Professional Documents

Culture Documents

ef04f4ed-2123-49c5-8d4f-eeec575b8c28

Uploaded by

Thiran Boy LingamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ef04f4ed-2123-49c5-8d4f-eeec575b8c28

Uploaded by

Thiran Boy LingamCopyright:

Available Formats

Available online at www.sciencedirect.

com

ScienceDirect

Procedia Technology 24 (2016) 169 178

International Conference on Emerging Trends in Engineering, Science and Technology (ICETEST

- 2015)

Development of Coir-Fibre Cement Composite Roofing Tiles

Darsana Pa Ruby Abraham b, Anu Josephc, Arakkal Jasheelad, Binuraj P.R e , Jithin

Sarmaa,b,c,d,e*

b

a

Department of applied mechanics ,national institute of technology,575025,India

Depaertment of civil engineering,Rajiv Ghandhi institute of Technology Kottayam,India

c

Consultant,Oracle OFSS Banglore,Karnataka,Indaia

e

Department of civil engineering Vedavyasa,673632,India

e

Bharat Petroleum Corporation Ltd. (BPCL),Jodhpur,India

a,b,c,d,e*

Saint gobain Structure glass solutions Chennai,India

Abstract

In order to optimize the cost of construction, engineers have always been on the lookout for efficient and light

roofing which requires minimum maintenance and labor to install. Coir is a green building material and has potential

as a raw material for the production of roofing materials like corrugated sheets and tiles. The main objective of the

paper is to produce cost effective roofing tiles without compromising their quality by replacing cement up to 15%

using coir fibre. On the basis of the results, a composite with a fibre volume of 10% was considered to be the

optimum composite. A comparison of material costs indicated that this composite tile was substantially cheaper than

the ordinary cement concrete tile.

2016 Published by Elsevier Ltd. This is an open access article under the CC BY-NC-ND license

2016 The Authors.Published by Elsevier Ltd.

(http://creativecommons.org/licenses/by-nc-nd/4.0/).

Peer-review

underresponsibility

responsibility

organizing

committee

of ICETEST

2015.

Peer-review under

of of

thethe

organizing

committee

of ICETEST

2015

Keywords: Cement concrete tile; Coir; Cost effective; Roofing tiles.

*Darsana P 9400772607

E-mail address: darshupcgmail.com

1.

Introduction

In almost all developing countries, there is a great shortage of roofing material. Local materials are often used, like

soil, stone, grass and palm leaves. These roofs require a lot of maintenance and are not always resistant to heavy

rain. Materials like Corrugated Iron Sheets (CIS) and asbestos cement sheets have replaced traditional materials.

2212-0173 2016 Published by Elsevier Ltd. This is an open access article under the CC BY-NC-ND license

(http://creativecommons.org/licenses/by-nc-nd/4.0/).

Peer-review under responsibility of the organizing committee of ICETEST 2015

doi:10.1016/j.protcy.2016.05.024

170

P. Darsana et al. / Procedia Technology 24 (2016) 169 178

Roofing materials tend to be the biggest expense for individual home builders.

The disadvantages of CIS roofs in tropical areas are that they give a poor indoor climate and make a lot of

noise when it rains. They also require a lot of energy to produce. Asbestos cement sheets should not even be

considered, because of the health hazard associated with making them. Ceramic tile roofs are good. However, if the

kiln does not allow adequate temperature control during firing, the quality of the finished tiles can be very much

uneven. Concrete tiles have partially replaced ceramic tiles for purely economic reasons but what limits the use of

concrete tiles is their weight on the roof, which requires a strong load bearing structure. Therefore, changing an

existing system of roof also requires strengthening of the roof framework. They can be made lightweight by

incorporating natural fibres into its composite matrix.

Coir fibre is one of the natural fibres abundantly available in tropical regions, and is extracted from the husk of

coconut fruit. Coir is stiff coarse fibre and is being found between the husk and the outer shell of a coconut. It is a

fibre abundantly available in India the second highest in the world after Philippines. The individual fibre cells are

narrow and hollow, with thick wall made of cellulose. There are two varieties of coir; (i) brown coir extracted from

a varieties ripe coconut which contains more lignin and less cellulose and are stronger but less flexible. (ii) White

coir extracted from coconut before they are ripe, which are white or light brown in colour and are smoother and

finer, but also weaker. There are many general advantages of coconut fibres e.g. they are moth-proof, resistant to

fungi and rot, provide excellent insulation against temperature and sound, not easily combustible, flame-retardant,

unaffected by moisture and dampness, tough and durable, resilient, springs back to shape even after constant use,

totally static free and easy to clean.

Owing to these general advantages and the rich availability of the material in the South Indian tropics, Coir

has found desirable applications in the field of construction with the advent of light-weight concrete technology. The

cheap availability of the raw material can also reduce the production costs and hence the housing expenditure on

roofing, which is otherwise the most expensive part in building construction, can be considerably truncated. The

main objectives of the study are to develop coir fibre reinforced cement concrete roof tiles and to seek its pros and

cons as a roofing material based on standard specifications. The structural behaviour and strength characteristic of

coir fibre reinforced tile were compared with Cement Concrete roofing tiles. Main objectives of the present study

are

x To develop lightweight concrete roofing tiles with coir reinforced cement concrete composite.

x To study the strength and behaviour of these tiles relative to the Cement Concrete roofing tiles.

