Professional Documents

Culture Documents

9200 9P 006 - R2

Uploaded by

Yuda SatriaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

9200 9P 006 - R2

Uploaded by

Yuda SatriaCopyright:

Available Formats

CONOCOPHILLIPS INDONESIA INC. LTD.

PROJECTS DEPARTM ENT

SPECIFICATION

DOCUMENT NUMBER

REV

TITLE

INSPECTION AND

TESTING REQUIREMENTS

FOR EQUIPMENT AND

MATERIAL

84501 -9200-9P-006

DATE

PAGE

8 March

04

2 of 3 4

REVISION CONTROL SHEET

LATEST REV

DATE ISSUED

PREPARED

REVIEWED

APPROVED

COMMENTS

1 Oct 2002

B. Burn

R.Ford

A.McIntosh

Issued For Use

1 Mar 2003

B. Burn

R.Ford

A.McIntosh

Department Name

Change

8 March 04

B. Burn

R. Ford

Cino Calfino

Section 7.4 AML

Number corrected

Paper Copies are UNCONTROLLED - Check with Document Control for latest available

Revision CONTROLLED copies should be RED stamped

CONOCOPHILLIPS INDONESIA INC. LTD.

PROJECTS DEPARTM ENT

TITLE

INSPECTION AND

TESTING REQUIREMENTS

FOR EQUIPMENT AND

MATERIAL

SPECIFICATION

DOCUMENT NUMBER

REV

84501 -9200-9P-006

DATE

PAGE

8 March

04

3 of 3 4

T ABLE OF CONTENTS

1.

INTRODUCTION ................................................................................................................4

2.

SCOPE .................................................................................................................................4

3.

PURPOSE............................................................................................................................4

4.

DEFINITIONS ......................................................................................................................4

5.

RESPONSIBILITIES..........................................................................................................6

6.

APPLICATION....................................................................................................................7

7.

PROCEDURE FOR PROCUREMENT............................................................................8

8.

PROCEDURE SITE FABRICATION/INSTALLATION ................................................9

APPENDIX 1 .....................................................................................................................10

APPENDIX 2 .....................................................................................................................12

APPENDIX 3 .....................................................................................................................13

APPENDIX 4 .....................................................................................................................21

APPENDIX 5 .....................................................................................................................22

APPENDIX 6 .....................................................................................................................26

APPENDIX 7 .....................................................................................................................29

APPENDIX 8 .....................................................................................................................30

APPENDIX 9 .....................................................................................................................31

APPENDIX 10 ...................................................................................................................33

Paper Copies are UNCONTROLLED - Check with Document Control for latest available

Revision CONTROLLED copies should be RED stamped

CONOCOPHILLIPS INDONESIA INC. LTD.

PROJECTS DEPARTM ENT

TITLE

INSPECTION AND

TESTING REQUIREMENTS

FOR EQUIPMENT AND

MATERIAL

1.

SPECIFICATION

DOCUMENT NUMBER

REV

84501 -9200-9P-006

DATE

PAGE

8 March

04

4 of 3 4

INTRODUCTION

This procedure, in addition to Project Procedure 84501-9200-9P-005, (Equipment

Criticality Rating),shall be used to establish project quality and certification and

program requirements

2.

SCOPE

This procedure is restricted to Contractors responsible for engineering and

design, procurement and construction activities.

3.

PURPOSE

The purpose of this procedure is to provide guidance in the determination of

inspection requirements for inclusion in the following documents produced by the

Contractor:

4.

Purchasing Inspection Specifications and Plans

Site Fabrication, Erection/Installation Specifications

Site Inspection and Testing Plan

DEFINITION

For the purpose of this procedure, the following definitions apply:

Shall - Denotes a mandatory action

Should - Denotes a strongly recommended action

Contractor - Each organization that carries out all or part of the detailed

engineering and design and procurement of project equipment and materials.

Owner ConocoPhillips Indonesia Inc. Ltd

Project

Quality Plan - A document produced by the Supplier and Contractor

summarizing the specific activities relevant to a Suppliers and Contractors scope

of work. The document shall reference those activities pertinent to the purchase

order scope and identify procedures appropriate to the management and control

of those activities.

Procurement Inspection Plan - A document produced by the Contractor

outlining the overall inspection requirements pertinent to the procurement of

Paper Copies are UNCONTROLLED - Check with Document Control for latest available

Revision CONTROLLED copies should be RED stamped

CONOCOPHILLIPS INDONESIA INC. LTD.

PROJECTS DEPARTM ENT

TITLE

INSPECTION AND

TESTING REQUIREMENTS

FOR EQUIPMENT AND

MATERIAL

SPECIFICATION

DOCUMENT NUMBER

REV

84501 -9200-9P-006

DATE

PAGE

8 March

04

5 of 3 4

equipment and materials. The plan shall ensure appropriate reference to or

incorporate Belanak Project inspection requirements.

Purchase Order Supplier Quality Control/Inspection Plan - A document

defining the requirements for the specific inspections to be performed during

manufacture, and test.

Site Inspection and Test Plan - A document produced by the Contractor

defining specific inspection and test activities relevant to site fabrication,

installation and test.

Positive Material Identification (PMI) - The ability to trace material to a Material

Test Report (MTR).

Alloy Verification (AV) - Physical verification of material composition using

material analyzers. It is used to supplement PMI in order to verify a Material Test

Report.

Material Test Report (MTR) - A document issued and authenticated by the

material manufacturer defining the chemical composition and mechanical

properties of a material.

Material Traceability - Ability to trace material to a material trac eability report

during any stage of procurement, manufacture, storage or installation.

Certificate of Conformance (COC) A document issued by a relevant

organization certifying that the products supplied conform in every respect to the

purchase specifications.

Inspection Certificate - A document certifying the satisfactory completion of a

stage inspection, final inspection or test. The document is authenticated by the

purchaser's appointed inspection authority and, where required by the design

code, also s igned by an independent inspection authority.

Concession Request - A formal document raised by a Supplier or Contractor

requesting the purchaser's permission to deviate from a purchase specification.

Positive Material Identification (PMI) Program - A document produced by the

Contractor defining the extent of PMI to be performed on specific materials in

order to enable verification and traceability of material to MTR's during any stage

of supply, storage, manufacture or final installation

Project Specifications - The project engineering standards those are developed

for a Specific Project incorporating requirements for specific inspections and tests

to be performed in the procurement, fabrication, installation and commissioning of

equipment, systems and materials.

Paper Copies are UNCONTROLLED - Check with Document Control for latest available

Revision CONTROLLED copies should be RED stamped

CONOCOPHILLIPS INDONESIA INC. LTD.

PROJECTS DEPARTM ENT

TITLE

SPECIFICATION

DOCUMENT NUMBER

REV

INSPECTION AND

TESTING REQUIREMENTS

FOR EQUIPMENT AND

MATERIAL

84501 -9200-9P-006

DATE

PAGE

8 March

04

6 of 3 4

Specification Deviation Request - A formal document issued by the Contractor

to request permission to deviate from a specification or Project inspection

requirement.

5.

RESPONSIBILITIES

5.1

Contractor

5.1.1 The Contractor is responsible for maintaining a documented system to ensure

that required inspection activities are planned, performed, witnessed and verified

and to provide adequate assurance that all equipment, materials fabrication,

installation and tests fully comply with the requirements of this procedure and

project specification and design code requirements.

5.1.2 The system shall provide an auditable trail verifying that inspection and

certification requirements satisfy quality and safety standards indicative of

equipment or system criticality as determined b y the Contractor.

5.1.3 Other responsibilities shall include the following:Preparation of the overall Procurement Inspection Plan for approval by Company.

Documenting the inspection practices to be considered in association with

procurement of equipment and materials. The Plan and associated Contractor's

procedures shall clearly define responsibilities within the Contractors organization

for specifying and approving inspection plans and performing inspection

activities.

