Professional Documents

Culture Documents

Seawater Intake Optimization Study - MWWD2016

Uploaded by

MVCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Seawater Intake Optimization Study - MWWD2016

Uploaded by

MVCopyright:

Available Formats

MWWD & IEMES 2016 - BULGARIA

SEAWATER INTAKE DESIGN AND OPTIMIZATION

CASE STUDY: AL JUBAIL SWI

Mario Valente (1 ), Hugo Costa (2 )

Summary

This paper will present the methodology adopted from the concept stage of the hydraulic design of Al Jubail seawater intake, until

detailed design stage, which can be applied to the design and optimization of similar seawater intakes. This study followed the standard

practices for design, and was completed with validation by CFD and physical modelling.

Keywords

Seawater Intake, Pumping Station, Desalination, CFD Modelling, Physical Modelling

Introduction

Al Jubail seawater intake is located near the common seawater intake for Al Jubail Industrial City in the Kingdom of Saudi Arabia

(KSA)(Figure 1). Consisting of 5 pumps (4 duty + 1 standby), the nominal intake flow rate for this system is 29,950 m/hr (8.32 m/s). The

intake is developed by Al-Fatah Water and Power.

Figure 1 - Project location (Source: Google Earth)

Conceptual and Preliminary Designs of the SWI were previously carried out by the client for civil and geotechnical works. ARTELIA

undertook a value engineering study to minimize the site footprint, optimize the intake layout, identify adverse hydraulic conditions and

ensure uniform approach flow to the pump inlets. Computational Fluid Dynamic (CFD) modelling was used as a design tool early in the

project to identify problematic flow patterns such as short-cutting and recirculation zones.

Modelling results were used to develop of a number of alternative intake configurations to resolve the problematic flow patterns. The

final configuration was confirmed by subsequent CFD modelling then submitted to a hydraulics laboratory for physical modelling

(Laboratory Clemson Engineering Hydraulics, Inc. (CEH) performed these studies on behalf of the pump supplier FLOWSERVE). The

laboratory report confirmed that the optimized configuration performance was satisfactory and that the CFD results were well aligned

with findings of physical modelling.

1

2

Mario Valente (Mr) (Project Director) (Sogreah Gulf ARTELIA Group), Dubai, UAE mario.valente@ae.arteliagroup.com

Hugo Costa (Mr) (Hydraulic Engineer) (Sogreah Gulf ARTELIA Group), Dubai, UAE hugo.costa@ae.arteliagroup.com

Torbaty - page 1 of 6

MWWD & IEMES 2016 - BULGARIA

Hydraulic Design

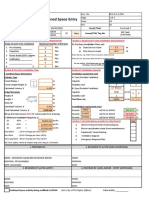

A preliminary design of the SWI pumping station was developed at early stages of the project. The hydraulic design philosophy has been

developed to:

Accommodate available screening equipment, and

Comply with site limitations resulting from existing civil works.

ARTELIA has followed the criteria and recommendations outlined in ANSI/HI 9.8-2012, the American National Standard for Rotodynamic

Pumps for Pump Intake Design (Hydraulic Institute, 2012). According to this Standard, a physical hydraulic model is required for pump

intakes where:

Flow per pump is greater than 2,520l/s, or total pumping station flow is greater than 6,310 l/s; and

Proper pump operation is critical and the total costs of pump repair, remediation of a poor design, and the impacts of

inadequate performance or pump failure would be more than ten times the cost of a model study.

ARTELIA performed a Computational Fluid Dynamics (CFD) analysis to confirm hydraulic performance of the proposed SWI layout at

concept stage. Based on results from the CFD modelling, ARTELIA proposed modifications on the pumping station, and these changes

were confirmed by physical model.

The SWI is a critical structure for the successful operation of the RO Plant and has therefore been designed with due consideration of the

requirements for redundancy and availability. The seawater intake channels and screening equipment incorporate 100% standby

capacity. Under normal operating mode, each screening channel will pass 50% of the required flow. During degraded operating mode,

when one screening channel is taken offline due to equipment failure or maintenance, 100% of the required intake flow can pass

through the remaining channel while maintaining suitable hydraulic conditions at the pumps.

Figure 2 - Al-Jubail pumping station 3D view

page 2 of 6

MWWD & IEMES 2016 - BULGARIA

CFD Modelling

CFD modelling was used to investigate the preliminary seawater intake configuration. The following points summarise the key findings

from the CFD modelling and the subsequent design optimizations.

