Professional Documents

Culture Documents

Bench - Classic Cedar Garden PDF

Uploaded by

marianrkwOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bench - Classic Cedar Garden PDF

Uploaded by

marianrkwCopyright:

Available Formats

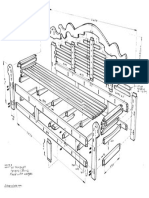

Garden Grace

How to build a classic cedar garden bench.

If the only thing you do in your yard is mow the lawn,

maybe it's time to add some creature comfort to your

outdoor space. Our stately cedar bench is ideal for relaxing

in the fresh air, enjoying the greenery and just getting away

from it all. And, it's more than just a great place to sit.

Featuring a design influenced by the Arts & Crafts style, the

piece will bring an upscale look to any yard. Best of all, the

construction details are solid and simple, giving you a longlasting piece of outdoor furniture that's relatively easy to

build.

We used red cedar for the bench--a material that's

generally available at lumberyards and home centers

throughout the country. Since cedar is widely used for

outdoor decking and trim, it's usually not kiln-dried and is

often sold with a high moisture content. For the best results

with this project, buy the material at least two to three

weeks before beginning construction. Stack the lumber in a

dry location with spacers between the boards, allowing for

good air circulation so the material will dry. And, be sure to

use a glue designated for exterior use. We used Titebond II

to assemble our bench.

MATERIALS LIST--GARDEN BENCH

Key No. Size and description (use)

2

2-3/4 x 5 x 35-1/2" cedar (rear

A

leg)

2

2-3/4 x 2-3/4 x 23-1/2" cedar

B

(front leg)

2

1 x 3 x 51" cedar (back rail)

C

2

1 x 4 x 51" cedar (seat rail)

D

1

1 x 2-1/2 x 51" cedar (front rail)

E

2

1 x 2-1/2 x 17-3/8" cedar (side

F

rail)

2

1 x 3-1/4 x 17-3/8" cedar (side

G

rail)

1

1-1/2 x 3-3/8 x 17-3/8" cedar

H

(center rail)

22 3/8 x 1-1/2 x 6-1/4" cedar

I

(bottom slat)

14 3/8 x 1-1/2 x 8-3/4" cedar (back

J

slat)

6

3/4 x 2-1/4 x 54-1/2" cedar

K

(seat slat)

2

1 x 4-1/4 x 20-5/8" cedar (arm)

L

36 1-1/2" No. 8 fh woodscrew

M

36 3/8"-dia. cedar plug

N

Misc.: Exterior glue; 120-grit sandpaper;

Cabot No. 1400 Decking Stain, Clear

(Samuel Cabot Inc., 100 Hale St.,

Newburyport, MA 01950;

www.cabotstains.com).

Preparing The Legs

The 2-3/4-in.-thick legs are made by gluing

together thinner stock. To make each rear leg,

crosscut a pair of 2 x 6 cedar pieces to about 40

in. Use a roller to spread glue on the mating

surfaces of the boards (Photo 1) and clamp the

pairs together to form the leg blanks. For the front

legs, follow the same procedure with 30-in.-long 2

x 4 stock.

When the glue dries, rip the rear blanks to a width

of 5 in. and use a band saw to trim them to 2-3/4

in. thick. Then saw the front legs to 2-3/4 in.

square. Plane the cut surfaces smooth and

crosscut the front legs to finished length.

Apply glue to pairs of 2 x 6s, and then

clamp them together to form the rear leg

blanks. Use 2 x 4s for the front legs.

Lay out the side profile of the rear legs on the

cedar blanks (Photo 2) and cut to the waste side

of the lines with a band saw (Photo 3). Then

plane the sawn surfaces (Photo 4). Use a sanding

block or scraper to smooth the inside corner of

each leg where the plane won't reach.

Use a plunge router with a spiral up-cutting bit

and an edge guide to remove most of the waste in

each leg mortise (Photo 5). Square the mortise

ends with a sharp chisel (Photo 6).

Band saw the rear leg blanks to 5 in. wide

and 2-3/4 in. thick. Plane them smooth

and lay out the side profile.

Notice that the arm mortises in the rear legs are

cut at a 7-1/2 angle to allow the arms to be level.

To start the angled mortises, clamp a block with a

square end to the vertical face of a leg and use it

as a guide to drill out most of the waste (Photo 7).

Then, use a sharp chisel to finish each mortise.

Crosscut the top end of each rear leg so that it's

square to the angled face of the leg. Chamfer the

ends with a block plane (Photo 8).

