Professional Documents

Culture Documents

2868-Glands & Pipe Fittings PDF

Uploaded by

syllavethyjim0 ratings0% found this document useful (0 votes)

34 views1 pageOriginal Title

2868-Glands & Pipe Fittings.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

34 views1 page2868-Glands & Pipe Fittings PDF

Uploaded by

syllavethyjimCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

By GEOMETER

GLANDS AND

PIPE FlTTINGS

or stuffing box is the

normal means of permitting

reciprocation of a piston

rod or plunger, or rotary motion

of a shaft, at the same time preventing leakage of steam or water,

oil, or whatever may be the fluid.

Essentially, soft resilient packing

is employed which will compress

on adjustment and lightly grip the

piston rod or plunger, eliminating

leakage but not setting up undue

friction.

Too much reliance,. however, must

not be placed on the inherent characteristic of a small degree of take up,

self-adjustment or compensation

which a gland possesses. It is important for associated metal parts to

be true and in good adjustment. In

particular, portions of piston rods

and plungers which actually work in

glands should be smooth and parallel,

for if the gland of a small engine has

to be over-tightened to prevent

leakage, power will be seriously

diminished or the engine prevented

from running. Repacking and adjusting a gland on a force pump (domestic

type, for example) cannot long

obviate leakage primarily caused by

wear of plunger or piston rod.

though owing to possible blow out,

the union is not really suitable for

pressure. For this, a flange on the

pipe F is desirable in conjunction with

packing in the nut if required.

The normal pipe flange G is secured

with two bolts, or by studs and nuts

when fitted to a cylinder, and requires a jointing washer or gasket of

paper or asbestos sheeting. Such a

flange may be a plain oval brazed on

the pipe, or have a small boss, as

shown, mto which the pipe fits and

is soldered.

A flange with a stepped seating H

prevents jointing blow out, and in

small sizes metal-to-metal connection

can be made by lightly grinding the

parts together.

Where a pipe needs to be at an

angle, a special flange may be used Z

or on a cylinder or other casting a

banjo fitting J employed or an elbow

K screwed in and set as required with

a lock-nut for connection by ordinary

union. The banjo union,. it will be

seen, has a circular sealing washer

top and bottom, an internal recess,

and a hollow fixing screw drilled

cross-wise to match with the recess. q

GLAND

Types and packing

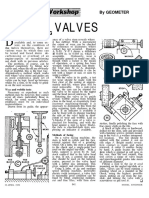

Diagrams A, B and C show the main

types of glands. That at A is the

common oval-flanged pattern, adjusted by nuts on two studs and

originally used for steam enginespossibly because the major work was

plain turning, no threads being

required other than those for the

studs. In model sizes other than the

smallest, construction is straightforward, but care is required to tighten

the nuts evenly, maintaining the flange

square and the piston rod free.

The gland at B utilises an internal

thread and has a hexagon or slotted

flange for adiusting. To avoid binding, thread and bore must be concentric-for which reason skill is

required in making, especially in

model sizes. In this respect, the gland

at C is sometimes preferred, where

the thread is external and a nut

screws on.

Either glands B or C may be used

on screw-down valves (domestic water

10 MAY 1956

taps), and small needle valves, D .

In the latter connection, it can be

said that the packing will compress

and seal in the thread, as shown,

providing it is true and smooth, and

an important saving in length can be

made, by comparison with valves

having a plain diameter for the

packing to bear on.

Most model and small commercial

glands can be packed with soft

asbestos string, loosened by untwisting,

and made into strands of suitable

size. Soft ordinary string or wool

can also be used. The strands should

be smeared with graphite or graphite

grease for steam, and for water can

be lubricated with water-resistant

grease, and wound round the piston

rod or plunger, in the direction in

which a screw gland tightens.

Pipe fittings

An adaptation of the external gland

(C and D) is to a simple union fitting

E which can be both smaller and

shorter than an ordinary pattern.

