Professional Documents

Culture Documents

Ethanol Amine Production

Uploaded by

Fatih FıratCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ethanol Amine Production

Uploaded by

Fatih FıratCopyright:

Available Formats

Korean J. Chem. Eng.

, 26(6), 1504-1511 (2009)

DOI: 10.1007/s11814-009-0254-z

RAPID COMMUNICATION

Simulation and optimization of ethanol amine production plant

Gholamreza Zahedi*,, Saeideh Amraei**, and Mazda Biglari***

*Process Systems Engineering Centre (PROSPECT), Faculty of Chemical and Natural Resources Engineering,

Universiti Teknologi Malaysia, UTM Skudai, 81310 Johor Bahru, Johor, Malaysia

**Simulation and Artificial Intelligence Research Center, Chemical Engineering, Department, Razi University, Iran

***Department of Chemical Engineering, Ryerson University, Toronto, Ontario, Canada M5B 2K3

(Received 6 April 2009 accepted 7 April 2009)

AbstractAn industrial Ethanol Amine (EA) production plant was simulated and optimized. Due to lack of accurate

reaction rate information, the first step involved obtaining reliable kinetic data from the SRI (Stanford Research Institute) industrial database and calculation using error minimization method. In the next step, by implementing the obtained reaction kinetics the whole plant was simulated using Hysys software. Simulation results were compared with

the SRI data and showed that there is acceptable agreement between simulation and the measured industrial data. In

the next step of study by applying the gradient search (GS) optimization technique the plant was optimized using: feeding

ammonia to ethylene oxide (EO) molar ratio, water flow rate in the feed stream, and reactor temperature as optimization

variables. Employing process profit as objective function the optimal operating conditions were found to be: ammonia

to EO ratio of 5 (mol/mol), water flow rate of 52.59 kg mol/hr and reactor temperature of 85 oC.

Key words: Simulation, Optimization, Ethanol Amine Production, Ethylene Oxide, Ammonia

sity and have ammonia-like odor. The EA freezing point is considerably decreased by adding water. MEA and DEA are soluble, with

any proportion, in water and alcohol but considerably less in ether.

All amines form white crystalline solids when freeze [7].

Very few quantitative studies have been conducted for EA synthesis. One source is the study conducted by Japanese researchers

[8], yet the lack of confirmed data renders it unsuitable to construct

further modeling and simulation based on a few kinetic data.

In Iran, EA is produced at Arak Petrochemical Complex (APC).

In this plant EA is produced from a direct reaction of EO and aqueous

ammonia solution in liquid phase (without addition of catalyst) in a

tubular fixed bed reactor. EO is also produced in the plant, whereas

the required ammonia is provided by the domestic petrochemical

industry. The annual APC production capacity of EA is 30,000 tons

consisting of 10,000 tons MEA, 8,000 tons TEA and the rest is DEA.

Purity of the produced MEA and DEA is 99%, while TEA is produced in 99% and 85% purities [6]. This paper aims to simulate

and investigate optimal operating condition of the MEA plant. Based

on our literature review no work has been done in this case regardless of the importance of MEA.

INTRODUCTION

Regarding the broad application of Ethanol Amine (EA), its production is of great interest to the petrochemical industry. The industrial production of EA was accomplished in 1930 followed by the

large-scale production in 1945, when alkoxylation with ethylene

oxide (EO) and propylene oxide was replaced by chlorohydrins [1,2].

The commercial importance of EA increased from 1970, when industrial production of EO began. The modern industrial production

of EA is operated exclusively by reaction of EO and excess amount

of ammonia in presence of water [3]. It has been proved that a

small amount of water is necessary to promote reaction. When there

is not any water in the system, EO does not react with ammonia.

In fact, water plays a catalytic role in the corresponding reactions

[2,4]. Based on operational conditions monoethanolamine (MEA),

diethanolamine (DEA) and triethanolamine (TEA) are produced

through three parallel-consecutive competitive reactions [1].

EAs react with a large number of compounds such as ammonia,

carbon dioxide, sulfuric acid, sodium hydroxide, carbon disulfide,

thionyl chloride and also with acids and aromatic aldehydes [4-6].

In general, they are very desirable as H2S and CO2 absorbents for

natural gas treatment [7]. Because of alcoholic characteristics, MEA

and DEA have broader industrial applications. On the other hand,

DEA and TEA are used in making detergents, textiles, pharmaceuticals, emulsifiers in drilling and excavation of oil wells, corrosion

inhibitors as well as additives to cement [2].

EAs are hygroscopic, colorless and viscous liquids at room temperature. TEA boils at 27 oC, whereas the other two EAs have higher

boiling points. Their densities are slightly greater than water den-

EA PROCESS DESCRIPTION

The commonly utilized process of EA production is the SRI process, which has been typically designed for producing 45,000 ton/

year EA from ammonia and EO, the production capacity that most

of the USA, Western Europe, and Japanese factories fall in. The

operational conditions of SRI process have been regulated to prohibit formation of any by-product. This designing concept, however,

is not employed in the industry, and the industrial applications differ from the SRI process in that the equipment and plant structure

are different, but the reaction is identical [1].

