Professional Documents

Culture Documents

Lifting Trunnion Calculations Sample

Uploaded by

shazanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lifting Trunnion Calculations Sample

Uploaded by

shazanCopyright:

Available Formats

Lifting Trunnion Calculations

Table of Contents

Cover Sheet............................................................................................................................. 2

Title Page................................................................................................................................. 3

Leg & Lug Analysis Trunnion - V.............................................................................................. 4

Leg & Lug Analysis Trunnion - H.............................................................................................. 7

Vessel Results Summary........................................................................................................ 10

Cover Page

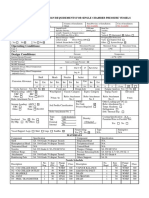

DESIGN CALCULATION

ASME Code Version

: 2015

Analysis Performed by : PHILS HEAVY ENGG PVT LTD

Date of Analysis

: Nov 30,2016

PV Elite 2016, January 2016

Title Page

Note: PVElite performs all calculations internally in U.S. Customary Units

to remain compliant with the ASME Code and any built in assumptions in

the ASME Code formulae. The U.S. Customary material database is used for

consistency. Finalized results are converted to the user set of selected

units using conversion constants with adequate significant digits.

PV Elite 2016 SP1 Licensee: PHILS HEAVY ENGG PVT LTD

FileName : 100-R-201-A-B

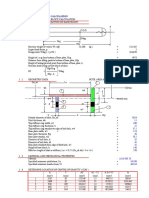

Leg & Lug Analysis Trunnion - V

Item: 1 11:20a Nov 30,2016

Input Echo, Leg & Lug Item

1,

Description: Trunnion - V

Design Internal Pressure

0.00 kgf/cm^2

Design Temperature for Attachment

TEMP

40.00 C

Vessel Outside Diameter

OD 3140.000 mm

Vessel Wall Thickness

Ts 95.0000 mm

Vessel Corrosion Allowance

Cas

1.5000 mm

Vessel Material

SA-516 70

Vessel Material UNS Number

K02700

Vessel Allowable Stress at Design

S

138.00 N/mm^2

Analysis Type:

Trunnion

Empty Weight of Vessel

Wemp 570000.00 N

Operating Weight of Vessel (vertical load )

W

0.00 N

Trunnion Material

SA-516 70

Trunnion Material UNS Number

K02700

Trunnion Yield Stress

SY

245.45 N/mm^2

Trunnion Outside Diameter

TOD 324.000 mm

Trunnion Thickness

TTHK 16.0000 mm

Trunnion Length

TL 200.0000 mm

Bail/Sling Width

TT 100.0000 mm

Ring Outside Diameter

Rod

525.00 mm

Ring Thickness

Rthk

16.00 mm

Trunnion Type

Hollow

Lift Orientation

Vertical

Impact Factor

Impfac

1.50

Force Along Vessel Axis

Fax 285000.00 N

Force Normal to Vessel

Fn

0.00 N

Force Tangential to Vessel

Ft

0.00 N

Perform WRC-107 Analysis on the Trunnion

Yes

Occasional Load Factor (AISC A5.2)

Occfac

1.00

Results for Trunnions, Description : Trunnion - V

Trunnion Lifting Load [Tlf]:

= ((Fa^2 + Ft^2)^1/2)

= ((285000.00^2 + 0.00^2)^1/2) * 1.50

= 427500.00 N

Z = pi * (TOD^4 - TID^4) / (32.0 * TOD)

= 3.14 * ( 324.00^4 - 292.00^4) / (32.0 * 324.00 )

= 1136285.75 mm ^3

Trunnion Bending Moment [Tmom]:

= (TL - 0.5 * TT)/1.000* Tlf

= ( 200.00 - 0.5 * 100.00 )/1.000 * 427500.00

= 64150.99 N-m

Trunnion Calculated Bending Stress [SBC]:

= TMOM * 1.000/ Z

= 64150.99 *1.000/ 1136285

= 56.44 N/mm^2[Passed] SBC < Min(0.66* SY* Occfac, .75* SY) (162.00)

PV Elite 2016 SP1 Licensee: PHILS HEAVY ENGG PVT LTD

FileName : 100-R-201-A-B

Leg & Lug Analysis Trunnion - V

Item: 1 11:20a Nov 30,2016

Trunnion Cross Section Area [Txsa]:

= pi / 4 * (TOD^2- TID^2)

= 3.14 /4 * ( 324.00^2- 292.00^2)

= 15481.77 mm^2

Trunnion Calculated Shear Stress [SSC]:

= Tlf / Txsa

= 427500.00 / 15481.77

= 27.61 N/mm^2[Passed] SSC < 0.4 * SY * Occfac (98.18)

Trunnion Unity Check [UCHK]:

= SBC / SBA + SSC / SSA

= 56.44 / 162.00 + 27.61 / 98.18

= 0.63 [Passed] UCHK, Must be less than 1.