5.2

approval of agreed Supplier or Inspection Plans prior to manufacture,

fabrication, installation and test.

performing necessary inspection and verification activities to ensure

equipment, materials and installation conform in every respect with relevant

approved Project specifications and design codes.

the review of Inspection Requirements to ensure the

requirements are incorporated in the final inspection plans.

issue of Deviation Requests for approval by the Project Team where

deviations from Project Inspection requirements are requested.

ensuring that inspection requirements are cost effective and fully comply

with relevant Project design codes.

necessary

Specific Project Development

5.2.1 The Contractors Engineering Manager shall be responsible for the maintenance,

revision, implementation and update of this procedure.

Paper Copies are UNCONTROLLED - Check with Document Control for latest available

Revision CONTROLLED copies should be RED stamped

CONOCOPHILLIPS INDONESIA INC. LTD.

PROJECTS DEPARTM ENT

TITLE

SPECIFICATION

DOCUMENT NUMBER

REV

INSPECTION AND

TESTING REQUIREMENTS

FOR EQUIPMENT AND

MATERIAL

84501 -9200-9P-006

DATE

PAGE

8 March

04

7 of 3 4

5.2.2 The Specific Project Team shall be responsible for providing guidance in the

interpretation of inspection and certification requirements to Contractors and

undertaking technical assessments and audits to ensure compliance with

requirements.

5.2.3 The Contractors engineering function shall be responsible for approving

deviations to Project Inspection Plans and communicating such concessions to

the Company for approval

5.2.4 When a deviation is deemed to be of a general nature and affects all Contractors,

this shall be notified accordingly to the Company the Project team shall be

responsible for ensuring that inspection requirements, particularly on systems or

equipment interfacing with other packages, are consistent.

5.3

Quality Assurance

5.3.1 The responsibilities defined in this section apply to both Company Project Team

and Contractors.

5.3.2 Quality Assurance shall be responsible for ensuring that systems and programs

employed by the Contractor's engineering, procurement, and construction

organizations demonstrate that quality objectives and Project requirements, as

defined in the contract document and described in this procedure, are being

achieved.

5.3.3 Contractors Quality Assurance shall perform and document assessment, and

audits relevant to engineering and design, procurement and construction

activities to provide assurance that the Project Quality Assurance Program and

contract requirements are being implemented by all organizations contracted to

supply products or services to the Project.

5.4

Safety

5.4.1 As a function of the Project Safety Reviews, shall ensure that in review and

implementation of the Contractors systems for control of design, procurement,

and construction activities that quality systems and inspection requirements are

consistent, documented, and provide confidence in the design and operational

safety of the facilities.

6.

APPLICATION

6.1

This procedure is for INTERNAL project use by Contractors, and shall not be

issued to Suppliers or Sub-Contractors.

6.2

This procedure shall be used by all Contractors following the establishment of

criticality ratings as a guidance document in the determination of Inspection

Paper Copies are UNCONTROLLED - Check with Document Control for latest available

Revision CONTROLLED copies should be RED stamped

CONOCOPHILLIPS INDONESIA INC. LTD.

PROJECTS DEPARTM ENT

TITLE

INSPECTION AND

TESTING REQUIREMENTS

FOR EQUIPMENT AND

MATERIAL

SPECIFICATION

DOCUMENT NUMBER

REV

84501 -9200-9P-006

DATE

PAGE

8 March

04

8 of 3 4

requirements pertaining to, Material Certification, Material Traceability, Positive

Material Identification requirements.

6.3

The Inspection requirements detailed in Appendices 3-10 defines the basis for

the inspection activities to be incorporated in supplier and site inspection plans.

They are NOT an instruction to Contractors to perform an inspection task.

6.4

The determination of Purchaser, Supplier and Site Inspection involvement is the

responsibility of each Contractor and will demonstrate to the Company that

adequate inspection tasks are being performed by the Contractor to provide

assurance of the integrity of equipment and the completed facilities.

6.5

Site inspection activities will be documented and agreed in appropriate Inspection

Plans and indicate the level of Inspection involvement performed by the

company, Contractor.

6.6

Certification shall be produced to certify satisfactory acceptance of products

during all stages of manufacture, fabrication, installation and testing.

6.7

Certification requirements shall be defined by the Contractor and shall satisfy the

requirements of the Contract document.

6.8

It shall be the Contractor's responsibility to ensure that requirements of any

Independent Inspection Authority, Company Project and applicable design codes

are defined in the appropriate Purchase Orders.

6.9

Requirements for Site Inspection and Testing are described in more detail in

Contractors Procedures.

7.

PROCUREMENT PROCEDURE

7.1

Following award of Criticality Rating and determination of Quality Program

requirements for an item of equipment (reference Project Procedures 845019200-9P-005), the Contractor shall use this procedure as a basis for advising the

supplier of the Inspection and Certification requirements associated with the

purchase order.

7.2

Appendices 2-10 shall be used to assist in preparing the appropriate

documentation to advise the Contractors Supplier of the required inspection,

material certification, Material traceability and positive material identification

requirements.

7.3

Depending on the equipment or material, the final clarification and agreement of

inspection and certification requirements with the supplier; the levels of purchaser

and any Independent Inspection Authority involvement will be determined by the

Paper Copies are UNCONTROLLED - Check with Document Control for latest available

Revision CONTROLLED copies should be RED stamped

CONOCOPHILLIPS INDONESIA INC. LTD.

PROJECTS DEPARTM ENT

TITLE

SPECIFICATION

DOCUMENT NUMBER

REV

INSPECTION AND

TESTING REQUIREMENTS

FOR EQUIPMENT AND

MATERIAL

84501 -9200-9P-006

DATE

PAGE

8 March

04

9 of 3 4

Contractor and prior agreement with Company or at Supplier pre-production

meeting or by return of an agreed QC Inspection Plan.

7.4

The originator of the material requisition or equivalent document shall determine

the extent of inspection in accordance with the requirements of 84501-9200-9P005 Equipment Criticality Rating to be imposed on supplier of bulk materials or

standard "off the shelf" items. Requirements for such suppliers to submit detailed

Quality Assurance Plans will be determined by the Contractor but such suppliers

should have demonstrated an ability to comply with appropriate project quality

requirements and be included on the Company Approved Manufacturers List.

84501-9400-9W-001

8.

SITE FABRICATION AND INSTALLATION PROCEDURES

8.1

The Contractor shall reference Appendices 2-10 to assist in the determination of

Site Inspection, Testing and Certification requirements for Project Site Fabrication

and Installation Specifications.

8.2

The Site Fabrication and Installation Specifications shall form the basis against

which Site QC and Inspection Plans are developed for each Sub-Contractor. The

Site Inspection, Test and Certification Requirements describe the requirements,

procedures, documentation and certification requirements to be utilized to verify

the acceptance of the prescribed site inspection activities.

8.3

Completed system certification packages are coming together with Suppliers

Certification in Fabrication Dossiers to form System Handover Packages.

8.4

The System Handover Packages are subsequently referenced in the appropriate

completion certificates prepared by the Contractor for Project Company

acceptance.

Paper Copies are UNCONTROLLED - Check with Document Control for latest available

Revision CONTROLLED copies should be RED stamped

CONOCOPHILLIPS INDONESIA INC. LTD.

PROJECTS DEPARTM ENT

SPECIFICATION

DOCUMENT NUMBER

REV

TITLE

INSPECTION AND

TESTING REQUIREMENTS

FOR EQUIPMENT AND

MATERIAL

84501 -9200-9P-006

DATE

PAGE

8 March

04

10 of 34

APPENDIX 1

GENERAL NOTES FOR DETERMINING INSPECTION

AND CERTIFICATION REQUIREMENTS

1.

It is the Contractors ultimate responsibility to ensure adequate levels of

inspection and test are performed and that certification and traceability provide

adequate verification to certify products and systems have been manufactured,

installed and tested to the satisfaction of the Company. The Company shall

perform such inspections and audits as desired to monitor activities of Contractor,

Suppliers

2.