To whom correspondence should be addressed.

E-mail: grzahedi@razi.ac.ir

1504

Simulation and optimization of ethanol amine production plant

1505

Fig. 1. Simplified flow diagram of ethanol amine production plant (Adapted from [1]).

Fig. 1 depicts a simplified flow diagram of an EA-producing plant.

The flow diagram has two major sections: the reactor and the product separation. EO is added to the concentrated ammonia solution

and sent to the reactor section. In general, this section consists of four

series of reactors that are adiabatically controlled by an inner coolant. The reactors each are 3 m in length and 0.47 m in diameter. In

the reactor section, the 99 wt% ammonia solution reacts with the

EO. Almost all of the EO is converted in this section. EO must be

added to ammonia solution; otherwise, an explosive polymeric reaction occurs. The output of the reactor enters the ammonia stripper

for un-reacted ammonia to be separated as vapor phase and to be

sent, after cooling, to an ammonia absorption tower as the makeup ammonia. In the absorber, ammonia is separated and recycled

to the feed. The bottom of the ammonia stripper is fed into a vaporizing system to separate water and send it to the absorber. The concentrated dried EAs from the bottom of vaporizer enter into the successive vacuum distillation columns. In the distillation towers MEA

(with purity of 99 wt%), DEA (98.5 wt% purity), commercial

TEA (85 wt% TEA and 15 wt% DEA) and TEA (with purity of

99 wt%) are produced [1,2,4].

An EA production plant is very flexible in order to adapt to market

trends and to produce the demanded EA [3]; i.e., many operational

parameters may be adjusted to optimize the system to produce desirable product.

One important operational variable affecting product quality is

temperature [3]. Higher than required temperature in the ammonia

stripper changes color of the product (EAs) and lowers its quaility.

Other targetted optimization variables include water content of ammonia solution, and ammonia/EO feedstock ratio. The higher the

water feed to the system, the lower the operational pressure and temperature would be, which in turn results in a higher product quality.

However, the water addition has to be limitted to decrease utility

consumption. Also, a significant amount of water content interferes

with the reactions of interest in favor of a side reaction of water with

EO to produce ethylene glycol.

The ammonia/EO ratio determines the proportion of final product of EA type [8]. Although this ratio is important, we did not find

a systematically optimized value among the literature for this ratio.

A non peer-reviewed estimation was identified [10] in which this

ratio was enveloped between 10 (when only MEA is virtually pro-

duced) to 3 (more even distribution of the three products).

Optimization of other equipment within the plant has been also

suggested. For example, the distillation columns can be optimized;

however, optimization of the EAs distillation columns is beyond the

scope of this work and may be found in other sources (for example, [11] and references therein).

EVALUATION OF REACTION RATE CONSTANTS

There are some industrial processes for the EAs production, including:

BASF Process

Dow Process

Union Carbide Process

Euteco SPA Process

Nippon Shokubai Process

Oxiten Process

All of the above processes exploit reaction of ammonia with EO

but are different in the operational conditions (such as residence

time, operational temperature and pressure, ammonia concentration

and other feed specifications) and equipment (such as adiabatic or

isothermal reactors and the number of reactors). Three reactions

have mainly been recognized in the ethyl amine production [3,8]:

(1)

(2)

(3)

All of the above reactions occur simultaneously in parallel and in

series. The ratio of each EA in the final product is controlled by controlling ammonia to EO ratio [8].

Kinetic information pertaining to the reaction of EO with ammonia is not conclusive. Reference [1] reports the effect of different

input aqueous ammonia solution on the produced EA characterisKorean J. Chem. Eng.(Vol. 26, No. 6)

1506

G. Zahedi et al.

tics. The reaction of EO with dilute aqueous ammonia solution (less

than 3 wt% of NH3) at 15 oC and variable molar ratio of 0.5/1 to

20/1 of ammonia to EO were studied. The data were explained by

an Arrhenius-type relationship (Eq. (4)) with activation energy, and

pre-exponential constants for the specific rate of the reactions are

given in Table 1.

E

k = k0 exp -------

RT

(4)

where E is activation energy and k0 is a pre-exponential constant.

Table 1. Arrhenius parameters for Eq. (4) [1]

Reaction

EO+NH3

EO+MEA

EO+DEA

EO+TEA

k0

14.6

15.7

15.1

12.7

4.111080

1.131010

2.941090

4.231060

Fig. 2. Optimization algorithm for EA kinetic parameter estimation.

November, 2009

Other relations were presented for the specific rate of contributing reactions as Eqs. (5) to (7) [8]:

11000

2

2

k1 = (41+ 4[ H2 O] ) 10 exp ------------------

RT

(5)

k2=(7.20.042[H2O])k1

(6)

k3=(160.22[H2O])k2

(7)

Assuming a first order conversion of EO in the temperature range of

20 oC to 125 oC and ammonia solution of 50 to 100 wt%, the general

equation has been proposed [12]:

C

k =1.3 107 ---------

100

7.6

14500

exp ------------------

RT

(8)

where C is the ammonia mass composition in the feeding solution.

