Professional Documents

Culture Documents

CV-Kamlesh-Piping Layout Engineer-4.0 Yrs. Exp.

Uploaded by

kamleshyadavmoneyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CV-Kamlesh-Piping Layout Engineer-4.0 Yrs. Exp.

Uploaded by

kamleshyadavmoneyCopyright:

Available Formats

OBJECTIVE

KAMLESH YADAV

To be a part of working team for the benefits of the organization by imparting

my knowledge, skills and efforts so as to accomplish common objective and

goals within the organization.

PIPING PROFILE

An engineering professional

working in detail engineering

company. Have in-depth

experience of preparing detail

design piping drawings for

petrochemical industries.

A result oriented professional with more than 4.5 years of

experience in Piping Engineering specifically in Plant, Equipment

& Piping Layout.

Having good exposure for lines connected to Pumps, Tanks and

other critical equipments.

Knowledge of PFD, P&ID, Equipment Drawings, Plot Plan,

Process Plant Layout, Piping Welding, Erection & Testing.

Detail engineering documents are prepared like Isometric, section

views, consolidated bill of material.

Piping supports selection and engineering.

MTO processing & consolidation.

Familiar with- international design codes & dimensional standards

such as ASME31.1 & ASME31.3, API610, API650, API 660,

WRC107, WRC297, ASME SEC.VIII DIV.1 & 2

Strong theoretical base with good analytical and problem solving

CORE COMPETENCIES

Detail engineering

Piping engineering

Designing piping

Pipe routing and related

engineering aspects.

skills.

Preparation of GA drawings and isometrics based on P&ID and

plant layout.- pipe support and rack design, expansion loop design.

Pressure design of process piping and component as per ASME B

31.3 [straight pipe, flanges, elbows and miter bends, reinforced

branch connections, blanks, blind flanges, expansion joints.

Preparation of skid 3d model in Cad Worx and extraction of GA

drawings & isometrics along with bom for fabrication.

Preparations of material take off from piping gad and isometrics.

Preparation of as built drawings according to site condition.

Pipe thickness calculation and Insulation thickness calculation.

Interface/co-ordination with stress group for critical lines/critical

stress systems, other functional disciplines

Maintaining standard piping layout procedures as per the clients

design basis.

Identifying the support location and types in Caesar II.

INDUSTRY FOCUS

Oil & Gas

Power Sector

Steel Industries

Cement Industries

Water and waste water

treatment

Contact Info:

TECHNICAL SKILLS

Cell: +91 941 023 1445

E-mail:

kamleshyadav625@gmail.com

Address:

C/O Yashveer Singh Sirohi

Gali No-8, New Defence

Colony, Muradnagar

Ghaziabad, U.P- 221011

SOFTWARE PROFICIENCY

AutoCAD 2014

AutoCAD Mechanical 2014

Aft Arrow & Aft Fathom

CAD WORX ( 3DPiping)

Caesar II 6.0

PDS

SP3D

ORGANISATION SCAN

ASMETECH Engineers Pvt. Ltd.

Engineer Piping

June12 Present

Accountabilities:

Starting from preparing detail design piping drawings for construction using AutoCAD, preparing

manual MTO using P&ID and equipments arrangement till doing the following activates:

Assisting in man-hours estimate for new project within the proposal phase.

Review the Piping Design documents (P&ID, Isometrics, GAs, Tie-ins list, Supports Details, and MTO).

Preparing complete 3D Model For petrochemical plants Using Cad Worx.

Review the piping activities and completion in accordance with schedule requirements.

Compilation of piping scope activities including MTOs, drawings, and project activity durations.

Prioritized scope activities to most efficiently meet project schedule requirements.

Ensuring implementation and adherence to project specifications and procedures.

Responsibility for monitored piping designers quality and taking necessary actions to maintain satisfactory

standards.

Handling Key Clients:

Project 1

Tata Kpo Ejectors Piping

Client

Vizag Steel

Description

A 200NB size steam header is coming from top-2 to RH Degasser unit. Different tapping of

stem line are going in booster. All condensate lines of steam system is going in hot well tank.

