Professional Documents

Culture Documents

Design, Construction and Evaluation of A Small Scale Solar Dryer

Uploaded by

Dinesh PoudelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design, Construction and Evaluation of A Small Scale Solar Dryer

Uploaded by

Dinesh PoudelCopyright:

Available Formats

See

discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/281821085

Design, construction and evaluation of Solar

dryer

RESEARCH SEPTEMBER 2015

DOI: 10.13140/RG.2.1.3370.2886

READS

274

1 AUTHOR:

Sunday Sobowale

Moshood Abiola Polytechnic

18 PUBLICATIONS 8 CITATIONS

SEE PROFILE

Available from: Sunday Sobowale

Retrieved on: 22 March 2016

Journal of Engineering and Applied Science

Volume 4, June 2012

2012 Cenresin Publications

www.cenresinpub.org

DESIGN, CONSTRUCTION AND EVALUATION OF A SMALL SCALE SOLAR DRYER

1

Onigbogi I.O, Sobowale, S. S and Ezekoma, O.S

Department of Food Technology,

Moshood Abiola polytechnic Abeokuta, Ogun State.

E-mail: sunsam_2003@yahoo.co.uk

ABSTRACT

The solar drying system utilizes solar energy to heat up air and to dry any food substance

loaded, which is beneficial in reducing wastage of agricultural product and helps in

preservation of agricultural product. Based on the limitations of the natural sun drying e.g.

exposure to direct sunlight, liability to pests and rodents lack of proper monitoring, and the

escalated cost of the mechanical dryer, a solar is therefore developed to cater for this

limitation. This project presents the design and construction of a domestic passive solar

dryer.The dryer is composed of solar collector (air heater) and a solar drying chamber

constraining rack of three cloth (net) trays both being integrated together. The air allowed in

through air inlet is heated up in the solar collector and channeled through the drying

chamber where it is utilized in drying. The design was based on the geographical location

which is Abeokuta and meteorological data were obtained for proper design specification.

The dimensions of the dryer is 94cm x 45cm x 101cm / 20cm (length x width x height).

Locally available material were used for the construction, chiefly comprising of wood

(gmelina), glass, aluminum metal sheet, copper and net cloth for the trays. The optimum

temperature of the dryer is 50.50OC with a corresponding ambient temperature of 34.50o C.

The moisture content removal of 43.2% and 40.6% in maize and plantain respectively using

the solar dryer was achieved as against 28.2% and 27.89% in maize and plantain using the

sun drying method and indication 15.0% and 12.71% difference respectively, the rapid rate

of drying in the dryer reveals its ability to dry food items reasonable rapidly to a safe

moisture.

Keywords: Solar dryer, Moisture loss, Design and Construction, Maize and Plantain

INTRODUCTION

Crop drying is the most energy consuming process in all processes on the farm. The purpose

of drying is to remove moisture from the agricultural produce so that it can be processed

safely and stored for increased periods of time. Crops are also dried before storage or, during

storage, by forced circulation of air, to prevent spontaneous combustion by inhibiting

fermentation. It is estimated that 20% of the worlds grain production is lost after harvest

because of inefficient handling and poor implementation of post-harvest technology, says

Hartmans (1991). Grains and seeds are normally harvested at a moisture level between 18%

and 40% depending on the nature of crop. These must be dried to a level of 7% to 11%

depending on application and market need. Once a cereal crop is harvested, it may have to

be stored for a period of time before it can be marketed or used as feed. The length of time

a cereal can be safely stored will depend on the condition it was harvested and the type of

storage facility being utilized. Grains stored at low temperature and moisture contents can

be kept in storage for longer period of time before its quality will deteriorate. Some of the

8

Design, Construction and Evaluation of a Small Scale

Solar Dryer

Onigbogi I.O, Sobowale, S. S and Ezekoma, O.S

cereals which are normally stored includes maize, rice, beans. Osagieand Eka (1998). Solar

drying may be classified into direct and indirect solar dryer. In direct solar dryers the air

heater contains the grains and solar energy which passes through a transparent cover and is

absorbed by the grains. Essentially, the heat required for drying is provided by radiation to

the upper layers and subsequent conduction into the grain bed. However, in indirect dryers,

solar energy is collected in a separate solar collector (air heater) and the heated air then

passes through the grain bed, while in the mixed-mode type of dryer, the heated air from a

separate solar collector is passed through a grain bed, and at the same time, the drying

cabinet absorbs solar energy directly through the transparent walls or the roof.

The objective of this study is to develop a mixed-mode solar dryer in which the grains are

dried simultaneously by both direct radiation through the transparent walls and roof of the

cabinet and by the heated air from the solar collector, as described by (Leon, et al 2002).

The problems of low and medium scale processor could be alleviated, if the solar dryer is

design and constructed with the consideration of overcoming the limitations of direct and

indirect type of solar dryer. So therefore, this work will be based on the importance of a

mixed mode solar dryer which is reliable and economically. The objectives of the work is to

design and construct a mixed mode solar dryer using locally available materials and to

evaluate the performance of the solar dryer.

MATERIALS AND METHODOLGY

Factors considered in selecting the engineering materials for the fabrication of the

equipment were:

i.

Cost of the fabrication.

ii.