Unlubricated packing should be used

and the nut screwed up tightly,

particularly if there is pressure767

MODEL ENGINEER

You might also like

- IMP Workshop ManualDocument336 pagesIMP Workshop Manualsyllavethyjim67% (3)

- 2890-Nuts & Spanners PDFDocument1 page2890-Nuts & Spanners PDFsyllavethyjimNo ratings yet

- 2889-Further Drilling Methods PDFDocument1 page2889-Further Drilling Methods PDFsyllavethyjimNo ratings yet

- 2884-Panel Beating PDFDocument1 page2884-Panel Beating PDFsyllavethyjim100% (1)

- 2887-Broken Drills & Taps PDFDocument1 page2887-Broken Drills & Taps PDFsyllavethyjimNo ratings yet

- 2885-Dent & Bulge Removal PDFDocument1 page2885-Dent & Bulge Removal PDFsyllavethyjimNo ratings yet

- 2880-Supporting & Steadying PDFDocument1 page2880-Supporting & Steadying PDFsyllavethyjimNo ratings yet

- 2888-Oblique Drilling PDFDocument1 page2888-Oblique Drilling PDFsyllavethyjimNo ratings yet

- 2886-Stud Fitting & Removal PDFDocument1 page2886-Stud Fitting & Removal PDFsyllavethyjimNo ratings yet

- 2881-Radii Functions and Checking PDFDocument1 page2881-Radii Functions and Checking PDFsyllavethyjimNo ratings yet

- Contours 1: Hile It CannotDocument1 pageContours 1: Hile It CannotsyllavethyjimNo ratings yet

- 2883-Metal Working PDFDocument1 page2883-Metal Working PDFsyllavethyjimNo ratings yet

- 2875-Belt Drives PDFDocument1 page2875-Belt Drives PDFsyllavethyjimNo ratings yet

- 2876-Belt Fasteners PDFDocument1 page2876-Belt Fasteners PDFsyllavethyjimNo ratings yet

- 2879-Clamping & Holding PDFDocument1 page2879-Clamping & Holding PDFsyllavethyjimNo ratings yet

- 2866-Hardening & Tempering PDFDocument1 page2866-Hardening & Tempering PDFsyllavethyjimNo ratings yet

- 2872-Circular Clips #2 PDFDocument1 page2872-Circular Clips #2 PDFsyllavethyjimNo ratings yet

- 2878-Chains & Sprockets PDFDocument1 page2878-Chains & Sprockets PDFsyllavethyjimNo ratings yet

- 2869-Fitting & Joining Pipes PDFDocument1 page2869-Fitting & Joining Pipes PDFsyllavethyjimNo ratings yet

- 2873-Cotters & Wedges PDFDocument1 page2873-Cotters & Wedges PDFsyllavethyjimNo ratings yet

- Roller Chains and Sprockets GuideDocument1 pageRoller Chains and Sprockets GuidesyllavethyjimNo ratings yet

- 2871-Circular Clips #1 PDFDocument1 page2871-Circular Clips #1 PDFsyllavethyjimNo ratings yet

- 2874-Fitting Core Plugs PDFDocument1 page2874-Fitting Core Plugs PDFsyllavethyjimNo ratings yet

- 2861-Wheel & Shaft PullersDocument1 page2861-Wheel & Shaft PullersSandra Barnett CrossanNo ratings yet

- 2870-Simple Screw Assembly PDFDocument1 page2870-Simple Screw Assembly PDFsyllavethyjimNo ratings yet

- 2865-Testing & Facing Valves PDFDocument1 page2865-Testing & Facing Valves PDFsyllavethyjimNo ratings yet

- 2867 Case HardeningDocument1 page2867 Case HardeningEr Sukhwinder SinghNo ratings yet

- 2864-Poppet Valves & Seating PDFDocument1 page2864-Poppet Valves & Seating PDFsyllavethyjimNo ratings yet

- 2863-Valve Seating Tools PDFDocument1 page2863-Valve Seating Tools PDFsyllavethyjimNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- (001, 104, 105, 137, 204, 205, 237, 300, 311, 350, 316, 700) Butterfly Valve DN 40 50 65 80 100 125 150 200 450 Pneum LTDocument26 pages(001, 104, 105, 137, 204, 205, 237, 300, 311, 350, 316, 700) Butterfly Valve DN 40 50 65 80 100 125 150 200 450 Pneum LTBata ZivanovicNo ratings yet

