Professional Documents

Culture Documents

Jeas 0715 2273 PDF

Uploaded by

pugal4Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jeas 0715 2273 PDF

Uploaded by

pugal4Copyright:

Available Formats

VOL. 10, NO.

13, JULY 2015

ARPN Journal of Engineering and Applied Sciences

ISSN 1819-6608

2006-2015 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com

GT HEURISTIC FOR SOLVING MULTI OBJECTIVE JOB SHOP

SCHEDULING PROBLEMS

M. Chandrasekaran1, D. Lakshmipathy1 and P. Sriramya2

1Department

2Department

of Mechanical Engineering, Vels University, Chennai, India

of Computer Science Engineering, Saveetha School of Engineering, Chennai, India

E-Mail: ch_sekaran@yahoo.com

ABSTRACT

The n-job, m-machine Job shop scheduling (JSP) problem is one of the general production scheduling problems in

manufacturing system. Scheduling problems vary widely according to specific production tasks but most are NP-hard

problems. Scheduling problems are usually solved using heuristics to get optimal or near optimal solutions because

problems found in practical applications cannot be solved to optimality using reasonable resources in many cases. In this

paper, optimization of three objectives mean job flow time, mean job tardiness and makespan are considered. New Game

theory based heuristic approach (GT) is used for finding optimal makespan, mean flow time, mean tardiness values of

different size problems and generating a feasible schedule that minimizes three objectives. This schedule is called a Pareto

optimal solution. A set of non-dominant solutions have been identified using Naive and Slow approach. The findings are

compared with Genetic Algorithm (GA) that tested the same problems. The proposed GT heuristic is competent and proves

to be a good problem-solving technique for multi objective optimization in job shop scheduling.

Keywords: job shop scheduling, multi objectives, GT heuristic, pareto optimal solution, nave, slow approach.

1.

INTRODUCTION

The classical job-shop scheduling problem (JSP)

is one of most difficult combinatorial optimization

problems. During the last decades a great deal of attention

has been paid to solving these problems with many

algorithms by considering single objective. But real world

scheduling problems naturally involve multiple objectives.

There are only few attempts available to tackle the multiobjective JSP.

In a multi-objective context, find as much

different schedules as possible, which are non-dominated

with regard to two or more objectives. Some frequently

used performance measures are makespan, mean flowtime and mean tardiness. Makespan is defined as the

maximum completion time of all jobs. Mean flow-time is

the average of the flow-times of all jobs. Mean tardiness is

defined as the average of tardiness of all jobs.

2.

LITERATURE REVIEW

a) Job shop scheduling

Bruker [1] show that the Job Shop scheduling

Problem (JSP) is an NP-hard combinatorial problem.

Because of the NP-hard characteristics of job shop

scheduling [2], it is usually very hard to find its optimal

solution, and an optimal solution in the mathematical

sense is not always necessary in practices [3]. Researchers

turned to search its near-optimal solutions with all kind of

heuristic algorithms [4]. In a single-objective context some

of the recent approaches have shown quite promising

results [5-6]. But real world scheduling problems naturally

involve multiple objectives. There are only few attempts to

tackle the multi-objective JSP [7]. Additionally, researches

on job shop scheduling problems have been concentrated

primarily on the optimisation of individual measures of

system performance. While a single objective may be

justified in certain situations, many scheduling problems

are more naturally formulated with multiple, often

competing, objectives to obtain a trade-off schedule.

Examples of multi-criteria scheduling approaches include

time based optimization in Daniels [8], Lee and Jung [9],

and Murata, Ishibuchi, and Tanaka [10].

b) Graph Theory based (GT) heuristic

Trees are more important data structures which

come in many forms. Sometimes trees are static in the

sense that their shape is determined before running of the

algorithm, and they do not change shape while the

algorithm runs. In other cases, trees are dynamic, meaning

that they undergo shape changes during the running of the

algorithm. In GT heuristic root node means origin or

stating node. Children mean sub nodes in the parent. Leaf

node means node with our children. Parent node means

node with children.