Appendices 3 through 8 define the basis for the determination of Inspection

Requirements with respect to the categories listed.

3.

For equipment, Criticality Rating 1 or Criticality Rating 2, these requirements shall

be mandatory as relevant to the type of equipment being considered and shall be

incorporated in appropriate manufacturing or fabrication inspection plans.

4.

These requirements do NOT preclude the Contractor from incorporating

additional requirements where considered necessary to provide assurance that

levels of equipment integrity have been achieved.

5.

The difference between levels of inspection for Criticality Rating 1 and Criticality

Rating 2 items are determined by the Contractor. These levels shall clearly

demonstrate that the percentage of inspection, non-destructive testing, leak and

pressure testing performed reflect the significance of the item being considered.

6.

Detailed requirements where listed on the attached inspection plans for Criticality

Rating 1 and Criticality Rating 2 equipment, supplement requirements outlined in

the present specification's. All present specification requirements for Inspection,

Testing, and Certification shall be complied with where referenced in Appendices

2 through 10.

7.

Facility to deviate from Project specifications and minimum inspection and

certification requirements as referenced herein shall be permitted where cost

effectiveness can be demonstrated without loss or risk to equipment or system

integrity. Contractor's deviations to inspection requirements on Criticality Rating 1

and Criticality Rating 2 equipment will be by exception only and must be fully

supported.

8.

For the purpose of satisfying the requirements of this procedure the Contractors

responsible for ensuring that requirements for deliverables, approvals, inspection,

documentation, traceability and certification, comply with those sections of the

Paper Copies are UNCONTROLLED - Check with Document Control for latest available

Revision CONTROLLED copies should be RED stamped

CONOCOPHILLIPS INDONESIA INC. LTD.

PROJECTS DEPARTM ENT

TITLE

INSPECTION AND

TESTING REQUIREMENTS

FOR EQUIPMENT AND

MATERIAL

SPECIFICATION

DOCUMENT NUMBER

REV

84501 -9200-9P-006

DATE

PAGE

8 March

04

11 of 34

contract document pertinent to the

engineering,

procurement

construction activities that may not be specifically stated in this document.

and

9.

It shall be deemed by the Company that the Contractor has considered and

incorporated all relevant inspection, test and certification requirements as

required by this and referenced documents contained herein and in all purchase

orders issued either by Contractor or by organizations acting on his behalf. The

Contractor shall also ensure that orders placed by suppliers comply with the

primary requirements.

10.

The Contractors system shall ensure that ALL concessions deviating from Project

Specifications are documented and controlled.

11.

Where necessary or considered appropriate by Company the requirements of this

procedure and shall also apply to modifications, refurbishment or tie-ins to

existing equipment.

12.

Requirements for Material Traceability, Material Test Reports (MTR's), Positive

Material Identification (PMI), and Alloy Verification (AV) apply to all engineering

disciplines and should be read in conjunction with the relevant sections of

Appendices 2-7

Paper Copies are UNCONTROLLED - Check with Document Control for latest available

Revision CONTROLLED copies should be RED stamped

CONOCOPHILLIPS INDONESIA INC. LTD.

PROJECTS DEPARTM ENT

SPECIFICATION

DOCUMENT NUMBER

REV

TITLE

INSPECTION AND

TESTING REQUIREMENTS

FOR EQUIPMENT AND

MATERIAL

84501 -9200-9P-006

DATE

PAGE

8 March

04

12 of 34

APPENDIX 2

MINIMUM INSPECTION REQUIREMENTS

CIVIL, ARCHITECTURAL, STRUCTURAL, HVAC

1.

Minimum inspection requirements for this category shall comply with the relevant

Project specifications; Project approved standards and design codes as stated in

the Contract document. These may be supplemented by Contractors established

codes, standards, and practices where approved by Company

NOTE:

Refer to Appendices 8-10 for Material Traceability, Certification and

Positive Material Identification requirements.

Paper Copies are UNCONTROLLED - Check with Document Control for latest available

Revision CONTROLLED copies should be RED stamped

CONOCOPHILLIPS INDONESIA INC. LTD.

PROJECTS DEPARTM ENT

SPECIFICATION

DOCUMENT NUMBER

REV

TITLE

INSPECTION AND

TESTING REQUIREMENTS

FOR EQUIPMENT AND

MATERIAL

84501 -9200-9P-006

DATE

PAGE

8 March

04

13 of 34

APPENDIX 3

MINIMUM INSPECTION REQUIREMENTS

VESSELS/EXCHANGERS/TANKAGE

GENERAL NOTES:

1.

The supplementary inspection requirements as defined in this Appendix only

apply to equipment with Criticality Rating 1 and Criticality Rating 2. In

distinguishing the requirements for levels of inspection between the two groups,

refer to General Notes Appendix 1, Paragraphs 1. and 5.

2.

The requirements of this Appendix cover the minimum engineering quality

control/inspection requirements for vessels, tankage and heat exchangers

whether individual or part of a package unit and supplement Project

specifications and Design Code Requirements.

3.

Where necessary, the requirements of this Appendix shall apply both o

t new

items and to modifications or refurbishment to existing equipment.

4.

Requirements for site erected tanks or fabricated equipment shall comply with all

relevant inspection requirements and supplemented by activities specific to the

type of equipment

5.

As a minimum, inspection requirements for Criticality Rating 3 equipment shall

comply with Project specifications and Project Approved design codes.

Deviations are subject to Company approval and should be sought where cost

effectiveness and proven established practices can be justified.

6.

Above equipment groups classified as Criticality Rating 4 shall satisfy the

Contractors purchasing specification requirements as defined by the Contractor.

Standard equipment or off the shelf items, which are tested and certified as

conforming to the product purchase specification would be acceptable.

NOTE:

Refer to Appendices 8-10 for Material Traceability, Certification and

Positive Material Identification requirements.

INSPECTION ACTIVITY

REF. DESCRIPTION OF INSPECTION ACTIVITY

1.

Pre-production visit to Supplier's works to monitor the Contractors adherence the

following:

-

Supplier has relevant Standards and Specifications.

Final drawings approved before manufacture commences.

Paper Copies are UNCONTROLLED - Check with Document Control for latest available

Revision CONTROLLED copies should be RED stamped

CONOCOPHILLIPS INDONESIA INC. LTD.

PROJECTS DEPARTM ENT

SPECIFICATION

DOCUMENT NUMBER

REV

TITLE

INSPECTION AND

TESTING REQUIREMENTS

FOR EQUIPMENT AND

MATERIAL

84501 -9200-9P-006

DATE

PAGE

8 March

04

14 of 34

Suppliers sub-orders have been placed and copies forwarded to

Purchaser.

Quality Control/Stage Inspection Plan agreed.

Schedule of Welding Procedures available and approved before

production commences.

COMMENTS:

2.

3.

4.

Record Specification and drawing numbers and status.

Copies of sub-orders where indicated in Quality Program and

Purchase Order to Contractor.

Review to include suppliers Quality Control Plans where indicated

in Quality Program.

Following materials inspected and positively identified against material test

certificates:

-

Plates, pressings, tubes, forging, castings and joint materials necessary

for pressure containment.

Materials forming internals welded to pressure containment parts,

Materials forming external appendices, e.g., compensating pads, saddles,

doubling plates where welded directly to pressure containing parts.

Alloy verification of above by portable material analyzer as per Contractors

PMI positive material identification program.

Check material control implemented at following stages and that identification

and traceability are maintained:

-

Stores inward (include free issue material)

During storage.

Fabrication through to final acceptance

Control of weld consumables.

Undertake full dimensional checks on:

-

Receipt of materials

Following set up of strakes/shell sections

On completion of welding of strakes

Prior to heat treatment, if applicable

Paper Copies are UNCONTROLLED - Check with Document Control for latest available

Revision CONTROLLED copies should be RED stamped

CONOCOPHILLIPS INDONESIA INC. LTD.