- Kenr5131kenr5131-02 PDocument60 pagesKenr5131kenr5131-02 PPaulo CNo ratings yet

- Jenis inspeksi compressor materialDocument5 pagesJenis inspeksi compressor materialRomi AfriansyahNo ratings yet

- Oil Mist Lubrication TrainingDocument70 pagesOil Mist Lubrication TrainingDelfinsh100% (3)

- Machine Alignment TestDocument4 pagesMachine Alignment TestSudhanwa KulkarniNo ratings yet

- Rotating Equipment API StandardsDocument1 pageRotating Equipment API StandardsGaurav Tripathi100% (2)

- Tie Rod 70 Bar Hydraulic Cylinders PDFDocument48 pagesTie Rod 70 Bar Hydraulic Cylinders PDFNilxon Alejandro Jaramillo DíazNo ratings yet

- Stetter Self Loading Mixer SLM 4000 S LDocument4 pagesStetter Self Loading Mixer SLM 4000 S LMahes WaranNo ratings yet

- Tyreflex v02 EbrochureDocument12 pagesTyreflex v02 EbrochureSebastian AguirreNo ratings yet

- Design 2 Q2 1Document15 pagesDesign 2 Q2 1HaveOfControlNo ratings yet

- PRD108Document2 pagesPRD108Rizki Heru HermawanNo ratings yet

- Dynamic Simulation of A Three-Phase Induction Motor Using MATLAB SimulinkDocument6 pagesDynamic Simulation of A Three-Phase Induction Motor Using MATLAB SimulinkRadu BabauNo ratings yet

- Spare Parts List Catalogue de Piece de Rechange: A 954 C-LI 450 36384Document1,115 pagesSpare Parts List Catalogue de Piece de Rechange: A 954 C-LI 450 36384jeffrey pelletierNo ratings yet

- CAMSHAFT INSTALLATION FOR QR25DEDocument3 pagesCAMSHAFT INSTALLATION FOR QR25DEmehralsmenschNo ratings yet

- Service Mechanics: 07/08 Rev. 5.01-02 Service Manual DPM - Pem - Alx 92XDocument93 pagesService Mechanics: 07/08 Rev. 5.01-02 Service Manual DPM - Pem - Alx 92Xarelyta8123No ratings yet

- Quick ExhaustDocument2 pagesQuick Exhaustsatheez3251No ratings yet

- Komatsu HD785-7 Shop Manual PDFDocument1,491 pagesKomatsu HD785-7 Shop Manual PDFIB EldinNo ratings yet

- Motor Grader mg330Document2 pagesMotor Grader mg330Yuli Wibowo63% (8)

- Rear Axle Diagram F-150Document3 pagesRear Axle Diagram F-150Henry PannellNo ratings yet

- ETERNAL A10V Series 52 53Document49 pagesETERNAL A10V Series 52 53Taller PahrNo ratings yet

- AODE-4R75E VacTest PDFDocument2 pagesAODE-4R75E VacTest PDFAlonso IbarraNo ratings yet

- Wind Turbine Control System SeminarDocument13 pagesWind Turbine Control System SeminarAkhil GuliaNo ratings yet

- Isuzu Cambio PDFDocument340 pagesIsuzu Cambio PDFjordi garcia0% (1)

- Kitec Price ListDocument10 pagesKitec Price ListvipinabrolNo ratings yet

- Specifications 800C EngineDocument28 pagesSpecifications 800C Enginetokotani torajaNo ratings yet

- Steering System: PART NO. 1565182 1600 SRM 1109Document34 pagesSteering System: PART NO. 1565182 1600 SRM 1109Juanjo Garcia Jimenez100% (1)

- Component Operation: Section 3Document82 pagesComponent Operation: Section 3Tú Xuân LươngNo ratings yet

- Wartsila Measurements W32Document18 pagesWartsila Measurements W32Oleksandr100% (2)

- 2 Stroke and 4 Stroke EngineDocument19 pages2 Stroke and 4 Stroke EngineArun KumarNo ratings yet