Mechanical properties of materials (e.g. stress, creep, fatigue etc).

iii.

Corrosion resistance.

iv.

Ease of fabrication (e.g. forming, nailing, bending, cutting etc)

v.

Service requirement.

Considerations were also given to the most economical materials that satisfy both

process and mechanical requirements, over the working life of the solar dryer,

allowing for easy loosening, maintenance and replacement. Finally the selected

materials to be used were ensured of having sufficient strength and easily worked

with.

Method

Construction of the mixed-mode solar dryer

The materials used for the construction of the mixed-mode solar dryer are cheap and easily

obtainable in the local market. The solar dryer consists of the solar collector (air heater), the

drying cabinet and drying trays.

Journal of Engineering and Applied Science

Volume 4, June 2012

Solar Dryer Components

Drying Chamber: The drying chambers is a highly polished plywood box held in place by

angle iron, the material has been chosen since wood is a poor conductor of heat and its

smooth surface finish, heat loss by radiation is minimized.

Cover plate: This is a transparent sheet used to cover the absorber, thereby preventing

dust and rain from coming in contact with the absorber, it also retards heat from escaping,

common materials used for cover plates is a glass.

Absorber plate: This is a metal painted black and placed below the cover to absorb the

incident solar radiation transmitted by cover, thereby heating the air between it and the

cover, here aluminum is chosen because of its quick response in the absorption of solarradiation.

Insulation: This is used to minimize heat loss from the system, it is under the absorber

plate, the insulator must be able to withstand stagnation temperature, it should be fire

resistant and not subject to out-going gassing and should not be damageable by moisture or

insect.

The Orientation of the Solar Collector:

The flat-plate solar collector is always tilted and oriented in such a way that it receives

maximum solar radiation during the desired season of used. The best stationary orientation

is due South in the northern hemisphere and due north in Southern hemisphere. Therefore,

solar collector in this work is oriented facing south and tilted at 17.110 to the horizontal. This

is approximately 100 more than the local geographical latitude (Abeokuta a location in

Nigeria, 7.110N), which according to Adegoke and Bolaji (2000), is the best recommended

orientation for stationary absorbers. This inclination is also to allow easy run off of water and

enhance air circulation.

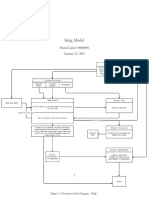

Design Consideration

Calculation: This entails all the mathematical approaches and formula used in

obtaining the dimensions.

Drawing: This shows the pictorials of the extended machine being designed.

Fabrication: This is the final structure developed from combination of the calculations and

drawing

Fig 1: Design of Solar Dryer (Sectional view).

Design Calculations

1.

Angle of Tilt () of Solar Collector/Air Heater.

The angle of tilt () of the solar collector is given by the formula

below:

= 100 + at

(Alamu, 2010)

where, lat is the attitude of the collector location,

10

Design, Construction and Evaluation of a Small Scale

Solar Dryer

2.

3.

Onigbogi I.O, Sobowale, S. S and Ezekoma, O.S

.

Insolation on the Collector Surface Area.

A researcher obtained the value of insolation for Abeokuta i.e. average daily

radiation H on horizontal surface as H = 978.69W/m2 (Olaleye 1996) and average

effective ration of solar energy on tilted surface to that on the horizontal surface R as;

R = 1.0035

(Olaleye 1996)

Determination of Collector Area and Dimension.

The air gap height was taken as 5.6cm 0.056m and the width of the collection

assumed to be 45cm 0.45m.

Thus, volumetric flow rate of air Va =Va x 0.056 x 0.38

Va = 0.15 x 0.056 x 0.38 = 3.19 x 10-3m3/s

Thus mass flow rate of air: Ma = vapa (dorf, 1989)

Density of air is taken as 1.2252kg/m3 at S.T.P.

4.

Determination of the Base Insulator Thickness for the Collector

For the design, the thickness of the insulator was taken as 7cm. The side of the collector

was made of wood, the loss through the side of the collector will be considered negligible.

5.

Dryer efficiency: This is given as,

Efficiency (%) = work output/work input x 100/1

(Ezekoye, 2006)

Where (work output) is the final mass of the crop after drying and (work input) is the

initial mass of the crop before drying.

6.

Moisture Content (M.C.): The moisture content is given as:

M.C =(M1-M2)/M1

(Ezekoye, 2006)

Where M1 = mass of sample before drying and M2 = mass of sample after drying.

7.

Moisture loss ML: The moisture Loss is given as

= (M1-M2) (g).

(Ezekoye, 2006)

Where M1 is the mass of the sample before drying and M2 is the mass of the sample

after.

8.

Design dimension of the chamber

Dimensions are in cm

1000cm = 1liter

capacity:

(L * W * B)/ 1000

11

Journal of Engineering and Applied Science

Volume 4, June 2012

RESULTS AND DISCUSSION

Results

1.

Angle of Tilt () of Solar Collector/Air Heater.

The angle of tilt () of the solar collector is given by the formula

below:

= 10o + at

(Alamu, 2010)

where lat is the attitude of the collector location, the latitude of Abeokuta where

the dryer was designed is latitude 7.110N.

Hence, the suitable value of use for the collector:

= 100 + 7.110 = 17.110.

2.

Insolation on the Collector Surface Area.