Non-uniform flow distribution within the forebay propagated downstream into the individual pump bays which resulted in

both dead zones and areas of high velocity. To improve flow conditions, one row of baffle blocks was added at the upstream

end of the forebay.

Figure 3 - Flow streamlines across the station

To improve the flow distribution within the pump bays, six baffles were added at the upstream end of each bay. Modelling

outputs showed that the resulting flow distribution was uniform and the pump approach velocity was less than 0.5 m/s, in

compliance with the ANSI/HI 9.8 standard.

Figure 4 - Velocity profile at level -3.50m.

Surface and submerged vortices of Type II and greater were observed. These vortices are deemed unacceptable according to

the ANSI/HI 9.8 standard. Vortices were addressed by adding geometry features such as wall fillets and flow splitters.

Based on previous experience with physical modeling studies, these particular double inlet pumps are prone to surface and

submerged vortices. As such, the CFD report recommended that physical modelling be used to further investigate vortex

formation and to develop suitable anti-vortex devices (AVDs).

Figure 5 shows the preliminary as well as the final geometry which was developed using CFD modeling.

page 3 of 6

MWWD & IEMES 2016 - BULGARIA

Figure 5 - Al-Jubail pumping station - preliminary layout and final proposed layout

Physical Modelling

After the CFD analysis was completed, the final configuration of the pump intake structure was submitted to a hydraulics laboratory for

physical modeling (Figure 6).

Figure 6 Physical model of Al-Jubail pumping station

The physical modeling study was conducted at a scale of 1:5.3. The overall physical model results confirmed that the intake was welldesigned with no major problems regarding the pump approach flow conditions. The testing also showed that flow conditions upstream

of the screen chambers were stable and uniform as shown in below figures.

Figure 7 - Uniform Flow in Screen Chamber (left) and mild Recirculation Downstream of Screen Exit (right)

Flow into the forebay was concentrated near the center with mild recirculation at the sides; this pattern is a typical pattern of the

screens used in this intake system. However, these flow conditions stabilized before reaching the pump bays. The flow straightening

baffles proposed by CFD modelling were also installed in the physical model at the pump bay entrances. Once through the baffles, the

flow was still slightly non-uniform across each bay, but uniform and steady by the time it reached the pumps. The physical model

demonstrated that the baffles were effective at stabilizing and distributing flow across each bay.

As predicted by CFD modeling, the physical model showed strong floor and side-wall vortices near the entrance to the lower pump

suction bellmouths. In addition, consistent vortex formation was observed on the cross-over arms above the upper suction bellmouths

(which is typical for this type of pump). These vortices entered the upper bellmouth but generally dissipated quickly. Well-organized

page 4 of 6

MWWD & IEMES 2016 - BULGARIA

Type III surface vortices were observed entering the upper bellmouths. Pre-swirl at the plane of the pump impeller was generally low

and turbulence/velocity variations were only slightly outside of the ANSI/HI 9.8 criteria. The baffles at the upstream end of the forebay

were found to be very beneficial in re-distributing the concentrated flow caused by discharge through the screens.

Figure 8 Sidewall vortex

The wall fillets and flow splitters were also found to be effective at dissipating floor and side-wall vortices from entering the lower

bellmouth. However, they did not prevent surface vortices from entering the upper bellmouth. A modified vortex suppression basket

was installed in the physical model to stabilize flows and dissipate vortices propagating towards the upper bellmouth.

Figure 9 Double inlet pump (left), Vortex Suppression Baskets (centre), proposed fillets/splitters (right)

From design to reality

The construction works of the pumping station are currently progressing on site. The hydraulic features to improve the approach flow to

the pumps, as the baffles walls are made of reinforced concrete as shown in Figure 10.

Figure 10 Progress of works on site. General view and forebay baffles.

Conclusions

A combined design approach using both CFD and physical modelling was adopted to develop and optimize the configuration of the AlJubail seawater intake. CFD modelling enabled the design team to quickly investigate various geometries with the objective to minimize

the intake footprint and reduce construction costs. Physical modelling validated the final configuration and was used to fine tune the

flow conditions and further reduce the risk of vortex propagation.

page 5 of 6

MWWD & IEMES 2016 - BULGARIA

Acknowledgements

We would like to thank Al Fatah Water and Power Company, Laboratory Clemson Engineering Hydraulics, Inc. (CEH) and Flowserve.