Due to the uncertainty in the kinetics data, in this study the data

from reference [1] were used to optimize k-values (ko corresponding to each specific rate) for the reactions.

Considering the reaction Eqs. of (1), (2) and (3), each compo-

Simulation and optimization of ethanol amine production plant

nent reaction rate can be described as follows [13]:

d [NH3 ]

------------------ = k1 [NH3 ][EO]

dt

(9)

d [EO ]

--------------- = k1 [NH3 ][ EO] k2[MEA ][EO] k3 [DEA ][EO]

dt

(10)

d [MEA ]

--------------------- = k1[NH3 ][EO] k2 [MEA][EO ]

dt

(11)

d [DEA ]

-------------------- = k2 [MEA][EO ] k3[DEA ][EO ]

dt

(12)

d [TEA ]

------------------- = k3[DEA] [EO]

dt

(13)

For the optimization, Matlab 7.6 with solver ODE23s [14] was used

to solve the series of above ordinary differential equations (ODEs).

Fig. 2 illustrates the proposed algorithm for obtaining kinetic constants. The algorithm first estimates the parameters (k1, k2, and k3),

followed by solving the ODEs and checking the error between results and the experimental data. The process continues until convergence to the experimental data is reached.

Results of the optimization of reaction rate constants are presented in Table 2.

PROCESS MODELING

1507

vestigate the effects of different parameters on the process and subsequent optimization of process operation. For the process modeling in this study Hysys 3.2 was used. Fig. 3 illustrates the process

flowchart made in Hysys, with the four reactors are labeled as R101A

to R101D.

Appropriate equations were selected in order to estimate the physical properties of all components in the system. The results of simulation are strongly influenced by the selected Hysys thermodynamic

model, i.e., selection of an inappropriate thermodynamic model will

result in error in model predictions. The thermodynamic models in the

Hysys environment are classified into three main groups: 1- equations

of state such as SRK; 2- equations of activity coefficient such as

NRTL; 3- special thermodynamic models such as the amine model

prepared for a system consisting of amines, acidic gas and water [15].

SIMULATION RESULTS

To build the process flow diagram in the Hysys environment,

the composition of materials, equation of state and reactions were

specified. The reactor feed specifications are presented in Table 3.

Table 4 provides a comparison between the simulation and process (SRI) data. For comparison, the errors in the simulation are

also given. Maximum error appears to be less than 4%, validating

the simulation approach.

For different towers Tables 5, 6 and 7 present the estimated pro-

The objective of mathematical modeling and simulation is to inTable 3. Characteristics of feed to the reactor

Table 2. Results of optimization algorithm for kinetic parameters

estimation

Reaction

EO+NH3

EO+MEA

EO+DEA

k0

19660

19660

19660

1.581107

04.92108

005.2108

Temperature (oC)

Pressure (KPa)

Total molar flow (kg mol/hr)

Molar flow of ammonia (kg mol/hr)

Molar flow of EO (kg mol/hr)

Molar flow water (kg mol/hr)

85

1.02104

687.83

529.09

105.82

052.92

Fig. 3. Hysys process flowchart of the EA production plant.

Korean J. Chem. Eng.(Vol. 26, No. 6)

1508

G. Zahedi et al.

Table 4. The characteristics of the reactors effluent stream (mole

ratio of ammonia to EO equals 5/1)

Compound

SRI result

(kg/hr)

Hysys result

(kg/hr)

Percent of

relative error

Ammonia

EO

Water

MEA

DEA

TEA

7842

0935

2456

2037

1338

7864

0935

2365

1966

1388

0.28

0.00

3.69

3.47

3.72

duction of different compounds including EAs and compare them

with SRI unseen data. Some significant differences between calculated and SRI data are observed. The main reason may be the limitation of the software, particularly in the thermodynamic models available in Hysys. Again, the differences between the simulated and

SRI data are mostly less than 10%, which seems acceptable.

PROCESS OPTIMIZATION

Optimization problems are made up of three basic ingredients:

An objective function that is to be minimized or maximized.

For instance, in a manufacturing process, the objective is to maximize profit or minimize cost.

A set of unknowns or variables that control the objective function value. In the manufacturing problem, the variables might include

the amounts of different resources used or the time spent on each

activity.

A set of constraints that allow the unknowns to take on certain

values but exclude others. For the manufacturing problem, it is meaningless to spend a negative amount of time on any activity, so all

the time variables are constrained to non-negative values [12].

