members may be increased by 25% in cases

where such increases are due solely to

the stresses induced by wind.

This higher working stress is

allowed because of the transient

nature of the load and also because

the structure is of a sufficiently elastic

nature, which allows it to absorb such

transient loads without permanent

defects.

In a more recent publication, this

insight was offered by Angus McDonald in Wind Loading on Buildings (1975):

It should be noted that a very high

wind load is a comparatively rare

occurrence and that the design wind

speeds specified in most codes of practice may never actually occur in the life

of a structure. For this reason, most

structural codes allow a 25% (sometimes as much as 33%) increase in permissible stress for wind loadings.

More evidence for answer no. 1 (the

transient nature of wind) is found in

the Building Construction Handbook,

chapter six, by H. Stetina (1975): For

wind or earthquake forces, acting alone

or in combination with the design live

and dead loads, allowable stresses may

be increased one-third. The increase is

allowed because wind and seismic

forces are of short duration.

This position was also supported by

Jack C. McCormacs Structural Steel

Design (1971): The maximum wind

and earthquake pressures for which

design is made occur at large intervals

of time and then last for only relatively short periods of time. It, therefore, seems reasonable to use higher

allowable stresses, such as the onethird AISC increase, for lateral forces

than for the relatively long-term gravity live loads.

A dissenting opinion is was offered in

a 1972 excerpt from Structural Engineering,Vol. 1, by R.N. White, P.

Gergely and R.G. Sexsmith: In recognition of the highly unlikely occurrence of maximum wind or earthquake loads simultaneously with the

full value of other live loads, codes

generally allow a 33% increase in

allowable stresses under these load

combinations.

Conclusions

Ellifritt wrote that the preponderance

of literature on the subject supports

answer no. 1the one-third stress

increase is allowed because of the transient nature of wind; because wind

loads are intermittent and seldom reach

their maximum; because a very high

wind load is a comparatively rare occurrence and may never actually occur;

and because wind forces are of short

duration. There was no support for

answer no. 2 (rate of loading), and only

two references to support answer no. 3

(simultaneous occurrence). [Authors

note: It is interesting to find that ASCE 702 Commentary Section C2.4.1 statements about the 0.75 load factor indicate

that it is essentially the same concept as

the one-third stress increase and that it is

primarily intended to address simultaneous occurrence.]

Ellifritt continued that the one-third

stress increase is rooted deeply in our

engineering tradition, during a time

when wind loads were not so well understood; that modern methods of applying

wind loads account for some of the factors used to rationalize the stress increase,

such as short duration and rare occurrence. Modern wind codes are based on

better meteorological information and

wind tunnels, which accurately model the

boundary layer. A rare occurrence in

wind velocity is now programmed into

the design pressure selection process in

the form of a Mean Recurrence Interval

Map. The short duration aspect is now

accounted for by gust factors.

Is the one-third stress increase

appropriate for design today?

Ellifritt said yes, with the following

reasoning: The gust factor as defined in

ANSI A58.1 (the precursor to ASCE 7 and

current load standard at the time of

Ellifritts writing) represents anywhere

from a 30% to a 120% increase in the basic

pressure. The increase, of course,

depends on the exposure type. If wind

loads are increased by 30% and the stress

increase disallowed, the net effect is a

load that is increased by 70%.

Modern wind codes may have higher

loads than previously used on some parts

of a structure (such as corners, eaves, and

ridges), but they may also have lower

loads on other parts. The resultant

should be about the same total load as we

have always used. However, it should be

distributed differently and more properly suited to location. On this basis,

Ellifritt wrote that there is no valid reason why modern wind standards with

gust factors, mean recurrence intervals,

and peak coefficients should not continue

to permit the designer to use the onethird stress increase.

The reasoning in Ellifritts 1977 paper

seems to contend that the one-third stress

increase should remain valid today, even

with the latest refinements to ASCE 7.

However, as outlined in the MSC article

by Keith Mueller and Charlie Carter,

changes in ASCE 7 itself, as well as in the

model building codes, have significantly

limited the traditional applications of the

one-third stress increase.

Charles J. Carter, S.E., P.E., is chief structural engineer with the American Institute of

Steel Construction, Inc. in Chicago.

AISCs Engineering Journal is available to all by subscription and is also

available to members (including all

back issues) through free electronic

access through AISCs ePubs at

www.aisc.org/epubs.