PROJECTS DEPARTM ENT

SPECIFICATION

DOCUMENT NUMBER

REV

TITLE

INSPECTION AND

TESTING REQUIREMENTS

FOR EQUIPMENT AND

MATERIAL

84501 -9200-9P-006

DATE

PAGE

8 March

04

15 of 34

COMMENTS:

5.

Dimensional check shall ensure manway/nozzle/ flange

orientations, hold-down orientations are in accordance with AFC

drawings, actual dimensions where different are noted on As Built

drawings.

On columns, checks to include: (a) Spacing and level of tray

supports. (b) Distance between downcomer and tray levels. (c)

Weir heights.

Witness welding procedure qualifications and welder qualifications (to include all

Mechanical Tests/NDT and test plates as required.

N.B.

Existing qualifications may be acceptable if they are current and valid in

accordance with code requirements. Review/approve WPS/PQR.

6.

Inspect welding set ups of longitudinal and circumferential seams.

7.

Check welding being performed in accordance with procedure and inspect:

-

Root pass

Filler runs

Final after capping run

Grinding back to sound metal where second side weld required.

COMMENTS:

-

Check to include:

Application of preheat and inter-pass temperature

Correct type and size of electrode or wire for root and capping runs

Each weld to carry welder's identification (method of identification to be agreed

with Purchaser for alloy, austenitic and low temperature steel plus non-ferrous

material).

8.

Inspect during fabrication and check shape and workmanship of dished head

manufacture as 5. through 7. above. Note minimum thickness at knuckle radius.

9.

Inspect branch connections before welding. Particularly for excessive root gap,

misalignment with hole penetration in plate/tube; surface condition of weld

preparation. Note: Flame cut holes to have all heat affected areas removed by

grinding.

10.

Inspection of completed branch attachment welds and flange/neck welds. Check

no flange face distortion or damage to joining faces. Ensure that where

Paper Copies are UNCONTROLLED - Check with Document Control for latest available

Revision CONTROLLED copies should be RED stamped

CONOCOPHILLIPS INDONESIA INC. LTD.

PROJECTS DEPARTM ENT

TITLE

SPECIFICATION

DOCUMENT NUMBER

REV

INSPECTION AND

TESTING REQUIREMENTS

FOR EQUIPMENT AND

MATERIAL

84501 -9200-9P-006

DATE

PAGE

8 March

04

16 of 34

compensating pads are fitted, API tapped vent holes are provided (provision for

vent holes in slip-on flanges where specified).

11.

Inspection of completed external attachment welds. Ensure API tapped vent

holes are provided on saddles/ doubling plates which cross main longitudinal or

circumferential shell welds.

N.B. Where vessel to be insulated, all tapped holes to be fitted with extension

tube extending beyond insulation prior to shipment from works.

12.

Check and approve NDT operator qualification meets NDT criteria. Where

Contractor has own NDT facility, check competence of operator and assess

facilities/ equipment.

13.

Check and approve NDT procedures:

14.

Dye penetrant

Magnetic particle

Ultrasonic

Radiographic

Witness following NDT:

Dye Penetrant:

-

Root run (including second side if applicable)

Completed weld

After heat treatment

Review all reports

Magnetic Particle:

-

Root run (including second side if applicable)

Completed weld

After heat treatment

Review all reports

Ultrasonic Examination:

-

Review examination report

Radiography:

-

Interpret radiographs

Review report

Paper Copies are UNCONTROLLED - Check with Document Control for latest available

Revision CONTROLLED copies should be RED stamped

CONOCOPHILLIPS INDONESIA INC. LTD.

PROJECTS DEPARTM ENT

TITLE

INSPECTION AND

TESTING REQUIREMENTS

FOR EQUIPMENT AND

MATERIAL

NB -

SPECIFICATION

DOCUMENT NUMBER

REV

84501 -9200-9P-006

DATE

PAGE

8 March

04

17 of 34

percentage radiography to include a random sample from each welder for

spot R.T.

Paper Copies are UNCONTROLLED - Check with Document Control for latest available

Revision CONTROLLED copies should be RED stamped

CONOCOPHILLIPS INDONESIA INC. LTD.

PROJECTS DEPARTM ENT

SPECIFICATION

DOCUMENT NUMBER

REV

TITLE

INSPECTION AND

TESTING REQUIREMENTS

FOR EQUIPMENT AND

MATERIAL

84501 -9200-9P-006

DATE

PAGE

8 March

04

18 of 34

COMMENTS:

-

MT of all seam/nozzle/ branch and internal attachment welds in

ferrous materials.

Review all required radiographs.

All seams covered by compensating pads on doubling plates to be

radiographed prior to their attachment.

15.

Visual examination; all external and internal attachment welds to the pressure

shell complete/ acceptable; (before stress relieving if applicable).

16.

Review Heat Treatment Procedures.

17.

Witness soapy water/air test on compensating and doubling plates (before stress

relieving where applicable). 10% witnessing as a minimum requirement and

review test reports.

18.

Check suitability and calibration records of thermal measurement equipment and

positioning of temperature probes.

19.

Review Heat Treatment Record chart for compliance with ASME Code and P.O.

specifications.

20.

Witness hydrotest. During test check for any undue deflections, pressure

drops/variations, water temperature and chloride content.

21.

Verify nameplate detail correct and stamped with relevant Inspection Authority

stamp when required. Ensure correct weight indicated and verified.

22.

Witness vessel draining; ensuring adequate venting and vessel fully drained prior

to shipment.

23.

Final external, internal inspection and dimensional check. Before final close

check that all relevant bolts and gaskets are in place and that vessel internals are

supported and protected to avoid damage in transit, e.g., dip pipes. All internal

bolts are tightened and locked. All external openings are protected and sealed.

24.

Inspect painting system or other protection specified. Ensure preparation,

application, thickness and paint specification in accordance with specified

requirements.

25.

Inspect insulation, ensure where vent holes have been provided in vessel

external attachments that vent pipes are fitted. Check vapour barrier, insulation

and cladding grade, thickness. All seams or apertures in cladding sealed with

mastic.

Paper Copies are UNCONTROLLED - Check with Document Control for latest available

Revision CONTROLLED copies should be RED stamped

CONOCOPHILLIPS INDONESIA INC. LTD.

PROJECTS DEPARTM ENT

TITLE

INSPECTION AND

TESTING REQUIREMENTS

FOR EQUIPMENT AND

MATERIAL

SPECIFICATION

DOCUMENT NUMBER

REV

84501 -9200-9P-006

DATE

PAGE

8 March

04

19 of 34

26.

Review, approve and countersign Manufacturing Data Books and Fabrication

Data Dossiers.

27.

Inspect shipment preparation, packing, opening protection, dry-out, purging and

marking.

28.

Additional minimum requirements for site erected tankage only.

-

Vacuum box test floor

MT/DP floor to shell welds internal/external

Air on water roof test.

Additional Requirements for Heat Exchangers

29.

Tube end weld procedure approved and in accordance with Contractors

specification (if applicable).

30.

Tube roll expansion procedure approved and in accordance with Contractors

specification.

31.

Inspect weld procedure qualification test blocks for tube end welding process and

approve mechanical testing and NDT results. (to include any shift test block

requirements where specified)

32.

Review and approve results of ultrasonic examination of tube-sheet before drilling

and following explosive cladding where applicable.

33.

Inspect tube-sheets following machining and check ligament size, weld

preparations and detail of rolling grooves in accordance with appropriate TEMA

classification. Tube holes to be checked for ovality, diameter, tolerance and

surface finish.

NOTE: Check minimum of 10%

34.

Inspect bellows assembly following welding of;

-

Root pass

Final capping run

Second side where applicable

35.

Witness dye penetrant/MT examination of bellows assembly finished weld.

36.

Review NDT reports, DP, MT, radiographic, other, bellows assembly.

