Professional Documents

Culture Documents

Advance Machine Design Paper

Uploaded by

VisHal SukHadia Jr.Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Advance Machine Design Paper

Uploaded by

VisHal SukHadia Jr.Copyright:

Available Formats

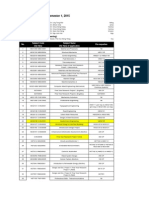

Seat No.

: ________

Enrolment No.___________

GUJARAT TECHNOLOGICAL UNIVERSITY

ME - SEMESTER I (New course) REMEDIAL EXAMINATION SUMMER 2015

Subject Code: 2710801

Subject Name: Advanced Machine Design

Time: 10:30 am to 1:00 pm

Date:14/05/2015

Total Marks: 70

Instructions:

1. Attempt all questions.

2. Make suitable assumptions wherever necessary.

3. Figures to the right indicate full marks.

Q.1

Q.2

(a)

(b)

Define Wear and discuss different mechanism of wear.

(a)

Explain the concept of design for X (DFX) along with steps for implementing a

DFX strategy.

What is stress concentration? Explain methods for reducing stress

concentration with suitable sketches.

OR

Discuss various factors for material selection.

07

Define octahedral normal stress and octahedral shear stress.

Derive;

1

s oct = (s 1 + s 2 + s 3 )

3

1/ 2

1

t oct = (s 1 - s 2 )2 + (s 2 - s 3 )2 + (s 3 - s 1 )2

3

Thin plate is tougher in comparison to thick plate, justify the statement with

reference to fracture mechanics.

OR

Component of strain tensor at a point in a body are given by; xx = 0.005, yy =

0.004, zz = -0.002, xy = 0.001, yz = 0.0005 and zx = 0.002. If E = 2 x 105

MPa and = 0.25, determine components of stress tensor.

Based on Griffiths analysis derive that stress required to advance a crack of

length 2a for plane stress cases is;

07

(b)

(b)

Q.3

(a)

Explain plane state of strain along with its mathematical expressions.

(b)

Q.3

(a)

(b)

2 Eg

sC

pa

07

07

07

07

07

07

07

1/ 2

Where, is surface energy per unit area of one surface and E is Youngs

modulus.

Q.4

(a)

(b)

A steel bar is subjected to two dimensional stresses; the tensile stress along the X-axis

varies from 45 MPa to 100 MPa, whereas the tensile stress along the Y-axis varies

from 5 MPa to 75 MPa. The corrected endurance strength of component is 260 MPa.

The ultimate tensile strength is 650 MPa. Determine the factor of safety by maximum

distortion energy theory. Use the Goodmans fatigue criterion for failure.

Define fatigue life, enlist the various fatigue life methods and explain any one.

OR

07

07

Q.4

(a)

(b)

Q.5

(a)

(b)

Q.5

(a)

(b)

The work cycle of a mechanical component is subjected to a complete reversed bending

stresses consisting of the following three elements; 350 N/mm2 for 85% of time,

500 N/mm2 for 3% of time and 400 N/mm2 for remaining time. If corrected

endurance strength is 280 N/mm2 and ultimate strength 660 N/mm2, Determine its life.

Define creep and discuss significance of creep curve in design along with its

mathematical representation.

07

(i). Define three modes of fracture with the help of neat sketch.

(ii). Discuss R-curve for ductile material and brittle material.

(i). Discuss effect of roughness, velocity and lubrication on friction.

(ii). Explain types of lubrication using Stribeck curve.

OR

03

04

03

04

Enlist the various theories of failure and explain any two of them in detail.

(i). Explain curved surface contact stresses in brief.

(ii). The ball and socket joint at the end of a rocker arm is shown in figure 1.

What maximum contact stress will result from a load of 2000 N?

For steel ball material; E = 207 GPa and = 0.30

For Bronze material; E = 110 GPa and = 0.33

07

03

04

07

Figure 1

*************

You might also like

- CAE Question Bank Unit 3Document4 pagesCAE Question Bank Unit 3Sandesh KaleNo ratings yet

- Vtu Number: Vel Tech DR - RR & DR .SR Technical UniversittyDocument3 pagesVtu Number: Vel Tech DR - RR & DR .SR Technical UniversittyPoyyamozhi Nadesan RanjithNo ratings yet

- Jaya Engineering College-7 SEM - B.E. / B.Tech MODEL EXAM-I 24.07.15 To 30.07.15Document1 pageJaya Engineering College-7 SEM - B.E. / B.Tech MODEL EXAM-I 24.07.15 To 30.07.15SEBI P RAJA BABUNo ratings yet

- MDID Machine Design GTU PaperDocument3 pagesMDID Machine Design GTU PaperjaydeepNo ratings yet