A research obtained the value of insolation for Abeokuta i.e. average daily

radiation H on horizontal surface as H = 978.69W/m2 (Olaleye 1996) and average

effective ration=of solar energy on tilted surface to that on the horizontal surface R

as; R = 1.0035 (Olaleye 1996).

Thus, insolation on the collector surface was obtained as

1c = HT = HR = 978.69 x 1.0035 = 982.11W/m2

(GEDA-Gujarat Energy

Development Agency, 2003).

3.

Determination of Collector Area and Dimension.

The air gap height was taken as 5.6cm 0.056m and the width of the collection

assumed to be 45cm 0.45m.

Thus, volumetric flow rate of air Va =Va x 0.056 x 0.38

Va = 0.15 x 0.056 x 0.38 = 3.19 x 10-3m3/s

Thus, mass flow rate of air: Ma = vapa (Dorf, 1989)

Density of air is taken as 1.2252kg/m3 at S.T.P.

Ma = 3.19 x 10.3 x 1.2252 = 3.91 x 10.3kg/s

Therefore, area of the collector AC

AC = (3.91 x 10-3 x 1000 x 30)/(0.5 c 982.11) = 0.239m2

The length of the solar collector (L) was taken as;

L = Ac/B = 0.3537/0.45 = 0.53m. Thus, the length of the solar collector was taken

approximately as 0.6m

Therefore, collector area was taken as (0.45 x 0.53) 2 = 0.239m2

4.

Determination of the Base Insulator Thickness for the Collector

For the design, the thickness of the insulator was taken as 7cm. The side of the

collector was made of wood, the loss through the side of the collector will be

considered negligible.

Where M1 is the mass of the sample before drying and M2 is the mass of the sample

after.

12

Design, Construction and Evaluation of a Small Scale

Solar Dryer

5.

Onigbogi I.O, Sobowale, S. S and Ezekoma, O.S

Design dimension of the chamber

Dimensions are in cm

1000cm = 1liter

Capacity: (45 * 45 * 50)/ 1000 = 101.25 liters

Mass of water removed = (560-318)g =242g

% of total moisture content loss in maize = initial mass final mass x 100

(On wet basis)

Initial mass

1

=560- 318 x 100

= 43.2%

560

1

% efficiency of the dryer with maize = work output/work input x 100/1

=

318 x 100

560

1

=56.78% per day

(for 9hrs during the day light)

Mass of water removed = (276- 163.8)g

=112.2g

% of total moisture content loss in plantain = initial mass final mass x 100

(On wet basis)

Initial mass

=

276- 163.2 x 100

= 40.6%

276

1

% efficiency of the dryer with plantain = work output/work input x 100/1

=

163.2 x 100

276

=59.13% per day

(for 9hrs during the day light)

Table 3 and 4 shows the variation in the moisture content removed in the case of both solar

drying and sun drying and Table 4.5 shows evaluated parameter of the solar dryer obtained.

DISCUSSION

Fig.2 shows a typical day results of the hourly variation of the temperatures in the solar

collector and the drying cabinet compared to the ambient temperature. The dryer is hottest

about mid-day when the sun is usually overhead. The temperatures inside the dryer and the

solar collector were much higher than the ambient temperature during most hours of the

daylight. The temperature rises inside drying cabinet for about three hours immediately after

12.00h (noon). This indicates prospect for better performance than open-air sun drying. Fig.

13

Journal of Engineering and Applied Science

Volume 4, June 2012

2 shows the diurnal variation of the relative humidity of the ambient air and drying chamber.

Comparison of this figure with Fig.1 shows that the drying processes were enhanced by the

heated air at very low humidity Fig. 3 shows the drying curve for maize and Plantain slices in

the solar dryer. It was observed that the drying rate increased due to increase in

temperatures between 10.00h and 14.00h but decreased thereafter, which shows the earlier

and faster removal of moisture from the dried item. The total moisture content removed are

43.2%and 40.6% in maize and plantain respectively using the solar dryer was achieved

against 28.2% and 27.89% in maize and plantain respectively using the sun drying method.

The efficiency of the mixed-mode solar dryer during the test period was found to be 56.78%

and 59.13% in maize and plantain respectively.

CONCLUSION

From the test carried out, the following conclusions were made.The solar dryer can raise the

ambient air temperature to a considerable high value for increasing the drying rate of

agricultural crops. The product inside the dryer requires less attentions, like attack of the

product by rain or pest (both human and animals), compared with those in the open sun

drying. Although the dryer was used to dry maize and plantain, it can be used to dry other

crops like yams, cassava etc. There is ease in monitoring when compared to the natural sun

drying technique. The capital cost involved in the construction of a solar dryer is much lower

to that of a mechanical dryer. The collector and dryer efficiencies are very reasonable.

RECOMMENDATION

The performance of existing solar food dryers can still be improved upon especially in the

aspect of reducing the drying time, and probably storage of heat energy within the system by

increasing the size of the solar collector. Also, meteorological data should be readily

available to users of solar products to ensure maximum efficiency and effectiveness of the

system. Such information will probably guide a local farmer on when to dry his agricultural

produce and when not to dry them.