Trunnion Bearing Contact Area [Tbca]:

= TOD * TT

= 324.00 * 100.00

= 32400.00 mm^2

Trunnion Bearing Stress [SBEC]:

= Tlf / Tbca

= 427500.00 / 32400.00

= 13.20 N/mm^2[Passed] SBEC < Min(0.75* SY* Occfac, 0.9* SY) (184.09)

Results of WRC-107 Analysis on the trunnion:

WRC 107 Stress Calculation for OCCasional loads:

Radial Load

P

0.0 N

Circumferential Shear

VC

0.0 N

Longitudinal Shear

VL

427500.0 N

Circumferential Moment

MC

0.0 N-m

Longitudinal Moment

ML

64151.0 N-m

Torsional Moment

MT

0.0 N-m

Dimensionless Parameters used : Gamma = 16.29

Dimensionless Loads for Cylindrical Shells at Attachment Junction:

------------------------------------------------------------------Curves read for 1979

Beta Figure Value Location

------------------------------------------------------------------N(PHI) / ( P/Rm )

0.093 4C

3.121 (A,B)

N(PHI) / ( P/Rm )

0.093 3C

2.987 (C,D)

M(PHI) / ( P )

0.093 2C1

0.134 (A,B)

M(PHI) / ( P )

0.093 1C

0.168 (C,D)

N(PHI) / ( MC/(Rm**2 * Beta) ) 0.093 3A

0.298 (A,B,C,D)

M(PHI) / ( MC/(Rm * Beta) ) 0.093 1A

0.102 (A,B,C,D)

N(PHI) / ( ML/(Rm**2 * Beta) ) 0.093 3B

1.104 (A,B,C,D)

M(PHI) / ( ML/(Rm * Beta) ) 0.093 1B

0.056 (A,B,C,D)

N(x)

N(x)

M(x)

M(x)

N(x)

M(x)

/ ( P/Rm )

0.093 3C

2.987 (A,B)

/ ( P/Rm )

0.093 4C

3.121 (C,D)

/(P)

0.093 1C1

0.173 (A,B)

/(P)

0.093 2C

0.134 (C,D)

/ ( MC/(Rm**2 * Beta) ) 0.093 4A

0.390 (A,B,C,D)

/ ( MC/(Rm * Beta) ) 0.093 2A

0.060 (A,B,C,D)

PV Elite 2016 SP1 Licensee: PHILS HEAVY ENGG PVT LTD

FileName : 100-R-201-A-B

Leg & Lug Analysis Trunnion - V

Item: 1 11:20a Nov 30,2016

N(x) / ( ML/(Rm**2 * Beta) ) 0.093 4B

M(x) / ( ML/(Rm * Beta) ) 0.093 2B

0.282 (A,B,C,D)

0.091 (A,B,C,D)

Stress Concentration Factors Kn = 1.00, Kb = 1.00

Stresses in the Vessel at the Attachment Junction

|

|

Stress Values at

(

N/mm2)

Type of

|

|

Stress

Load| Au

Al

Bu

Bl

Cu

Cl

Du

Dl |

------------------------------------------------------------------------Circ. Memb. P | 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0|

Circ. Bend. P | 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0|

Circ. Memb. MC | 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0|

Circ. Memb. MC | 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0|

Circ. Memb. ML | -3.5 -3.5 3.5 3.5 0.0 0.0 0.0 0.0|

Circ. Bend. ML | -17.4 17.4 17.4 -17.4 0.0 0.0 0.0 0.0|

|

|

Tot. Circ. Str.| -20.9 13.9 20.9 -13.9 0.0 0.0 0.0 0.0|

------------------------------------------------------------------------Long. Memb. P | 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0|