2.

Previous studies on coconut fibre reinforced composites

Cook et.al. (1978) [3] reported the use of randomly distributed coir fibre reinforced cement composites as low cost

materials for roofing sheets. The studied parameters were fibre lengths, fibre volumes and casting pressure. They

concluded that the optimum composite was a composite with a fibre length of 3.75 cm, a fibre volume fraction of

7.5 % and cast at a pressure of 1.67 MPa. Cost comparison revealed that this composite was substantially cheaper

than the locally available roofing materials.

Research output of Ramaswamy et.al. (1983)[9] revels that, natural fibres such as jute, coir and bamboo can be used

with advantage in concrete, in a manner similar to other fibres. It was also observed that, improvement in impact

strength of over 25% and increased ductility under static loading and considerably lower shrinkage characteristics of

the order of 50% to 70% compared to those of plain concrete, are obtained when natural fibres are added.

Bo Johansson (1995)[5] has presented a simple method to produce a roofing material with cement as the binding

agent. Ramakrishna et.al. (2005)[8] studied the durability of natural fibres and the effect of corroded fibres on the

strength of mortar. Coir fibres were found to retain higher percentages of their initial strength than all other fibres

after the specified exposure in the various mediums.

Peamora, et.al. (2005)[7] explains the manufacturing process of Coir Fibre Cement Boards (CFB) created from a

mix of cement and coir fibre in 70:30 ratio. Fibres are extracted from husks, soaked in water, mixed and blended

with pre-weighed cement, pressed and finally trimmed before drying and conditioning. They also illustrated its

application in wall panel, roofing, flooring, partitioning and formwork systems. Mohd Hisbany Bin Mohd Hashim

(2005)[11] did an experimental study to develop a new material for wall boards in a composite of cement, gypsum

and coconut fiber as reinforcement. An experimental study was conducted by Li et.al. (2006)[12] on coir mesh

reinforced mortar (CMRM) using non-woven coir mesh matting. The results indicate that the addition of coir mesh

P. Darsana et al. / Procedia Technology 24 (2016) 169 178

171

to mortar significantly improves the composite post-cracking flexural stress, toughness, ductility, and toughness

index, compared to plain mortar materials.

Asasutjarit et.al. (2007)[2] studied the properties of panels strengthened with treated coir fibres. It was observed that

the treatments (immersion in cold and hot water) increased the efficiency of coir fibres as a compound

strengthening, increasing the interfacial adherence between the coir and the matrix.

Indian Coir, a Reference Book by the Coir Board (2007)[4] gives the details of coir, coir products and coir

composites. It lists out the physical properties of coir, pointing out that coir composites are antifungal and termiteresistant. Coir-Cement, Coir-Veneer, Rubberized Coir, Coir-Gypsum Board and Coir-Husk composites, their

structural and mechanical properties are also given in detail. Development of coir-cement composite panels, blocks,

sheets and flooring tiles is also explained.

Sivaraja.M. et al. (2009)[10] studied the durability of natural fibre concrete composites using mechanical strength

and micro structural properties and concluded that, natural fibres enhance the strength and flexural performance of

concrete. The effect of curing ages on mechanical properties such as compressive strength, split tensile strength,

modulus of rupture , flexural performance and micro structural properties have been ascertained and discussed

through this paper. It was found that, at all the curing ages, both the natural fibres such as coir and sugarcane fibres

enhance all the three mechanical strength properties such as compressive strength, split tensile strength, modulus of

rupture and flexural performance. Though the natural fibres enhance the strength properties at earlier curing ages,

the rate of increments are lower than conventional concrete specimen at later curing. Ali (2010)[6] studies the

versatility of coconut fibres in civil engineering as a construction material. They are reported to be ductile and

energy absorbent material and also have the potential to be used in composites for different purposes and as

reinforcement in composites for non-structural components. Cost comparison revealed that this composite was

substantially cheaper than the locally available roofing materials.

Abdullah et.al. (2011)[1] reports the effect of natural fibre content on the physical and mechanical properties as well

as fracture behaviour of composite cement reinforced with coconut fibre. It was observed that the composite

reinforced with 9 wt. % of coconut fibre demonstrated the highest strength of modulus of rupture and compressive

strength. Indian Plywood Industries Research & Training Institute and Coir Board, Bangalore explains the procedure

adopted for treated coir sheets. The basic steps involved are procuring the coir felt, dimensioning the coir fibres,

compressing the fibres, application of preservative and bonding resins, stabilization and drying coir mats, hot

pressing them to make hard sheets and finishing of the sheets.

3.

Methodology

After selecting suitable materials like cement, sand and coir fibres , material properties were determined. In order to

replace cement with coir fibre, initial studies were conducted to finalise the % replacement of cement with fibres.