- PR 2303Document4 pagesPR 2303Karthik Srinivas0% (1)

- 3330604Document3 pages3330604dhwaniNo ratings yet

- Solutions To AssignmentDocument22 pagesSolutions To AssignmentNeo TarunNo ratings yet

- Rubber in Shear ReportDocument5 pagesRubber in Shear Reportميسرة86% (7)

- Vallurupalli Nageswara Rao Vignana Jyothi Institute of Engineering and TechnologyDocument48 pagesVallurupalli Nageswara Rao Vignana Jyothi Institute of Engineering and TechnologyRathod VakilNo ratings yet

- Gujarat Technological University: InstructionsDocument1 pageGujarat Technological University: InstructionsPalak AriwalaNo ratings yet

- MSMBM April 2022Document2 pagesMSMBM April 2022battuarunNo ratings yet

- 01feb2016-Industrial Robotics,Design With Advanced Materials,Applied Mathematics,Optical Communication Technology,Advanced Data Structures and Algorithm Analysis,Mathematical Modeling,Analysis OfDocument15 pages01feb2016-Industrial Robotics,Design With Advanced Materials,Applied Mathematics,Optical Communication Technology,Advanced Data Structures and Algorithm Analysis,Mathematical Modeling,Analysis OfsirapuNo ratings yet

- G.C.R.G.Memorial Trust'S Group of Institutions: Advanced Welding Technology EME-022Document1 pageG.C.R.G.Memorial Trust'S Group of Institutions: Advanced Welding Technology EME-022Andrea DouglasNo ratings yet

- M.tech SE I Sem TE March 10Document1 pageM.tech SE I Sem TE March 10vempadareddyNo ratings yet

- III and IV UnitDocument3 pagesIII and IV Unitbalusharma1212No ratings yet

- Finite Element Analysis of Structures and Heat Transfer ProblemsDocument11 pagesFinite Element Analysis of Structures and Heat Transfer Problemssimalaravi100% (2)

- Fluid Mechanics AssignmentDocument6 pagesFluid Mechanics AssignmentVikram NikhilNo ratings yet

- SRI VELLAPPALLY NATESAN COLLEGE MICROWAVE DEVICE EXAMDocument1 pageSRI VELLAPPALLY NATESAN COLLEGE MICROWAVE DEVICE EXAManupvasuNo ratings yet

- Fatigue of Materials Solved Problems UnlockedDocument20 pagesFatigue of Materials Solved Problems UnlockedMAT-LIONNo ratings yet

- Psna College of Engineering & Technology, Dindigul-624 622 Centralized Serial Test-IDocument3 pagesPsna College of Engineering & Technology, Dindigul-624 622 Centralized Serial Test-IbalajigandhirajanNo ratings yet

- Gujarat Technological University: InstructionsDocument1 pageGujarat Technological University: InstructionsDeepaRavalNo ratings yet

- GTU Power Quality Exam ReviewDocument1 pageGTU Power Quality Exam ReviewKàûshálBáriàNo ratings yet

- GTU BE Semester VI Instrumentation Measurement-II ExamDocument2 pagesGTU BE Semester VI Instrumentation Measurement-II ExamBhautik DaxiniNo ratings yet

- Surrey SE1M94 2001s PaperDocument4 pagesSurrey SE1M94 2001s PaperphilipyapNo ratings yet

- Advanced Mechanical Engineering DesignDocument1 pageAdvanced Mechanical Engineering DesignIbmWasuserNo ratings yet

- Dynamics and Design of MachineryDocument10 pagesDynamics and Design of MachineryelsonpaulNo ratings yet

- MSMBM Oct 2018Document2 pagesMSMBM Oct 2018battuarunNo ratings yet

- Polytechnic Diploma Second Year Main Examination, September 2013 (Mechanical Engineering) Strength of MaterialDocument3 pagesPolytechnic Diploma Second Year Main Examination, September 2013 (Mechanical Engineering) Strength of MaterialNiral MehtaNo ratings yet

- University of Mauritius Faculty of EngineeringDocument4 pagesUniversity of Mauritius Faculty of EngineeringKeshav GopaulNo ratings yet

- Fluctuating Stresses and Fatigue FailureDocument9 pagesFluctuating Stresses and Fatigue FailureMelese AschalewNo ratings yet

- Theory of PlasticityDocument10 pagesTheory of Plasticitybabu1434100% (1)

- Metal Fatigue - Understanding the ProcessDocument69 pagesMetal Fatigue - Understanding the Processaap1No ratings yet

- Experimental Stress Analysis PaperDocument2 pagesExperimental Stress Analysis PaperAbdul FattahNo ratings yet