References

[1] American National Standards Institute, Intake Design for Rotodynamic Pumps (ANSI/HI 9.8-2012), 2012

[2] Clemson Engineering Hydraulics, Jubail SWRO Seawater Pump Intake Physical Model Study (2016)

page 6 of 6

You might also like

- Chapter 17 - MathematicsDocument13 pagesChapter 17 - MathematicsLivingston JosephNo ratings yet

- Service Manual 900 OG Factory 16V M85-M93Document572 pagesService Manual 900 OG Factory 16V M85-M93Sting Eyes100% (1)

- Bid ProcessDocument85 pagesBid ProcessRobiatol Adawiah Mohammad ShamsidiNo ratings yet

- Pipeline Design for Water EngineersFrom EverandPipeline Design for Water EngineersRating: 5 out of 5 stars5/5 (1)

- U TE4 FH Dxa 0 Yb IP6 F VMG YVAIIa R03 BVV 7Document51 pagesU TE4 FH Dxa 0 Yb IP6 F VMG YVAIIa R03 BVV 7JJ KohNo ratings yet

- AWWA M51 SummaryDocument10 pagesAWWA M51 Summaryvtsusr fv0% (1)

- Partially Full Pipe Flow Calculations Using Excel Spreadsheets 7-18-14Document28 pagesPartially Full Pipe Flow Calculations Using Excel Spreadsheets 7-18-14hrol310600% (1)

- 2010 AWWA Life Cycle HDPE in PW Apps Camille RubeizDocument37 pages2010 AWWA Life Cycle HDPE in PW Apps Camille RubeizmbobterateraNo ratings yet

- Well Design PDFDocument29 pagesWell Design PDFPratul ChoudhuryNo ratings yet

- The Crime of Galileo - de Santillana, Giorgio, 1902Document372 pagesThe Crime of Galileo - de Santillana, Giorgio, 1902Ivo da Costa100% (2)

- New Appendix 1 Non Revenue Water and Large Water Meter Calibration. Johnson E 6 May 2016Document11 pagesNew Appendix 1 Non Revenue Water and Large Water Meter Calibration. Johnson E 6 May 2016engkj100% (1)

- Infiltration Gallery Yamna PDFDocument5 pagesInfiltration Gallery Yamna PDFshamoojeeNo ratings yet

- Odor and Corrosion Control in Sanitary Sewerage Systems and Treatment PlantsDocument142 pagesOdor and Corrosion Control in Sanitary Sewerage Systems and Treatment PlantsLuis Antonio OrtegaNo ratings yet

- 2-New Completion Technology4Document7 pages2-New Completion Technology4klibiNo ratings yet

- UG Pipe CheckingDocument6 pagesUG Pipe Checkingnoto.sugiartoNo ratings yet

- Dosing Pump Technical Specification for Sardasht Water Treatment PlantDocument2 pagesDosing Pump Technical Specification for Sardasht Water Treatment PlantmeisamNo ratings yet

- TP40 20 Water TransmissionDocument24 pagesTP40 20 Water TransmissionNestor Augusto OyarceNo ratings yet

- False CeilingDocument70 pagesFalse CeilingBharti Sikri93% (15)

- Data Sheet Filter MediaDocument1 pageData Sheet Filter MediaNeelkantNo ratings yet

- Water Intake BrochureDocument16 pagesWater Intake BrochureNurliyana Abdul Raof100% (3)

- Passavant E&E Company Profile-4th QTRDocument77 pagesPassavant E&E Company Profile-4th QTRSami Sawalha100% (1)

- Water Transmission and Distribution SystemsDocument71 pagesWater Transmission and Distribution SystemsDr. Akepati Sivarami Reddy100% (6)

- Sea Water Intake & Outfall System For Coastal Power ProjectsDocument3 pagesSea Water Intake & Outfall System For Coastal Power ProjectsAldy NovaldyNo ratings yet

- Curtis E50 Pump Parts ListDocument8 pagesCurtis E50 Pump Parts ListrobertNo ratings yet

- Water Transmission PipelinesDocument16 pagesWater Transmission Pipelinesdownloadused33% (3)

- PDF IIHR402Document61 pagesPDF IIHR402Sanjib MazumderNo ratings yet

- Branding & Advertising (T NG H P) PDFDocument44 pagesBranding & Advertising (T NG H P) PDFNguyễn Ngọc Quỳnh Anh100% (1)

- Intake Discharge Report VipDocument154 pagesIntake Discharge Report VipMurali Krishna100% (1)

- Surge Analysis and The Wave Plan Method IntroDocument22 pagesSurge Analysis and The Wave Plan Method IntroVivek100% (2)