After finalising the same, tile specimens were prepared using specially prepared mould. Accelerated curing was

given to the specimens using oven. Tests were conducted as per Indian Standard specification for tiles.

4.

Material properties

Details of materials used for the preparations of the roofing tiles are discussed in the following sections.

4.1 Cement

Portland Pazolona cement was used throughout the experimental programme. The different laboratory tests were

conducted as per IS 4031:1991 to determine the properties of the cement used. The obtained properties of cement

are shown in Table 1. The properties of cement conform to the IS 1489(Part 1):1991 specifications.

172

P. Darsana et al. / Procedia Technology 24 (2016) 169 178

Table 1.Properties of ppc

Property

Value

Standard Consistency of Cement

35%

Compressive strength at 7 Days

32.80 MPa

Compressive strength at 28 days

45.50 MPa

4.2 Fine aggregate

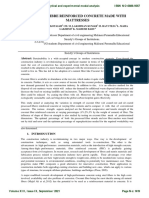

Manufactured sand (Fig. 1 (a) ) passing through 4.75mm IS sieve was used for the study. The different tests as per

IS 2386:1963 (Part III) were conducted on fine aggregate. The properties of fine aggregates are given in the Table 2.

The particle size distribution curve for fine aggregate is shown in Fig 1(b). The properties of fine aggregates

conforms to the IS 2386:1963 Specifications.

a

Fig 1. (a) Manufactured Sand used in the study (b) Grading curve of fine aggregate

Table 2. Properties of fine aggregate

Property

Value

Recommended Value

(for river sand)

Sieve

Grading

Analysis

zone I

Bulk density

1.82 g/cc

1.42 g/cc-1.65 g/cc

2.20

2.5-2.66

Porosity

17.3%

Void ratio

0.21

3.16

2-3.5

Specific

Gravity

Fineness

Modulus

Zone I, Zone II, Zone III

4.3 Coir fibre

Processed coir yarns are cut to fibres (Fig.2) of length 1 inch (25 mm approx.) and diameter of the order of a few

micrometers were used .

P. Darsana et al. / Procedia Technology 24 (2016) 169 178

173

Fig. 2 Coir fibre used in the study

5 . Experimental Investigation

5.1 Preparation of cube specimen

A mix proportion of 1:4 was selected for the experimental study. Based on previous studies, proportions of coir

considered for replacement of cement were 10% and 15% by weight of cement.15% mix resulted in a harsh mix

where as the 10% mix produced satisfactory results. Hence the mix was selected with cement mortar of 1:4 with

10% replacement of coir fibre and water cement ratio of 0.6(CF 10). Cube specimens were prepared and 7 day and

28day compressive test was done. Test results shown in Table 3 show that results are comparable with that of

control specimen (CF0).

Table 3. Compressive strength test results

Average Compressive Strength (in MPa)

Specimen Details

7 day

28 day

Control Specimen, CF0

31.06

42.30

CF10

29.10

40.10

CF15

23.40

28.80

5.2 Casting of tile specimen

Tile specimen moulds of size 320mm x 280mm x 15mm (Fig.3 (a)) were manufactured for the preparation of tiles.

The prepared mould with cover is shown in Fig 3 (b). Five such moulds were manufactured for the study.

174

P. Darsana et al. / Procedia Technology 24 (2016) 169 178

Fig. 4 (a) Tile Specimen dimensions,(b)Tile Moulds with cover

The required quantity of cement, fine aggregate, coir fibres (10% replacement of cement) and water were weighed

and a cement composite mix was prepared. The mixing was continued until a uniform mix of required consistency

was obtained. The mix was then filled in the prepared moulds after placing a plastic sheet on the mould for easy

demoulding. A table vibrator (Fig. 4) was used to compact the mix within the mould. After compacting, the mould

cover was removed carefully and the top surface was levelled using a trowel, whenever necessary. Then the

specimens were kept undisturbed for 24 hours.

Fig 5. Tile under Vibration

5.3 Curing of specimens

After 24 hours, the moulds were stripped off and the specimens were kept in a chamber (hot air oven) at 450 C to

accelerate curing as shown in Fig 6 . The specimens were cured for 5 days. While curing, the tiles should not be

allowed to dry out and hence, moisture was applied on the surfaces of the tiles on each day.

Fig. 6. Specimens in hot air oven for dry (or temperature) curing

P. Darsana et al. / Procedia Technology 24 (2016) 169 178

175

5.4 Testing of specimens

Strength parameters were tested against the standard specifications given by IS 654:1992 (tests on Mangalore

Pattern Tiles). Following are the details of the tests(Stress controlled) conducted: The paper presents the results of

preliminary investigation. Durability studies were not conducted. From literature[13]it is known that the presence of

lignin and hemicelluloses coir fibres are found to retain around 40-60% of their tensile strength when subjected to

alternate wetting and drying . These tiles are better suitable as floor tiles.