Use a band saw to cut the rear legs from

the blanks. Be sure to keep the saw kerf

on the waste side of the layout line.

Use a sharp plane to smooth the sawn

surfaces. Switch to sandpaper or a

scraper at the back inside corner.

Mark the mortise locations on the front

and rear legs, and use a plunge router

and edge guide to make the cuts.

After the routing has been completed, use

a sharp chisel to square the rounded ends

of each leg mortise.

To cut the angled arm mortises, clamp a

board to the leg to act as a guide. Bore

holes, then finish with a chisel.

Crosscut the leg top so that it's square to

the angled face of the leg. Use a chisel or

block plane to chamfer the end.

Bench Rails

Rip and crosscut 1-in.-thick stock for the rails.

Also, cut a piece of 2 x 4 stock to size for the

center seat-support rail. Use a scrap stick as a

beam compass to mark the 39-3/4-in. radius on

the top side rails and center rail, but don't cut the

curves at this point. Install a dado blade in the

table saw and cut the tenons on the ends of the

side, front and back rails (Photo 9). Use the table

saw rip fence as a stop to ensure that the tenons

are of equal length. Readjust the blade height to

cut the shoulder at the top and bottom edge of

each tenon.

Clamp a scrap fence to the table saw fence and

position it so that only 1/2 in. of the dado blade

will be exposed. Turn on the saw and raise the

blade to a height of 7/8 in., and cut the tenons on

the top ends of the front legs (Photo 10). Readjust

the saw again to cut the tenons on the ends of the

center seat-support rail.

Use a dado blade in the table saw to cut

the rail tenons. The rip fence acts as a

stop to ensure tenons of equal length.

Next, mark the locations of the slat mortises in the

side, front and back rails and use a plunge router

to cut them (Photo 11). Since the rails are narrow,

clamp a second board to the workpiece to help

support the router base. Square the mortise ends

with a sharp chisel. Work carefully when making

these cuts, as there are no shoulders on the slats

to hide oversize mortises.

Lay out the mortises for the center seat-support

rail in the front and back rails. Use a Forstner bit

in a drill press to remove most of the waste

(Photo 12), and square with a chisel. Then, cut

the curved profiles on the side and center support

rails, and rip and crosscut the bench slats to

finished size.

To cut the tenons on top of the legs, raise

the dado blade into a scrap fence to yield

a 1/2-in.-wide x 7/8-in.-high cut.

Assembly

Begin assembly by joining a set of slats to the

side rails (Photo 13). It isn't necessary to glue the

slats in place since they will be held captive

between the rails, but if they fit too loosely, you

can place a spot of glue in the mortises to prevent

them from rattling.

Spread glue in the leg mortises and on the side

rail tenons, assemble one of the bench sides, and

clamp until the glue sets (Photo 14). Repeat the

process for the other side.

Rout the slat mortises in the bench rails.

Clamp a second board to the workpiece to

help support the router base.

Mark the mortise locations for the center

seat-support rail. Use a Forstner bit to

remove most of the waste.

After cutting the curved rail profiles, press

the side slats firmly into their mortises. It's

not necessary to use glue.

Spread glue in the leg mortises and side

rail tenons, and assemble one of the

bench sides. Clamp until the glue sets.

Join the slats to the front rails. If necessary, use

three or four clamps to press the slats all the way

into the joints (Photo 15). Then, spread glue in the

front and back rail mortises and on the center rail

tenons, and join the parts (Photo 16). Use a

clamp to pull the joints tight, and set the assembly

aside to let the glue dry (Photo 17).

Assemble the back rails and slats and join this

subassembly to one of the bench sides (Photo

18). When the glue cures, join the front and back

seat rail assembly to the same side. Complete the

bench frame by joining the opposite side to the

rail ends.

Rip and crosscut 3/4-in. stock to size for the seat

slats. Adjust the table saw blade angle to 9-1/2

and bevel one edge of the front and back slats.

Leave the rest of the slat edges square. Use a

combination bit to bore screw pilot holes and 3/8in.-dia. x 5/16-in.-deep counterbores in the seat

Use three or four clamps to squeeze the

front rail assembly, pressing the slats to

the bottom of the mortises.

slats. Then, fasten the slats with galvanized deck

screws. Maintain an equal space between the

slats. Use a 3/8-in. plug cutter in your drill press to

cut screw plugs in a cedar board (Photo 19).

Then, spread glue in the screwholes and on the

plugs, and insert a plug into each hole (Photo 20).