- FEA TutorialsDocument14 pagesFEA Tutorialsbalusharma1212No ratings yet

- Gujarat Technological University BE SEM-VI Examination-Nov/Dec-2011 Subject Code: 162903 Date: 25/11/2011 Subject Name: Physical Testing Time: 10.30 Am - 1.00 PM Total Marks: 70Document1 pageGujarat Technological University BE SEM-VI Examination-Nov/Dec-2011 Subject Code: 162903 Date: 25/11/2011 Subject Name: Physical Testing Time: 10.30 Am - 1.00 PM Total Marks: 70hiren_1810No ratings yet

- Finite Element Analysis Questions OnlyDocument9 pagesFinite Element Analysis Questions OnlyAeronaughtycs Hamdan100% (1)

- Question Paper ETEDocument2 pagesQuestion Paper ETEPta NhiNo ratings yet

- Fatigue Life: Nguyen Van Chuong, Ul Rizwan HassanDocument3 pagesFatigue Life: Nguyen Van Chuong, Ul Rizwan HassanNguyễnVănChươngNo ratings yet

- Machine Design Model PaperDocument2 pagesMachine Design Model PaperVinay Karanam100% (1)

- Lab AssignmentDocument11 pagesLab Assignmentsherif115040 BueNo ratings yet

- MTP 5Document4 pagesMTP 5tinku singhNo ratings yet

- Tensile Testing - Submission and ReportingDocument3 pagesTensile Testing - Submission and ReportingHaldrian IriawanNo ratings yet

- Rr412104 Experimental Stress AnalysisDocument4 pagesRr412104 Experimental Stress AnalysisSrinivasa Rao GNo ratings yet

- FEM-Aided Fatigue Testing of 34CrNiMo6 SteelDocument4 pagesFEM-Aided Fatigue Testing of 34CrNiMo6 SteelNiku PascaNo ratings yet

- Dynamics and Design of MachineryDocument10 pagesDynamics and Design of MachineryBen JoeNo ratings yet

- AME6006-exam Paper 2019 - 25th of August, 2019Document10 pagesAME6006-exam Paper 2019 - 25th of August, 2019Sameera AlweeraNo ratings yet

- Exp 4 - Strut-Buckling (Revised July 2010)Document7 pagesExp 4 - Strut-Buckling (Revised July 2010)Darker SoraNo ratings yet

- MM207E | Materials Science | Lab2_Tensile Test | Mechanic LabDocument4 pagesMM207E | Materials Science | Lab2_Tensile Test | Mechanic LabKerem Taha TekinNo ratings yet

- MP II - Nov 2011Document2 pagesMP II - Nov 2011abhay_15865099No ratings yet

- Strength of Materials Courseware by A.A JimohDocument37 pagesStrength of Materials Courseware by A.A JimohSamuelShinaAyodele100% (2)

- NTU - Mechanical Engineering - MP 4J02 - MArine and Offshore Structural Integrity - Sem 2 09-10Document4 pagesNTU - Mechanical Engineering - MP 4J02 - MArine and Offshore Structural Integrity - Sem 2 09-10awy02No ratings yet

- Dynamic Damage and FragmentationFrom EverandDynamic Damage and FragmentationDavid Edward LambertNo ratings yet

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysFrom EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysNo ratings yet

- Materials Science and Technology of Optical FabricationFrom EverandMaterials Science and Technology of Optical FabricationNo ratings yet

- 10 M2 Heat Exchanger - GMPDocument1 page10 M2 Heat Exchanger - GMPVisHal SukHadia Jr.No ratings yet

- Toshimoku's Trading Tips & Tricks - Bitcoin InsiderDocument60 pagesToshimoku's Trading Tips & Tricks - Bitcoin InsiderVisHal SukHadia Jr.No ratings yet

- SyllabusDocument3 pagesSyllabusVisHal SukHadia Jr.No ratings yet

- Me1998 PDFDocument15 pagesMe1998 PDFVisHal SukHadia Jr.No ratings yet

- 7.12 Analysis of A Rigid Eccentric CamDocument7 pages7.12 Analysis of A Rigid Eccentric CamNAGU2009No ratings yet

- U.V.Patel College of Engineering Ganpat UniversityDocument24 pagesU.V.Patel College of Engineering Ganpat UniversityVisHal SukHadia Jr.No ratings yet

- Dda AlgorithmDocument13 pagesDda AlgorithmVishal FalakeNo ratings yet

- Fundamentals of FractureDocument22 pagesFundamentals of FractureChristina HillNo ratings yet