-

Interpret radiographs

Paper Copies are UNCONTROLLED - Check with Document Control for latest available

Revision CONTROLLED copies should be RED stamped

CONOCOPHILLIPS INDONESIA INC. LTD.

PROJECTS DEPARTM ENT

TITLE

INSPECTION AND

TESTING REQUIREMENTS

FOR EQUIPMENT AND

MATERIAL

SPECIFICATION

DOCUMENT NUMBER

REV

84501 -9200-9P-006

DATE

PAGE

8 March

04

20 of 34

37.

Check and inspect test rings/glands available for leak and hydrostatic testing

where applicable; i.e.; "U" tube and floating head exchangers (will be supplied as

specified in Purchase Order).

38.

Material inspected and positively identified against material certificate.

39.

Examine assembly of tubes, baffles, tie rods, spacers. Note provision of sliding

strips on floating head and 'U' tube exchangers. Check tolerances before tube

end welding or expansion is performed; baffle clearance correct, tube/tube hole

clearances in baffles correct; tube/tube-sheet is fully de-greased prior to welding.

40.

Where measured tube expansion is specified check tube ends for scoring or

damage after expansion.

NOTE: Examine a minimum of 50%

41.

Inspect during tube expanding or tube end welding for compliance with

procedure.

NOTE: Examine as necessary to determine compliance.

42.

Witness dye penetrant examination of tube end welds.

-

Final

NOTE: Examine 100%

43.

Witness leak test of tube end welds (before and after post weld tube expansion if

called for) before hydrotest. Assess results of test and if leaks exceed 1% of the

tube welds per tube-sheet refer to Contractor for full investigation.

44.

Check gasket material and installation is correct prior to assembly for test. Also

conduct following test if bundle removed. In such cases, new gaskets to be fitted.

45.

Witness shell side hydrostatic test (tube sheets exposed).

46.

Witness tube side hydrostatic tests including channels and covers.

47.

Ensure all exchanger test rings/glands, etc. as specified on purchase order are

available for shipment with exchanger. Test rings should be those incorporated

in final hydrostatic test.

48.

Witness tubing bundle insertion to assure no undue strain is imposed.

Paper Copies are UNCONTROLLED - Check with Document Control for latest available

Revision CONTROLLED copies should be RED stamped

CONOCOPHILLIPS INDONESIA INC. LTD.

PROJECTS DEPARTM ENT

SPECIFICATION

DOCUMENT NUMBER

REV

TITLE

INSPECTION AND

TESTING REQUIREMENTS

FOR EQUIPMENT AND

MATERIAL

84501 -9200-9P-006

DATE

PAGE

8 March

04

21 of 34

APPENDIX 4

MINIMUM INSPECTION REQUIREMENTS

PIPING

1.

Minimum inspection requirements for piping systems incorporating all pipe,

valves, flanges, fittings etc. shall be in accordance with ANSI B31.3

supplemented by any additional requirements defined in Company specifications.

2.

All piping system specifications shall be reviewed by Company to ensure

consistency in application of inspection and certification requirements with

respect to piping classes, components, material and duty. This requirement is

particularly important on piping systems interfacing with other Contractors where

consistency of requirements is essential both on safety grounds and also to

facilitate system handover.

3.

Procurement specifications for bulks shall, as a minimum, comply with the

requirements of the Contract documents.

4.

Procurement specifications for valves shall comply with Project approved codes

and standards and should be consistent with respect to Contractors piping

classes, duty and materials of construction.

5.

Requirements for supplementary inspection and certification as referenced in

applicable codes and standards shall be determined by the Contractor.

NOTE:

Refer to Appendices 8-10 for Material Traceability and Certification

and Positive Material Identification requirements.

Paper Copies are UNCONTROLLED - Check with Document Control for latest available

Revision CONTROLLED copies should be RED stamped

CONOCOPHILLIPS INDONESIA INC. LTD.

PROJECTS DEPARTM ENT

SPECIFICATION

DOCUMENT NUMBER

REV

TITLE

INSPECTION AND

TESTING REQUIREMENTS

FOR EQUIPMENT AND

MATERIAL

84501 -9200-9P-006

DATE

PAGE

8 March

04

22 of 34

APPENDIX 5

MINIMUM INSPECTION REQUIREMENTS

MACHINERY

1.

The supplementary inspection requirements as defined in this Appendix only

apply to machinery in Criticality Rating 1 and Criticality Rating 2. In distinguishing

the requirement for levels of inspection between the two classifications, refer to

the General Notes, Appendix 1 Notes 1. and 5.

2.

The requirements of this Appendix cover the minimum engineering QC/

Inspection requirements for machinery whether individual or part of a package

unit.

3.

As a minimum, all Criticality Rating 3 machinery shall comply Project

specifications Deviations are subject to Company approval and should be sought

where cost effectiveness and proven established practice can be justified.

4.

Machinery classified as Criticality Rating 4 shall satisfy the Contractors

procurement specification requirements. Standard equipment or off the shelf

items as determined by the Contractor, which have been tested and certified as

conforming with the product purchasing specification would be acceptable.

NOTE: Refer to Appendices 8-10 for Material Traceability, Certification and

Positive Material Identification requirements.

INSPECTION ACTIVITY

5.

Pre-production visit to Supplier's works to check the following:

-

Supplier has and understands all relevant standards and specifications.

Drawings approved before manufacture commences.

Any special manufacturing process as defined by the Contractors or

suppliers specification or standards are approved.

Sub orders have been placed and contain relevant specifications,

standards, and drawings as appropriate.

Manufacturing

commences

Documentation, certification, mechanical data and fabrication data dossier

requirements defined.

quality

control

plan

approved

before

manufacture

COMMENTS:

-

Check and record all document/drawing numbers and revision

status.

Paper Copies are UNCONTROLLED - Check with Document Control for latest available

Revision CONTROLLED copies should be RED stamped

CONOCOPHILLIPS INDONESIA INC. LTD.

PROJECTS DEPARTM ENT

SPECIFICATION

DOCUMENT NUMBER

REV

TITLE

INSPECTION AND

TESTING REQUIREMENTS

FOR EQUIPMENT AND

MATERIAL

6.

7.

84501 -9200-9P-006

DATE

PAGE

8 March

04

23 of 34

Special manufacturing procedures should typically include:

Welding procedures

NDT procedures

Heat treatment procedures

Hard facing/coating procedures

Forming procedures unique to manufacturing process.

Function and Performance Test procedures.

Inspect material and verify compliance with certification, design and specification

requirements for:

-

Chemical analysis and physical properties

Material tests

Heat treatment

NDT examinations

Alloy verification (portable material analyzer)

Check that material control implemented at following stages and that

identification and traceability are maintained:

-

Stores inward

During storage

During manufacture through to final acceptance

Control of welding consumables

8.

Check material in accordance with Purchaser's specification; i.e.; ASTM, API;

schedule/rating, welded or screwed connections.

9.

Witness welding procedure qualification (to include all mechanical tests, NDT and

test plates as required by code).

Review/approve WPS weld procedure specification and

procedure qualification record

WPQR weld

N.B. existing weld procedures may be acceptable if they are current and valid as

determined by applicable code.

10.

Verify welder qualifications current and applicable to approved procedure.

11.

Dimensional check of:

-

Major static/rotating components

Paper Copies are UNCONTROLLED - Check with Document Control for latest available

Revision CONTROLLED copies should be RED stamped

CONOCOPHILLIPS INDONESIA INC. LTD.

PROJECTS DEPARTM ENT

SPECIFICATION

DOCUMENT NUMBER

REV

TITLE

INSPECTION AND

TESTING REQUIREMENTS

FOR EQUIPMENT AND

MATERIAL

84501 -9200-9P-006

Bearing/sleeve/thrust/seal sizes; clearances

Nozzle elevation/orientations

Bed-plate/hold down bolt hole location

DATE

PAGE

8 March

04

24 of 34

12.