When the glue dries, pare each plug flush.

Rip blanks to 4-1/4 in. wide for the arms, and

crosscut them a few inches longer than finished

length. Use a dado blade in your table saw to cut

a square shoulder tenon on the end of each

blank. Then, lay out the angled shoulder and cut

the finished tenon with a sharp backsaw (Photo

21). Refine the cuts with a sharp chisel where

necessary. With the tenons done, crosscut the

arms to finished length.

Mark the location of the mortise on the underside

of each bench arm, and use your drill press with a

Forstner bit to bore overlapping holes that remove

most of the waste. Then, use a sharp chisel to

square the mortise walls. Note that the arm

mortise is elongated so the tenon at the opposite

end of the arm will easily slide into the leg

mortise.

Spread glue in the shallow center rail

mortises and on the seat-support rail

tenons. Then join the parts.

Use a clamp to pull the front rail and back

rail assembly tight to the center seatsupport rail.

Lay out the finished shape of the arms on the

blanks and cut to the lines with a band saw. After

smoothing the sawn edges, join the arms to the

bench using two clamps to ensure pressure is

applied to both joints while the glue sets (Photo

22).

Finishing

Sand the bench with 120-grit sandpaper. Brush

off all sanding dust before applying a finish. We

applied a coat of Cabot Clear Decking Stain to

our bench. This finish is easy to apply and

provides good protection for outdoor pieces.

Brush on a liberal coat and allow it to dry for at

least 24 hours before using the bench.

Join the back to one of the bench sides.

When the glue cures, add the front and

back seat rail assembly to the same side.

Use a plug cutter to make cedar plugs to

cover the seat screws. Pop the plugs free

with a flat-tip screwdriver.

Spread glue in the holes and on the plugs

and place a plug into each hole. Pare

each one flush with a sharp chisel.

After cutting square tenons at the arm

ends, use a backsaw to cut the angled

shoulders. Refine tenons with a chisel.

Join the arms to the bench using two

clamps so pressure is applied to both

joints while the glue sets.

You might also like

- Dancing ClockDocument8 pagesDancing Clockbehnamin_rahmani100% (2)

- The Pochade and Wet Panel Carrier Do It Yourself PlanFrom EverandThe Pochade and Wet Panel Carrier Do It Yourself PlanRating: 4 out of 5 stars4/5 (1)

- Samsung Hw-E450 SM PDFDocument57 pagesSamsung Hw-E450 SM PDFmarianrkwNo ratings yet

- Samsung HW-F450 (ZC) PDFDocument59 pagesSamsung HW-F450 (ZC) PDFboroda2410100% (2)

- Samsung HW-F450 (ZC) PDFDocument59 pagesSamsung HW-F450 (ZC) PDFboroda2410100% (2)

- TimberDocument35 pagesTimberMuskaan Chowdhary75% (8)

- Make A Rocking Muskoka Chair Out of Composite Wood 2 PDFDocument8 pagesMake A Rocking Muskoka Chair Out of Composite Wood 2 PDFCocis CosminNo ratings yet

- Domino Zigzag ChairDocument6 pagesDomino Zigzag ChairAlex Johnston0% (1)

- Oriental Box of Drawers PDFDocument10 pagesOriental Box of Drawers PDFAleksandar Nikolic100% (2)

- Sheet Metal Bench Shear PDFDocument14 pagesSheet Metal Bench Shear PDFmarianrkw100% (1)

- Vastu of Space Directions AlchemyDocument7 pagesVastu of Space Directions AlchemySudhanshu Goswami100% (4)

- WSmith 240Document70 pagesWSmith 240peter100% (3)

- Whittling Is EasyDocument12 pagesWhittling Is EasyRiff Raff100% (6)

- WWMM Stacking SawhorsesDocument8 pagesWWMM Stacking SawhorsesldvierteNo ratings yet

- Dining Room ChairsDocument16 pagesDining Room Chairsrhinorod100% (1)

- Coffe TableDocument15 pagesCoffe TableJun Vargas100% (1)

- Bench - Langcrest - LoveseatDocument5 pagesBench - Langcrest - LoveseatvdbrogerNo ratings yet

- WJ088 Garden BenchDocument13 pagesWJ088 Garden BenchOsvaldo Moraes100% (1)

- Build a boat-shaped barDocument6 pagesBuild a boat-shaped barMark MihalkoNo ratings yet