Generally, in optimization of processes, many parameters like

temperature, pressure, raw materials flow rate, operational equipment size and the process economy can be considered. To maximize production rate, the optimum values of these parameters should

be obtained. For the EA production process in this case, as the sizes

of apparatus were already designed, this parameter is considered

constant. The operational pressure was also assumed to be constant. Temperature, raw materials flow rate (feed) such as ammonia, EO and water were considered as optimization variables, and

the process simulation was carried out for different rates. EA production and cost objective function can be set as the objective func-

Table 5. Comparison between simulation and SRI data (kg/hr)

Component

Ammonia

EO

Water

MEA

DEA

TEA

Bottom product of flash tower

Bottom product of ammonia tower

Bottom product of drying tower

SRI data

Hysys result

SRI result

Hysys result

SRI result

Hysys result

470.0

934.0

2456.60

2037.12

1338.73

0491.60

934.0

2366.33

1966.43

1479.61

0024.53

0934.21

2454.34

2037.12

1338.73

0024.49

0933.90

2366.33

1966.43

1479.61

0006.35

2444.36

2036.67

1338.73

0006.03

2354.10

1966.43

1388.91

Table 6. Comparison between simulation and SRI data (kg/hr)

Component

Ammonia

EO

Water

MEA

DEA

TEA

Overhead product of MEA tower

Bottom product of MEA tower

Bottom product of DEA tower

SRI result

Hysys result

SRI result

Hysys result

SRI result

Hysys result

2426.22

0016.32

0000.45

2329.03

0015.29

0000.51

0018.14

2020.34

1338.28

0018.66

1966.42

1479.56

001.36

468.50

000.96

615.80

Table 7. Comparison between simulation and SRI data (kg/hr)

Component

Ammonia

EO

Water

MEA

DEA

TEA

November, 2009

Overhead product of DEA tower

The side product DEA tower

SRI result

Hysys result

SRI result

Hysys result

Overhead product of TEA tower

SRI result

Hysys result

0018.14

1867.96

0006.35

0015.17

1541.75

0005.74

150.56

410.86

145.94

410.86

001.36

421.75

000.52

423.12

Simulation and optimization of ethanol amine production plant

1509

Table 8. Price of the raw materials and products [18]

Fig. 4. Variation of objective function with molar ratio of ammonia to EO.

Compound

Price ($/tonne)

Ammonia

EO

Water

MEA

DEA

TEA (%99)

TEA (%85)

025.25

155.26

018.00

177.40

193.95

190.92

187.19

tion in this part of study. As there was not any idea about a suitable

practical objective function, both of the objective functions were

examined. The GS method was first applied to optimize the molar

production of MEA as the objective function as follows:

Objective function (J)=MoleMEA

(14)

Figs. 4 to 6 depict effect of feed specification (ammonia molar flow/

EO molar flow) on the content of three EA types as final products.

Increasing ammonia content in the feed increases the production

of MEA and decreases the DEA and TEA in the product: no optimal

point appeared in the above figures. As a result, the objective function was changed to the profit function as a realistic approach defined below [13]:

Objective function (J)=[products price][raw materials price]

(15)

J=[kgMEApriceMEA+kgDEApriceDEA+kgTEA(%85)priceTEA(%85)

J=+kgTEA(%99) priceTEA(%99)][kgNH3priceNH +kgEOpriceEO

J=+kgH OpriceH O].

(16)

Fig. 5. Effect of ammonia to EO molar ratio on DEA production

rate.

Table 8 presents price of the raw materials and products [18].

The constraints exposed to the optimization process were selected

based on operationally practical conditions [3,7,10] and included

the ammonia to EO molar flow of 5 to 20, and temperature range

of 85 oC to 120 oC. Temperatures beyond this range results mainly

in occurrence of side reactions.

OPTIMIZATION RESULTS

Figs. 7, 8 and 9 exhibit the variations of profit function (Eq. (16))

with changes in three selected controlling factors. At the maximum

profit, the optimum values of the variables were found to be: ammonia to EO molar ratio 5/1; water molar flow 52.92 kg mol/hr and

reaction temperature 85 oC. As observed in Fig. 7, the ratio ammonia/EO=5/1 generates maximum profit which overlaps the maximum profit observed in Figs. 8 and 9.

CONCLUSION AND REMARKS

Fig. 6. Effect of ammonia to EO molar ratio on TEA production

rate.

An EA production plant was simulated by using Hysys software. The results of simulation revealed that the simulated data have

a good agreement with the SRI data. There are, however, some errors

in the predicted data, mainly because of the softwares weakness in

this study, and particularly due to the available Hysys thermodynamic models.

The simulation also necessitates using accurate reaction rates.

Korean J. Chem. Eng.(Vol. 26, No. 6)

1510

G. Zahedi et al.

Since there are not convincing studies on the EAs production in

the literature, a simple kinetics optimization was carried out and results were confirmed by comparison with the available experimental data.

Next step involved optimization of the process to evaluate the

effects of feed flow rates and input reactor temperature, while the

pressure and equipment size were deemed constant. The MEA yield

appeared as an improper objective function having monotonic trends

with the selected controlling variables; therefore, no feasible results

were found. Consequently, the process profit was set as the objective function. Results of optimization showed that the optimal operation points are the ammonia to EO molar ratio of 5, reaction temperature of 85 oC and water flow rate of 52.92 kg mol/hr.

