Professional Documents

Culture Documents

Bolt Load Calculation Steps

Uploaded by

Srikanth ShankarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bolt Load Calculation Steps

Uploaded by

Srikanth ShankarCopyright:

Available Formats

Advanced inputs Problem specific inputs

R0

Determining nominal diameter and checking limiting size

R2

Determining required minimum clamp load

R3

Dividing working load and calculation of load introduction factor

R4

Preload changes

R5&6 Determining maximum and minimum assembly preload

R7

Determining assembly stresses and checking bolt size

R8

Determining working stresses and verifying in case of yield point exceed

R9

Determining Alternating stresses

R10

Determining the surface pressure

R11

Determining minimum length of engagement

R12

Determining safety against Slipping and Shearing

R13

Determining the tightening torque

Results Results

General Inputs

Max Inertia force + bearing load on each bolt [N] =

Application of the load =

Type of clamping =

Type of bolted joint =

Type of tightening method =

Type of bolt =

Type of bolt thread =

n,Bolt size and Validation check

The final load introduction factor given by linear interpolation =

Joint type =

Selected bolt size

Selected bolt strength

Validation check in case of eccentric clamping or loading

Min clamp load

Total Minimum clamp load required [N] =

Resilience,Load factor

Total axial resilience of bolt is given as (mm/N) =

Total Bending resilience of bolt is given as (mm^-1*N^-1)

Total resilience of the plate in case of concentric clamping(mm/N) =

Axial load factor of bolt

Bending load factor of bolt in case of pure bending moment (MB)

Extra load applied on BOLT due to external load application on bolted joint (N) =

Extra load applied on JOINT due to external load application on bolted joint (N) =

Preload Losses

The material of clamped part =

The total amount of embedding for entire bolted joint [in m] =

Resultant loss in preload due to embedding effects [in N] =

Change in preload due to temperature effect [N] =

Min and Max Preload

Minimum assembly preload that need to be given to bolted joint =

Maximum assembly preload that is acheived w.r.t tightening in bolted joint =

Assembly stresses

Utilization factor of yield point stress during tightening =

Allowable maximum stress for selected bolt is[Mpa]=

Permissible assembly preload to be applied for selected bolt is [N] =

Is the bolted joint sufficient for preload to be applied =

Working stresses,Yield point FOS

Comparative stresses in working state[MPa] =

So did the joint preload is sufficient to maintain mimum required clamp load even in exceeded scenario of yield

point of bolt =

Safety margin against exceeding Yield point =

Alternating stresses,Fatigue FOS

The bolts are

Endurance limit [Mpa]

Continous alternating stress acting on the bolt [MPa] =

Safety margin against fatigue failure [Sd] =

Surface pressure and FOS

Actual surface pressure (pgmax) [Mpa or N/mm^2] =

Limiting surface pressure that can be given to the clamped parts [Mpa or N/mm^2] =

Safety margin against surface pressure [Sp] =

Min length of thread engagement

Which thread is critical

Minimum length of engagement that should be present between bolt and nut(or internal threaded component)

[mm] =

Residual Clamp load,FOS slipping and shearing

Minimum residual clamp load in the bolted joint [N] =

Safety margin against slipping [Sg] =

Safety margin against shearing of bolt [Sa] =

Tightening Torque

Tightening torque that can be given to the bolted joint [Nm] =

You might also like

- Yield Stress Working StressDocument3 pagesYield Stress Working Stressdinesh11rNo ratings yet

- Bolted Connections: 1.1 Range and Class of The Screw FastenersDocument8 pagesBolted Connections: 1.1 Range and Class of The Screw FastenersksNo ratings yet

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsFrom EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNo ratings yet

- COMPRESS Saddle DesignDocument2 pagesCOMPRESS Saddle Designarif99pakNo ratings yet

- Crimp PLTDocument5 pagesCrimp PLTSai SushankNo ratings yet

- Chapter 8 Two-Dimensional Problem SolutionDocument51 pagesChapter 8 Two-Dimensional Problem SolutionJoseph Daguio JrNo ratings yet

- 2400 Tema DCDocument7 pages2400 Tema DCMasoodMiyanNo ratings yet

- Thermal Stress ExamplesDocument10 pagesThermal Stress ExamplesVishal V BhagwatNo ratings yet

- Analysis of Self-Supported Steel Chimney With The Effects of Geometrical ParametersDocument6 pagesAnalysis of Self-Supported Steel Chimney With The Effects of Geometrical Parametersvikram413No ratings yet