- Build Classic Cedar Garden Bench Under 40 CharactersDocument11 pagesBuild Classic Cedar Garden Bench Under 40 Charactersvdbroger100% (1)

- Easy-to-Build Kitchen StoolDocument3 pagesEasy-to-Build Kitchen StoolJvlValenzuela100% (1)

- Lawn Swing: IMPORTANT: Read This Before You StartDocument6 pagesLawn Swing: IMPORTANT: Read This Before You StartBill RNo ratings yet

- Swing Garden SwingDocument7 pagesSwing Garden SwingAlicia MariaNo ratings yet

- Roll Around Kitchen Cart: MLCS Items UsedDocument15 pagesRoll Around Kitchen Cart: MLCS Items UsedTETSUO111No ratings yet

- Arbor - Lath Arch Rose ArborDocument6 pagesArbor - Lath Arch Rose ArborDaniel LourençoNo ratings yet

- Porch Swing: Project 16258EZDocument5 pagesPorch Swing: Project 16258EZBSulli100% (1)

- Country Bench: Project 10307EZDocument8 pagesCountry Bench: Project 10307EZBSulliNo ratings yet

- Woodworking Guide - Basic JoineryDocument6 pagesWoodworking Guide - Basic JoineryMrPaulCorcoran100% (1)

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideFrom EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideNo ratings yet

- Building Outdoor Furniture: Classic Deck, Patio & Garden Projects That Will Last a LifetimeFrom EverandBuilding Outdoor Furniture: Classic Deck, Patio & Garden Projects That Will Last a LifetimeNo ratings yet

- Boxes to Build: Sturdy & Stylish Projects to Organize Your Home & ShopFrom EverandBoxes to Build: Sturdy & Stylish Projects to Organize Your Home & ShopNo ratings yet

- Easy DIY Adirondack Chair and Table PlansDocument11 pagesEasy DIY Adirondack Chair and Table PlansMoises Martins RochaNo ratings yet

- Small Colonial Bench: Project 10297EZDocument5 pagesSmall Colonial Bench: Project 10297EZmhein68No ratings yet

- Build Beautiful Mendocino BenchDocument5 pagesBuild Beautiful Mendocino BenchvdbrogerNo ratings yet

- The Lutyens Garden BenchDocument8 pagesThe Lutyens Garden BenchAdrian CocisNo ratings yet

- Barn Door Baby GateDocument17 pagesBarn Door Baby GateNovitates1No ratings yet

- Intermediate Project Storage BinsDocument10 pagesIntermediate Project Storage BinsTyler BassNo ratings yet

- Çalışma Tezgahı PlanıDocument14 pagesÇalışma Tezgahı PlanıÖmür Eryüksel50% (2)

- Picture BoxDocument3 pagesPicture BoxEmilian BalutaNo ratings yet

- 2 - Woodworking Plans - OakplateDocument6 pages2 - Woodworking Plans - OakplatemacpatorNo ratings yet

- Mission Style Open Shelf Bathroom Vanity: AdvancedDocument22 pagesMission Style Open Shelf Bathroom Vanity: AdvancedMaricruz Valdivieso de PalaciosNo ratings yet

- Stickley Done Lightly in Curly MapleDocument6 pagesStickley Done Lightly in Curly Mapleroose1100% (2)

- Rotating Barrel ComposterDocument3 pagesRotating Barrel Compostertraction9261No ratings yet

- Adirondack Chair: ModerateDocument15 pagesAdirondack Chair: ModeratealexnmNo ratings yet

- Slatted Outdoor SofaDocument12 pagesSlatted Outdoor SofaJh CtNo ratings yet

- Stacking Desk Tray: Project 19874EZDocument4 pagesStacking Desk Tray: Project 19874EZBSulliNo ratings yet

- Tilting Mirror Stand - FH96DJADocument7 pagesTilting Mirror Stand - FH96DJAJvlValenzuelaNo ratings yet

- Folding chair planDocument16 pagesFolding chair planOswal OsunaNo ratings yet

- Box Joint Jig PlanDocument8 pagesBox Joint Jig PlanLarry MullinsNo ratings yet

- Hank Ou: Get More From Your Table SawDocument6 pagesHank Ou: Get More From Your Table Sawasg0401No ratings yet

- Simple Elegance: A Table With Few Parts and Uncomplicated Joinery Proves That Less Is MoreDocument5 pagesSimple Elegance: A Table With Few Parts and Uncomplicated Joinery Proves That Less Is Moreanca mariaNo ratings yet