NOMENCLATURE

Fig. 7. Economical profit (objective function) in terms of feeding

molar ratio of Ammonia to EO.

C

: concentration [%wt]

E

: activation energy [kcal mole1]

J

: objective function

k0

: frequency factor [L mol1 min1]

k1, k2, k3 : kinetics constants [L mol1 min1]

ODE : ordinary differential equation

R

: gas constant [kcal mol1 K1]

T

: temperature [K], or otherwise stated

t

: time [min]

Greek Letter

: error

REFERENCES

Fig. 8. Variation of objective function with change of water molar

inflow.

Fig. 9. Effect of reactor temperature on the process profit.

November, 2009

1. T. McMillan, SRI International 193(6), 1 (1991).

2. H. Hammer, Ethanolamines and propanolamines, Ullmanns Encyclopedia of Industrial Chemistry, 6th Ed., New York, Wiley-VCH,

10, 1 (2003).

3. P. Fassler and A. Celeghin, A new approach to an established product: Cost-efficient production of ethanolamines, Sulzer Technical

Review, Issue No. 3 (2008).

4. M. Frauenkron, Ethanolamines and propanolamines, Ullmanns

Encyclopedia of Industrial Chemistry, 7th Ed., New York, WileyVCH, 12, 475 (2008).

5. A. L. Kohl and R. Nielsen, Gas purification, 5th Ed., Houston, Texas,

Gulf Publishing Company, 41 (1997).

6. J. G. Spight, Chemical and process design handbook, New York,

McGraw-Hill (2002).

7. K. Weissermel, H.-J. Arpe, C. R. Lindley and S. Hawkins, Oxidation products of ethylene, Industrial Organic Chemistry, Wiley-VCH,

159 (2003).

8. M. Hatta, T. Ito, M. Miki and T. Okabe, Reaction of ethylene oxide

with ammonia, Yukagaku (Journal of Japan Oil Chemists Society),

15, 215 (1966).

9. Http://www.arpc.ir/Default.aspx?tabid=143 (2008).

10. C. Ruehl, C. Hou, P. Lee and L. Armstrong, Design of a system of

ethanolamine reactors, Course project CENG 403, Rice University, Houston, Texas (1997).

11. K. Kolmetz, W. K. Ng, P. W. Faessler, K. Senthil, Y. T. Lim, A. W.

Slolev and T. M. Zygula, Hydrocarbon Processing, 84(5), 77 (2005).

Simulation and optimization of ethanol amine production plant

12. C. Ruehl, C. Hou, P. Lee and L. Armstrong, Design of a system of

ethanolamine reactor, CENG 403 (1997).

13. O. Levenspiel, Chemical reaction engineering, 3th Ed., New York,

Wiley (1998).

14. MATLAB R2008a, Http://www.mathwork.com (2008).

15. Aspen Technolgoy, Inc., Hysys user guide, Ten Canal park, Cambridge, USA (2005).

1511

16. T. F. Edgar, D. M. Himmelblau and L. S. Lasdon, Optimization of

chemical processes, 2th Ed., New York, McGraw-Hill (2001).

17. M. E. Masoumi, S. M. Sadrameli, J. Towfighi and A. Niaei, Journal of Energy, 31, 516 (2006).

18. Http://www.petrochem-ir.net/esales-internetsales-prodprice-fa.html/

(2008).

Korean J. Chem. Eng.(Vol. 26, No. 6)

You might also like

- Ethanol Amine Production PDFDocument8 pagesEthanol Amine Production PDFFatih FıratNo ratings yet

- Pressure-Swing Reactive Distillation Process For Transesterification of Methyl Acetate With IsopropanolDocument3 pagesPressure-Swing Reactive Distillation Process For Transesterification of Methyl Acetate With IsopropanolMahesh ChantarkarNo ratings yet

- Design and Simulation of A Reactive Distillation Process To Produce High-Purity Ethyl AcetateDocument9 pagesDesign and Simulation of A Reactive Distillation Process To Produce High-Purity Ethyl AcetateAjib Sari PutraNo ratings yet

- Sablin Alpha Raab FDocument3 pagesSablin Alpha Raab Fsk281No ratings yet

- 1998 - Chang - Simulation of Pervaporation Process For Ethanol DehydrationDocument9 pages1998 - Chang - Simulation of Pervaporation Process For Ethanol DehydrationViraj EdirisingheNo ratings yet

- Aspen-Hysyssimulation Sultana2011Document4 pagesAspen-Hysyssimulation Sultana2011Wassim KTARINo ratings yet

- Triethanolamine Synthesis in A Continuous Ow Microchannel ReactorDocument6 pagesTriethanolamine Synthesis in A Continuous Ow Microchannel ReactorMido FahmyNo ratings yet