Long. Bend. P | 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0|

Long. Memb. MC | 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0|

Long. Bend. MC | 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0|

Long. Memb. ML | -0.9 -0.9 0.9 0.9 0.0 0.0 0.0 0.0|

Long. Bend. ML | -28.3 28.3 28.3 -28.3 0.0 0.0 0.0 0.0|

|

|

Tot. Long. Str.| -29.2 27.4 29.2 -27.4 0.0 0.0 0.0 0.0|

------------------------------------------------------------------------Shear VC | 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0|

Shear VL | 0.0 0.0 0.0 0.0 -9.0 -9.0 9.0 9.0|

Shear MT | 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0|

|

|

Tot. Shear| 0.0 0.0 0.0 0.0 -9.0 -9.0 9.0 9.0|

------------------------------------------------------------------------Str. Int. | 29.2 27.4 29.2 27.4 18.0 18.0 18.0 18.0|

SUMMARY OF RESULTS:

Trunnion unity check value: 0.6296

Actual

Bending Stress (N/mm^2)

Shear Stress (N/mm^2)

Bearing Stress (N/mm^2)

Allowable

56.44

27.61

13.20

Pass/Fail

162.00

Pass

98.18

Pass

184.09

Pass

Vessel Maximum Stress Intensity Comparison:

At Nozzle Edge: 29.19

Allowable: 1.5 * S: 207.00 N/mm^2[Passed]

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2016

PV Elite 2016 SP1 Licensee: PHILS HEAVY ENGG PVT LTD

FileName : 100-R-201-A-B

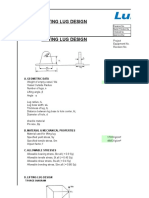

Leg & Lug Analysis Trunnion - H

Item: 2 11:20a Nov 30,2016

Input Echo, Leg & Lug Item

2,

Description: Trunnion - H

Design Internal Pressure

0.00 kgf/cm^2

Design Temperature for Attachment

TEMP

40.00 C

Vessel Outside Diameter

OD 3140.000 mm

Vessel Wall Thickness

Ts 95.0000 mm

Vessel Corrosion Allowance

Cas

1.5000 mm

Vessel Material

SA-516 70

Vessel Material UNS Number

K02700

Vessel Allowable Stress at Design

S

138.00 N/mm^2

Analysis Type:

Trunnion

Empty Weight of Vessel

Wemp 570000.00 N

Operating Weight of Vessel (vertical load )

W

0.00 N

Trunnion Material

SA-516 70

Trunnion Material UNS Number

K02700

Trunnion Yield Stress

SY

245.45 N/mm^2

Trunnion Outside Diameter

TOD 324.000 mm

Trunnion Thickness

TTHK 16.0000 mm

Trunnion Length

TL 200.0000 mm

Bail/Sling Width

TT 100.0000 mm

Ring Outside Diameter

Rod

525.00 mm

Ring Thickness

Rthk

16.00 mm

Trunnion Type

Hollow

Lift Orientation

Horizontal

Impact Factor

Impfac

1.50

Force Along Vessel Axis

Fax

0.00 N

Force Normal to Vessel

Fn

0.00 N

Force Tangential to Vessel

Ft 245000.00 N

Perform WRC-107 Analysis on the Trunnion

Yes

Occasional Load Factor (AISC A5.2)

Occfac

1.00

Results for Trunnions, Description : Trunnion - H

Trunnion Lifting Load [Tlf]:

= ((Fa^2 + Ft^2)^1/2)

= ((0.00^2 + 245000.00^2)^1/2) * 1.50

= 367500.00 N

Z = pi * (TOD^4 - TID^4) / (32.0 * TOD)

= 3.14 * ( 324.00^4 - 292.00^4) / (32.0 * 324.00 )

= 1136285.75 mm ^3

Trunnion Bending Moment [Tmom]:

= (TL - 0.5 * TT)/1.000* Tlf

= ( 200.00 - 0.5 * 100.00 )/1.000 * 367500.00

= 55147.35 N-m

Trunnion Calculated Bending Stress [SBC]:

= TMOM * 1.000/ Z

= 55147.35 *1.000/ 1136285

= 48.52 N/mm^2[Passed] SBC < Min(0.66* SY* Occfac, .75* SY) (162.00)

PV Elite 2016 SP1 Licensee: PHILS HEAVY ENGG PVT LTD

FileName : 100-R-201-A-B

Leg & Lug Analysis Trunnion - H

Item: 2 11:20a Nov 30,2016

Trunnion Cross Section Area [Txsa]:

= pi / 4 * (TOD^2- TID^2)

= 3.14 /4 * ( 324.00^2- 292.00^2)

= 15481.77 mm^2

Trunnion Calculated Shear Stress [SSC]:

= Tlf / Txsa

= 367500.00 / 15481.77

= 23.74 N/mm^2[Passed] SSC < 0.4 * SY * Occfac (98.18)

Trunnion Unity Check [UCHK]:

= SBC / SBA + SSC / SSA

= 48.52 / 162.00 + 23.74 / 98.18

= 0.54 [Passed] UCHK, Must be less than 1.

Trunnion Bearing Contact Area [Tbca]:

= TOD * TT

= 324.00 * 100.00

= 32400.00 mm^2

Trunnion Bearing Stress [SBEC]:

= Tlf / Tbca

= 367500.00 / 32400.00

= 11.34 N/mm^2[Passed] SBEC < Min(0.75* SY* Occfac, 0.9* SY) (184.09)

Results of WRC-107 Analysis on the trunnion:

WRC 107 Stress Calculation for OCCasional loads:

Radial Load

P

0.0 N

Circumferential Shear

VC -367500.0 N

Longitudinal Shear

VL

0.0 N

Circumferential Moment

MC

55147.3 N-m

Longitudinal Moment

ML

0.0 N-m

Torsional Moment

MT

0.0 N-m

Dimensionless Parameters used : Gamma = 16.29

Dimensionless Loads for Cylindrical Shells at Attachment Junction:

------------------------------------------------------------------Curves read for 1979

Beta Figure Value Location

------------------------------------------------------------------N(PHI) / ( P/Rm )

0.093 4C

3.121 (A,B)

N(PHI) / ( P/Rm )

0.093 3C

2.987 (C,D)

M(PHI) / ( P )

0.093 2C1

0.134 (A,B)

M(PHI) / ( P )

0.093 1C

0.168 (C,D)

N(PHI) / ( MC/(Rm**2 * Beta) ) 0.093 3A

0.298 (A,B,C,D)

M(PHI) / ( MC/(Rm * Beta) ) 0.093 1A

0.102 (A,B,C,D)

N(PHI) / ( ML/(Rm**2 * Beta) ) 0.093 3B

1.104 (A,B,C,D)

M(PHI) / ( ML/(Rm * Beta) ) 0.093 1B

0.056 (A,B,C,D)

N(x)

N(x)

M(x)

M(x)

N(x)

M(x)

/ ( P/Rm )

0.093 3C

2.987 (A,B)

/ ( P/Rm )

0.093 4C

3.121 (C,D)

/(P)

0.093 1C1

0.173 (A,B)

/(P)

0.093 2C

0.134 (C,D)

/ ( MC/(Rm**2 * Beta) ) 0.093 4A

0.390 (A,B,C,D)

/ ( MC/(Rm * Beta) ) 0.093 2A

0.060 (A,B,C,D)

PV Elite 2016 SP1 Licensee: PHILS HEAVY ENGG PVT LTD

FileName : 100-R-201-A-B

Leg & Lug Analysis Trunnion - H

Item: 2 11:20a Nov 30,2016

N(x) / ( ML/(Rm**2 * Beta) ) 0.093 4B

M(x) / ( ML/(Rm * Beta) ) 0.093 2B

0.282 (A,B,C,D)

0.091 (A,B,C,D)

Stress Concentration Factors Kn = 1.00, Kb = 1.00

Stresses in the Vessel at the Attachment Junction

|

|

Stress Values at

(

N/mm2)

Type of

|

|

Stress

Load| Au

Al

Bu

Bl

Cu

Cl

Du

Dl |

------------------------------------------------------------------------Circ. Memb. P | 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0|

Circ. Bend. P | 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0|

Circ. Memb. MC | 0.0 0.0 0.0 0.0 -0.8 -0.8 0.8 0.8|

Circ. Memb. MC | 0.0 0.0 0.0 0.0 -27.4 27.4 27.4 -27.4|

Circ. Memb. ML | 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0|

Circ. Bend. ML | 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0|

|

|

Tot. Circ. Str.| 0.0 0.0 0.0 0.0 -28.2 26.5 28.2 -26.5|

------------------------------------------------------------------------Long. Memb. P | 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0|