TABLE 1: Hourly Moisture Loss and Mass of the maize

Time

9.00

10.00

11.00

12.00

13.00

14.00

15.00

16.00

17.00

18.00

Mass

of Moisture

maize(g)

loss

(g)

560

547

13

528

19

503

25

474

29

436

38

399

37

365

34

338

27

318

20

%

Moisture

loss

2.3

3.4

4.5

5.2

6.8

6.6

6.0

4.8

3.6

14

Total

Moisture

Loss (%)

58

55.7

52.3

47.8

42.6

35.8

29.2

23.2

18.4

14.8

Design, Construction and Evaluation of a Small Scale

Solar Dryer

Onigbogi I.O, Sobowale, S. S and Ezekoma, O.S

TABLE 2: Hourly Moisture Loss and mass of the Plantain

9.00

10.00

11.00

12.00

13.00

14.00

15.00

16.00

18.00

18.00

Time Mass

of Moisture

plantain(g)

loss

(g)

276

271.9

4.1

263.5

8.4

252.8

10.7

238.6

14.2

222.9

15.7

205.4

17.5

188.9

16.5

175

13.9

163.8

11.2

%

Moisture

Loss

1.5

3

3.9

5.2

5.7

6.3

6

5

4.1

TABLE 3: Solar drying

MAIZE

Initial

Mass

(g)

560

PLANTAIN

Final

Mass

(g)

318

Total % moisture loss

43.2%

TABLE 4: Sun-drying

MAIZE

Initial

Final

Mass

Mass

(g)

(g)

560

402

Total % moisture loss

28.2%

Initial

Mass

(g)

276

Final

Mass

(g)

163.8

Total % moisture loss

40.6%

PLANTAIN

Initial

Mass

(g)

276

Final

Mass

(g)

199

Total % moisture loss

27.89%

15

Total

moisture

loss (%)

72

70.5

67.5

63.6

58.4

52.7

46.4

40.4

35.4

31.3

Journal of Engineering and Applied Science

Volume 4, June 2012

Table 5: Evaluated Parameters of the Dryer

Parameter

Values Obtain

Insolation on the Collector Surface

982.11 W/m2

Total moisture content loss

(on wet

basis)

For maize

43.2%

For plantain

40.6%

Dryer capacity

9kg (but depends on the volume and

nature of the product)

Dryer efficiency

With maize

56.78% per day for 9hrs during

With plantain

59.13% per day the day light

Volume of Dryer chamber

101.25liters

r (V)

Collector Area (A)

0.238m2

Collector Efficiency c

37.9% (average)

Collector slope ()

17.11o

The Design

Sectional view

45

50

70

53

20

45

98

17

16

Design, Construction and Evaluation of a Small Scale

Solar Dryer

Onigbogi I.O, Sobowale, S. S and Ezekoma, O.S

Temperature (oC)

70

Collector

Drying chamber

Ambient

60

50

40

30

20

10

0

9

11

13

15

17

19

Local time (hour)

Fig. 2: A typical day results of the diurnal variation of temperatures in the

solar dryer.

17

Journal of Engineering and Applied Science

Volume 4, June 2012

Relative Humidity

(%)

90

80

70

60

50

40

30

Ambient

Drying chamber

20

10

0

9

11

13

15

Local time (hour)

17

19

Fig. 3: A typical day results of the diurnal variation of relative humidity in the

dryer.

18

Design, Construction and Evaluation of a Small Scale

Solar Dryer

Onigbogi I.O, Sobowale, S. S and Ezekoma, O.S

Total % moisture loss

80

70

60

Plantain

Maize

50

40

30

20

10

0

9

11

13

15

Local time (hour)

17

19

Fig. 4: Drying curve for maize and plantain slices

Journal of Engineering and Applied Science

Volume 4, June 2012

REFERENCES

1. Adegoke, C. O.; and Bolaji, B.O. 2000. Performance evaluation of solar-operated

thermo siphon hot water system in Akure, International Journal of Technology 2(1);

35-40.

2. Adegoke, G. O. and Adebayo, C. O. (1994). Production, nutritional profiles

and storability of aadun and kokoro, two corn products. Plant food Hum.

Nutr. 45,139-144.

19

Journal of Engineering and Applied Science

Volume 4, June 2012

3. Akinola, A.O. and Fapetu O.P. 2006, Exergetic analysis of a mixed mode solar dryer.

Journal of Solar Energy and Applied. Science 1:205-10

Akinola, O.A; Akinyemi, A.A.; and Bolaji B.O. 2006. Evaluation of traditional and solar

fish drying systems towards enhancing fish storage and preservation in Nigeria.

J. Fish. Int., Pakistan 1(3-4); 44.9

4. Alamu O.J., Nwachucha C.N and Adunola O. 2010. Design and construction of a

domestic passive solar food dryer, Leonardo Journal of Sciences, P.71-82.

5. Bahnasawy. A.J. and Shenana J.R. 2004. Evaluation of a solar crop dryer for rural

application in Nigeria, Botswana Journal Technology 11(2); 58-62

6. Bena T.Y. and Fuller K.K. 2002. Determination of the average coefficient of internal

moisture transfer during the drying of a thin bed of potato slice. Journal Food

Engineering. 48(2) 95-101.

7. Bolako B.O 2005. Performance evaluation of a simple solar dryer for food

preservation. proc.6th Ann. Engin. Conf. of School of engineering and Engineering

Technology. Minna, Nigeria. Pp.8-13.