5.4.1 Water absorption test:

The test specimen were dried in an oven at a temperature of about 105-110 C prior to the test. Dry weights were

measured after atmospheric cooling and were immersed in clean water at room temperature (24-30C) for about 24

hrs

(Fig 7). The specimen was then removed from water and surface dried and weighed. The increase in weight

with respect to the original dry weight was taken as the water absorption for that sample. Mean water absorption of

the three samples was taken as the water absorption of the prepared mix. A sample set of results obtained is given in

table IV. IS specifications for MP tiles advocates that its water absorption should not be more than 18% (for class

AA) and 20% (for class A) of its weight. As per Peamora and Melencion.[7] a cement concrete tile should not

absorb more water than 6% of its dry weight during 24 hrs in a water bath. A slightly higher value of water

absorption% is mainly due to the presence of coir fibres

Fig 7 .Specimens in water for water absorption test

Table 4. Test results of water absorption

Dry weight

2.525 kg

Wet weight

2.683 kg

% Water absorption

6.25 %

176

P. Darsana et al. / Procedia Technology 24 (2016) 169 178

5.4.2 Breaking Load test:

Three tiles were tested after soaking them in water at 270 C for 24 hrs in the wet condition using 30 T- UTM. The

tiles were placed evenly flat-wise on the bearers set with a span of 27 cm, resting on the bottom surface (Fig 8). The

load was applied in a direction perpendicular to the span, at a uniform rate of 450 to 550 N/min.

Fig. 8. Testing of specimen in UTM

The individual breaking load of the three tiles was recorded in wet condition separately and the average was taken

as the load carrying capacity. Test results are shown in Table 5. Tests are also conducted to find the strength of

temperature cured specimen. As per literature, the required bending strength is an average load of at least 60kg for

the five tiles, and a minimum load of 50kg for any single tile. During testing it was observed that tiles with coir

fibres exhibit better ductility comparing with those of ordinary concrete tile. Also the load carrying capacity was

increased by 25%. This increased strength can only be substantiated as due to the reinforcing material(coir) used

here which will act as crack arresters.

Table 5 sample test results for breaking load

Specimen details

Average Breaking Load ( in kg)

CF0

48

CF10

60

5.4.3 Permeability test:

Permeability test was conducted as per the procedure given in [3]. The test was conducted in a rectangular trough,

open at the bottom, the dimensions being equal to the size of tile under test. The tile was fitted at the bottom of the

trough and the space between the tile and the sides of the trough were plugged water-tight with a suitable material

like wax, bitumen, etc. Water was poured into the mould so that it stands over the lowest tile surface to a height of 5

cm. The water in the trough was allowed to stand for a period of 24 hours. The bottom of the tile was carefully

examined to see whether the water has seeped through the tile. The experimental set up is shown in Fig 9.

In the study, three specimens were tested and two of them showed a little dampness at the bottom. The

water absorbent behaviour of the tile, attributed to the presence of coir fibres in it. The same test was carried out by

coating the tiles with cement mortar. It was observed that the tile does not indicate any dampness.

P. Darsana et al. / Procedia Technology 24 (2016) 169 178

177

Fig. 9. Permeability test

6.

Cost estimation

The cost estimation of the Tile is given in Table 6. Approximate cost for one Mangalore Pattern tile is Rs. 30 and

that of a Cement Concrete tile ranges within Rs.60-90 for various sizes. Only the cost of replaced cement could be

saved here. When process gets mechanized, percentage coir fraction can be increased and hence more savings.can

be ensured.

Table 6 estimation of the project

Quantity

Rate (Rs)

Amount (Rs)

59.4Kg

340/Bag

403.93

COIR

6.6Kg

150/Kg

990.00

3.

M-SAND

240Kg

2/Kg

480.00

4.

LABOUR

Sl No.

Materials

1.

CEMENT

2.

(for 100 tiles)

2000.00

For 100 tiles

3873.93

For 1 tile

38.74

7. Conclusion

An eco-friendly product was developed using locally available material.

In the present study, only 10% replacement of cement was possible. But the percentage can be increased

with mechanization of the manufacturing process.

Addition of more fibres will result in reduction in self-weight and cost.

Properties like breaking load and ductility were improved with the addition of fibres. From the difference

in cracking pattern of tiles which used coir fibre and those without coir fibre it was observed that the cracks

are more sharp in the latter. This can be justified because of the presence coir fibres in the roofing tile it has

shown a cracking pattern with less sharpness and this physical observation lead to this conclusion

178

P. Darsana et al. / Procedia Technology 24 (2016) 169 178

Acknowledgment

The financial support from Centre for Engineering Research and Development (CERD) Trivandrum is gratefully

acknowledged

References

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

Abdullah, Shamsul Baharin Jamaludin, Mazlee Mohd Noor, Kamarudin Hussin, (2011) Composite Cement Reinforced Coconut Fiber:

Physical and Mechanical Properties and Fracture Behaviour, Australian Journal of Basic and Applied Sciences, 5(7): 1228-1240,2011.

Asasutjarit C, Hirunlabh J, Khedari J, Charoenvai S, Zeghmati B, and Shin U.C, (2007) Development of coconut coir-based lightweight

cement board, Construction and Building Materials, vol. 21, no. 2, pp. 277288.