October 2004 Modern Steel Construction

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- HUB Contractors and Suppliers for UNC WilmingtonDocument76 pagesHUB Contractors and Suppliers for UNC Wilmingtonsati67% (6)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Cost EstimationDocument28 pagesCost Estimationmayur1980100% (1)

- Jan10 Steelwise Web PDFDocument4 pagesJan10 Steelwise Web PDFamachmouchiNo ratings yet

- Theory of Indeterminate Structure by Syed Ali Rizwan PDFDocument470 pagesTheory of Indeterminate Structure by Syed Ali Rizwan PDFZain Ashfaq100% (2)

- HYDRAULIC BRIDGE DETAILSDocument4 pagesHYDRAULIC BRIDGE DETAILSPurdiansyah100% (1)

- Gutter and Down Spout CalculationDocument1 pageGutter and Down Spout CalculationzelmishaNo ratings yet

- Plant Commissioning and StartupDocument31 pagesPlant Commissioning and StartupEric Fisher100% (5)

- AISC ExamI1&2&3Document11 pagesAISC ExamI1&2&3Dhurai KesavanNo ratings yet

- Step ColDocument21 pagesStep ColamachmouchiNo ratings yet

- Step ColDocument21 pagesStep ColamachmouchiNo ratings yet

- Welder's Visual Inspection HandbookDocument77 pagesWelder's Visual Inspection HandbookamachmouchiNo ratings yet

- Gutter Sizing CalculatorDocument5 pagesGutter Sizing CalculatorWinnie ChungNo ratings yet

- LRFD Shear Connector Design Procedure and EquationsDocument21 pagesLRFD Shear Connector Design Procedure and EquationsvklsNo ratings yet

- Abus Overhead Cranes InfoDocument12 pagesAbus Overhead Cranes Infoamachmouchi100% (1)

- Gutter CalculationDocument5 pagesGutter CalculationamachmouchiNo ratings yet

- Texture WallDocument2 pagesTexture WallamachmouchiNo ratings yet

- This Is To Calculate The Input Values For Crane Software: 1,769 KG 6,580 KGDocument1 pageThis Is To Calculate The Input Values For Crane Software: 1,769 KG 6,580 KGamachmouchiNo ratings yet

- TrussDocument6 pagesTrussamachmouchiNo ratings yet

- Plan SketchDocument43 pagesPlan SketchIngenieria Estructural AplicadaNo ratings yet

- 022012Document2 pages022012amachmouchiNo ratings yet

- Roof DeckDocument9 pagesRoof DeckDhimas Surya NegaraNo ratings yet

- Connection Tips For Steel Wide Flange SectionsDocument7 pagesConnection Tips For Steel Wide Flange SectionsJuan Carlos VillalbaNo ratings yet

- Connection Tips For Steel Wide Flange SectionsDocument7 pagesConnection Tips For Steel Wide Flange SectionsJuan Carlos VillalbaNo ratings yet

- 022012Document2 pages022012amachmouchiNo ratings yet

- Stair Calculator: Calculate Approx Number of Steps Calculate Approx Number of StepsDocument2 pagesStair Calculator: Calculate Approx Number of Steps Calculate Approx Number of StepstannuNo ratings yet

- Ebsl Quote Request Form / Work Order Form Page 1 of 1: Arjun Bhise West WestDocument2 pagesEbsl Quote Request Form / Work Order Form Page 1 of 1: Arjun Bhise West WestamachmouchiNo ratings yet

- CladdingDocument1 pageCladdingamachmouchiNo ratings yet

- Advantages and Disadvantages of Composite Materials - Resin SystemsDocument2 pagesAdvantages and Disadvantages of Composite Materials - Resin SystemsAdil Alper CoskunNo ratings yet

- Pds Hempathane Hs 55610 En-GbDocument2 pagesPds Hempathane Hs 55610 En-GbThines KumarNo ratings yet

- Roof Bracing DesignDocument4 pagesRoof Bracing Designrodriguez.gaytanNo ratings yet

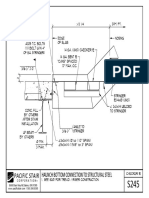

- s245 Checker Plate Haunch Bottom Stair Connection To Structural SteelDocument1 pages245 Checker Plate Haunch Bottom Stair Connection To Structural SteelamachmouchiNo ratings yet