- Types of Damping 1. Viscous DampingDocument6 pagesTypes of Damping 1. Viscous DampingZandro GagoteNo ratings yet

- Design in Reinforced Concrete To BS 8110 1Document14 pagesDesign in Reinforced Concrete To BS 8110 1Anish KumarNo ratings yet

- 3 5mDocument8 pages3 5mSanjay sharmaNo ratings yet

- Simple joint design in steel structuresDocument8 pagesSimple joint design in steel structuresNikola PejatovicNo ratings yet

- Vibration Suppression and Control: William J. Palm IIIDocument47 pagesVibration Suppression and Control: William J. Palm IIIMaJo0oDe100% (1)

- Tension RodDocument4 pagesTension RodMarkNo ratings yet

- Calculation note for compressor shelter steel structure designDocument54 pagesCalculation note for compressor shelter steel structure designmaniaxpdfNo ratings yet

- Pin Base ModuleDocument16 pagesPin Base ModuleMd Ahsanul KabirNo ratings yet

- Moment Baseplate Design Rev. 0Document3 pagesMoment Baseplate Design Rev. 0Bok MortegaNo ratings yet

- GratingDocument8 pagesGratingGhanshyam PandeyNo ratings yet

- Steel Beam DesignDocument36 pagesSteel Beam DesignTan Choon LengNo ratings yet

- Member Stability CheckDocument3 pagesMember Stability CheckdamindaNo ratings yet

- C06-C09 Beam Connection Design CalculationsDocument7 pagesC06-C09 Beam Connection Design CalculationsKrish ChandNo ratings yet

- PV Elite ResultDocument239 pagesPV Elite ResultChaitanya Sai TNo ratings yet

- Slot Expansion CalculationDocument1 pageSlot Expansion CalculationSarfaraz KhanNo ratings yet

- Master Foods 12 MDocument16 pagesMaster Foods 12 MSarfarazNo ratings yet

- Wind LoadDocument5 pagesWind LoadPATEL JIGARNo ratings yet

- Final 2Document21 pagesFinal 2roan sthaNo ratings yet

- Software Verification: Example 17Document8 pagesSoftware Verification: Example 17sancloudNo ratings yet

- Calculation of Base Shear (Ubc-1997) Location: Rancakusumba SubstationDocument2 pagesCalculation of Base Shear (Ubc-1997) Location: Rancakusumba SubstationDS IchaqueNo ratings yet

- Wind and Earthquake Analysis Results SummaryDocument8 pagesWind and Earthquake Analysis Results SummaryBrahim HammamiNo ratings yet

- Basic Data:: Calculation of Gust Effect FactorDocument1 pageBasic Data:: Calculation of Gust Effect FactorYaser ShabasyNo ratings yet

- Is800-2007 Appendix PDFDocument85 pagesIs800-2007 Appendix PDFDebasish MondalNo ratings yet

- Welds of A Fin Plate ConnectionDocument2 pagesWelds of A Fin Plate Connectioncretz2No ratings yet

- Calculating Wind Load on a Dish AntennaDocument1 pageCalculating Wind Load on a Dish AntennadovermanNo ratings yet

- تصميم الكمرات بطريقة ultimate PDFDocument42 pagesتصميم الكمرات بطريقة ultimate PDFqaisalkurdyNo ratings yet

- P-M interaction check wall capacity comparisonDocument5 pagesP-M interaction check wall capacity comparisonVILCA100% (2)

- Fdocuments - in Insert Plate Design LugsDocument8 pagesFdocuments - in Insert Plate Design Lugsarchetype designNo ratings yet

- Exhibition Stand - REV 0Document12 pagesExhibition Stand - REV 0shibu4321No ratings yet

- Design of Stairs Design of Stairs From Ground To Landing Material PropertiesDocument3 pagesDesign of Stairs Design of Stairs From Ground To Landing Material PropertiesJohn Paul Hilary EspejoNo ratings yet

- Shear design of hollow core slabs using modified compression field theoryDocument17 pagesShear design of hollow core slabs using modified compression field theoryjrandeepNo ratings yet

- General Catalogue VOL1Document330 pagesGeneral Catalogue VOL1lifib23970No ratings yet

- WeldDocument43 pagesWeldAuggie AranzadoNo ratings yet

- Design of Ring Girder SupportDocument3 pagesDesign of Ring Girder Supportvishal guptaNo ratings yet