- Feasibility Study and Master Plan For Developing New Water Sources For Nairobi and Satellite Towns - Part 1 - Chapter 1-4Document136 pagesFeasibility Study and Master Plan For Developing New Water Sources For Nairobi and Satellite Towns - Part 1 - Chapter 1-4Plan Omwamba John KebariNo ratings yet

- Sea Water IntakeDocument9 pagesSea Water IntakeChungath LineshNo ratings yet

- Water Loss Analysis &reduction FinalDocument19 pagesWater Loss Analysis &reduction FinalpoornimaenvNo ratings yet

- Intake and outfall structure design optimizationDocument4 pagesIntake and outfall structure design optimizationMurali KrishnaNo ratings yet

- A Case Study On The Effect of Production Segmentation CompletionDocument9 pagesA Case Study On The Effect of Production Segmentation CompletionSara Kamil Abd Al-RedahNo ratings yet

- Multimedia Filtration: 3-Layer Water Filters Trap More ContaminantsDocument2 pagesMultimedia Filtration: 3-Layer Water Filters Trap More ContaminantsRavNo ratings yet

- Wastewater Pumping Stations Standard Specification FinalDocument37 pagesWastewater Pumping Stations Standard Specification FinalLuis ChavarriaNo ratings yet

- Ventilation Plan For Confined Space EntryDocument9 pagesVentilation Plan For Confined Space EntryMohamad Nazmi Mohamad Rafian100% (1)

- Sea Water IntakeDocument29 pagesSea Water IntakeDanang Rahadian100% (1)

- AWWADocument24 pagesAWWAhani_shaabanNo ratings yet

- SEA PUMP STATION OPERATIONDocument17 pagesSEA PUMP STATION OPERATIONJayne Mawusi Siaw-Botchway100% (1)

- Raw Water Intake DesignDocument6 pagesRaw Water Intake DesignCallidus101100% (2)

- 6.large Submersible Centrifugal PumpsDocument16 pages6.large Submersible Centrifugal PumpsOzren DjuricNo ratings yet

- Ch00 FM Wef Mop8 WebDocument21 pagesCh00 FM Wef Mop8 Webignacio51730% (1)

- SG 28 Intakes OutfallsDocument44 pagesSG 28 Intakes OutfallsMurali KrishnaNo ratings yet

- AGITAN Defoamer Technologies PDFDocument15 pagesAGITAN Defoamer Technologies PDFMarco Lopez100% (1)

- DESIGNING HYDRAULIC AIR Chamber in Water Sys PipelineDocument7 pagesDESIGNING HYDRAULIC AIR Chamber in Water Sys PipelinesaishankarlNo ratings yet

- Book 2: Chapter 4 - Fluid Flow: Application LimitationsDocument20 pagesBook 2: Chapter 4 - Fluid Flow: Application LimitationsVaniya GoelNo ratings yet

- OM14 Sea Water Intake StructuresDocument42 pagesOM14 Sea Water Intake StructuresIgnatius Samraj100% (1)

- General notes on water intake well constructionDocument4 pagesGeneral notes on water intake well constructionanil pkNo ratings yet

- AW MEM T 10 0004 Infiltration Gallery Seepage 20160808 R01Document75 pagesAW MEM T 10 0004 Infiltration Gallery Seepage 20160808 R01Adrian FrantescuNo ratings yet

- Sea Water System OperationsDocument28 pagesSea Water System Operationsrmm99rmm99No ratings yet

- 0.8 MLD STP Design DrawingsDocument9 pages0.8 MLD STP Design DrawingsAminur RahmanNo ratings yet

- Mineral Scale Prediction and Control at Extreme TDSDocument12 pagesMineral Scale Prediction and Control at Extreme TDSchanjunkaiNo ratings yet

- Fluor Piping TraingTOCDocument1 pageFluor Piping TraingTOCSergio SmithNo ratings yet

- JJGGJKDocument2 pagesJJGGJKTeuku M. Zachari AlamsyahNo ratings yet

- Faida WTP - Control PhilosophyDocument19 pagesFaida WTP - Control PhilosophyDelshad DuhokiNo ratings yet

- Siemens Forty X Disc Filters Tech. Specs.Document25 pagesSiemens Forty X Disc Filters Tech. Specs.Alfonso José García LagunaNo ratings yet

- Hyundai Pipe CatalogueDocument36 pagesHyundai Pipe Cataloguefelram100% (2)

- Biofouling in Reverse Osmosis: Phenomena, Monitoring, Controlling and RemediationDocument15 pagesBiofouling in Reverse Osmosis: Phenomena, Monitoring, Controlling and RemediationLê Duy NgọcNo ratings yet