Cook D.J, Pama R.P, Weerasingle, (1978) Coir fibre reinforced cement as a low cost roofing material, Building and Environment, 13(3),

193-198

Indian Coir - A Reference Book (2007), a Reference Book by the Coir Board, Ministry of MS & ME, Published at India International

Coir Fair, Dec. 2007

Johansson Bo``Concrete Roofing tileAccessed http://www.hdm.lth.se/fileadmin/hdm/BI_Volume_04_2_1992_Concrete_Roofing_Tiles.pdf

on 02-01-2014.

Majid Ali (2010) Coconut Fibre A Versatile Material and its Applications in Engineering Accessed www.cl 2010%20papers/k13.pdf

on 03-08-2013

Peamora L.J , Melencion N.J and Palomar Rolendio, (2005) Coconut Fiber-Cement Board Production and Application Project, Accessed

http://www.ecocoboard.net/ on 05-08-2013

Ramakrishna G, Sundararajan T, (2005) Studies on the durability of natural fibres and the effect of corroded fibres on the strength of

mortar,Cement and Concrete Composites - Volume 27, Issue 5, May 2005, Pages 575582..

Ramaswamy H.S, Ahuja B.M and Krishnamoorthy S, (1983) Behaviour of Concrete reinforced with jute, coir and bamboo fibres,The

International Journal of Cement Composites and Lightweight Concrete, Volume 5, Number 1, February 1983.

Sivaraja M, Kandasamy N, Velmani N, Sudhakaran Pillai M (2009) Study on durability of natural fibre concrete composites using

mechanical strength and micro structural properties Accessed http://www.ias.ac.in/matersci/ bmsdec2010/719.pdf on 10-08-2013.

Mohd

hisbany

bin

mohd

hashim

(2005)

coconut

fiber

reinforced

wall

panellingsystemAccessedhttp://www.efka.utm.my/thesis/images/4MASTER/2005/1JSB/Part1/mohdhisbanyma031111d05ttt.pdf

Li Z, Wang X, Wang L (2006). Properties of hemp fibre reinforced concrete composites. Compos. Part A Appl. Sci. Manuf., 37(3): 497505. Munawar SS,

Ramkrishna.G,Sundararajan T, Studies on the durability of natural fibres and the effect of corroded fibres on the strength o mortarvol.27

You might also like

- Elastic, Plastic and Yield Design of Reinforced StructuresFrom EverandElastic, Plastic and Yield Design of Reinforced StructuresNo ratings yet

- Natural Fibre Reinforced Cement Concrete: Avenue Through Some InvestigationsDocument5 pagesNatural Fibre Reinforced Cement Concrete: Avenue Through Some InvestigationsKirsten CarlosNo ratings yet

- Comparative Study of Sisal Fibre and Glass Fibre Reinforced Concrete - A ReviewDocument6 pagesComparative Study of Sisal Fibre and Glass Fibre Reinforced Concrete - A ReviewIJRASETPublicationsNo ratings yet

- International Journal of Engineering Research and DevelopmentDocument4 pagesInternational Journal of Engineering Research and DevelopmentIJERDNo ratings yet

- 9 ArticleText 5 1 10 20190603Document7 pages9 ArticleText 5 1 10 20190603hhNo ratings yet

- Light Weight Aggregate Concrete by Using Coconut Shell: S. A. Kakade, Dr. A. W. DhawaleDocument3 pagesLight Weight Aggregate Concrete by Using Coconut Shell: S. A. Kakade, Dr. A. W. DhawaleGelo LibanNo ratings yet

- Compressive Behavior of Rice Straw-Reinforced Concrete For Rigid PavementsDocument8 pagesCompressive Behavior of Rice Straw-Reinforced Concrete For Rigid PavementsAngelica CabreraNo ratings yet

- Coconut Fibre Reinforced Concrete Made With MattressesDocument8 pagesCoconut Fibre Reinforced Concrete Made With MattressesDharma banothuNo ratings yet

- Coir Fibre Used in Reinforced ConcreteDocument6 pagesCoir Fibre Used in Reinforced ConcreteVIVA-TECH IJRINo ratings yet

- Application of Coconut and Palm Oils in Cement-Based MaterialDocument37 pagesApplication of Coconut and Palm Oils in Cement-Based MaterialShimbarlu AtwiksonNo ratings yet

- Application and Analysis of Waste Plastic As A Effective Pavement MaterialsDocument34 pagesApplication and Analysis of Waste Plastic As A Effective Pavement MaterialsPrashanthryakamNo ratings yet

- Journal For Kalai Publication.Document12 pagesJournal For Kalai Publication.Kalai ArasanNo ratings yet

- ChaptersDocument64 pagesChapterssrivathsabestharNo ratings yet

- Research For TilesDocument7 pagesResearch For Tilesjobcustodio54No ratings yet

- Concrete Using Coconut Fiber - An AlternativeDocument4 pagesConcrete Using Coconut Fiber - An AlternativeSenthil KumarNo ratings yet

- Study of Flexural Strength and Flexural Modulus of Reinforced Concrete Beams With Raffia Palm FibersDocument8 pagesStudy of Flexural Strength and Flexural Modulus of Reinforced Concrete Beams With Raffia Palm FibersPremier PublishersNo ratings yet