- Design and Control of Acetaldehyde Production Process: January 2014Document12 pagesDesign and Control of Acetaldehyde Production Process: January 2014nabila OktavianiNo ratings yet

- Ethylene Oxide-Ethylene Glycol - InfoDocument10 pagesEthylene Oxide-Ethylene Glycol - InfoAmeya SavnalNo ratings yet

- 1263 3507 1 PBDocument5 pages1263 3507 1 PBJohn TorrezNo ratings yet

- Full BibilographiDocument10 pagesFull BibilographiDilfredo RuizNo ratings yet

- Full TextDocument8 pagesFull TextAbril FgNo ratings yet

- Thermodynamic Process Simulation of The Digestion Unit in Iran Alumina RefineryDocument6 pagesThermodynamic Process Simulation of The Digestion Unit in Iran Alumina RefineryFarizan Rahmat ReksoprodjoNo ratings yet

- Intro To Process SimulationDocument44 pagesIntro To Process SimulationAakriti BhandariNo ratings yet

- Aspen Example Test - EO v2018Document2 pagesAspen Example Test - EO v2018marij233No ratings yet

- Mixing AmineDocument5 pagesMixing AmineWalid Ben HuseinNo ratings yet

- Modeling and Optimization of Ethane Steam Cracking Process in An Industrial Tubular Reactor With Improved Reaction SchemeDocument9 pagesModeling and Optimization of Ethane Steam Cracking Process in An Industrial Tubular Reactor With Improved Reaction Schemejessica sarabiaNo ratings yet

- Eo ADocument4 pagesEo AiwansaputratekimNo ratings yet

- ICGSCE Paper SyaeraDocument7 pagesICGSCE Paper SyaeraYustinusNo ratings yet

- Separation of Ethanol-Heptane Azeotropic Mixtures by Solvent Extraction With An ILDocument7 pagesSeparation of Ethanol-Heptane Azeotropic Mixtures by Solvent Extraction With An ILJohnSmithNo ratings yet

- Design and Control of Ethyl Acetate Production Process: January 2015Document13 pagesDesign and Control of Ethyl Acetate Production Process: January 2015mahmoudmaamoun640No ratings yet

- BM15-17 UdaanDocument105 pagesBM15-17 UdaanAnonymous HzljLSMcNo ratings yet

- 1ethanol To Ethylene B1 - ProcessdesignDocument7 pages1ethanol To Ethylene B1 - ProcessdesignAdi PutraNo ratings yet

- Slurry Phase Reactor Technology For DME Direct SynthesisDocument13 pagesSlurry Phase Reactor Technology For DME Direct SynthesischusnuhNo ratings yet

- General Operating Problems and Their Solutions of Natural Gas Sweetening Process (Amine System)Document15 pagesGeneral Operating Problems and Their Solutions of Natural Gas Sweetening Process (Amine System)mahmoud3814No ratings yet

- Ethylene Oxide AppDocument2 pagesEthylene Oxide AppSyifa AnggrainiNo ratings yet

- Ethyl Acetate ProjectDocument60 pagesEthyl Acetate ProjectBaskarrajaNo ratings yet

- Biodiesel Fuel QualityDocument37 pagesBiodiesel Fuel Qualityminh1981No ratings yet

- Catalytic Distillation Process Modelling and Simulation For The TAEE Synthesis On Amberlyst35Document7 pagesCatalytic Distillation Process Modelling and Simulation For The TAEE Synthesis On Amberlyst35Elena Raluca DraguNo ratings yet

- AlkyDocument37 pagesAlkyMỹ PhanNo ratings yet

- Pro/Ii Casebook Methyl Tertiary Butyl Ether (MTBE) PlantDocument0 pagesPro/Ii Casebook Methyl Tertiary Butyl Ether (MTBE) PlantridhajamelNo ratings yet

- Glycol PlantDocument8 pagesGlycol PlantDian Risti PurwantiNo ratings yet

- Ethanolamines and Secondary Products: 15.1. Ethanolamine ProcessDocument8 pagesEthanolamines and Secondary Products: 15.1. Ethanolamine ProcessNetchanok BoontekNo ratings yet

- Mixed Amines Application in Gas Sweetening PlantsDocument6 pagesMixed Amines Application in Gas Sweetening PlantsAshish ShahNo ratings yet

- 2008-01-0317 - Measurement of Vapor Pressures and Enthalpies of Formation of Gasoline and Ethanol Blends - Raine - Auckland PDFDocument15 pages2008-01-0317 - Measurement of Vapor Pressures and Enthalpies of Formation of Gasoline and Ethanol Blends - Raine - Auckland PDFFabio GuedesNo ratings yet

- Chemi Properties (Full Permission)Document9 pagesChemi Properties (Full Permission)Vinay BabuNo ratings yet

- 2 2 2 Raphael Idem, Malcolm Wilson, Paitoon Tontiwachwuthikul, Amit Chakma, Amornvadee Veawab, Adisorn Aroonwilas, and Don GelowitzDocument7 pages2 2 2 Raphael Idem, Malcolm Wilson, Paitoon Tontiwachwuthikul, Amit Chakma, Amornvadee Veawab, Adisorn Aroonwilas, and Don GelowitznakurawNo ratings yet