- How To Build Modern Barstools Like A ProDocument17 pagesHow To Build Modern Barstools Like A Progerman100% (1)

- Pine Desk Organizer: Project 13782EZDocument6 pagesPine Desk Organizer: Project 13782EZBSulli100% (1)

- Blanketchest PlanDocument15 pagesBlanketchest PlanGuillermo WeylandNo ratings yet

- Dresser PlanDocument11 pagesDresser PlanGsmHelpNo ratings yet

- Creating A Ring HolderDocument3 pagesCreating A Ring Holderapi-522254901No ratings yet

- Leg Tapering Jig: Project 14585EZDocument5 pagesLeg Tapering Jig: Project 14585EZBSulliNo ratings yet

- PostarA Bench Built To LastDocument6 pagesPostarA Bench Built To Lastbonte01100% (2)

- Precision Drill Frame ConstructionDocument7 pagesPrecision Drill Frame ConstructionMahesa SanggadipaNo ratings yet

- Garden Bench: Woodworks: Intermediate ProjectDocument9 pagesGarden Bench: Woodworks: Intermediate ProjectRenos Konstantinou100% (1)

- Wall Hung Magazine and Book Rack: Project 14211EZDocument3 pagesWall Hung Magazine and Book Rack: Project 14211EZBSulliNo ratings yet

- ParquetDocument4 pagesParquetFernando FrayreNo ratings yet

- Triple Tier Jewelry BoxDocument8 pagesTriple Tier Jewelry BoxRossNo ratings yet

- Chiefsshop Rockinghorse PDFDocument13 pagesChiefsshop Rockinghorse PDFNicolas TerjekNo ratings yet

- Bowl Basics 2Document5 pagesBowl Basics 2api-522254901No ratings yet

- Deluxe Router TableDocument27 pagesDeluxe Router Tableiacob_gilberto6473100% (1)

- Kreg Tool - Innovative Solutions For All of Your Woodworking and DIY Project NeedsDocument5 pagesKreg Tool - Innovative Solutions For All of Your Woodworking and DIY Project NeedsFernandoNo ratings yet

- Lista de Preturi2Document1 pageLista de Preturi2Ene Alexandru-MihaiNo ratings yet

- Compatible ModemsDocument1 pageCompatible ModemsmarianrkwNo ratings yet

- Bench - Gardening Bench PDFDocument2 pagesBench - Gardening Bench PDFmarianrkwNo ratings yet

- Bench - Lawn-Bench PDFDocument5 pagesBench - Lawn-Bench PDFmarianrkwNo ratings yet

- The Hacker's Manual 2015Document146 pagesThe Hacker's Manual 2015Amanda Dean100% (7)

- Bench - Mendicino Bench PDFDocument3 pagesBench - Mendicino Bench PDFmarianrkwNo ratings yet

- Bench Sun Lounge With PlantersDocument7 pagesBench Sun Lounge With PlantersmarianrkwNo ratings yet

- Bench - Greenhouse-Benches PDFDocument1 pageBench - Greenhouse-Benches PDFmarianrkwNo ratings yet

- Bench - Outdoor Table and Bench PDFDocument9 pagesBench - Outdoor Table and Bench PDFmarianrkwNo ratings yet

- Bench - Gardenbench PDFDocument4 pagesBench - Gardenbench PDFmarianrkwNo ratings yet

- Bench - Garden-Sofa PDFDocument6 pagesBench - Garden-Sofa PDFmarianrkwNo ratings yet

- Bench - Garden Seat 3 SeaterDocument3 pagesBench - Garden Seat 3 SeatervdbrogerNo ratings yet

- Build Beautiful Mendocino BenchDocument5 pagesBuild Beautiful Mendocino BenchvdbrogerNo ratings yet

- 4 Board BenchDocument3 pages4 Board Bench- yAy3e -No ratings yet

- BancaDocument1 pageBancabogd32000No ratings yet

- 4 Board BenchDocument3 pages4 Board Bench- yAy3e -No ratings yet

- Bench - Garden-Bench2 PDFDocument1 pageBench - Garden-Bench2 PDFmarianrkwNo ratings yet

- Bench - Garden Redwood Bench PlansDocument3 pagesBench - Garden Redwood Bench PlansvdbrogerNo ratings yet

- Bench - Entryway Storage Bench Plans PDFDocument9 pagesBench - Entryway Storage Bench Plans PDFmarianrkw100% (1)