The remainder of the paper is organized as

follows. Section 3 describes the Problem formulation.

Section 4 introduces the new GT heuristic for JSP

problem. Section 5 shows Implementation of GT heuristic.

Section 6 shows the Results and discussion. Finally,

section 7 presents the conclusion of this work.

3.

PROBLEM FORMULATION

In a multi-objective context, find as much

different schedules as possible, which are non-dominated

with regard to two or more objectives. Performance

measures are makespan, mean flow-time and mean

tardiness. Makespan is defined as the maximum

completion time of all jobs. Mean flow-time is the average

of the flow-times of all jobs. Mean tardiness is defined as

the average of tardiness of all jobs.

The combined objective function for the multi

objective Job Shop Problem is,

5472

VOL. 10, NO. 13, JULY 2015

ARPN Journal of Engineering and Applied Sciences

ISSN 1819-6608

2006-2015 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com

COF = Min [w1 (msi/ms*) + w2 (Ti/T*) + w3 (mfi/mf*)]

Where, w1 = (R1/R), w2 = (R2/R),

w3 = (R3/R)

R = (R1+ R2 +R3),

where R1, R2, R3 - Random numbers

ms*Make Span Global minimum

T* Mean Tardiness Global minimum

mf* Mean Flow Time Global minimum

msi Make span Iteration minimum

Ti Mean Tardiness Iteration minimum

mfi Mean Flow Time Iteration minimum

w1, w2, w3- Weightage factors

MFT- Mean flow time,

MT - Mean Tardiness

COF- Combined Objective Function

in n's right subtree is greater than or equal to n. Thus, the

left subtrees in order, using a recursive call, and then visit

n, and then visit the right subtree in order. Assume the

recursive calls correctly visit the subtrees in order using

the mathematical principle of structural induction. Flow

chart of GT Heuristic is shown in Figure-1.

4.

PROPOSED NEW HEURISTIC FOR MULTI

OBJECTIVE JSP PROBLEM

GT Heuristic for solving JSP

Step-1: Initialization

Initial sequences are generated randomly.

Objective values for initial sequences are calculated.

Roulette wheel method is used for ranking the sequences.

Step-2: Depth First Search

In depth first search, initial sequences are

changed in tree structure format. Based on the tree, the

sequence generated by traversing root node then leaf node

and finally parent node. In this order, sequence is traversed

and the corresponding objective values are calculated.

Step-3: Breadth First Search

Based on the tree, the sequence generated by

traversing root node then parent node and finally leaf

node. In this order, sequence is traversed and the

corresponding objective values are calculated.

Step-4: Tree traversal

In computer science, tree traversal is the process

of visiting each node in a tree data structure. Tree

traversal, also called walking the tree, provides for

sequential processing of each node in what is, by nature, a

non-sequential data structure.

Such traversals are classified by the order in which the

nodes are visited.

i)

Pre-order traversal: Each node is visited before

any of its children.

ii)

iii)

Post-order traversal: Each node would be visited

after all of its children. In both cases, values in

the left subtree are printed before values in the

right subtree.

In-order traversal: Visits each node between the

nodes in its left subtree and the nodes in its right

subtree. This is a particularly common way of

traversing a binary search tree, because it gives

the values in increasing order.

If n is a node in a binary search tree, then

everything in n's left subtree is less than n, and everything

Figure-1. Flow chart of GT heuristic.

5.

IMPLEMENTATION OF GT HEURISTIC (GT)

a) GT heuristic parameters

The following parameters are considered in trail

and error basis.