8. Ekechukwu I. and Norton S.D. 1999. Development and use of solar drying

technologies. Nigerian Journal of Solar Energy 89: 133-64.

9. Enein N.E. 2000. Experimental investigation of solar air heater with free and fixed

fins: efficiency and energy loss. International Journal of Science 1(1); 75-82.

10. Ertekin, C,; and Yaldiz, O. 2004, Drying of egg plant and selection of a suitable thin

layer drying model, Journal Food Engineering 63:349-59

11. Hartmans, E.H. (1991). Strategies for Solving Crop Production Problems of

Subsaharan Africa. International Institute of Tropical Agriculture, Ibadan. pp.

7-8.

12. Ihekoronye, A.I. and Ngoddy, P.O. (1991). Integrated Food Science and

Technology for the Tropics. Macmillan Publishers, Hong Kong. p. 386.

13. Ikejiofor, I.D, 1985. Passive solar cabinet dryer for drying agricultural products. In

O.Awe (Editor), African Union of Physics, Solar Energy Conversion, University of

Ibadan, Nigeria, pp.157-65.

14. Osagie, A.U. and Eka, O.U. [Eds.] (1998). Nutritional Quality of Plant Foods.

Post Harvest Research Unit, University of Benin, Benin. pp. 34 -41.

20

Design, Construction and Evaluation of a Small Scale

Solar Dryer

Onigbogi I.O, Sobowale, S. S and Ezekoma, O.S

15. Soponronnarit. O. 1995. A solar air heater with composite absorber systems for

food dehydration Renewable Energy 27:27-37.

16. Waewsak, J; Chindaruksa, S.; and Punlek, C. 2006. A mathematical modeling study

of hot air drying for some agricultural products. Thammasat International Journal

of Science 11(1); 14-20.

21

You might also like

- Design and Fabrication of Spice DryersDocument80 pagesDesign and Fabrication of Spice DryersANAND KRISHNAN100% (2)

- Final Thesis - 2Document48 pagesFinal Thesis - 2pratik giradkarNo ratings yet

- Solar Dryer Final ThesisDocument61 pagesSolar Dryer Final ThesisAdeela Umar100% (4)

- Design and Fabrication of an Oyster Shell Grinding MachineDocument16 pagesDesign and Fabrication of an Oyster Shell Grinding MachineenadburatNo ratings yet

- Design Development of Continuous Flow Grain DryerDocument139 pagesDesign Development of Continuous Flow Grain DryerVishal DuggalNo ratings yet

- ASTM TablesDocument185 pagesASTM Tableslahiru198367% (3)

- C680Document22 pagesC680dinhtung2210100% (2)

- Study of Solar Dryer and Role of Convex Lens in Solar DryerDocument5 pagesStudy of Solar Dryer and Role of Convex Lens in Solar Dryermukesh poundekarNo ratings yet

- Design and Fabrication of Solar DryerDocument10 pagesDesign and Fabrication of Solar DryerAdeela Umar100% (1)

- Thesis Paper On Performance of Enhanced Solar Dryer Integrated With Heat Storage System For Fruits & Vegetables DryingDocument80 pagesThesis Paper On Performance of Enhanced Solar Dryer Integrated With Heat Storage System For Fruits & Vegetables Dryinglily67% (6)

- Commissioning of A Solar Dryer ThesisDocument54 pagesCommissioning of A Solar Dryer ThesishashimhasnainhadiNo ratings yet

- Projects Mech 35-36-4Document85 pagesProjects Mech 35-36-4Angela FasuyiNo ratings yet

- Design Development and Performance Evaluation of Solar Dryer For Drying of Tomato and Onion Slices PDFDocument98 pagesDesign Development and Performance Evaluation of Solar Dryer For Drying of Tomato and Onion Slices PDFErin Walker100% (4)

- Design, Fabrication, and Testing of A Fluidized-Bed Paddy Dryer That Uses A Rice Hull-Fueled Furnace For Prototyping (Journal Article)Document14 pagesDesign, Fabrication, and Testing of A Fluidized-Bed Paddy Dryer That Uses A Rice Hull-Fueled Furnace For Prototyping (Journal Article)Caleb del MundoNo ratings yet

- Grain Drying in Asia Part 4 86776 PDFDocument41 pagesGrain Drying in Asia Part 4 86776 PDFdiego.peinado8856No ratings yet

- Design and Fabrication of Solar DryerDocument45 pagesDesign and Fabrication of Solar DryerKms Basheer100% (1)

- Design and Study of Grain DryerDocument101 pagesDesign and Study of Grain DryerAD DNo ratings yet

- LSU Dryer DesignDocument9 pagesLSU Dryer Designifos upscNo ratings yet

- Biomass Briquetting MachineDocument27 pagesBiomass Briquetting MachinePrincess Joy Tubera GarciaNo ratings yet

- Coconut DryerDocument11 pagesCoconut DryerJohn Joseph MoralNo ratings yet

- Solar DryerDocument41 pagesSolar Dryerchinmay swain100% (2)

- Design and Analysis of Manually Operated Seed Sowing MachineDocument12 pagesDesign and Analysis of Manually Operated Seed Sowing MachinePiyush Narkhede0% (1)