- Ethyl Acetate Design ProjectDocument60 pagesEthyl Acetate Design ProjectAhmed Ali100% (4)

- ErwerDocument9 pagesErwerPriska Jesika MonanginNo ratings yet

- (Polish Journal of Chemical Technology) Process Simulation of Dimethyl Ether Synthesis Via Methanol Vapor Phase DehydrationDocument6 pages(Polish Journal of Chemical Technology) Process Simulation of Dimethyl Ether Synthesis Via Methanol Vapor Phase DehydrationKaramYassNo ratings yet

- Aspenhysys Simulation of Methanol To Dimethylether (Dme) : Hassan Babiker, Babiker.A.Karma, Adil. A.MohammedDocument7 pagesAspenhysys Simulation of Methanol To Dimethylether (Dme) : Hassan Babiker, Babiker.A.Karma, Adil. A.MohammedFernadez Ramos CarolayNo ratings yet

- 1 s2.0 S0263876215003330 MainDocument11 pages1 s2.0 S0263876215003330 MainAhmad MuzammilNo ratings yet

- Simulation Studies On Reactive Distillation For Synthesis of - Amyl Ethyl EtherDocument6 pagesSimulation Studies On Reactive Distillation For Synthesis of - Amyl Ethyl EtherElena Raluca DraguNo ratings yet

- Aspen-Hysys Simulation of Sulfuric Acid PlantDocument3 pagesAspen-Hysys Simulation of Sulfuric Acid PlantacckypenrynNo ratings yet

- Ammonia PlantDocument16 pagesAmmonia Plantganeshan67% (6)

- Fluidized Bedreactor Modeling and SimulaDocument13 pagesFluidized Bedreactor Modeling and Simulabader291No ratings yet

- Excess Methanol RecoveryDocument6 pagesExcess Methanol RecoverySteven Putra HalimNo ratings yet

- Performance of Bubble Column ReactorDocument6 pagesPerformance of Bubble Column ReactorArtha WijayaNo ratings yet

- Optimization of Synthesis Gas (Autothermal) Reactor in Methanol Production Process Using Natural Gas As Feed StockDocument18 pagesOptimization of Synthesis Gas (Autothermal) Reactor in Methanol Production Process Using Natural Gas As Feed StockainmnrhNo ratings yet

- Activated Carbon-Tungstophosphoric Acid Catalysts For The Synthesis of Tert-Amyl Ethyl Ether (TAEE)Document8 pagesActivated Carbon-Tungstophosphoric Acid Catalysts For The Synthesis of Tert-Amyl Ethyl Ether (TAEE)Elena Raluca DraguNo ratings yet

- Barbu 2013Document15 pagesBarbu 2013Siddharth VermaNo ratings yet

- Synthesis of Isoamyl AcetateDocument10 pagesSynthesis of Isoamyl AcetateMikaila Denise LoanzonNo ratings yet

- Direct Methane to Methanol: Foundations and Prospects of the ProcessFrom EverandDirect Methane to Methanol: Foundations and Prospects of the ProcessNo ratings yet

- Hydrogen Production TechnologiesFrom EverandHydrogen Production TechnologiesMehmet SankirNo ratings yet

- Natural Gas Processing from Midstream to DownstreamFrom EverandNatural Gas Processing from Midstream to DownstreamNimir O. ElbashirNo ratings yet

- Analytical Characterization Methods for Crude Oil and Related ProductsFrom EverandAnalytical Characterization Methods for Crude Oil and Related ProductsAshutosh K. ShuklaNo ratings yet

- Maersk Olie Og Gas AS Esplanaden 50 DK-1263 Copenhagen K. Denmark Attn. Mr. L. AnderssonDocument21 pagesMaersk Olie Og Gas AS Esplanaden 50 DK-1263 Copenhagen K. Denmark Attn. Mr. L. AnderssonFatih FıratNo ratings yet

- Improved Control Valve Sizing For Multiphase FlowDocument5 pagesImproved Control Valve Sizing For Multiphase FlowFatih FıratNo ratings yet

- API 620 Appendix R Tanks For Storage of Refrigerated Product PDFDocument16 pagesAPI 620 Appendix R Tanks For Storage of Refrigerated Product PDFFatih FıratNo ratings yet

- Ejector Data SheetDocument5 pagesEjector Data SheetFatih FıratNo ratings yet

- Heat Exchanger Input Correction FactorDocument11 pagesHeat Exchanger Input Correction FactorFatih FıratNo ratings yet

- Catalyst To EthanolDocument26 pagesCatalyst To EthanolFatih FıratNo ratings yet

- Venturi CD at Laminar FlowDocument6 pagesVenturi CD at Laminar FlowFatih Fırat100% (1)