Long. Bend. P | 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0|

Long. Memb. MC | 0.0 0.0 0.0 0.0 -1.1 -1.1 1.1 1.1|

Long. Bend. MC | 0.0 0.0 0.0 0.0 -16.1 16.1 16.1 -16.1|

Long. Memb. ML | 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0|

Long. Bend. ML | 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0|

|

|

Tot. Long. Str.| 0.0 0.0 0.0 0.0 -17.2 15.0 17.2 -15.0|

------------------------------------------------------------------------Shear VC | -7.7 -7.7 7.7 7.7 0.0 0.0 0.0 0.0|

Shear VL | 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0|

Shear MT | 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0|

|

|

Tot. Shear| -7.7 -7.7 7.7 7.7 0.0 0.0 0.0 0.0|

------------------------------------------------------------------------Str. Int. | 15.4 15.4 15.4 15.4 28.2 26.5 28.2 26.5|

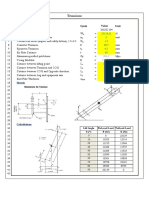

SUMMARY OF RESULTS:

Trunnion unity check value: 0.5413

Actual

Bending Stress (N/mm^2)

Shear Stress (N/mm^2)

Bearing Stress (N/mm^2)

Allowable

48.52

23.74

11.34

Pass/Fail

162.00

Pass

98.18

Pass

184.09

Pass

Vessel Maximum Stress Intensity Comparison:

At Nozzle Edge: 28.17

Allowable: 1.5 * S: 207.00 N/mm^2[Passed]

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2016

PV Elite 2016 SP1 Licensee: PHILS HEAVY ENGG PVT LTD

FileName : 100-R-201-A-B

Vessel Results Summary

Item: 1 11:20a Nov 30,2016

Leg Lug Results Summary for Item 1 : Trunnion - V

The Vessel outside diameter is

The Trunnion outside diameter is

Force along Vessel axis

Force normal to Vessel

Force tangential to Vessel

3140.000 mm

324.000 mm

285000.000 N

0.000 N

0.000 N

Stress Results (N/mm^2):

Actual

Allowable Pass/Fail

Max Vessel WRC-107 Stress at Nozzle 29.19

207.00

Passed

Trunnion Bending Stress

56.44

162.00

Passed

Trunnion Shear Stress

27.61

98.18

Passed

Trunnion Unity Check

0.63

Must be < 1 Passed

Trunnion Bearing Stress

13.20

184.09

Passed

Leg Lug Results Summary for Item 2 : Trunnion - H

The Vessel outside diameter is

The Trunnion outside diameter is

Force along Vessel axis

Force normal to Vessel

Force tangential to Vessel

3140.000 mm

324.000 mm

0.000 N

0.000 N

245000.000 N

Stress Results (N/mm^2):

Actual

Allowable Pass/Fail

Max Vessel WRC-107 Stress at Nozzle 28.17

207.00

Passed

Trunnion Bending Stress

48.52

162.00

Passed

Trunnion Shear Stress

23.74

98.18

Passed

Trunnion Unity Check

0.54

Must be < 1 Passed

Trunnion Bearing Stress

11.34

184.09

Passed

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2016

10

You might also like

- TrunnionDocument7 pagesTrunnionRUDHRA DHANASEKAR100% (1)

- Trunnion & Tailing Lug DesignDocument25 pagesTrunnion & Tailing Lug Designvpjagannaath100% (2)

- Lifting Trunnion Calculations On Horizontal Vessel - 1Document1 pageLifting Trunnion Calculations On Horizontal Vessel - 1miteshpatel191No ratings yet

- Lifting analysis of vessel equipmentDocument1 pageLifting analysis of vessel equipmentshaishav100% (2)

- Lifting Trunnion AnalysisDocument1 pageLifting Trunnion Analysisprajwal86No ratings yet

- 17 TonsDocument8 pages17 Tonsabuzahrau100% (3)

- Lifting PadeyeDocument16 pagesLifting PadeyeLưu XuânNo ratings yet

- Gross weight lifting lug dimensionsDocument10 pagesGross weight lifting lug dimensionsReda Elawady100% (1)

- Lifting Lug Excel SheetDocument8 pagesLifting Lug Excel Sheetshazan67% (3)

- Lifting Lug CalculationDocument2 pagesLifting Lug CalculationDaison Paul63% (8)