- Structural Properties of Rice Husk and Sawdust Composite BricksDocument28 pagesStructural Properties of Rice Husk and Sawdust Composite BricksAbijithNo ratings yet

- Studies On Stabilized Mud Block As A Construction MaterialDocument6 pagesStudies On Stabilized Mud Block As A Construction MaterialIJIRAE- International Journal of Innovative Research in Advanced Engineering100% (1)

- Chapter One 1.0 1.1 Background of StudyDocument45 pagesChapter One 1.0 1.1 Background of StudyUzoma FrancisNo ratings yet

- Oup2 LEA CHADocument4 pagesOup2 LEA CHAfranciscocedie178No ratings yet

- Effect of Coconut Husk On The Properties of ConcreteDocument2 pagesEffect of Coconut Husk On The Properties of ConcreteRalph Christian ZenarosaNo ratings yet

- Thermal Resistant Interlocking Bricks With FlyashDocument14 pagesThermal Resistant Interlocking Bricks With FlyashJanley AresNo ratings yet

- Structural Behavior of Fiber Reinforced Stabilized Mud Block Masonr1-1-63Document63 pagesStructural Behavior of Fiber Reinforced Stabilized Mud Block Masonr1-1-63srivathsabestharNo ratings yet

- Utilization of Sisal Fiber in Portland Cement Concrete ElementsDocument6 pagesUtilization of Sisal Fiber in Portland Cement Concrete ElementsLucero Vasquez LopezNo ratings yet

- Coconut Fiber in Concrete To Enhance Its Strength and Making Lightweight ConcreteDocument5 pagesCoconut Fiber in Concrete To Enhance Its Strength and Making Lightweight ConcreteIndrawan Soleh PutraNo ratings yet

- Evaluation of Properties of Coconut Coir Fiber Reinforced ConcreteDocument86 pagesEvaluation of Properties of Coconut Coir Fiber Reinforced ConcreteROHIT PRADEEP BABJE100% (3)

- ResearchPaperElsevier 4Document5 pagesResearchPaperElsevier 4NIEDO ADRIENNENo ratings yet

- Duhat Abaca Fiber Research PaperDocument13 pagesDuhat Abaca Fiber Research PaperJarred Allen Z. ServañaNo ratings yet

- Irjet V4i5503Document8 pagesIrjet V4i5503Malik ZainNo ratings yet

- A Review On Utilization of Coconut Shell As Coarse Aggregate in ConcreteDocument3 pagesA Review On Utilization of Coconut Shell As Coarse Aggregate in ConcreteAnujKumarVermaNo ratings yet

- 2017 Question Paper Part A: 1) Contributions of Design Aspect To Cost Effective ConstructionDocument20 pages2017 Question Paper Part A: 1) Contributions of Design Aspect To Cost Effective ConstructionBlessy FrancisNo ratings yet

- 2017 Question Paper Part A: 1) Contributions of Design Aspect To Cost Effective ConstructionDocument20 pages2017 Question Paper Part A: 1) Contributions of Design Aspect To Cost Effective ConstructionBlessy FrancisNo ratings yet

- NALPASDocument10 pagesNALPASAeron Dave LopezNo ratings yet

- Study of Strength of Concrete by Using Coconut Shell: Is The Hydraulic Binder (HydraulicDocument5 pagesStudy of Strength of Concrete by Using Coconut Shell: Is The Hydraulic Binder (HydraulicShivam ShekharNo ratings yet

- Comparative Study of Natural Fiber Reinforced ConcreteDocument5 pagesComparative Study of Natural Fiber Reinforced Concretesbaia amineNo ratings yet

- Chapter 1-3Document25 pagesChapter 1-3Janley AresNo ratings yet

- 1 - A Comparative Study On Erosion Characterstics of Red Mud Filled Bambo-Epoxy and Glass-Epoxy Composites - Biswas - SatapathyDocument16 pages1 - A Comparative Study On Erosion Characterstics of Red Mud Filled Bambo-Epoxy and Glass-Epoxy Composites - Biswas - Satapathygirish KulkarniNo ratings yet

- Materials: Mechanical and Durability Performance of Coconut Fiber Reinforced Concrete: A State-of-the-Art ReviewDocument24 pagesMaterials: Mechanical and Durability Performance of Coconut Fiber Reinforced Concrete: A State-of-the-Art ReviewBenmark JabayNo ratings yet

- Papercrete4 PDFDocument9 pagesPapercrete4 PDFPrasad TekadeNo ratings yet

- Experimental Study On Steel Fiber Concrete: October 2016Document6 pagesExperimental Study On Steel Fiber Concrete: October 2016AbhishekNo ratings yet

- A Feasibility Study of Cofi Net: Conventional Concrete Bricks Using Coco Coir and Waste Fishing Net FibreDocument2 pagesA Feasibility Study of Cofi Net: Conventional Concrete Bricks Using Coco Coir and Waste Fishing Net FibreJoanna Marie AlvarezNo ratings yet