- Bench - Fifers BenchDocument6 pagesBench - Fifers BenchvdbrogerNo ratings yet

- Bench - Deacons Bench (Part 2) PDFDocument1 pageBench - Deacons Bench (Part 2) PDFmarianrkwNo ratings yet

- Bench - Deacons BenchDocument6 pagesBench - Deacons BenchvdbrogerNo ratings yet

- Bench - Deacons Bench (Part 1) PDFDocument1 pageBench - Deacons Bench (Part 1) PDFmarianrkwNo ratings yet

- Principles of Macroeconomics 8Th Edition Mankiw Solutions Manual Full Chapter PDFDocument36 pagesPrinciples of Macroeconomics 8Th Edition Mankiw Solutions Manual Full Chapter PDFwilliam.hayslett748100% (12)

- Woodworking Crafts May 2016Document92 pagesWoodworking Crafts May 2016Frederico WernerNo ratings yet

- Wooden Flooring: A Presentation by - Bapi BiswasDocument17 pagesWooden Flooring: A Presentation by - Bapi BiswasPriya RamyaNo ratings yet

- 2 07P01 PDFDocument28 pages2 07P01 PDFMike2322No ratings yet

- Veneer and Laminates in Residential Construction PresentationDocument36 pagesVeneer and Laminates in Residential Construction PresentationVishakhaBhardwajNo ratings yet

- FMT Pro Chapters 4-7Document34 pagesFMT Pro Chapters 4-7MitRomneyNo ratings yet

- Catalogue Specimen 2016Document66 pagesCatalogue Specimen 2016LiteHouseNo ratings yet

- Woodworking Plans and Projects For Beginners The Step-By-Step Guide To Modern Design, Techniques, and Tools To Safely Realize... (White, Woody) (Z-Library)Document122 pagesWoodworking Plans and Projects For Beginners The Step-By-Step Guide To Modern Design, Techniques, and Tools To Safely Realize... (White, Woody) (Z-Library)GordinhorsNo ratings yet

- 134-084 - Dovetail Jig ReviewDocument6 pages134-084 - Dovetail Jig Reviewzalfien1118No ratings yet

- The Technology of Fire: An IntroductionDocument28 pagesThe Technology of Fire: An IntroductionFEI RIENo ratings yet

- Good Woodworking - December 2015 PDFDocument100 pagesGood Woodworking - December 2015 PDFmajdirossross0% (1)

- Pole LoadingDocument27 pagesPole LoadingKho C AhlNo ratings yet

- Abrasive & Cutting Tools Product CatalogueDocument4 pagesAbrasive & Cutting Tools Product CataloguejengandxbNo ratings yet

- Measure and Mark Tools for WoodworkingDocument5 pagesMeasure and Mark Tools for Woodworkingtayah_16090No ratings yet

- Detailed Lesson Plan I. ObjectivesDocument4 pagesDetailed Lesson Plan I. ObjectivesRonnel RemediosNo ratings yet

- Merkel HouseDocument15 pagesMerkel HouseschanleyNo ratings yet

- The Manufacturing Process of The Decorative Laminates Involves Many Steps Starting From Impregnating The Paper To Thermosetting To FinishingDocument22 pagesThe Manufacturing Process of The Decorative Laminates Involves Many Steps Starting From Impregnating The Paper To Thermosetting To Finishingaliyah khalidNo ratings yet

- Dwnload Full Design of Wood Structures Asd LRFD 6th Edition Donald Breyer Solutions Manual PDFDocument36 pagesDwnload Full Design of Wood Structures Asd LRFD 6th Edition Donald Breyer Solutions Manual PDFmarieramirezsaqdmkpfgb100% (12)

- Chapter ReviewsDocument16 pagesChapter ReviewsLélio CaiadoNo ratings yet

- Terminalia Catappa Tropical AlmondDocument21 pagesTerminalia Catappa Tropical AlmondAndrea May PolvorosaNo ratings yet

- Plywood Spec 6V.3Document27 pagesPlywood Spec 6V.3Warren DenholmNo ratings yet

- Yellow Discoloration in OakDocument4 pagesYellow Discoloration in Oakmeans.infoNo ratings yet

- Carpentry and Joinery Draft.Document3 pagesCarpentry and Joinery Draft.vincent rotichNo ratings yet

- Catalogo 14 PDFDocument258 pagesCatalogo 14 PDFJuan Manuel VizosoNo ratings yet

- BST (Basic Tecchnology) JSS 2Document111 pagesBST (Basic Tecchnology) JSS 2Moses AhmedNo ratings yet