Verify NDT operators' qualifications are current and applicable to NDT scope.

Where supplier has own NDT facility, assess suitability and operator

competence.

13.

Witness following NDT activities of castings or welded fabricated components:

-

Dye penetrant

Magnetic particle

Ultrasonic (Review reports only)

Radiography (Inte rpret radiographs and review reports, only)

COMMENTS:

-

Machined components only; extent of NDT examination to be in

accordance with procurement specification and as agreed on

Suppliers manufacturing quality plan.

NDT requirements for ancillary equipment and pipe work to be in

accordance with this section of the procedure.

14.

Check surface finish in accordance with specification requirements on critical

components, i.e.; bearings, journals, thrust collars, and fitted bonnets.

15.

Witness balancing of rotating element:

16.

Couplings

Impellers

Gearwheels

Rotor and rotor assembly

Witness over-speed checks on rotating components:

-

Impellers

17.

Where applicable, check heat treatment procedure approved; verify calibration

and location of temperature probes correct. (stress relieving of fabricated

components)

18.

Where applicable, check heat treatment record chart, verify treatment controlled

within parameters.

Paper Copies are UNCONTROLLED - Check with Document Control for latest available

Revision CONTROLLED copies should be RED stamped

CONOCOPHILLIPS INDONESIA INC. LTD.

PROJECTS DEPARTM ENT

TITLE

INSPECTION AND

TESTING REQUIREMENTS

FOR EQUIPMENT AND

MATERIAL

SPECIFICATION

DOCUMENT NUMBER

REV

84501 -9200-9P-006

DATE

PAGE

8 March

04

25 of 34

19.

Hydrostatic test of machine casing, to include where applicable, all ancillary pipe

work and equipment.

20.

Mechanical running test of machine and auxiliaries when specified.

21.

Performance test, when specified on equipment data sheet.

22.

Strip test - bearing and seal examination.

23.

String test (complete unit test) when specified on equipment data sheet.

24.

Witness and verify noise level measurement complies with contractor's

specification.

25.

Witness and verify vibration levels within limits as defined in Contractors

specification.

26.

Final inspection and cleanliness check prior to shipment. Ensure all machine

surfaces protected, openings sealed, paint coatings applied where specified; all

nameplates fitted and correctly labelled (including ancillary components). Ensure

any temporary transportation restraints, supports secure and clearly identified.

27.

Review and approve Mechanical Data and Fabrication dossiers, Operating and

Maintenance Manuals, Spares Schedules.

28.

NPSH test to API and ANSI standard, as required.

29.

Operational tests of lube oil console, including cleanliness test. (API) standard

minimum supplemented by Contractor's standard.)

30.

Final dimensional check for field corrections in relation to anchor bolt holes,

grade, etc are per approved outline drawing.

31.

Electrical function test to NEMA and order specifications.

32.

Witness gas leak test when specified. (API standard)

Paper Copies are UNCONTROLLED - Check with Document Control for latest available

Revision CONTROLLED copies should be RED stamped

CONOCOPHILLIPS INDONESIA INC. LTD.

PROJECTS DEPARTM ENT

SPECIFICATION

DOCUMENT NUMBER

REV

TITLE

INSPECTION AND

TESTING REQUIREMENTS

FOR EQUIPMENT AND

MATERIAL

84501 -9200-9P-006

DATE

PAGE

8 March

04

26 of 34

APPENDIX 6

MINIMUM INSPECTION REQUIREMENTS

ELECTRICAL

1.

The supplementary inspection requirements as defined in this Appendix only

apply to electrical equipment such as motors, transformers, variable speed drives

and switch gear in Criticality Rating 1 and Criticality Rating 2. In distinguishing the

requirements for levels of inspection between the two classifications, refer to the

General Notes, Appendix 1 notes 1. and 5.

2.

The requirements of this section cover the minimum engineering quality

control/inspection requirements for classes of electrical equipment as defined in

1.0 above and whether individual or part of a package unit.

3.

As a minimum, inspection requirements for all Criticality Rating 3 electrical

equipment shall comply with appropriate IEEE Institute of Electric al and

Electronic Engineers inc. regulations, Contractor's specifications and Deviations

are subject to Company approval. Company approval should also be sought

where cost effectiveness and proven established practice can be justified.

4.

Electrical equipment classified as Criticality Rating 4 shall satisfy the Contractors

procurement specification requirements. Standard proprietary equipment or off

the shelf items as determined by the Contractor, and which has been tested and

certified as conforming with the product purchasing specification would be

acceptable.

5.

For major electrical machines, refer also to Appendix 5, Machinery inspection

Requirements.

NOTE:

Refer to Appendices 8 and 9 for Material Traceability and

Certification Requirements.

INSPECTION ACTIVITY

6.

Pre-production visit to Supplier's works to check the following:

-

Supplier has and understands all relevant standards and specifications.

Drawings approved before manufacture commences when required in the

purchase order.

Any special manufacturing process as defined or supplier's specification or

standards are approved.

Sub orders have been placed and contain relevant specifications,

standards, and drawings as appropriate.

Paper Copies are UNCONTROLLED - Check with Document Control for latest available

Revision CONTROLLED copies should be RED stamped

CONOCOPHILLIPS INDONESIA INC. LTD.

PROJECTS DEPARTM ENT

SPECIFICATION

DOCUMENT NUMBER

REV

TITLE

INSPECTION AND

TESTING REQUIREMENTS

FOR EQUIPMENT AND

MATERIAL

84501 -9200-9P-006

DATE

PAGE

8 March

04

27 of 34

Manufacturing quality control plan approved

commences (including those of sub suppliers).

before

manufacture

Documentation, certification, data dossier and QC dossier requirements

defined.

COMMENTS:

-

Check and record all document/drawing numbers and revision

status.

7.

Audit/examine material and verify compliance with material certification, design,

specification and IEEE regulations as defined in the Contractors specification.

Review manufacturers test certificate.

8.

Where specified, check that material control is implemented and that

identification and traceability are maintained throughout manufacture and final

acceptance.

9.

Pre-assembly components inspection, ensure all components which make up a

complete item/system are inspected and checked to ensure:

10.

Traceability maintained

Rating in accordance with specifications

Components are free from injurious defects.

Where specified in Contractors specification or IEEE regulations ensure all

pressure containment components are hydrostatically tested.

-

Review certificate of test only.

COMMENTS:

Where ancillary items or pipe work are used to provide cooling, etc., these

shall be subjected to hydrostatic test

-

Associated motor oil coolers, etc.

Electrical items such as oil reservoirs on transformers.

11.

Initial assembly and function test (including all calibration checks, tests as defined

in the Contractors specifications, engineering standards and IEEE regulations

referred to therein).

12.

Final acceptance test.

13.

Review and approve Mechanical Data and Fabrication dossiers, Operating and

Maintenance Manuals and Spares Schedules.

Paper Copies are UNCONTROLLED - Check with Document Control for latest available

Revision CONTROLLED copies should be RED stamped

CONOCOPHILLIPS INDONESIA INC. LTD.

PROJECTS DEPARTM ENT

TITLE

INSPECTION AND

TESTING REQUIREMENTS

FOR EQUIPMENT AND

MATERIAL

14.

SPECIFICATION

DOCUMENT NUMBER

REV

84501 -9200-9P-006

DATE

PAGE

8 March

04

28 of 34

Preparation of shipment, ensure all machine surfaces are protected, openings

are sealed, paint coatings are applied where specified; all nameplates are fitted

and correctly labelled, including hazard warning labels.

Ensure that all temporary transportation restrain ts and supports are secure and

clearly identified.

Paper Copies are UNCONTROLLED - Check with Document Control for latest available

Revision CONTROLLED copies should be RED stamped

CONOCOPHILLIPS INDONESIA INC. LTD.