- Duhat Abaca Fiber Research Paper 2Document12 pagesDuhat Abaca Fiber Research Paper 2Jarred Allen Z. ServañaNo ratings yet

- Paper Crete: A Sustainable Building Material: Jil Tushar Sheth, Saransh JoshiDocument6 pagesPaper Crete: A Sustainable Building Material: Jil Tushar Sheth, Saransh JoshiAnishma AyyappanNo ratings yet

- 5IJAEMS NOV 2015 7 TurningNaturalFiberReinforcedCementCompositeasInnovativeAlternativeSustainableConstructionMaterial - AReviewPaper PDFDocument9 pages5IJAEMS NOV 2015 7 TurningNaturalFiberReinforcedCementCompositeasInnovativeAlternativeSustainableConstructionMaterial - AReviewPaper PDFGalih supriyantoNo ratings yet

- Alternative Low-Cost Building Material - Ar - Vidya & Ar - RadhaDocument7 pagesAlternative Low-Cost Building Material - Ar - Vidya & Ar - RadhaPrasadNo ratings yet

- 1 s2.0 S095006182300805X MainDocument16 pages1 s2.0 S095006182300805X Maind_diasol38No ratings yet

- Studies On Metakaolin Based Coir Fibre Reinforced ConcreteDocument31 pagesStudies On Metakaolin Based Coir Fibre Reinforced ConcreteIAEME PublicationNo ratings yet

- Conference PaperDocument8 pagesConference PaperVijayakumarNo ratings yet

- Advocacy For The Production of Geopolymer Concrete Using Plantain Fiber and Coal AshDocument8 pagesAdvocacy For The Production of Geopolymer Concrete Using Plantain Fiber and Coal AshEmmanuel OgunjioforNo ratings yet

- Batch 6Document11 pagesBatch 620311a0135No ratings yet

- Human Hair As Fibre Material in Reinforced Concrete: March 2018Document13 pagesHuman Hair As Fibre Material in Reinforced Concrete: March 2018JERIN K GEORGENo ratings yet

- A Review of Bamboo As A Reinforcement Material in Modern ConstructionDocument12 pagesA Review of Bamboo As A Reinforcement Material in Modern ConstructionSantosh BasnetNo ratings yet

- Prospects of Low Cost Housing in IndiaDocument6 pagesProspects of Low Cost Housing in IndiaRam Prabesh YadavNo ratings yet

- Artigo Fibra de Juta em Concretos 40064-015-1504-7Document8 pagesArtigo Fibra de Juta em Concretos 40064-015-1504-7Lidianne FariasNo ratings yet

- Hybrid CompositeDocument91 pagesHybrid Compositemanoharbyalal100% (3)

- Experimental Studieson Glass Fiber ConcreteDocument6 pagesExperimental Studieson Glass Fiber ConcreteramyaNo ratings yet

- Study On Durability of Natural Fibre Concrete Composites Using Mechanical Strength and Microstructural PropertiesDocument11 pagesStudy On Durability of Natural Fibre Concrete Composites Using Mechanical Strength and Microstructural PropertiessfsdffedsNo ratings yet

- Banana Fibre Reinforced Concrete 1Document18 pagesBanana Fibre Reinforced Concrete 1ved100% (1)

- Natural Fibre Composites and Its Potential As BLDG MaterialDocument6 pagesNatural Fibre Composites and Its Potential As BLDG Materialarunvenkat76No ratings yet

- An Experimental Study To Address The Issues of Low Durability and Low Compressive Strength of Mud PlasterDocument39 pagesAn Experimental Study To Address The Issues of Low Durability and Low Compressive Strength of Mud PlasterRafiq MirNo ratings yet

- CH 22 ADocument81 pagesCH 22 AThiran Boy LingamNo ratings yet

- CH 24 ADocument38 pagesCH 24 AThiran Boy LingamNo ratings yet

- Theory of Metal MachiningDocument63 pagesTheory of Metal MachiningThiran Boy LingamNo ratings yet

- Flat Face Die PDFDocument2 pagesFlat Face Die PDFThiran Boy LingamNo ratings yet

- Effect of Chip Size On Mechanical Property and Microstructure of AZ91D Magnesium Alloy Prepared by Solid State Recycling PDFDocument5 pagesEffect of Chip Size On Mechanical Property and Microstructure of AZ91D Magnesium Alloy Prepared by Solid State Recycling PDFThiran Boy LingamNo ratings yet

- METAL FORMING AND THE Fenite Element Method PDFDocument9 pagesMETAL FORMING AND THE Fenite Element Method PDFThiran Boy Lingam0% (1)

- Chapter 5Document35 pagesChapter 5Thiran Boy LingamNo ratings yet

- Electrical and Electronic Technology (BEX17003) : DR Soon Chin FhongDocument58 pagesElectrical and Electronic Technology (BEX17003) : DR Soon Chin FhongThiran Boy LingamNo ratings yet

- Chapter 6bDocument35 pagesChapter 6bThiran Boy LingamNo ratings yet

- Electrical TechnologyDocument11 pagesElectrical TechnologyThiran Boy LingamNo ratings yet

