Professional Documents

Culture Documents

Research Note On Electric Cum Solar System

Uploaded by

ArmanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Research Note On Electric Cum Solar System

Uploaded by

ArmanCopyright:

Available Formats

RESEARCH NOTE ON ELECTRIC

CUM SOLAR SYSTEN

TEAM REVANTA

NIT JAMSHEDPUR

INTRODUCTION

As we are fabricating an electric solar hybrid vehicle, we are

supposed to use a battery as well as solar energy

independently to power the vehicle.

A battery is an active element which produces or generates

electricity using electrochemical reactions and, whenever

required it can be used to serve the same function what

gasoline serves in an internal combustion engine i.e. to power

the vehicle.

In present scenario as we have limited source of non-renewable

energy to power the vehicle and since it also has more harmful

effect on environment, we are now mostly dependent on

renewable sources of energy like tidal energy, wind energy,

solar energy etc. Solar energy proves to be the most vital and

long lasting source of renewable energy. We can use solar

panels to store solar energy and use it in powering a vehicle.

The renewable energy is vital for todays world as in near future

the non-renewable sources that we are using are going to get

exhausted. The solar vehicle is a step in saving these nonrenewable sources of energy. The basic principle of solar car is

to use energy that is stored in a battery during and after

charging it from a solar panel. The charged batteries are used

to drive the motor which serves here as an engine and moves

the vehicle in reverse or forward direction. The electrical

tapping rheostat is provided so as to control the motor speed.

This avoids excess flow of current when the vehicle is supposed

to be stopped suddenly as it is in normal cars with regards to

fuel. This idea, in future, may help protect ourfuels from getting

extinguished.

BATTERY A SOURCE OF ENERGY FOR

ELECTRIC VEHICLE:

There are many batteries available to power an electric vehicle

like Ni-Cd battery, Lead acid battery, Li-ion battery etc. Ni-cd

batteries are not very efficient and reliable as they have

memory effect i.e. if the Ni-Cd battery is discharged (not

completely) then, when it will be again charged the plates and

cells of the batteries retain or remember the past and the

unused active material cannot be used again thus resulting in

reduced capacity.

So, we are left with Lead acid and Li-ion battery. Lead acid

battery utilizes two plates of lead oxide and sponge lead with

an aqueous solution of sulphuric acid as an electrolyte. Lead

acid batteries are broadly categorised in two groups. First one is

conventional lead acid battery and second one is upgradation

of the first one known as deep cycle or valve regulated lead

acid (VRLA) battery.

Conventional Lead acid battery requires more maintenance as

it contains an aqueous solution of electrolyte. It cannot be used

in any orientation and should be held always in an upright

position so as to eliminate the risk of acid spill or leakage. It

also requires a proper ventilation for the escaping of gas as

there is evolution of gas during its operation because of

imperfect charging and discharging cycles. It can also not be

used for smooth driving of a vehicle but can only be used for

starting and lightning purposes.

But, VRLA battery is a proper solution for all the above

mentioned problem. The basic design and chemical structure of

VRLA are almost same as of conventional lead acid battery with

a little bit difference. VRLA can further be divided into two

groups VRLA Gel battery and AGM battery. The Gel battery

utilizes a solution of sulphuric acid as an electrolyte with

silicone dust added to it which gives it a gel like characteristic.

Thus the paste or gelled electrolyte eliminates the risk of acid

leakage or spill and renders it maintenance free. It can be used

in any orientation and there is almost low to no requirement of

ventilation. There is a self-resealing pressure releasing valve for

the extreme or severe condition of gas evolution due to overcharging. AGM battery, on the other hand utilizes a glass fibre

which serves both functions as a separator for positive and

negative plates to eliminate the risk of short circuit and as a

blotter to absorb the electrolyte. AGM batteries are almost

similar in function as Gel batteries. Both are maintenance free,

both boost more resistance to temperature variation, shocks &

vibrations, can be used in any orientation and are leakage proof

etc.