- Saddle Road Transportation Analysis 1Document2 pagesSaddle Road Transportation Analysis 1vpjagannaathNo ratings yet

- Lifting Calculation REV ADocument1 pageLifting Calculation REV APohn Myint HanNo ratings yet

- Boiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFDocument4 pagesBoiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFAlexandru AsmarandeiNo ratings yet

- Lifting LugDocument39 pagesLifting LugSasikumar JothiNo ratings yet

- Zick Analysis For Saddle SupportDocument8 pagesZick Analysis For Saddle Supportfuransu777100% (1)

- Spreader Bar CalculationDocument1 pageSpreader Bar Calculationjirrsama100% (1)

- Lifting Lug Design (3064)Document37 pagesLifting Lug Design (3064)Ganesh Bhardwaj50% (2)

- Spreader Beam BLOCK EDocument23 pagesSpreader Beam BLOCK Evaminos85% (13)

- Spreader Beam (Planning)Document28 pagesSpreader Beam (Planning)AKSHAY BHATKARNo ratings yet

- Sample Section Modulas CalculationDocument18 pagesSample Section Modulas CalculationShamik ChowdhuryNo ratings yet

- Calculation Sheet: Padeye Calculations LoadsDocument14 pagesCalculation Sheet: Padeye Calculations Loadsandi_nu0% (1)

- Shell Lifting AttachmentsDocument12 pagesShell Lifting AttachmentsjesusgameboyNo ratings yet

- Vitec Equipments PVT LTD Filename: Spreader Beam CalculationDocument48 pagesVitec Equipments PVT LTD Filename: Spreader Beam CalculationDarshan PanchalNo ratings yet

- Lifting Lug CalculationsDocument6 pagesLifting Lug CalculationsYash RamiNo ratings yet

- Spreader Beam CalculationDocument2 pagesSpreader Beam Calculationhombre.muerto595977% (13)

- Spreader Calculation (ISMC-200)Document4 pagesSpreader Calculation (ISMC-200)mechmohan26No ratings yet

- LIFTING LUG AND LIFTING COVER DESIGN REFERENCEDocument4 pagesLIFTING LUG AND LIFTING COVER DESIGN REFERENCERohith V VNo ratings yet

- Load analysis and strength evaluation of vessel lifting lugDocument3 pagesLoad analysis and strength evaluation of vessel lifting lugMudasir MughalNo ratings yet

- Acceleration Calculations TeoryDocument3 pagesAcceleration Calculations TeoryBolarinwaNo ratings yet

- Lifting Lug CalculationDocument5 pagesLifting Lug CalculationAndy Chan100% (1)

- Calculation of Trunnions Rev3Document3 pagesCalculation of Trunnions Rev3Bilel MahjoubNo ratings yet

- CEN TOOL - Standard Padeyes - V4-Rollup Padeye SheaveDocument5 pagesCEN TOOL - Standard Padeyes - V4-Rollup Padeye SheaveLaurentiu TeacaNo ratings yet

- Vessel lifting lug design data and stress analysisDocument3 pagesVessel lifting lug design data and stress analysismiteshpatel191100% (1)

- Report Rectangular Tank - REV 0 - 28.11.12Document26 pagesReport Rectangular Tank - REV 0 - 28.11.12JijinJohn100% (1)

- Pveng: Pressure Vessel Engineering LTDDocument5 pagesPveng: Pressure Vessel Engineering LTDBruno TrujilloNo ratings yet

- Lifting LugDocument24 pagesLifting LugMas Arman Tewo100% (6)

- Input Rev. NO: L + (c1 + c2) TWDocument6 pagesInput Rev. NO: L + (c1 + c2) TWMudasir MughalNo ratings yet

- Padeye .5MT CHKDocument12 pagesPadeye .5MT CHKDhanraj VasanthNo ratings yet

- Lifting Lug CalculationDocument4 pagesLifting Lug CalculationLokesh PatelNo ratings yet

- Lifting Beam CalculationDocument2 pagesLifting Beam Calculationராபர்ட் ஆன்றோ ரெனி100% (4)

- ASME SpreaderBar CalcsDocument5 pagesASME SpreaderBar Calcsganesh100% (1)

- ASME Horizontal Vessel AnalysisDocument10 pagesASME Horizontal Vessel AnalysisSyedZainAliNo ratings yet