- Comp 2Document9 pagesComp 2YYo YudiNo ratings yet

- Design Slip-Critical Steel ConnectionDocument9 pagesDesign Slip-Critical Steel ConnectionKURONo ratings yet

- Beam Column Web ConnectionsDocument9 pagesBeam Column Web Connectionsmsiddiq1No ratings yet

- RC COLUMN CAPACITY CALCULATIONDocument6 pagesRC COLUMN CAPACITY CALCULATIONnicolaemariusNo ratings yet

- Wind LoadDocument45 pagesWind LoadglaydelleNo ratings yet

- Ansys Analysis-Trolley Beam 3T1Document13 pagesAnsys Analysis-Trolley Beam 3T1Ye Wint ThuNo ratings yet

- Bolt TighteningDocument6 pagesBolt TighteningahmedbeaetNo ratings yet

- Circular Tube End Plate Calculation PDFDocument4 pagesCircular Tube End Plate Calculation PDFALPHYL BALASABASNo ratings yet

- Ramset Specifiers Resource Book Ed3 - Mechanical AnchoringDocument52 pagesRamset Specifiers Resource Book Ed3 - Mechanical Anchoringapsapsaps19880% (1)

- Design of Face Mounted BracketDocument4 pagesDesign of Face Mounted Bracketvishal tomarNo ratings yet

- Excel Fatigue AnalysisDocument11 pagesExcel Fatigue AnalysisAli GhNo ratings yet

- KBC2009 풍하중산정 (YJ, 110427)Document48 pagesKBC2009 풍하중산정 (YJ, 110427)이영준100% (2)

- OlDocument66 pagesOlcarlosfilipegomes3994No ratings yet

- Steel Design Standards and Load Combinations in ASD and LRFD MethodsDocument50 pagesSteel Design Standards and Load Combinations in ASD and LRFD Methodsadarsh31No ratings yet

- Calculation of bolted connection strength and stressesDocument4 pagesCalculation of bolted connection strength and stressesjuantamad02No ratings yet

- LCF & HCFDocument1 pageLCF & HCFSrikanth ShankarNo ratings yet

- Conecting RodDocument1 pageConecting RodSrikanth ShankarNo ratings yet

- Gear RatiosDocument1 pageGear RatiosSrikanth ShankarNo ratings yet

- FatigueDocument1 pageFatigueSrikanth ShankarNo ratings yet

- CG 53Document2 pagesCG 53calvinabsNo ratings yet

- Drop Box TransfercaseDocument1 pageDrop Box TransfercaseSrikanth ShankarNo ratings yet

- Functioning of TCDocument1 pageFunctioning of TCSrikanth ShankarNo ratings yet

- Turbo ChargerDocument1 pageTurbo ChargerSrikanth ShankarNo ratings yet

- Method of Multiplying TorqueDocument1 pageMethod of Multiplying TorqueSrikanth ShankarNo ratings yet

- Clutch HSGDocument1 pageClutch HSGSrikanth ShankarNo ratings yet

- General Inputs CalcDocument2 pagesGeneral Inputs CalcSrikanth ShankarNo ratings yet

- Different Types of Throttle Body Designs Used in Various Applications of Gasoline EngineDocument4 pagesDifferent Types of Throttle Body Designs Used in Various Applications of Gasoline EngineSrikanth ShankarNo ratings yet

- Torque ConverterDocument1 pageTorque ConverterSrikanth ShankarNo ratings yet

- Drop box transmission for 4WD vehiclesDocument1 pageDrop box transmission for 4WD vehiclesSrikanth ShankarNo ratings yet

- Load CalcDocument2 pagesLoad CalcSrikanth ShankarNo ratings yet

- FlywheelDocument1 pageFlywheelSrikanth ShankarNo ratings yet

- ContentDocument1 pageContentSrikanth ShankarNo ratings yet

- Rough CalcDocument2 pagesRough CalcSrikanth ShankarNo ratings yet

- Aerodynamic Resistance Rolling Resistance Gradient Resistance Tractive Effort - Front Tractive Effort - Rear Draw Bar LoadDocument1 pageAerodynamic Resistance Rolling Resistance Gradient Resistance Tractive Effort - Front Tractive Effort - Rear Draw Bar LoadSrikanth ShankarNo ratings yet