Population size (n) = 10

Fitness function

= makespan

Root node

= origin or starting point node

Leaf node

= node without children

Parent node

= node with children on both side

Ranking method

= Roulette Wheel Method

Non-dominated set = Naive and Slow approach

5473

VOL. 10, NO. 13, JULY 2015

ARPN Journal of Engineering and Applied Sciences

ISSN 1819-6608

2006-2015 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com

Termination Criteria = Number of iterations (100)

Step 1: Initialization

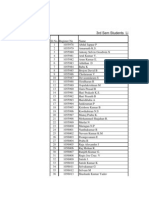

Initial sequences for JSP1 problem is generated

randomly. Table-1 shows the initial sequence with its

objective values. Roulette wheel method is used for

ranking the sequences.

b) Numerical illustration

Test Problems JSP1 & JSP2 is taken from Bagchi

[7] for evaluating the performance of GT Heuristic

Table-1. Initial sequence.

10

10

10

10

10

Makespan =236

Mean flow time =176.30

Mean tardiness =33.38

COF = 0.6802

children (parent nodes) are taken for traversing process.

Sequence is traversed and the corresponding objective

values are calculated. Table-2 gives the values obtained

from depth first search process.

Step 2: Depth First Search

In depth first search, initial sequences are

changed in tree structure format with 10 as root node. In

this search, root node is first selected then nodes without

children (leaf nodes) are considered and finally nodes with

Table-2. Depth First Search process

10

10

10

10

10

Step 3: Breadth First Search

In breadth first search, sequence is generated

with the root node i.e. 10. Parent nodes are considered

Makespan=197

Mean flow time =152.39

Mean tardiness = 31.77

COF = 0.676182

next and then finally leaf nodes. At the end of Breath First

search method, the sequence obtained with objective

values are shown in Table-3.

Table-3. Breadth First Search process.

10

10

10

10

10

Makespan=165

Mean flow time =109.697

Mean tardiness = 26.11

COF = 0.3218

5474

VOL. 10, NO. 13, JULY 2015

ARPN Journal of Engineering and Applied Sciences

ISSN 1819-6608

2006-2015 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com

then the root node and finally the right sub tree nodes. In

order traversal process results are reported in Table-4.

Step 4: In order traversal

Tree consists of Left sub tree and Right sub tree. The

traversal is done for by considering left sub tree nodes

Table-4. In order traversal process.

1

10

10

10

10

10

Makespan =187

Mean flow time =138.00

Mean tardiness = 24.84

COF= 0.5857

sequence the corresponding objective values are calculated.

Table-5 illustrates the results obtained from post traversal

process.

Step 5: Post order traversal

The traversal is carried out for traversing the

sequence by considering Left Sub tree nodes first then Right

Sub Tree nodes and finally Root node. For the traversed

Table-5. Post traversal process.

2

10

10

10

10

10

Makespan = 200

Mean flow time =141.39

Mean tardiness = 25.38

COF = 0.3812

process, the value of makespan, mean flow time and mean

tardiness is calculated. Final results obtained after the first

iteration is shown in Table-6.

Step 6: Preorder traversal

The traversal is carried out from Root node then

Left Sub Tree nodes and Right Sub Tree nodes. After

traversing the sequence based on preorder traversal

Table-6. Pre traversal process.

10

10

10

10

10

Makespan=179

Mean flow time = 122.39

Mean tardiness = 13.77

COF =0.3616

5475

VOL. 10, NO. 13, JULY 2015

ARPN Journal of Engineering and Applied Sciences

ISSN 1819-6608

2006-2015 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com

Step 7: The final results obtained for JSP1 from GT

heuristic is as follows

After 100 iterations, the results obtained by using

GT heuristic are as follows:

Table-7. Results from GT Heuristic for JSP1.

Makespan

Mean tardiness

Mean flow time

COF

152

16.845

117.8

0.5811

162

16.805

121.2

0.6450

163

15.802

128.5

0.5674

164

12.97

125.28

0.5714

168

12.042

124.7

0.5396

170

14.985

131.65

0.6167

172

11.442

133.42

0.5061

175

12.804

129.58

0.6412

177

17.822

119.91

0.6829

178

19.759

139.3

0.6323

6.

RESULTS AND DISCUSSION

The new heuristic is developed and implemented

in C language on personal computer Pentium IV 2.4 GHz.