PROJECTS DEPARTM ENT

SPECIFICATION

DOCUMENT NUMBER

REV

TITLE

INSPECTION AND

TESTING REQUIREMENTS

FOR EQUIPMENT AND

MATERIAL

84501 -9200-9P-006

DATE

PAGE

8 March

04

29 of 34

APPENDIX 7

MINIMUM INSPECTION REQUIREMENTS

INSTRUMENTATION

1.

The minimum inspection requirements for standard instruments shall comply with

relevant Company specifications and Contractors procedures and sta ndards.

2.

Instrument "specials" i.e. items which are not normal supply, or are unique to the

process design requirements shall be identified on a specific list copied to the

Company. Such instrumentation particularly where manufacturing processed

involve specialized techniques, i.e. specialized castings, welding, NDT or heat

treatment, adequate levels of inspection and test in the purchase order

specifications.

NOTE:

Refer to Appendices 8-10 for Material Traceability, Certification and

Positive Material Identification requirements.

Paper Copies are UNCONTROLLED - Check with Document Control for latest available

Revision CONTROLLED copies should be RED stamped

CONOCOPHILLIPS INDONESIA INC. LTD.

PROJECTS DEPARTM ENT

SPECIFICATION

DOCUMENT NUMBER

REV

TITLE

INSPECTION AND

TESTING REQUIREMENTS

FOR EQUIPMENT AND

MATERIAL

84501 -9200-9P-006

DATE

PAGE

8 March

04

30 of 34

APPENDIX 8

MATERIAL TRACEABILITY REQUIREMENTS

To be read in conjunction with Appendices 9 and 10. Refer to the Contract document for

definition of Material Traceability.

1.

Material traceability is the ability to trace to Material Test Reports (MTR's) at any

stage from purchase to installation.

2.

The scope of Material Traceability required is outlined in Appendices 9 & 10.

3.

Marking of materials shall as a minimum comply with relevant US codes and

standards and be transferred to off cuts where appropriate to maintain required

levels of traceability.

4.

Individual Contractors shall be responsible for implementing their own systems to

achieve required levels of material traceability. The system shall demonstrate that

material control, segregation, marking and traceability is planned and

documented to provide the necessary level of assurance to the Company that

installed materials of construction are certified and fully comply with the

applicable code and specification requirements.

5.

Where Material Test Reports are required, heat numbers will be traceable to the

individual material component.

6.

Where Material Test Reports are not required, marking shall be in accordance

with relevant Codes and Standards.

7.

The Contractors system for Material Traceability during site fabrication shall

facilitate compliance with requirements of the Contract document with respect to

system acceptance certification.

8.

Material color coding requirements shall comply with Project specifications

requirements.

Paper Copies are UNCONTROLLED - Check with Document Control for latest available

Revision CONTROLLED copies should be RED stamped

CONOCOPHILLIPS INDONESIA INC. LTD.

PROJECTS DEPARTM ENT

SPECIFICATION

DOCUMENT NUMBER

REV

TITLE

INSPECTION AND

TESTING REQUIREMENTS

FOR EQUIPMENT AND

MATERIAL

84501 -9200-9P-006

DATE

PAGE

8 March

04

31 of 34

APPENDIX 9

M ATERIAL TEST REPORT REQUIREMENTS

To be read in conjunction with Appendices 8 and 10. Refer to the Contract document for

definition of Material Test Reports (MTR's).

1.

General Notes:

Section A: For ANSI/ASME P1 Material Grades

I.

MTR's will only be required if specifically requested in Contractors

specifications. Approved design codes or purchase orders. Typically the

following examples would be advised:

-

carbon steel vessels where metallurgy is critical i.e. low

temperature equipment.

boiler code piping; SA 106

materials are required to satisfy NACE standards in H2S or other

similar duties where composition and metallurgy of finished

condition is critical.

materials restricted to maximum carbon content below standard.

II.

Contractor will be clearly defined in the appropriate design and purchase

documents.

III.

For vessels fabricated in accordance with ASME rules, the Authorized

Inspection may require MTR's for other specific cases in which case they

will be provided.

IV.

Other standard carbon steel products will require a certificate of

conformance issued by the organization qualified to certify that products

comply with specified requirements.

Section B: For ANSI/ASME materials higher than P1

V.

MTR's shall be required for all materials higher than P1, i.e. alloy steels,

stainless steel grades, etc.

VI.

Exceptions to the above may be referred to the Project Specialist where

use of the material is not relevant to process design conditions or for

safety reasons but constitutes Contractors or manufacturers normal

standard i.e. instrumentation components. Such concessions shall be

documented in accordance with the Company specifications.

Paper Copies are UNCONTROLLED - Check with Document Control for latest available

Revision CONTROLLED copies should be RED stamped

CONOCOPHILLIPS INDONESIA INC. LTD.

PROJECTS DEPARTM ENT

TITLE

SPECIFICATION

DOCUMENT NUMBER

REV

INSPECTION AND

TESTING REQUIREMENTS

FOR EQUIPMENT AND

MATERIAL

84501 -9200-9P-006

DATE

PAGE

8 March

04

32 of 34

Section C: Form of Certificates

VII.

Standard Material Test Report/Material Certificates satisfying the

applicable Code requirements are acceptable. The European

requirements for type A, B, or C material certificates shall not be

mandatory.

VIII.

The form of the certificate shall contain a record of chemical composition,

supplied condition and physical properties, including the results of any

specific tests required by the purchase order or specification; i.e. hardness

values, Charpy impact test results etc.

IX.

Such MTR's shall be furnished and authenticated by the material

manufacturers and traceable to individual components. Copies of original

MTR's are acceptable.

Section D: Civil

X.

As a minimum, the Contractor shall provide MTR's for structural

assemblies employing critical materials of construction. The scope shall be

determined by the Contractor but should typically include for:

- primary structural steel

- lifting devices, runway beams, gantries, cranes, etc.

- equipment anchor bolts where critical to security of the item.

Section E: Electrical

XI.

As a minimum, the Contractors system shall ensure certification is

available for electrical equipment consistent with an item's electrical rating

and classification in compliance with hazardous zone ratings. Certification

is to be verified during installation and site acceptance.

Section F: Bolting

XII.

`The Contractors system for the inspection and verification that bolting

materials comply with specified requirements shall ensure incorrect or

rogue bolting materials are rejected at the suppliers or prior to receipt in

module yard or site stores.

Paper Copies are UNCONTROLLED - Check with Document Control for latest available

Revision CONTROLLED copies should be RED stamped

CONOCOPHILLIPS INDONESIA INC. LTD.

PROJECTS DEPARTM ENT

TITLE

INSPECTION AND

TESTING REQUIREMENTS

FOR EQUIPMENT AND

MATERIAL

SPECIFICATION

DOCUMENT NUMBER

REV

84501 -9200-9P-006

DATE

PAGE

8 March

04

33 of 34

APPENDIX 10

POSITIVE MATERIAL IDENTIFICATION REQUIREMENTS

To be read in conjunction with Appendices 8 and 9 for definition of Positive Material

Identification (PMI) and Alloy Verification (AV).

1.

Attention is drawn to the need for each Contractor to read and familiarize itself

with the Contract Document.

2.

Alloy materials shall as a minimum comply with the Project requirements for PMI,

which includes the requirements of MTR's, marking, traceability and AV.

3.

Specific traceability to as built drawings will not be required by the Company as

part of the final handover documentation; refer to Project Procedure 84501-92009L-002

4.

The Contractors PMI program shall demonstrate that the system for tracing

material to MTR's provides for simple traceability during purchasing, stores

control, fabrication and installation. The following sections provide guidance to

the Contractor for the determination of PMI requirements, but does not relieve the

contractor from its obligation to include any additional materials in the PMI

programme where it considers this to be justified or necessary.

5.

Components subject to PMI:

5.1

Vessels and Piping Systems

All pressure retaining parts. PMI for internals as determined by the Contractor

and defined in procurement documentation.