- NVH TestingDocument1 pageNVH TestingSrikanth ShankarNo ratings yet

- ConrodDocument1 pageConrodSrikanth ShankarNo ratings yet

- Aidc All Indian Driving Cycle Midc Modified Indian Driving Cycle Eudc European Union Driving Cycle 28.75 5.25 34Document2 pagesAidc All Indian Driving Cycle Midc Modified Indian Driving Cycle Eudc European Union Driving Cycle 28.75 5.25 34Srikanth ShankarNo ratings yet

- International Material Grade Comparison TableDocument9 pagesInternational Material Grade Comparison Tablenyamuk06100% (4)

- Can This Point Be Expressed in Another Way?Document2 pagesCan This Point Be Expressed in Another Way?Srikanth ShankarNo ratings yet

- Intellectual Standards for Clear ThinkingDocument2 pagesIntellectual Standards for Clear ThinkingSrikanth ShankarNo ratings yet

- Engine Hot Testing: Test ProcessDocument2 pagesEngine Hot Testing: Test ProcessSrikanth ShankarNo ratings yet

- Gas StandDocument2 pagesGas StandSrikanth ShankarNo ratings yet

- Sport R S 01Document9 pagesSport R S 01Srikanth ShankarNo ratings yet

- NX Step File SummaryDocument1 pageNX Step File SummarySrikanth ShankarNo ratings yet

- 2023-05-01 2023 FSAE Tech Form - May CompDocument10 pages2023-05-01 2023 FSAE Tech Form - May CompAbdulla Al AhsunNo ratings yet

- Design Bolted & Welded Connections Baja 1Document115 pagesDesign Bolted & Welded Connections Baja 1furqan yunarNo ratings yet

- Ultra - 300lx Service ManualDocument577 pagesUltra - 300lx Service ManualKerri Puglisi Caputo100% (1)

- Bolt Tensioning: What is it and how does it workDocument2 pagesBolt Tensioning: What is it and how does it work4jawwy markme026No ratings yet

- Alternator and Regulator-1Document12 pagesAlternator and Regulator-1Khinmg Aye 554No ratings yet

- Specification Section S40: Structural SteelworkDocument24 pagesSpecification Section S40: Structural Steelworkkiet eelNo ratings yet

- 2016 AAA HuDocument13 pages2016 AAA HuAnis SuissiNo ratings yet

- Flanges General - Bolting Torque Tables - Table 2 - ASTM 193 Grade B7 and ASTM 193 Grade B16 Stud BoltsDocument3 pagesFlanges General - Bolting Torque Tables - Table 2 - ASTM 193 Grade B7 and ASTM 193 Grade B16 Stud BoltsHakan ŞahinoğluNo ratings yet

- Shop Manual for WB97S-5E0 Backhoe-LoaderDocument616 pagesShop Manual for WB97S-5E0 Backhoe-LoaderJan Konieczny100% (3)

- Method Statements For Eskom Substations - Stringing, Erection, Earthing and Cabling PDFDocument27 pagesMethod Statements For Eskom Substations - Stringing, Erection, Earthing and Cabling PDFTreenel TradingNo ratings yet

- Fasteners Guide - Threaded, Non-Threaded Types and Design for Fatigue StrengthDocument41 pagesFasteners Guide - Threaded, Non-Threaded Types and Design for Fatigue StrengthGcwalisile DlaminiNo ratings yet

- Ford Transit 2000 20061Document801 pagesFord Transit 2000 20061Lmibvg Klijkugfr50% (2)

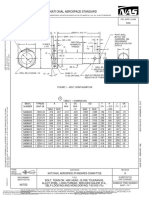

- National Aerospace Standard: Fed. Supply ClassDocument7 pagesNational Aerospace Standard: Fed. Supply ClassjuanNo ratings yet

- Vector Techlok BrochureDocument34 pagesVector Techlok BrochureRobert Murray100% (2)

- Guppa - Se Ultra300x Servicemanual PDFDocument560 pagesGuppa - Se Ultra300x Servicemanual PDFPatrik Benjaro100% (1)

- DNV CG 0372Document40 pagesDNV CG 0372Steven Salazar ArangoNo ratings yet

- BOLTEC MC 9852 2207 01a Maintenance Instructions Mark 7Document377 pagesBOLTEC MC 9852 2207 01a Maintenance Instructions Mark 7gkqztsy9skNo ratings yet

- BS en Iso 05210-2017 PDFDocument26 pagesBS en Iso 05210-2017 PDFMichael BelinskyNo ratings yet

- ENG2019 Part 4 - Torsion CompleteDocument32 pagesENG2019 Part 4 - Torsion Completewag naNo ratings yet