Though they have many similarities, yet they are different in

many respect. Since AGM batteries have more efficient oxygen

recombination cycle and low internal resistance, it draws more

float current at constant float voltage and thus generates a

large amount of heat in comparision to gel battery. Also the

float current rises with the increase in temperature resulting in

more heat generation. So VRLA Gel battery is more ideal to be

used.

Li-ion battery is also a better option for powering an electric

vehicle. But, it has some disadvantages in comparision to VRLA

Gel battery. First one and most important is the cost. While

VRLA Gel battery is of less cost or almost inexpensive in

contrast, Li-ion batteries cost approximately 6 to 7 times more.

VRLA Gel battery can be used in any temperature condition but,

Li-ion battery cannot be used efficiently in sub-zero conditions.

Moreover, charge retention property of VRLA Gel battery is

much better than Li-ion battery. Also, the self discharge

property of VRLA Gel battery is much less than Li-ion battery

resulting in much less or no wastage of active materials and no

loss in the capacity of the battery.

VRLA Gel battery and internal construction:

SOLAR PANEL:- An

Equipment to store Solar

Energy

This paper discusses about the usage of solar energy to power

up the vehicle.

The electrical charge is consolidated from the solar panel and

directed to the output terminals to produce low voltage (Direct

Current). The charge controllers direct this power acquired from

the solar panel to the batteries. According to the state of the

battery, the charging is done, so as to avoid overcharging and

deep discharge. The voltage is then boosted up using the boost

power converter, ultimately running the BLDC motor which is

used as the drive motor for our vehicle application.

The first part of this paper deals about how to acquire the

power from the sun, and there on to recharge the battery.The

second part deals with using the power from battery in running

and controlling the motor and recharging the battery

simultaneously.The rating of the components required for this

work is completely based on the motor which is to be used for

the application. We are using the 800Watts (48V, 10.5A) BLDC

motor for our application. According to the rating of the motor

the other hardware components are selected. In order to drive

the BLDC motor through the batteries, we would require four

batteries of rating 12V/42Ah connected in series. The solar

module consists of a set of solar cells connected in parallel and

series to meet up the power requirement.

ACQUIRING SOLAR ENERGY

FROM SUN

In the next phase of the work, the power which is stored in the

batteries is used in driving the BLDC motor.In this phase the

detail study of motor is done and simulated.The specification of

the BLDC motor is given in below.From the specification its well

understood that the required voltage to run the motor is 48V,

while the rated voltage of a single battery is 12V.Thus to

achieve the rated voltage of the motor; we are in need of four

batteries which when connected in series can satisfy the

requirement.

MAXIMUM POWER

RATED VOLTAGE

RATED CURRENT

MAXIMUM SPEED

MAXIMUM TORQUE

NO LOAD CURRENT

800 W

48 V

1335 RPM

9.5 Nm

Driving the Motor:

The Brushless DC (BLDC) motor is used as the drive motor for

the vehicle.Its a permanent magnet square wave motor.BLDC

motor uses feedback directly of the rotor angular position so

that the input armature current can be switched among the

motor phases in exact synchronization with the rotor

motion.The specification of the BLDC motor is given in Table

3.The reason for opting for the BLDC motor is because of its

efficiency, noiseless operation, dynamic response and high

torque to weight ratio.

The integration of the whole system evolves as the Solar

Powered BLDC Motor Driven Electric Vehicle

ADVANTAGES OF THE VEHICLE:

The solar vehicles are the future of the automobile industry. They are highly

feasible and can be manufactured with ease. The main advantages of a solar

vehicle are that they are pollution less and are very economical. Since they

cause no pollution they are very eco-friendly and are the only answer to the

increasing pollution levels from automobiles in the present scenario. By

harvesting the renewable sources of energy like the solar energy we are helping

in preserving the non-renewable sources of energy. The other main advantages

of the solar vehicle are that they require less maintenance as compared to the

conventional automotives and are very user friendly.