A complete design of system includes pipe routing, support design, isometric drawings, and

complete bill of material for system.

Project 3

Hot Oil Fad Reactors

Client

Titan Metal Fabricators , USA

Description

Complete design and detail engineering of 317 stainless steel reactors, carbon steel hot oil

piping, and carbon steel skids for field installation. The reactors will be erected on three

individual skids to allow for shipment. Interconnecting piping will be required to connect the

skids. The material of construction for the reactors will be 317/317L stainless steel. The

material of construction for the skids will be painted carbon steel. Reactor R-100 is a

jacketed pipe with 317/317L SS 1 1/2 Sch. XXH core pipe and a 317/317L SS 3 Sch. 160

jacket. Reactor R-101 is a jacketed pipe with 317/317L SS 1 1/2" Sch. 80 core pipe and a

317/317L SS 5 Sch. 40 jacket. Reactor R-102 is a 317/317L 6 Sch. 160 pipe. Carbon steel

Hot Oil supply and return piping will be required. Interconnecting pipe spools will also be

required to connect each reactor section.

Project 4

Pru N2 To Stack Rerouting.

Client

Hmel Refinary, Bhatinda

Description

Rerouting of 100NB flare line branching from 200nb from PRU N2 to stack flare main 36inch

main header, through main pipe rack by providing additional cantilever support.

Project 5

Phosphoric Acid Unit

Client

Paradeep Phosphate Limited (Odissa)

Description

Piping layout and detail engineering of suction line connected from phosphoric acid tank to

pump and discharge line connected to reactor tank.

Project 6

Coke Oven Battery Piping

Client

Bhusan Power And Steel Limited

Description

A complete detail engineering of coke oven battery piping which includes coke oven gas

distribution header, ammonia header, and other utilities piping including seal pot piping.

Project 7

Sagar Samrat Conversion Project-Topside Engineering

Client

Ongc

Description

Complete modeling of primary fuel gas conditioning gas skid in Cad Worx and extraction of

complete sets off gas and section drawings along with pipe isometrics with bill of material.

Project 8

HRD process platform project

Client

ONGC

Description

Complete modeling of primary fuel gas conditioning gas skid in Cad Worx and extraction of

complete sets off gas and section drawings along with pipe isometrics with bill of material.

Project 9

Fuel Hydrant System For Boing Jet,

Client

L&T Engineering And Construction

Description

Worked on Piping General Arrangement Drawing (GAD), Support Detailing, Isometrics,

MTO.

ACADEMIA

Bachelor of Technology (B.Tech)

UPTU

Intermediate

CBSE Board

S.S.C.

CBSE Board

75%

77%

82%

PERSONAL DOSSIER

Name

Fathers Name

Date of Birth

Languages

Mb. No .

Permanent Address

Current Address

Marital Status

References

:

:

:

:

:

:

:

:

:

Kamlesh Yadav

Rama Shankar Yadav

01-Feb-1990

English, Hindi

+91-9410231445 / +91-8004349017

House No. 135 Bhimpura No.-2, Ballia U.P

Muradnagar, GZB

Bachelor

Available on request.

Date: 25-Sep- 2016

Kamlesh Yadav

You might also like

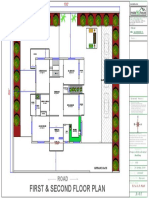

- Mr. Kamlesh - Yadav-19. 1st+2nd Floor Electrical LayoutDocument1 pageMr. Kamlesh - Yadav-19. 1st+2nd Floor Electrical LayoutkamleshyadavmoneyNo ratings yet

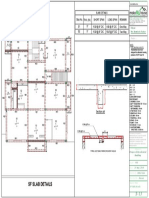

- SF Slab DetailsDocument1 pageSF Slab DetailskamleshyadavmoneyNo ratings yet

- Caesar II Training Covers Static and Dynamic Pipe Stress AnalysisDocument3 pagesCaesar II Training Covers Static and Dynamic Pipe Stress AnalysiskamleshyadavmoneyNo ratings yet