The maximum number of iterations has been set to 100 X

n, where n is the number of jobs. Multi-objective

optimization differs from single-objective optimization in

many ways [11]. For two or more conflicting objectives,

each objective corresponds to a different optimal solution,

but none of these trade-off solutions is optimal with

respect to all objectives. Thus, multi-objective

optimization does not try to find one optimal solution but

all trade-off solutions.

For multi-objective scheduling the proposed new

GT heuristic is used to optimize makespan, mean flow

time and mean tardiness of the two JSP given by Bagchi

[7] are the basis of the following experiments. The first

problem, called JSP1, is a ten job five machine instance.

The second problem, called JSP2, is a ten job ten machine

instance. Apparently, the GT heuristic minimizes all

objectives simultaneously. GT heuristic is compared with

the similar previous work using GA [12] and shown in

Table-8 and Table-9.

CONCLUSIONS

In this paper, a new heuristic approach has been

used for solving multi objective job shop scheduling

problems with the objective of minimization of makespan,

mean flow time and mean tardiness. This approach uses

simple but effective techniques depth first search, Breadth

first search and tree traversal. This approach has been

tested on JSP 1 and JSP 2 problem instances given in

Bagchi [7]. The findings were compared with Genetic

Algorithm [12] that tested the same problems. The New

heuristic gives better results than the genetic algorithm.

The proposed new heuristic is competent and proves to be

a good problem-solving technique for job shop scheduling.

Notations Used

MS

=

MFT

=

MT

=

COF

=

Makespan

Mean Flow Time

Mean Tardiness

Combined Objective Function.

REFERENCES

[1] Bruker P. 1995. Scheduling Algorithms 2nd Edn,

Springer-Verlag, Berlin.

[2] Garey M. et al. 1976. The complexity of flow shop

and job shop scheduling, Mathematics of Operations

Research, 1, pp. 117-129.

[3] Erschler J.F., Roubellat J.P. and Vernhes. 1976.

Finding some essential characteristics of the feasible

solutions for a scheduling problem, Operations

Research, 24, pp. 774-783.

[4] French S. 1982. Sequencing and scheduling: An

introduction to the mathematics of the job shop, New

York, Wiley.

7.

[5] Mattfeld D.C. 1996. Evolutionary Search and the Job

Shop, Physica-Verlag.

[6] Ono I., Yamamura M. and Kobayashi S. 1996. A

genetic algorithm for job-shop scheduling problems

using job-based order crossover. In Proceedings of

ICEC '96, pp. 547-552.

[7] Bagchi T.P. 1999. Multiobjective Scheduling By

Genetic Algorithms, Kluwer Academic Publishers.

[8] Daniels D.L. 1994. Incorporating performance

information into multiobjective scheduling. European

Journal Operational Research, Vol. 77, pp. 272286.

5476

VOL. 10, NO. 13, JULY 2015

ARPN Journal of Engineering and Applied Sciences

ISSN 1819-6608

2006-2015 Asian Research Publishing Network (ARPN). All rights reserved.

www.arpnjournals.com

[9] Lee S.M. and Jung H.J. 1989. A multi-objective

production planning model in A flexible

manufacturing environment. International Journal

Production Research, Vol. 27, No. 11, pp. 19811992.

[10] Murata T., Hisao I. and Tanaka H. 1996. Multiobjective genetic algorithm and its applications to

flow shop scheduling. Computer Industrial

Engineering, Vol. 30, No. 6, pp. 957968.

[11] Deb K. 2001. Multi-Objective Optimization Using

Evolutionary Algorithms. John Wiley & Sons.

[12] Garen J. 2003. Multi objective Job-Shop Scheduling

with Genetic Algorithms using a New Representation

and Standard Uniform Crossover, MH WORKSHOP.