- Rice Husk Furnace Paddy Dryer-Recirculating Dryer-BelonioDocument2 pagesRice Husk Furnace Paddy Dryer-Recirculating Dryer-BelonioEd CasasNo ratings yet

- Design and Fabrication of Waste Paper Recycling Machine For Laboratory and Medium Scale OperationDocument7 pagesDesign and Fabrication of Waste Paper Recycling Machine For Laboratory and Medium Scale OperationKenn MendozaNo ratings yet

- Microclimatic Modification PartsDocument12 pagesMicroclimatic Modification PartsJermaine Aceremo De CastroNo ratings yet

- Solar Rice Dehusking Machine 2 PHASEDocument16 pagesSolar Rice Dehusking Machine 2 PHASEDeiva K100% (1)

- Solar Powered and Hydroelectricity Rice Grain Dryer With GSM Monitoring System - NOMARKUPDocument39 pagesSolar Powered and Hydroelectricity Rice Grain Dryer With GSM Monitoring System - NOMARKUPAris SoloNo ratings yet

- Dokumen - Tips Solar DryerDocument13 pagesDokumen - Tips Solar DryerDashaddNo ratings yet

- Design of Portable Coffee Roaster For Home Industr PDFDocument6 pagesDesign of Portable Coffee Roaster For Home Industr PDFGilberto MontaniNo ratings yet

- .Design and Fabrication of Sand Sieving and Cement Mixing Machine PDFDocument3 pages.Design and Fabrication of Sand Sieving and Cement Mixing Machine PDFPANG JIA JIANNo ratings yet

- Groundnut Thrasher DesignDocument27 pagesGroundnut Thrasher DesignBoopathi KalaiNo ratings yet

- Battery Operated Paddy Dryer With Humidity Level SensorsDocument10 pagesBattery Operated Paddy Dryer With Humidity Level SensorsEm MendozaNo ratings yet

- Chapter 11-Refrigeration CyclesDocument24 pagesChapter 11-Refrigeration CyclesAbas S. AcmadNo ratings yet

- Design Copra DryerDocument5 pagesDesign Copra DryerJulius TajoneraNo ratings yet

- WEAST HEAT RECOVERY Heating Purpose For Woldia University CaftiriaDocument10 pagesWEAST HEAT RECOVERY Heating Purpose For Woldia University CaftiriaMisge ChekoleNo ratings yet

- De-Husking Mechanism For Mini Rice Milling MachineDocument32 pagesDe-Husking Mechanism For Mini Rice Milling MachineSanjay Kang Chul100% (1)

- Aula06 2 Grain DryersDocument27 pagesAula06 2 Grain DryersHarish KumarNo ratings yet

- Design and Fabrication of Coconut de HuskingDocument5 pagesDesign and Fabrication of Coconut de HuskingKenneth LorenzoNo ratings yet

- Paddy Drying: Agricultural Engineering UnitDocument49 pagesPaddy Drying: Agricultural Engineering Unitgirishkumararies0% (1)

- Progress in solar dryersDocument15 pagesProgress in solar dryersvivianaNo ratings yet

- Chapter Four Design and Analysis of Mixer: Material SelectionDocument48 pagesChapter Four Design and Analysis of Mixer: Material SelectionHailemariam WeldegebralNo ratings yet

- III 5 CropProcessing 1 8Document8 pagesIII 5 CropProcessing 1 8SannyBombeoJomocNo ratings yet

- Paes 201 Heated-Air Mechanical Grain Dryer SpecsDocument8 pagesPaes 201 Heated-Air Mechanical Grain Dryer SpecsEdsel Jay RaperNo ratings yet

- Energy and Exergy Analysis of Cassava Starch Dried in Hybrid Solar DryerDocument16 pagesEnergy and Exergy Analysis of Cassava Starch Dried in Hybrid Solar DryerEvan EduardNo ratings yet

- Abstract, Intro, Objectives Tray DryerDocument3 pagesAbstract, Intro, Objectives Tray DryerNawal DaBombNo ratings yet

- Power Operated Coconut Dehusker DevelopmentDocument88 pagesPower Operated Coconut Dehusker DevelopmentSuresh NatarajanNo ratings yet

- Chapter 5.design of Sowing and Planting MachineDocument5 pagesChapter 5.design of Sowing and Planting MachineSiraj Busse100% (2)

- Design of A Modified Hand Operated Maize ShellerDocument15 pagesDesign of A Modified Hand Operated Maize ShellergemeeNo ratings yet

- Machine DesignDocument36 pagesMachine DesignArman Atienza MagcawasNo ratings yet

- Drying Part 1Document166 pagesDrying Part 1WalterNo ratings yet

- Fabrication of Bean Shelling Machine SynopsisDocument2 pagesFabrication of Bean Shelling Machine SynopsisUNITED CADDNo ratings yet

- Unit 1 Solar EnergyDocument176 pagesUnit 1 Solar EnergyAkhil Dayalu100% (1)

- Agricultural Power and Energy EngineeringDocument40 pagesAgricultural Power and Energy EngineeringBlack PhanterNo ratings yet

- Final ProjectDocument64 pagesFinal ProjectMaster MindNo ratings yet

- Dryers and Drying ProcessesDocument65 pagesDryers and Drying ProcessesEyra AngelesNo ratings yet