- Lifting LugsDocument11 pagesLifting LugsISEDAC21No ratings yet

- Guide PV analysis resultsDocument4 pagesGuide PV analysis resultsSiri SiriNo ratings yet

- Earthquake Analysis and Horizontal Vessel Stress ResultsDocument20 pagesEarthquake Analysis and Horizontal Vessel Stress ResultsankitNo ratings yet

- Rotating Drum CalculationDocument12 pagesRotating Drum Calculationمحمد أزها نو الدينNo ratings yet

- Verifica Giunto Secondo AsmeDocument5 pagesVerifica Giunto Secondo AsmeFabio TemporiniNo ratings yet

- Trunnion 6 TonDocument3 pagesTrunnion 6 TonEngr Khurram Jaan RamayNo ratings yet

- Lifting Lug Calc - VerticalDocument7 pagesLifting Lug Calc - Verticaljahiranazri100% (1)

- Ball Screw Selection ExerciseDocument7 pagesBall Screw Selection ExercisemaddyaugNo ratings yet

- Flat Plate - Roark & YoungDocument15 pagesFlat Plate - Roark & YoungPrasad Pingle0% (1)

- Horizontal Vessel Stress AnalysisDocument12 pagesHorizontal Vessel Stress AnalysissridharNo ratings yet

- CO2 AbsorberDocument11 pagesCO2 AbsorberDhrumil Gandhi100% (2)

- 03 CalDocument56 pages03 Calnatarajan RavisankarNo ratings yet

- Cylinder #1 ASME Section VIII Division 1, 2001 Edition: S S TV SDocument10 pagesCylinder #1 ASME Section VIII Division 1, 2001 Edition: S S TV Sevrim77No ratings yet

- ASME Horizontal Vessel AnalysisDocument16 pagesASME Horizontal Vessel AnalysisAsep Darojat100% (1)

- Torsion: Torsional Deformation of A Circular Shaft, Torsion Formula, Power TransmissionDocument26 pagesTorsion: Torsional Deformation of A Circular Shaft, Torsion Formula, Power TransmissionHafiezul HassanNo ratings yet

- EC3 Example ReportDocument10 pagesEC3 Example Reportscribd_namnNo ratings yet

- Checking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumberDocument1 pageChecking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumbershazanNo ratings yet

- Cleat Summary Excel SheetDocument4 pagesCleat Summary Excel SheetshazanNo ratings yet

- Clearance CalculationDocument12 pagesClearance CalculationshazanNo ratings yet

- Flange Details & DrawingsDocument338 pagesFlange Details & DrawingsshazanNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Weld CalculationsDocument12 pagesWeld Calculationshakr5100% (1)

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Static Equipment A Look Inside The How and Why of SpecificationDocument19 pagesStatic Equipment A Look Inside The How and Why of SpecificationshazanNo ratings yet

- Clearance Calculation For Skirt OpeningDocument3 pagesClearance Calculation For Skirt OpeningshazanNo ratings yet

- Welding EngineeringDocument1 pageWelding EngineeringshazanNo ratings yet

- MN-V-02 Sump - NozDocument1 pageMN-V-02 Sump - NozshazanNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Manhole MH PDFDocument1 pageManhole MH PDFshazanNo ratings yet

- U Stamp - KK Form - SampleDocument5 pagesU Stamp - KK Form - SampleshazanNo ratings yet

- Gasket Selection GuideDocument6 pagesGasket Selection GuiderezaNo ratings yet

- Lecture2 (Petrochemical)Document12 pagesLecture2 (Petrochemical)ToniAndiwijaya100% (1)

- MN-V-02 M-01 - NozDocument1 pageMN-V-02 M-01 - NozshazanNo ratings yet

- Seismic Calculation IS 1893 - RSMDocument3 pagesSeismic Calculation IS 1893 - RSMshazanNo ratings yet

- Test Flange TypeDocument1 pageTest Flange TypeshazanNo ratings yet

- Midrex Case StudyDocument1 pageMidrex Case StudyshazanNo ratings yet

- Flange GeometryDocument1 pageFlange GeometryshazanNo ratings yet

- Test Ring1 ModelDocument1 pageTest Ring1 ModelshazanNo ratings yet

- ASME BPVC Latest Edition Design and FabricationDocument2 pagesASME BPVC Latest Edition Design and Fabricationshazan100% (1)