5477

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Unit I Maintenance of Records and SchedulesDocument19 pagesUnit I Maintenance of Records and Schedulespugal4No ratings yet

- 16 - Properties and Applications of Materials PDFDocument65 pages16 - Properties and Applications of Materials PDFmpcd07No ratings yet

- TALAT Lecture 1502: Criteria in Material SelectionDocument36 pagesTALAT Lecture 1502: Criteria in Material SelectionCORE MaterialsNo ratings yet

- Engineering Thermodynamics (Nov, Dec2013)Document2 pagesEngineering Thermodynamics (Nov, Dec2013)Siva2sankarNo ratings yet

- 15 Chapter10 PDFDocument23 pages15 Chapter10 PDFpugal4No ratings yet

- Engineering Thermodynamics (May2014) PDFDocument4 pagesEngineering Thermodynamics (May2014) PDFpugal4No ratings yet

- Material Selection Processes in The Automotive Industry: December, 1993Document48 pagesMaterial Selection Processes in The Automotive Industry: December, 1993Manica LucianNo ratings yet

- PDFDocument17 pagesPDFpugal4No ratings yet

- Jeas 1013 957 PDFDocument6 pagesJeas 1013 957 PDFpugal4No ratings yet

- Optimizing The Total Completion Time in Process Planning Using The Random Simulation AlgorithmDocument8 pagesOptimizing The Total Completion Time in Process Planning Using The Random Simulation Algorithmpugal4No ratings yet

- Selecting and Planning The Process of ManufactureDocument24 pagesSelecting and Planning The Process of ManufactureMagitha MagiNo ratings yet

- Engineering Thermodynamics (May2013)Document3 pagesEngineering Thermodynamics (May2013)Siva2sankarNo ratings yet

- Em Teaching Plan FormattedDocument3 pagesEm Teaching Plan Formattedpugal4No ratings yet

- Ge6253 Engineering Mechanics L T P c3 1 0 4Document1 pageGe6253 Engineering Mechanics L T P c3 1 0 4VarunNo ratings yet

- Engineering Mechanics 1 Tutorial QuestionsDocument4 pagesEngineering Mechanics 1 Tutorial Questionspugal4No ratings yet

- Engineering Mechanics 1 Tutorial QuestionsDocument3 pagesEngineering Mechanics 1 Tutorial Questionspugal4No ratings yet

- Engineerimg Mechanics 1 Tutorial QuestionsDocument3 pagesEngineerimg Mechanics 1 Tutorial Questionspugal4No ratings yet

- Measuring Devices Frequently Used in Mechanical EngineeringDocument7 pagesMeasuring Devices Frequently Used in Mechanical Engineeringpugal4No ratings yet

- Degree Standards-Mechanical and Production Engineering (Mechanical Engg)Document3 pagesDegree Standards-Mechanical and Production Engineering (Mechanical Engg)pugal4No ratings yet

- Measuring Devices Frequently Used in Mechanical EngineeringDocument7 pagesMeasuring Devices Frequently Used in Mechanical Engineeringpugal4No ratings yet

- Measuring Forecast AccuracyDocument16 pagesMeasuring Forecast AccuracyAshiabuonwu Julius FreemanNo ratings yet

- 2nd Year 3rd Sem Student List Arrears ListDocument4 pages2nd Year 3rd Sem Student List Arrears Listpugal4No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Core Beliefs Worksheet PDFDocument3 pagesCore Beliefs Worksheet PDFMarieSmithNo ratings yet

- SOCIAL GROUPS ON CONTACTDocument14 pagesSOCIAL GROUPS ON CONTACTParth Tiwari100% (1)

- Future Hopes and Plans - Be Going To - Present Continuous - Will - Be AbleDocument31 pagesFuture Hopes and Plans - Be Going To - Present Continuous - Will - Be AbleDouglasm o Troncos RiosNo ratings yet

- Niche Travel High CPCDocument399 pagesNiche Travel High CPCSuparman JaiprajnaNo ratings yet

- Manual Lymph DrainageDocument6 pagesManual Lymph DrainageArdelean Dragos100% (1)

- Classification Calculator - Foundation Degree / Diploma of Higher Education / Diploma / Certificate of Higher Education / CertificateDocument1 pageClassification Calculator - Foundation Degree / Diploma of Higher Education / Diploma / Certificate of Higher Education / CertificateShammus SultanNo ratings yet