- T.L. Anderson Fracture Toughness Testing CompleteDocument22 pagesT.L. Anderson Fracture Toughness Testing CompleteVisHal SukHadia Jr.No ratings yet

- Electromagnetic Piston Engine CarDocument70 pagesElectromagnetic Piston Engine CarVisHal SukHadia Jr.No ratings yet

- Boiler Energy Audit ManualDocument29 pagesBoiler Energy Audit ManualAnubhav100% (11)

- Thermotron CE Catalogue 2022 VOL10 - MidresDocument54 pagesThermotron CE Catalogue 2022 VOL10 - MidresChristy LaheteNo ratings yet

- ChemDocument29 pagesChemPearl LingbawanNo ratings yet

- ASTM D7740 Optimizing AASDocument9 pagesASTM D7740 Optimizing AASarufatoNo ratings yet

- Sky Air Seasonal Classic Conductos Baja Silueta Serie DDocument1 pageSky Air Seasonal Classic Conductos Baja Silueta Serie DmiroNo ratings yet

- Assignment 1 and SolutionDocument5 pagesAssignment 1 and Solutionamin alzuraikiNo ratings yet

- HM 289 Experiments With A Pelton Turbine Gunt 848 PDF 1 en GBDocument3 pagesHM 289 Experiments With A Pelton Turbine Gunt 848 PDF 1 en GBbeshirNo ratings yet

- SpectrOil 100 Series DatasheetDocument2 pagesSpectrOil 100 Series DatasheetClydeA.SardoncilloNo ratings yet

- Propagation of Surface Waves in Thermoelastic Materials with VoidsDocument10 pagesPropagation of Surface Waves in Thermoelastic Materials with VoidsSOUMIK DASNo ratings yet

- Basic GreaseDocument20 pagesBasic Greasefahreez100% (3)

- PT Statika Mitra Sarana Compressive Strength TestDocument6 pagesPT Statika Mitra Sarana Compressive Strength Testfajar sNo ratings yet

- ProjectDocument16 pagesProjectEhmida PofjraNo ratings yet

- The Weather and The Seasons 53858Document2 pagesThe Weather and The Seasons 53858Aftiniei IulianNo ratings yet

- JEE Adv. - Growth - Sample Paper-2 - StudentDocument15 pagesJEE Adv. - Growth - Sample Paper-2 - Studentanurag jaiswalNo ratings yet

- Week 1 Basics of OscillationsDocument5 pagesWeek 1 Basics of OscillationsqqqqqqNo ratings yet

- Fluorescence SpectrosDocument10 pagesFluorescence SpectrosChamith HerathNo ratings yet

- Units Offered S1 2015 Engineering DegreeDocument4 pagesUnits Offered S1 2015 Engineering DegreescytheVSNo ratings yet

- CHME 789 Soft Matter Exam No. 1Document8 pagesCHME 789 Soft Matter Exam No. 1Laura GTNo ratings yet

- Spectroscopic Atlas 2 0 EnglishDocument124 pagesSpectroscopic Atlas 2 0 Englishspj_uhNo ratings yet

- Acoustic ReportDocument17 pagesAcoustic Reportgia hân phamNo ratings yet

- Wave & Oscillation AS levelDocument22 pagesWave & Oscillation AS levelDewan Olin Chotepadae0% (1)

- Verification of steam ejector refrigeration model performanceDocument8 pagesVerification of steam ejector refrigeration model performance고현No ratings yet

- Ecosystem Lesson PlanDocument3 pagesEcosystem Lesson PlanClarence RiveraNo ratings yet

- and its resistivity is 8.8 x 10 Ωm.: Electromagnetic force on wireDocument3 pagesand its resistivity is 8.8 x 10 Ωm.: Electromagnetic force on wireMuhamad Zahwan AnwarNo ratings yet

- 1 - Quiz - 1D - KinematicsDocument2 pages1 - Quiz - 1D - KinematicsMiya GomezNo ratings yet

- NTN Ball and Roller Bearing CatalogDocument399 pagesNTN Ball and Roller Bearing Catalogdaniarsalan100% (2)

- Fluids 05 00240Document16 pagesFluids 05 00240Liviu BadeaNo ratings yet

- How To Calculate Filler Metal ConsumptionDocument3 pagesHow To Calculate Filler Metal ConsumptionASHIL PRABHAKAR100% (2)

- Choi 2012Document5 pagesChoi 2012tuanhoa123No ratings yet

- Astm A781 PDFDocument13 pagesAstm A781 PDFIslam Fawzy100% (6)

- Discrete Dislocation DynamicsDocument10 pagesDiscrete Dislocation DynamicsFabian de Jesus Orozco MartinezNo ratings yet