- Ebsl Quote Request Form / Work Order Form Page 1 of 1: Arjun Bhise West WestDocument2 pagesEbsl Quote Request Form / Work Order Form Page 1 of 1: Arjun Bhise West WestamachmouchiNo ratings yet

- Hollow Core Building BrochureDocument16 pagesHollow Core Building Brochurelbhnsw5930No ratings yet

- A325m 12165Document8 pagesA325m 12165amachmouchiNo ratings yet

- Construction Folio: Advanced Structural Concrete TechniquesDocument24 pagesConstruction Folio: Advanced Structural Concrete TechniquesShikhar SinghalNo ratings yet

- Design of An INTZE TankDocument78 pagesDesign of An INTZE TankSTAR PRINTING100% (1)

- Military Wire Replaces MIL-W-22759 StandardsDocument1 pageMilitary Wire Replaces MIL-W-22759 StandardsRoberto RocheNo ratings yet

- Tugas Akhir M.radinalDocument82 pagesTugas Akhir M.radinalSepNo ratings yet

- Greenesol HPH Safety Valve Data SheetDocument11 pagesGreenesol HPH Safety Valve Data SheetRavi YadavNo ratings yet

- DPT 100Document72 pagesDPT 100Gregory StewartNo ratings yet

- BRICKS Answer Q & ADocument17 pagesBRICKS Answer Q & ARajha RajeswaranNo ratings yet

- Assist. Prof. DR - Thaar S. Al-Gasham, Wasit University, Eng. College 136Document49 pagesAssist. Prof. DR - Thaar S. Al-Gasham, Wasit University, Eng. College 136Hundee HundumaaNo ratings yet

- Soft Rock PillarsDocument34 pagesSoft Rock PillarsvttrlcNo ratings yet

- Unit 1 QuestionsDocument10 pagesUnit 1 Questions015-RAJKUMARNo ratings yet

- Is 1200 13 1994 PDFDocument10 pagesIs 1200 13 1994 PDFSudarshan GadalkarNo ratings yet

- Pressure Vessels Lectures 87Document1 pagePressure Vessels Lectures 87Adeel NizamiNo ratings yet

- Daily Concrete Pouring Schedule - 19-Apr-2020Document2 pagesDaily Concrete Pouring Schedule - 19-Apr-2020Micheal B HaizenNo ratings yet

- Jointing Tech - MV Joints & TermsDocument48 pagesJointing Tech - MV Joints & TermsMichael Hamudikuwanda100% (1)

- Proofex GP TDSDocument2 pagesProofex GP TDSvinoth kumar SanthanamNo ratings yet

- Thermoplastics - Properties and ApplicationsDocument19 pagesThermoplastics - Properties and Applicationslenojerin3486No ratings yet

- U-BOOTS (1) Technical SeminarDocument18 pagesU-BOOTS (1) Technical SeminarBasavaraj M PatilNo ratings yet

- Bijan Khaleghi 6ADocument56 pagesBijan Khaleghi 6AKY PengNo ratings yet

- Asme B16.9 Int 1993Document13 pagesAsme B16.9 Int 1993SUSEINCANo ratings yet

- COST ESTIMATE FOR CROSS DRAINAGEDocument12 pagesCOST ESTIMATE FOR CROSS DRAINAGEManish PatelNo ratings yet

- The Best Choice for Network Solutions - Zimmlink IndonesiaDocument21 pagesThe Best Choice for Network Solutions - Zimmlink IndonesiapuspitagdNo ratings yet

- Manual Del Porton Electrico 1120e LiftmasterDocument64 pagesManual Del Porton Electrico 1120e LiftmasterClaudio Bravo MoreiraNo ratings yet

- Gate, Globe and Check Valves (Amendments/Supplements To Iso 15761)Document13 pagesGate, Globe and Check Valves (Amendments/Supplements To Iso 15761)윤규섭100% (1)

- Hta (Halfen Deha)Document4 pagesHta (Halfen Deha)Anonymous zvQGXzNo ratings yet

- Fox Running Manual: Wed, 13 May 2020 12:46:25 +0000 Valid at Time of DownloadDocument14 pagesFox Running Manual: Wed, 13 May 2020 12:46:25 +0000 Valid at Time of Downloadcorsini999No ratings yet

- Presentasi Kel.1 Aeon MallDocument43 pagesPresentasi Kel.1 Aeon MallospurbaNo ratings yet