5.2

Machinery:

Pressure containing casing. PMI of ancillary components and internals as

determined by the Contractor and defined in procurement documentation.

5.3

Instruments:

As determined by the Contractor.

5.4

Bolting:

As determined by the Contractor, but as a minimum:

-

to include sampling check of all bulk alloy steel stud bolts included in the

ASTM A-193 classification.

alloy bolts critical to and used in equipment subject to PMI.

Paper Copies are UNCONTROLLED - Check with Document Control for latest available

Revision CONTROLLED copies should be RED stamped

CONOCOPHILLIPS INDONESIA INC. LTD.

PROJECTS DEPARTM ENT

TITLE

INSPECTION AND

TESTING REQUIREMENTS

FOR EQUIPMENT AND

MATERIAL

5.5

SPECIFICATION

DOCUMENT NUMBER

REV

84501 -9200-9P-006

DATE

PAGE

8 March

04

34 of 34

Welding:

As determined by the Contractor but as a minimum PMI of sample deposit of

finished weld.

Paper Copies are UNCONTROLLED - Check with Document Control for latest available

Revision CONTROLLED copies should be RED stamped

You might also like

- Detail Waktu - Per Tim DisiplinDocument1 pageDetail Waktu - Per Tim DisiplinYuda SatriaNo ratings yet

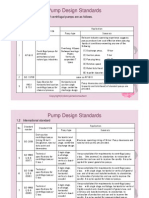

- Pump Standards ComparisonDocument4 pagesPump Standards ComparisonAnish Dani50% (2)

- 9200 9P 009 - R1Document14 pages9200 9P 009 - R1Yuda SatriaNo ratings yet

- Toyo 56-87Document123 pagesToyo 56-87Yuda SatriaNo ratings yet

- Asme InterpretationDocument72 pagesAsme Interpretationbbmoksh100% (2)

- 9200 9P 007 - R1Document25 pages9200 9P 007 - R1Yuda SatriaNo ratings yet

- 9200 9P 005 - R2Document23 pages9200 9P 005 - R2Yuda Satria100% (1)

- 9200 9L 039 - R2Document17 pages9200 9L 039 - R2Yuda SatriaNo ratings yet

- CONOCO PHILLIPS SpecDocument21 pagesCONOCO PHILLIPS SpecYuda Satria100% (1)

- 9200 9L 039 - R2Document17 pages9200 9L 039 - R2Yuda SatriaNo ratings yet

- Asme b18.2.3Document19 pagesAsme b18.2.3amrandconanNo ratings yet

- Toyo 1-55Document435 pagesToyo 1-55Yuda Satria100% (1)

- Stds XrefDocument2 pagesStds XrefAnonymous qhVGVpNo ratings yet

- Asme V Si UnitsDocument3 pagesAsme V Si UnitsvidhisukhadiyaNo ratings yet

- Asme 1 CodesDocument3 pagesAsme 1 CodesmilesmiconNo ratings yet

- H99appnf IIDocument2 pagesH99appnf IIYuda SatriaNo ratings yet

- Appendix I - Mandatory Preparation of Technical Inquiries To TheDocument1 pageAppendix I - Mandatory Preparation of Technical Inquiries To TheJason501No ratings yet

- Sec 1 PT PWT PDFDocument7 pagesSec 1 PT PWT PDFYuda SatriaNo ratings yet

- ARTICLE NF-8000 Certificates of Authorization and Certificates of ConformanceDocument2 pagesARTICLE NF-8000 Certificates of Authorization and Certificates of ConformanceYuda SatriaNo ratings yet

- Test Standard Benefits ArticleDocument8 pagesTest Standard Benefits Articleverat81No ratings yet

- Pump Standards ComparisonDocument4 pagesPump Standards ComparisonAnish Dani50% (2)

- Part PR Requirements For Boilers Fabricated by RivetingDocument1 pagePart PR Requirements For Boilers Fabricated by RivetingYuda SatriaNo ratings yet

- Summary of Code ChangesDocument4 pagesSummary of Code ChangesAlfredo MedinaNo ratings yet

- H 99 Sec 3 NF 5000Document4 pagesH 99 Sec 3 NF 5000Yuda SatriaNo ratings yet

- Appendix I - Mandatory Preparation of Technical Inquiries To TheDocument1 pageAppendix I - Mandatory Preparation of Technical Inquiries To TheJason501No ratings yet

- Summary of Code ChangesDocument4 pagesSummary of Code ChangesAlfredo MedinaNo ratings yet

- Appendix Nf-I: (In The Course of Preparation)Document2 pagesAppendix Nf-I: (In The Course of Preparation)Yuda SatriaNo ratings yet

- Asme V Si UnitsDocument3 pagesAsme V Si UnitsvidhisukhadiyaNo ratings yet

- Sec3ne 6000Document6 pagesSec3ne 6000Yuda SatriaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Technical Catalogue: Voidcon GroupDocument24 pagesTechnical Catalogue: Voidcon GrouprendaninNo ratings yet

- Sublimation Heat Press Quick Guide 1Document2 pagesSublimation Heat Press Quick Guide 1renato jr baylasNo ratings yet

- Catálogo EC200DDocument912 pagesCatálogo EC200DCasa da Madeira100% (1)

- Modern Infrastructure Scheme for Food ProcessingDocument11 pagesModern Infrastructure Scheme for Food Processingsomen79100% (1)

- COMPATIBILITY OF KNOCKOUTS AND FITTINGSDocument4 pagesCOMPATIBILITY OF KNOCKOUTS AND FITTINGSTinkyTonk86No ratings yet

- Glass Survey For Interior DesignerDocument23 pagesGlass Survey For Interior DesignerShiv Kumar0% (1)

- ProjectSchedulingHandbook 1Document391 pagesProjectSchedulingHandbook 1Lucio Loyloy SanchezNo ratings yet

- Building Consultants Quantity Surveyors ReportDocument151 pagesBuilding Consultants Quantity Surveyors ReportDante MutzNo ratings yet

- MSS - SP 9 2013Document10 pagesMSS - SP 9 2013Денис ПекшуевNo ratings yet

- Pour CardDocument2 pagesPour Cardsuchendra singhNo ratings yet

- Fire Safety of Concrete Structures:: Background To BS 8110 Fire DesignDocument47 pagesFire Safety of Concrete Structures:: Background To BS 8110 Fire DesigntorNo ratings yet

- ELECT-TIC-7.2-Installation of Grounding System, Grounding and Bonding AccessoriesDocument2 pagesELECT-TIC-7.2-Installation of Grounding System, Grounding and Bonding AccessoriesMuhammad IrfanNo ratings yet

- William Atienza's ResumeDocument4 pagesWilliam Atienza's ResumeMarie TamayoNo ratings yet

- Detailed Lesson Plan in Grade 8 EIMDocument5 pagesDetailed Lesson Plan in Grade 8 EIMMark Edison Mirando100% (7)

- Steel Cross-Section ClassificationDocument2 pagesSteel Cross-Section ClassificationMohan BhalmeNo ratings yet

- General Overview On Site Drawings & TSSRDocument35 pagesGeneral Overview On Site Drawings & TSSRNazmul Hossain RakibNo ratings yet

- CompanyListG LDocument198 pagesCompanyListG LMahasar SiddiquiNo ratings yet

- Door Reinforcement DesignDocument1 pageDoor Reinforcement DesignP.MannaNo ratings yet

- Cable LadderDocument164 pagesCable Ladderalfonso.parkerNo ratings yet

- EXPERIMENT and Latest EquipmentDocument10 pagesEXPERIMENT and Latest EquipmentMaria Cecille Sarmiento GarciaNo ratings yet

- Annexure To B.O. ULD 2018Document37 pagesAnnexure To B.O. ULD 2018pksunil_77No ratings yet

- ROTARY SCREW AIR COMPRESSOR SAFETY MANUALDocument86 pagesROTARY SCREW AIR COMPRESSOR SAFETY MANUALpabloNo ratings yet