- 9852 3281 01b Maintenance Instructions COP 1640plus Ver. FDocument44 pages9852 3281 01b Maintenance Instructions COP 1640plus Ver. FHugo EstradaNo ratings yet

- Ultrasonic Bolt Tension MeasurementDocument8 pagesUltrasonic Bolt Tension MeasurementshingkeongNo ratings yet

- 132kV Substation Accessories BOQ-20231101.xlsx - 1Document1 page132kV Substation Accessories BOQ-20231101.xlsx - 1sparkCENo ratings yet

- NL Superbolt TensionersDocument39 pagesNL Superbolt Tensionersmohit_mgNo ratings yet

- Is 3063 Spring Washers PDFDocument11 pagesIs 3063 Spring Washers PDFAyman Hamed Malah100% (1)

- Petrofac Piping Inspection Handbook PDFPDFDocument25 pagesPetrofac Piping Inspection Handbook PDFPDFpediNo ratings yet

- Steel Connection Failure ModesDocument22 pagesSteel Connection Failure ModesJoshua CalaNo ratings yet

- MOLYKOTE 1000 Solid Lubricant 71-0218G-01Document2 pagesMOLYKOTE 1000 Solid Lubricant 71-0218G-01Budi HandokoNo ratings yet

- Field BoltingDocument42 pagesField BoltingJ. Fabián MenaNo ratings yet

- Combining Spatial Components in Seismic DesignDocument11 pagesCombining Spatial Components in Seismic DesignjemanuelvNo ratings yet

- Differences Between Bearing, Shear & Tear-Out StressesDocument2 pagesDifferences Between Bearing, Shear & Tear-Out StressesFitra VertikalNo ratings yet

- The Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsFrom EverandThe Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsRating: 4.5 out of 5 stars4.5/5 (6)

- Building Construction Technology: A Useful Guide - Part 2From EverandBuilding Construction Technology: A Useful Guide - Part 2Rating: 5 out of 5 stars5/5 (1)

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (241)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsFrom EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsNo ratings yet

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionFrom EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionRating: 4.5 out of 5 stars4.5/5 (2)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Atlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceFrom EverandAtlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceRating: 5 out of 5 stars5/5 (9)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- An Architect's Guide to Construction: Tales from the Trenches Book 1From EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1No ratings yet

- In the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkFrom EverandIn the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkRating: 5 out of 5 stars5/5 (1)

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseFrom EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseRating: 5 out of 5 stars5/5 (3)

- Building Construction Technology: A Useful Guide - Part 1From EverandBuilding Construction Technology: A Useful Guide - Part 1Rating: 4 out of 5 stars4/5 (3)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Comprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessFrom EverandComprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessNo ratings yet

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Dark Aeon: Transhumanism and the War Against HumanityFrom EverandDark Aeon: Transhumanism and the War Against HumanityRating: 5 out of 5 stars5/5 (1)

- The Fourth Age: Smart Robots, Conscious Computers, and the Future of HumanityFrom EverandThe Fourth Age: Smart Robots, Conscious Computers, and the Future of HumanityRating: 4.5 out of 5 stars4.5/5 (115)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Civil Engineer's Handbook of Professional PracticeFrom EverandCivil Engineer's Handbook of Professional PracticeRating: 4.5 out of 5 stars4.5/5 (2)

- Field Guide for Construction Management: Management by Walking AroundFrom EverandField Guide for Construction Management: Management by Walking AroundRating: 4.5 out of 5 stars4.5/5 (3)

- The E-Myth Contractor: Why Most Contractors' Businesses Don't Work and What to Do About ItFrom EverandThe E-Myth Contractor: Why Most Contractors' Businesses Don't Work and What to Do About ItRating: 4 out of 5 stars4/5 (16)

- Robotics: Designing the Mechanisms for Automated MachineryFrom EverandRobotics: Designing the Mechanisms for Automated MachineryRating: 4.5 out of 5 stars4.5/5 (8)

- Markup & Profit: A Contractor's Guide, RevisitedFrom EverandMarkup & Profit: A Contractor's Guide, RevisitedRating: 5 out of 5 stars5/5 (11)

- Woodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsFrom EverandWoodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsRating: 1 out of 5 stars1/5 (4)

- Artificial Intelligence: From Medieval Robots to Neural NetworksFrom EverandArtificial Intelligence: From Medieval Robots to Neural NetworksRating: 4 out of 5 stars4/5 (3)