- 39-Article Text-131-1-10-20191111Document9 pages39-Article Text-131-1-10-20191111berlian gurningNo ratings yet

- BA 301 Syllabus (Summer 2018) Chuck Nobles Portland State University Research & Analysis of Business ProblemsDocument11 pagesBA 301 Syllabus (Summer 2018) Chuck Nobles Portland State University Research & Analysis of Business ProblemsHardlyNo ratings yet

- Adjectives, movie predictions, and a story about a boy buying a runt rabbitDocument3 pagesAdjectives, movie predictions, and a story about a boy buying a runt rabbitzandiNo ratings yet

- Teaching Reading Skills in A Foreign Language: Christine E Nuttall J. Charles AldersonDocument1 pageTeaching Reading Skills in A Foreign Language: Christine E Nuttall J. Charles AldersonQyQynNo ratings yet

- Reading1 Richards - Rodgers Task Based - Language - Teaching HighlightedDocument10 pagesReading1 Richards - Rodgers Task Based - Language - Teaching HighlightedSara ArenasNo ratings yet

- Psychological Testing ExplainedDocument12 pagesPsychological Testing ExplainedUniversity of Madras International Conference100% (2)

- Describing Character 1,2 PDFDocument3 pagesDescribing Character 1,2 PDFalexinEnglishlandNo ratings yet

- Lamm, J. Schleiermacher's PlatoDocument278 pagesLamm, J. Schleiermacher's PlatonicodeloNo ratings yet

- 4GRADE 1P O1 Progress Test (Reparado)Document4 pages4GRADE 1P O1 Progress Test (Reparado)Olga NabaisNo ratings yet

- SteelDocument23 pagesSteelMelinda GordonNo ratings yet

- Craniosacral Fascial Therapy for ADHD Case StudyDocument7 pagesCraniosacral Fascial Therapy for ADHD Case Studyharmno1No ratings yet

- Manning and Construction Agencies: Tel No/s: 09171882711 / 09128402946 Official Representative: ARTURO C. SICATDocument22 pagesManning and Construction Agencies: Tel No/s: 09171882711 / 09128402946 Official Representative: ARTURO C. SICATXer Jr GnacagNo ratings yet

- 1st Grade PYP Planner Unit 3Document4 pages1st Grade PYP Planner Unit 3Irish CortezNo ratings yet

- Personal Position PaperDocument18 pagesPersonal Position Paperapi-258330934No ratings yet

- IT1 ReportDocument1 pageIT1 ReportFranz Allen RanasNo ratings yet

- Ryan G Sharma - EPQ (Final)Document26 pagesRyan G Sharma - EPQ (Final)ryan sharmaNo ratings yet

- Pepsi ScreeningDocument13 pagesPepsi Screeningapi-459936554No ratings yet

- .Ukmedia3349ican DLD Guide Final Aug4 PDFDocument44 pages.Ukmedia3349ican DLD Guide Final Aug4 PDFraneemghandour28No ratings yet

- First Quarter Exam in Reading and Writing SkillsDocument3 pagesFirst Quarter Exam in Reading and Writing SkillsCamille Wu50% (4)

- Letterhead Doc in Bright Blue Bright Purple Classic Professional StyleDocument2 pagesLetterhead Doc in Bright Blue Bright Purple Classic Professional StyleKriszzia Janilla ArriesgadoNo ratings yet

- Scoliosis Guide: Causes, Symptoms, Diagnosis & TreatmentDocument5 pagesScoliosis Guide: Causes, Symptoms, Diagnosis & TreatmentDimple Castañeto CalloNo ratings yet

- Guideline, Research WritingDocument70 pagesGuideline, Research WritingBilal Kemal89% (18)

- 7C.3 Particles and ForcesDocument19 pages7C.3 Particles and Forcesharold hargridNo ratings yet

- Assignment OutlineDocument3 pagesAssignment OutlineQian Hui LeeNo ratings yet