- The Difference Between API, DIN, IsO, ASME PumpsDocument1 pageThe Difference Between API, DIN, IsO, ASME PumpstoicantailieunhatNo ratings yet

- Vortex Prediction in A Pump Intake System Using Computational Fluid DynamicsDocument6 pagesVortex Prediction in A Pump Intake System Using Computational Fluid DynamicsHema KumarNo ratings yet

- Ipa14 e 065Document13 pagesIpa14 e 065Ryan PermanaNo ratings yet

- SPE-196592-MS Comprehensive Review of Artificial Lift System Applications in Tight FormationsDocument21 pagesSPE-196592-MS Comprehensive Review of Artificial Lift System Applications in Tight Formationscarloszapata1No ratings yet

- Simulation of Flow Through A Pump Sump and Its Validation: IJRRAS 4Document11 pagesSimulation of Flow Through A Pump Sump and Its Validation: IJRRAS 4Adelmo FilhoNo ratings yet

- Anand 2018Document35 pagesAnand 2018umair qureshiNo ratings yet

- Computational Fluid Dynamics (CFD) Modeling of Run-of-River IntakesDocument9 pagesComputational Fluid Dynamics (CFD) Modeling of Run-of-River Intakessuman kilaniaNo ratings yet

- Keurig Gourmet Single Cup Home Brewing System: Section 1Document11 pagesKeurig Gourmet Single Cup Home Brewing System: Section 1Tijuan MuhammadNo ratings yet

- Appendix 1c Bridge Profiles Allan TrussesDocument43 pagesAppendix 1c Bridge Profiles Allan TrussesJosue LewandowskiNo ratings yet

- Crones Student Teacher Lesson 1 1Document7 pagesCrones Student Teacher Lesson 1 1api-530321748No ratings yet

- MECHANICAL ENGINEERING DEPARTMENT - Copy (Repaired)Document10 pagesMECHANICAL ENGINEERING DEPARTMENT - Copy (Repaired)Wan Mohd AfnanNo ratings yet

- SAPA Presentation - 8-31-18Document34 pagesSAPA Presentation - 8-31-18Roi AlcaideNo ratings yet

- Adjustment: - Electronic Modulated Air SuspensionDocument2 pagesAdjustment: - Electronic Modulated Air SuspensionThar KyiNo ratings yet

- A Pilot's Guide To ILS PRM ApproachesDocument4 pagesA Pilot's Guide To ILS PRM ApproachesgregmNo ratings yet

- Customer Satisfaction: Measuring and Ensuring Customer LoyaltyDocument16 pagesCustomer Satisfaction: Measuring and Ensuring Customer Loyaltyomermirza2009No ratings yet

- Sick GM31Document54 pagesSick GM31Magdy SalehNo ratings yet

- Sany - SCC8300 Crawler CraneDocument52 pagesSany - SCC8300 Crawler CraneNunoNo ratings yet

- Installation Procedure for Castwel Supercast-II CastableDocument3 pagesInstallation Procedure for Castwel Supercast-II CastableRAJKUMARNo ratings yet

- Rexroth HABDocument20 pagesRexroth HABeleceng1979No ratings yet

- HP t410 Smart Zero Client: Zero Management. Zero Configuration. Zero CompromiseDocument5 pagesHP t410 Smart Zero Client: Zero Management. Zero Configuration. Zero Compromisekonan09No ratings yet

- No Curfew for College Dorm StudentsDocument2 pagesNo Curfew for College Dorm Students陳玟蓁No ratings yet

- How To Review A Book in Up To 5,000 Words: First StepsDocument3 pagesHow To Review A Book in Up To 5,000 Words: First StepsAnnaNo ratings yet

- Cahyadi J Malia Tugas MID TPODocument9 pagesCahyadi J Malia Tugas MID TPOCahyadi J MaliaNo ratings yet

- Map Book 4Document58 pagesMap Book 4executive engineerNo ratings yet

- BrainSpace - January 2024 CADocument46 pagesBrainSpace - January 2024 CARafal ZawadkaNo ratings yet

- English Test 03Document6 pagesEnglish Test 03smkyapkesbi bjbNo ratings yet

- WHLP in Reading and Writing Week 8Document4 pagesWHLP in Reading and Writing Week 8Manuel Despabiladeras0% (2)

- Open Newel StaircaseDocument4 pagesOpen Newel StaircaseSujan Dhoj KhadkaNo ratings yet

- Let's Mingle Chat Invite ExamplesDocument22 pagesLet's Mingle Chat Invite ExamplesCarmen BalbuenaNo ratings yet