- Mechanics of Language: Noor Shahariah BT Saleh Faculty of Science, Technology and Human DevelopmentDocument57 pagesMechanics of Language: Noor Shahariah BT Saleh Faculty of Science, Technology and Human DevelopmentThiran Boy LingamNo ratings yet

- Chapter 2Document25 pagesChapter 2Thiran Boy LingamNo ratings yet

- Tig Front PrintDocument1 pageTig Front PrintThiran Boy LingamNo ratings yet

- Abbas Ali Mandviwala 200640147: Ba1530: Information Systems and Organization StudiesDocument11 pagesAbbas Ali Mandviwala 200640147: Ba1530: Information Systems and Organization Studiesshayan sohailNo ratings yet

- Guidelines For Plenipotentiary - 1Document6 pagesGuidelines For Plenipotentiary - 1Oladimeji Ibukun IjaodolaNo ratings yet

- ArrowrootDocument8 pagesArrowrootSevi CameroNo ratings yet

- AAR Shell ProgrammingDocument13 pagesAAR Shell ProgrammingMarimuthu MuthaiyanNo ratings yet

- Biscotti: Notes: The Sugar I Use in France, Is CalledDocument2 pagesBiscotti: Notes: The Sugar I Use in France, Is CalledMonica CreangaNo ratings yet

- Business Plan: Muzammil Deshmukh, MMS From Kohinoor College, MumbaiDocument6 pagesBusiness Plan: Muzammil Deshmukh, MMS From Kohinoor College, MumbaiMuzammil DeshmukhNo ratings yet

- Digestive System Worksheet 2013 2Document3 pagesDigestive System Worksheet 2013 2contessa padonNo ratings yet

- Property House Invests $1b in UAE Realty - TBW May 25 - Corporate FocusDocument1 pageProperty House Invests $1b in UAE Realty - TBW May 25 - Corporate FocusjiminabottleNo ratings yet

- Instruction Manual 115cx ENGLISHDocument72 pagesInstruction Manual 115cx ENGLISHRomanPiscraftMosqueteerNo ratings yet

- ICU General Admission Orders: OthersDocument2 pagesICU General Admission Orders: OthersHANIMNo ratings yet

- Work Site Inspection Checklist 1Document13 pagesWork Site Inspection Checklist 1syed hassanNo ratings yet

- English For General SciencesDocument47 pagesEnglish For General Sciencesfauzan ramadhanNo ratings yet

- Economizer DesignDocument2 pagesEconomizer Designandremalta09100% (4)

- ProbDocument10 pagesProbKashif JawaidNo ratings yet

- Physico-Chemical Properties of Nutmeg (Myristica Fragrans Houtt) of North Sulawesi NutmegDocument9 pagesPhysico-Chemical Properties of Nutmeg (Myristica Fragrans Houtt) of North Sulawesi NutmegZyuha AiniiNo ratings yet

- Chunking Chunking Chunking: Stator Service IssuesDocument1 pageChunking Chunking Chunking: Stator Service IssuesGina Vanessa Quintero CruzNo ratings yet

- Case Study On Goodearth Financial Services LTDDocument15 pagesCase Study On Goodearth Financial Services LTDEkta Luciferisious Sharma0% (1)

- Furnace Temperature & PCE ConesDocument3 pagesFurnace Temperature & PCE ConesAbdullrahman Alzahrani100% (1)

- Ethiopian Airlines-ResultsDocument1 pageEthiopian Airlines-Resultsabdirahmanguray46No ratings yet

- The History of Music in Portugal - Owen ReesDocument4 pagesThe History of Music in Portugal - Owen ReeseugenioamorimNo ratings yet

- Remedy MidTier Guide 7-5Document170 pagesRemedy MidTier Guide 7-5martin_wiedmeyerNo ratings yet

- Caso Estudio: Reliability Analysis of Power Distribution System. A Case StudyDocument6 pagesCaso Estudio: Reliability Analysis of Power Distribution System. A Case StudyCarlos HernandezNo ratings yet

- Jones Et - Al.1994Document6 pagesJones Et - Al.1994Sukanya MajumderNo ratings yet

- Sickle Cell DiseaseDocument10 pagesSickle Cell DiseaseBrooke2014No ratings yet

- Integrator Windup and How To Avoid ItDocument6 pagesIntegrator Windup and How To Avoid ItHermogensNo ratings yet

- PNGRB - Electrical Safety Audit ChecklistDocument4 pagesPNGRB - Electrical Safety Audit ChecklistKritarth SrivastavNo ratings yet

- IPS PressVest Premium PDFDocument62 pagesIPS PressVest Premium PDFLucian Catalin CalinNo ratings yet

- What Is Product Management?Document37 pagesWhat Is Product Management?Jeffrey De VeraNo ratings yet

- What Is Denim? Why It's Called Denim?: Properties of Denim FabricDocument21 pagesWhat Is Denim? Why It's Called Denim?: Properties of Denim Fabricrahmanshanto623100% (1)

- BA 4722 Marketing Strategy SyllabusDocument6 pagesBA 4722 Marketing Strategy SyllabusSri GunawanNo ratings yet