- Kitchen Catalog New-25!01!17Document28 pagesKitchen Catalog New-25!01!17rakeshkchouhanNo ratings yet

- FF Slab Details PDFDocument1 pageFF Slab Details PDFkamleshyadavmoneyNo ratings yet

- FF Column Plan PDFDocument1 pageFF Column Plan PDFkamleshyadavmoneyNo ratings yet

- Sub:Risk Assumption Letter: Insured Vehicles DetailsDocument4 pagesSub:Risk Assumption Letter: Insured Vehicles DetailskamleshyadavmoneyNo ratings yet

- Water Hammer Analysis ReportDocument22 pagesWater Hammer Analysis ReportAh Leng LauNo ratings yet

- EIL BrochureDocument16 pagesEIL BrochureAnonymous ORBFjUf5No ratings yet

- Client Mr. Kamlesh Yadav: NotesDocument1 pageClient Mr. Kamlesh Yadav: NoteskamleshyadavmoneyNo ratings yet

- Luminous NXG Solar UpsDocument1 pageLuminous NXG Solar UpskamleshyadavmoneyNo ratings yet

- GF Slab DetailsDocument1 pageGF Slab DetailskamleshyadavmoneyNo ratings yet

- F.F. & S.F. Kamlesh Yadav Triplex Complete Set-Plan-1Document1 pageF.F. & S.F. Kamlesh Yadav Triplex Complete Set-Plan-1kamleshyadavmoneyNo ratings yet

- Foundation ScheduleDocument1 pageFoundation SchedulekamleshyadavmoneyNo ratings yet

- Column Centerline PlanDocument1 pageColumn Centerline PlankamleshyadavmoneyNo ratings yet

- Staircase DetailsDocument1 pageStaircase DetailskamleshyadavmoneyNo ratings yet

- Tank DesignDocument2 pagesTank DesignkamleshyadavmoneyNo ratings yet

- Terrace Slab DetailsDocument1 pageTerrace Slab DetailskamleshyadavmoneyNo ratings yet

- Training Content Static EquipmentDocument6 pagesTraining Content Static Equipmentkamleshyadavmoney100% (1)

- Nozzle Detail of Recovered Oil Tank-ModelDocument1 pageNozzle Detail of Recovered Oil Tank-ModelkamleshyadavmoneyNo ratings yet

- Plant Design and Management System PDMS - An Overview PDFDocument9 pagesPlant Design and Management System PDMS - An Overview PDFkamleshyadavmoneyNo ratings yet

- ORINOX-Catalogue Commercial GuideDocument11 pagesORINOX-Catalogue Commercial Guidevinurules20No ratings yet

- Evdt 219 Wdu 1901 PDFDocument1 pageEvdt 219 Wdu 1901 PDFkamleshyadavmoneyNo ratings yet

- Air Ducts Velocity Friction LossDocument3 pagesAir Ducts Velocity Friction LossVanne Jo PajoNo ratings yet

- Solved SSC CGL Tier 1 9 August 2015 Shift 1 Paper With SolutionsDocument84 pagesSolved SSC CGL Tier 1 9 August 2015 Shift 1 Paper With SolutionskamleshyadavmoneyNo ratings yet

- ASUS E203NA - Laptops - ASUS IndiaDocument4 pagesASUS E203NA - Laptops - ASUS IndiakamleshyadavmoneyNo ratings yet

- First & Second Floor Plan: Client Mr. Kamlesh YDocument1 pageFirst & Second Floor Plan: Client Mr. Kamlesh YkamleshyadavmoneyNo ratings yet

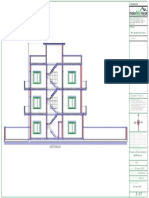

- Mr. Kamlesh - Yadav-10. Section A-A'Document1 pageMr. Kamlesh - Yadav-10. Section A-A'kamleshyadavmoneyNo ratings yet

- Mr. Kamlesh - Yadav-18. G. Floor Electrical LayoutDocument1 pageMr. Kamlesh - Yadav-18. G. Floor Electrical LayoutkamleshyadavmoneyNo ratings yet