- Multi Agri Cutter - AbstractDocument4 pagesMulti Agri Cutter - AbstractShankar G75% (4)

- CH 3 Gas Refrigeration CycleDocument20 pagesCH 3 Gas Refrigeration CycleMeleseNo ratings yet

- Corn ThresherDocument3 pagesCorn ThresherAnonymous 1P2S4tbMNo ratings yet

- Design Construction and Evaluation of A Small Scale Solar DryerDocument15 pagesDesign Construction and Evaluation of A Small Scale Solar DryerzahreldinelaliNo ratings yet

- Design Construction and Evaluation of A Small Scale Solar DryerDocument15 pagesDesign Construction and Evaluation of A Small Scale Solar DryerDashaddNo ratings yet

- RETDocument7 pagesRETprathameshdabade15No ratings yet

- Effect of Openings Collectors and Solar Irradiance On The Thermal Efficiency of Flat Plate-Finned Collector For Indirect-Type Passive Solar DryerDocument8 pagesEffect of Openings Collectors and Solar Irradiance On The Thermal Efficiency of Flat Plate-Finned Collector For Indirect-Type Passive Solar DryerSari Farah DinaNo ratings yet

- Steel Bridge AnalysisDocument21 pagesSteel Bridge AnalysisDinesh PoudelNo ratings yet

- Pavement Thickness Measurement MethodDocument7 pagesPavement Thickness Measurement MethodDinesh PoudelNo ratings yet

- TIADRP Final v1-2Document136 pagesTIADRP Final v1-2Dinesh PoudelNo ratings yet

- Fagun & Chaitra 2076 Variation With Cases DORDocument6 pagesFagun & Chaitra 2076 Variation With Cases DORDinesh PoudelNo ratings yet

- Pavement BasicsDocument30 pagesPavement BasicsDinesh PoudelNo ratings yet

- SW Road V2 Operating ManualDocument92 pagesSW Road V2 Operating ManualDinesh PoudelNo ratings yet

- Safety ReportDocument54 pagesSafety ReportDinesh PoudelNo ratings yet

- C 135 ContentDocument122 pagesC 135 ContentDinesh PoudelNo ratings yet

- AH Map - 2018 2Document1 pageAH Map - 2018 2Dinesh PoudelNo ratings yet

- Civil Aviation Authority of Nepal Aerodrome Inspector HandbookDocument188 pagesCivil Aviation Authority of Nepal Aerodrome Inspector HandbookDinesh PoudelNo ratings yet

- Revised Guideline For Estimating Equipment CostDocument2 pagesRevised Guideline For Estimating Equipment CostDinesh PoudelNo ratings yet

- संघ,प्रदेश तथा स्थानिय निकायको पुर्वाधार विकास कार्य क्षेत्र मापदण्ड, - 2076Document24 pagesसंघ,प्रदेश तथा स्थानिय निकायको पुर्वाधार विकास कार्य क्षेत्र मापदण्ड, - 2076Saroj KarkiNo ratings yet

- Issues Road Maintenance PDFDocument19 pagesIssues Road Maintenance PDFJia IdrisNo ratings yet

- Solved CMAT 2021 Slot-1 Paper With SolutionsDocument40 pagesSolved CMAT 2021 Slot-1 Paper With SolutionsAnshul BhallaNo ratings yet

- Construction of Runway of TIA Resumes - Tourism MailDocument3 pagesConstruction of Runway of TIA Resumes - Tourism MailDinesh PoudelNo ratings yet

- Travel Safety and Personal Safety: Resources ChecklistDocument17 pagesTravel Safety and Personal Safety: Resources ChecklistDinesh PoudelNo ratings yet

- SKF CoverDocument9 pagesSKF CoverDinesh PoudelNo ratings yet

- Paving Cost Comparisons Warm-Mix Asphalt vs. ConcreteDocument13 pagesPaving Cost Comparisons Warm-Mix Asphalt vs. ConcreteAira CabacunganNo ratings yet

- Geogrid IntroductionDocument8 pagesGeogrid IntroductionVamsikrishnaGavadakatlaNo ratings yet

- Secugrid Range: No Limits With TheDocument4 pagesSecugrid Range: No Limits With TheDinesh PoudelNo ratings yet

- Norms DUDBC PDFDocument60 pagesNorms DUDBC PDFDebendra Dev Khanal84% (19)

- Secugrid: Advantages of PET/PPDocument4 pagesSecugrid: Advantages of PET/PPDinesh PoudelNo ratings yet

- kathmandu दररेट 78-79Document290 pageskathmandu दररेट 78-79Dinesh PoudelNo ratings yet

- Elecrical Rate 066-067Document146 pagesElecrical Rate 066-067Dinesh PoudelNo ratings yet

- Online SPL Process ManualDocument15 pagesOnline SPL Process ManualDinesh PoudelNo ratings yet

- Heavy Equipment Division Itahari Equipment Hire Rate 2019Document6 pagesHeavy Equipment Division Itahari Equipment Hire Rate 2019santosh sah100% (1)

- Earthworks and Soil CompactionDocument41 pagesEarthworks and Soil Compactiondhan singhNo ratings yet