- Dynamic Modeling and Simulation of Low Density Polyethylene Production - A Comparative StudyDocument6 pagesDynamic Modeling and Simulation of Low Density Polyethylene Production - A Comparative StudyFatih FıratNo ratings yet

- DWC Column SimulationDocument14 pagesDWC Column SimulationFatih FıratNo ratings yet

- Paraxylene From CornDocument295 pagesParaxylene From CornMinjdeDiosNo ratings yet

- Appendix 4-S KSM Project HDS Pilot PlantDocument156 pagesAppendix 4-S KSM Project HDS Pilot PlantAmandaNo ratings yet

- O U P R: Description of The Process Industry Scale OptimizationDocument5 pagesO U P R: Description of The Process Industry Scale OptimizationAditya PatilNo ratings yet

- ReviewDocument119 pagesReviewlhphong021191No ratings yet

- Flud ZedDocument10 pagesFlud Zedashe zinabNo ratings yet

- Sizing Vacuum Pump or Ejector For Chemical ProcessDocument4 pagesSizing Vacuum Pump or Ejector For Chemical ProcessscranderiNo ratings yet

- Mod. REC1/EV Mod. REC1c/EV Mod. REC1a/EV: Continuous Reaction (CSTR) Pilot PlantDocument2 pagesMod. REC1/EV Mod. REC1c/EV Mod. REC1a/EV: Continuous Reaction (CSTR) Pilot Plantcgjp120391No ratings yet

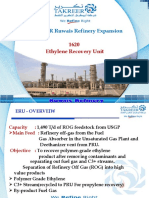

- Vdocuments - MX 1620 Ethylene Recovery Unitpptx 1601970425506Document31 pagesVdocuments - MX 1620 Ethylene Recovery Unitpptx 1601970425506Shabir MansuriNo ratings yet

- Group 10 Design Parameters, HazopDocument69 pagesGroup 10 Design Parameters, HazopM. AkmalNo ratings yet

- Design1 of A Plant For The Production of Ammonia and Urea Using Aspen Hysys1Document18 pagesDesign1 of A Plant For The Production of Ammonia and Urea Using Aspen Hysys1Aji PratamaNo ratings yet

- Limitation and Misuse LOPADocument4 pagesLimitation and Misuse LOPARoslinormansyah RidwanNo ratings yet

- PC SlideDocument34 pagesPC SlideRadhashyam GiriNo ratings yet

- Final ReportjavDocument35 pagesFinal Reportjavalotte12No ratings yet

- Process Design For The Production of Ethylene From EthanolDocument145 pagesProcess Design For The Production of Ethylene From EthanolsaeidNo ratings yet

- Simulation of The Pyrolysis Reactions and Coke Deposition in Industrial LPG Cracking FurnaceDocument16 pagesSimulation of The Pyrolysis Reactions and Coke Deposition in Industrial LPG Cracking FurnacerezaimamNo ratings yet

- 4500MB Parr Stirred Reactors and Pressure Vessels Catalog v15 Literature 2Document178 pages4500MB Parr Stirred Reactors and Pressure Vessels Catalog v15 Literature 2asdasdNo ratings yet

- MTBE Production Material Balance Project: Process DescriptionDocument39 pagesMTBE Production Material Balance Project: Process DescriptionmoheedNo ratings yet

- Coke Formation in Catalytic CrackingDocument9 pagesCoke Formation in Catalytic CrackingwiboonwiNo ratings yet

- Design of Batch ProcessesDocument19 pagesDesign of Batch ProcessesMathilda PasaribuNo ratings yet

- CKRD-MS-02 (2020)Document133 pagesCKRD-MS-02 (2020)Shakoor MalikNo ratings yet

- Extra ExercisesDocument55 pagesExtra ExercisesRahul RNo ratings yet

- Indian Forest Service Examination SyllabusDocument46 pagesIndian Forest Service Examination SyllabusamulrajvincentNo ratings yet

- Lab 3 Plug FlowDocument29 pagesLab 3 Plug FlowHikaru MokaNo ratings yet

- Thin Film ReactorsDocument9 pagesThin Film ReactorsThanh HuongNo ratings yet

- Production of Chlorobenzene From Benzene and Chlorine: BackgroundDocument2 pagesProduction of Chlorobenzene From Benzene and Chlorine: BackgroundArash AbbasiNo ratings yet

- Basic Design Equations For Multiphase ReactorsDocument32 pagesBasic Design Equations For Multiphase ReactorsKiran DasNo ratings yet

- Topsoe MethanolDocument14 pagesTopsoe Methanolk_selv321100% (2)

- LAB Plug FlowDocument24 pagesLAB Plug FlowZalina SamsuddinNo ratings yet

- Catalytic Conversion of Glycerol To Propylene GlycolDocument215 pagesCatalytic Conversion of Glycerol To Propylene Glycolbarbara_ropeNo ratings yet

- CP Marlin Book Chapters 1 - 2Document44 pagesCP Marlin Book Chapters 1 - 2David pollitoNo ratings yet