- Toilet Detail DrawingsDocument1 pageToilet Detail Drawingskamleshyadavmoney100% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Lux Unilever extends soap brand Lux with 'Festive Glow' variantDocument66 pagesLux Unilever extends soap brand Lux with 'Festive Glow' variantNitesh KumarNo ratings yet

- Assignment 2 (Database Systems)Document4 pagesAssignment 2 (Database Systems)muhammad waseemNo ratings yet

- ITC Catalogue Issue 9Document168 pagesITC Catalogue Issue 9ayalabrNo ratings yet

- OMN SunCryl - CL223BDocument2 pagesOMN SunCryl - CL223BdhruvrakeshNo ratings yet

- CERC Dell BestDocument35 pagesCERC Dell BestDan FilibiuNo ratings yet

- Test 3 ReadingDocument29 pagesTest 3 ReadingThinh LeNo ratings yet

- Life Cycle AssessmentDocument12 pagesLife Cycle AssessmentaliNo ratings yet

- Requisition Slip 1 7Document2 pagesRequisition Slip 1 7vlad tanNo ratings yet

- Airline Case Study 1time FinalDocument3 pagesAirline Case Study 1time Finalcorporate businessNo ratings yet

- Alw AE1F OoptiflowwDocument12 pagesAlw AE1F OoptiflowwCarlos LópezNo ratings yet

- 96tbrog1e PDFDocument321 pages96tbrog1e PDFlinein_lineoutNo ratings yet

- CRM Final Ppt-6Document21 pagesCRM Final Ppt-6Niti Modi ShahNo ratings yet

- Fault Data 1Document24 pagesFault Data 1Vaghela UttamNo ratings yet

- AWS Compete: Microsoft's Response to AWSDocument6 pagesAWS Compete: Microsoft's Response to AWSSalman AslamNo ratings yet

- Design and Frabrication of Pneumatic Bore Well Child Rescue SystemDocument7 pagesDesign and Frabrication of Pneumatic Bore Well Child Rescue SystemAnonymous kw8Yrp0R5rNo ratings yet

- Ais Sart BrochureDocument18 pagesAis Sart Brochureborisgolodenko100% (1)

- Estimation and CostingDocument19 pagesEstimation and CostingAditi ShahNo ratings yet

- 2ST Seated Leg Curl DiagramDocument10 pages2ST Seated Leg Curl DiagramJEREMEE MICHAEL TYLERNo ratings yet

- Integrating IDOs With External Applicati (3040)Document88 pagesIntegrating IDOs With External Applicati (3040)Wojciech FiNo ratings yet

- Re-Engineering of Business Processes in The IntegrDocument13 pagesRe-Engineering of Business Processes in The Integrsara eltonyNo ratings yet

- Bollhoff HeliCoil Aerospace Blue BookDocument35 pagesBollhoff HeliCoil Aerospace Blue BookAce Industrial SuppliesNo ratings yet

- 2013 Collin Technologies Case StudyDocument81 pages2013 Collin Technologies Case StudyChiNo ratings yet

- Roles IncludeDocument14 pagesRoles IncludeAisha IshuNo ratings yet

- Is 6862 2005Document11 pagesIs 6862 2005sarath6725No ratings yet

- Fuel Oil System Check SheetsDocument7 pagesFuel Oil System Check Sheetsvhin84No ratings yet

- Use Case StudyDocument4 pagesUse Case StudyDustin ShepherdNo ratings yet

- Shafiq UlDocument3 pagesShafiq UlSyedSalmanRahmanNo ratings yet

- ER Cyient AR 2015 Full Book EN2Document228 pagesER Cyient AR 2015 Full Book EN2lokesh38No ratings yet

- Introduction Wps and PQRDocument4 pagesIntroduction Wps and PQRdhasdj100% (1)

- LAUSD Procure to Pay Process BlueprintDocument217 pagesLAUSD Procure to Pay Process Blueprintrtmathew12No ratings yet