- Earth Moving Equipment: Power Shovel, Back Hoe, Dragline, Scraper, Dozer and Power ShovelDocument48 pagesEarth Moving Equipment: Power Shovel, Back Hoe, Dragline, Scraper, Dozer and Power ShovelSuson DhitalNo ratings yet

- Engineering CPWD Analysis of Rates - 1Document571 pagesEngineering CPWD Analysis of Rates - 1javedk_33No ratings yet

- Heavy Equipment Division Itahari Equipment Hire Rate 2019Document6 pagesHeavy Equipment Division Itahari Equipment Hire Rate 2019santosh sah100% (1)

- Steam Drum Design CalsDocument78 pagesSteam Drum Design Calsabdulrehmandescon100% (1)

- PhoneticsDocument5 pagesPhoneticsKarensita Totty' HerreraNo ratings yet

- Stepper Motor Driven Solar Tracker SystemDocument4 pagesStepper Motor Driven Solar Tracker SystemFAHMY RINANDA SAPUTRI (066629)No ratings yet

- Pore Structure of Air-Entrained Hardened Cement PasteDocument9 pagesPore Structure of Air-Entrained Hardened Cement Paste1mattelliottNo ratings yet

- History of Contingency Theory: Reporter: Emiliana J. LozanoDocument23 pagesHistory of Contingency Theory: Reporter: Emiliana J. Lozanoaireenclores100% (3)

- CPM cc1 - CH 2 VocabularyDocument3 pagesCPM cc1 - CH 2 Vocabularyapi-252110147No ratings yet

- Joint Design For Reinforced Concrete Buildings: P Ei ErDocument79 pagesJoint Design For Reinforced Concrete Buildings: P Ei ErSergey MatyuninNo ratings yet

- (Architecture Ebook) Alvar Aalto, Alvar Aalto and The Bio-ArchitectureDocument5 pages(Architecture Ebook) Alvar Aalto, Alvar Aalto and The Bio-Architecturepooh86poohNo ratings yet

- Standing Waves On A StringDocument6 pagesStanding Waves On A StringamirpouyanNo ratings yet

- Numerical MethodsDocument9 pagesNumerical Methodsshaz_donNo ratings yet

- Antilinear OperatorsDocument12 pagesAntilinear OperatorsjofoltssonNo ratings yet

- Ising ModelDocument5 pagesIsing Modeldecerto252No ratings yet

- Luo Shu Ancient Chinese Magic Square On Linear AlgDocument12 pagesLuo Shu Ancient Chinese Magic Square On Linear AlgAJAY KUMAR JAINNo ratings yet

- Calcul Evaltn-Embankments Reinforced With geocells-FEM-2015Document14 pagesCalcul Evaltn-Embankments Reinforced With geocells-FEM-2015Rakesh KapoorNo ratings yet

- Clarke and Park TransfomationDocument9 pagesClarke and Park TransfomationGREATJUSTGREATNo ratings yet

- A Study of The Effect of Blasting Vibration On Green ConcreteDocument160 pagesA Study of The Effect of Blasting Vibration On Green ConcreteNattHemat HulinNo ratings yet

- Chocolate RheologyDocument7 pagesChocolate RheologyAdil AnwarNo ratings yet

- Culvert DesignDocument18 pagesCulvert Designseagull700% (1)

- Lucia 1995 Rock-FabricPetrophysical Classification of Carbonate Pore SpaceDocument26 pagesLucia 1995 Rock-FabricPetrophysical Classification of Carbonate Pore SpaceMarcos Antonio Romero Arteaga100% (1)

- Design of Gain Compensator: DR Mirza Tariq HamayunDocument19 pagesDesign of Gain Compensator: DR Mirza Tariq HamayunAsad RehanNo ratings yet

- Sedimentary Geology 188-189 (2006) 357 - 378Document22 pagesSedimentary Geology 188-189 (2006) 357 - 378dvrmtNo ratings yet

- Gear Motors: Achieving The Perfect Motor & Gearbox MatchDocument16 pagesGear Motors: Achieving The Perfect Motor & Gearbox MatchJohn LeeNo ratings yet

- CE 470-Lect-3 (Analysis of Biaxially Loaded Columns) (Read-Only)Document22 pagesCE 470-Lect-3 (Analysis of Biaxially Loaded Columns) (Read-Only)Jamal RkhNo ratings yet

- D Mec Frac Fatigue Part IIDocument38 pagesD Mec Frac Fatigue Part IIsure516vNo ratings yet

- Especificacion SHY73MC4 UDocument3 pagesEspecificacion SHY73MC4 UYgor Salgado100% (3)

- Lightweight SUV Frame Design DevelopmentDocument50 pagesLightweight SUV Frame Design DevelopmentAltairEnlightenNo ratings yet

- G.D.GOENKA PUBLIC SCHOOL CLASS 10 CHEMISTRY CHAPTER 2 ACIDS BASES SALTS ASSIGNMENTDocument3 pagesG.D.GOENKA PUBLIC SCHOOL CLASS 10 CHEMISTRY CHAPTER 2 ACIDS BASES SALTS ASSIGNMENTvikas aggarwal100% (1)

- 3 RPM and 6 RPMDocument4 pages3 RPM and 6 RPMAnonymous T32l1RNo ratings yet