- Saddle DrawingDocument1 pageSaddle DrawingshazanNo ratings yet

- Abertura Livre Como Função Das PropriedadesDocument5 pagesAbertura Livre Como Função Das PropriedadesNellio PiassaNo ratings yet

- Similar Triangle Word ProblemsDocument2 pagesSimilar Triangle Word Problemsapi-314332531No ratings yet

- 10th Important QuestionsDocument4 pages10th Important Questionsasad janNo ratings yet

- ISO Turning Inserts GuideDocument36 pagesISO Turning Inserts GuideferNo ratings yet

- Anchor Bolt DesignDocument3 pagesAnchor Bolt DesignDanielNo ratings yet

- Exam SolutDocument12 pagesExam Solutnunulovin911No ratings yet

- Fs 4041 TG Package, Rev-0Document88 pagesFs 4041 TG Package, Rev-0Othman RejabNo ratings yet

- TDS Byk-1780 enDocument2 pagesTDS Byk-1780 enabhijit.home2022No ratings yet

- Soalan Matematik Pertengahan Tahun Ting 5 Smksbu 2019 Kertas 1Document24 pagesSoalan Matematik Pertengahan Tahun Ting 5 Smksbu 2019 Kertas 1ZULKFELI BIN ISMAIL AWANG MoeNo ratings yet

- Operating Manual Parts List: 660/850VMC (FANUC 0iMD)Document276 pagesOperating Manual Parts List: 660/850VMC (FANUC 0iMD)apodshNo ratings yet

- Rechargeable Sealed Lead-Acid Battery: 12 Volt 18.0 Amp. HrsDocument2 pagesRechargeable Sealed Lead-Acid Battery: 12 Volt 18.0 Amp. HrsJuan EsNo ratings yet

- Penebar BrochureDocument4 pagesPenebar BrochureBhavish SeejoreNo ratings yet

- Physics Form 4: Force & Motion 1Document55 pagesPhysics Form 4: Force & Motion 1NORSHAZLINDA BINTI ROSLI MoeNo ratings yet

- BIOLOGY SUMMARY TOPIC 3 IgcseDocument5 pagesBIOLOGY SUMMARY TOPIC 3 IgcsesameehaNo ratings yet

- Design Provisions for Shear Walls Research PaperDocument13 pagesDesign Provisions for Shear Walls Research PaperRm1262No ratings yet

- Surveying Elem HigherDocument14 pagesSurveying Elem HigherNeilCyrus RamirezNo ratings yet

- Electrostatics 1Document78 pagesElectrostatics 1Ramesh BadamNo ratings yet

- Module3.Measurement of Vertical DistancesDocument25 pagesModule3.Measurement of Vertical DistancesJohn Greg ChavezNo ratings yet

- Samil Power Solar Lake - Transformerless, Grid-Connected PV InvertersDocument4 pagesSamil Power Solar Lake - Transformerless, Grid-Connected PV InvertersCALİNo ratings yet

- LUCID Time of Flight GuideDocument18 pagesLUCID Time of Flight GuideGiovaniAricettiNo ratings yet

- Series of Frequency Inverter: Yantai Huifeng Electronics Co.,LtdDocument6 pagesSeries of Frequency Inverter: Yantai Huifeng Electronics Co.,LtdEzequiel Victor HugoNo ratings yet

- BC 640Document5 pagesBC 640Miguel AngelNo ratings yet

- Geometry Worksheet on Shapes and AnglesDocument4 pagesGeometry Worksheet on Shapes and AnglesairinputNo ratings yet

- Pavement Evaluation PaperDocument14 pagesPavement Evaluation Paperbehzad afridiNo ratings yet

- Tech Drilling DirDrilling3Document36 pagesTech Drilling DirDrilling3fannyadilaNo ratings yet

- Bomb Hidraulic BCRDocument88 pagesBomb Hidraulic BCRAlexis BriceñoNo ratings yet

- Sample Handling in IRDocument33 pagesSample Handling in IRPoornima ANNo ratings yet

- Chords Arcs Central Angles and Inscribed AnglesDocument11 pagesChords Arcs Central Angles and Inscribed AnglesMaylieh MayNo ratings yet

- PE Jaw crusher manual-英文Document22 pagesPE Jaw crusher manual-英文Edwin Forero100% (3)

- Chapter 1Document15 pagesChapter 1BACHA NEGERINo ratings yet