CONCLUSION

The solar vehicle solves many problems related to the

environment and is the best pollution free method. We need to

make use of them so that we can reduce our dependence on

fossil fuels. Solar vehicles do have some disadvantages like

small speed range, initial cost is high. Also, the rate of

Conversion of energy is not satisfactory (only 17%). But these

disadvantages can be easily overcome by conducting further

research in this area; like the problem of solar cells can be

solved by using the ultra efficient solar cells that give about 3035% efficiency. As this field of automobiles will be explored the

problems will get solved. The solar automobiles have a

hugeprospective market and we should start using them in our

day-to-day life. We have already completed making a solar

vehicle prototype as our project and the vehicle is running

successfully on solar power.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- How Fuel PumpDocument3 pagesHow Fuel PumpCarlos Carvajal AlvarezNo ratings yet

- 2806a E18tagDocument5 pages2806a E18tagabas aliannejadiNo ratings yet

- I SUZUDocument45 pagesI SUZUDblogic GatesNo ratings yet

- SERV1852 - TXT3 Controles y Bombas Hidraulicas PrincipalesDocument35 pagesSERV1852 - TXT3 Controles y Bombas Hidraulicas PrincipalesDiego Alonso Huaraca Baleriano100% (2)

- Volvo VNL Trucks Usa 2017 PDFDocument29 pagesVolvo VNL Trucks Usa 2017 PDFdionisio emilio reyes jimenez100% (1)

- Delta Electronics Hybrid PowertrainDocument25 pagesDelta Electronics Hybrid PowertrainAbhigyanLiebhaber100% (5)

- Hybrid Electric VehiclesDocument16 pagesHybrid Electric VehiclesRitesh100% (11)

- J 616Document4 pagesJ 616UsAmaImtiAz0% (1)

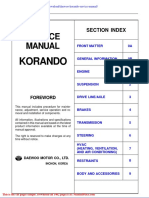

- Daewoo Korando Service ManualDocument20 pagesDaewoo Korando Service ManualConstance100% (54)

- Pipe - 2Document3 pagesPipe - 2Victor John PingkianNo ratings yet

- ISA 960201 SPBoard November2007Document24 pagesISA 960201 SPBoard November2007Heymonth ChandraNo ratings yet

- The Various Types of EnclosuresDocument4 pagesThe Various Types of Enclosuresshan1009No ratings yet

- F425 Service Manual Lit - 18616-03-83Document585 pagesF425 Service Manual Lit - 18616-03-83G S100% (3)

- 330C Excavator Hydraulic System PDFDocument16 pages330C Excavator Hydraulic System PDFoctavio hernandez91% (11)

- Trax PDFDocument573 pagesTrax PDFccastell23100% (2)

- Idwal Pre-Inspection Details (Ver 2.3)Document9 pagesIdwal Pre-Inspection Details (Ver 2.3)eildrian22No ratings yet

- ABS Part4 - Vessel Systems & Machinery - 2001Document710 pagesABS Part4 - Vessel Systems & Machinery - 2001AndréMenezesNo ratings yet

- Wacker Manual 6' 32HPDocument106 pagesWacker Manual 6' 32HPRodrigoChavesNo ratings yet

- GranTurismo enDocument0 pagesGranTurismo enaiigee100% (1)

- Piston Pin Plug Wear InspectionDocument3 pagesPiston Pin Plug Wear InspectionAlberto ColinNo ratings yet

- Energies 14 04847Document24 pagesEnergies 14 04847ranjitv10No ratings yet

- Tds Biodiesel 20Document2 pagesTds Biodiesel 20Gian TeryNo ratings yet

- 966K and 972K Wheel Loader Electrical SystemDocument4 pages966K and 972K Wheel Loader Electrical SystemFlorencio MaximilianoNo ratings yet

- DurstDocument6 pagesDurstAryoSatrioNo ratings yet

- Göksu: Rascal 1500 / Rascal 1500 TsDocument6 pagesGöksu: Rascal 1500 / Rascal 1500 TsСергей ДедовNo ratings yet

- 05 MGS1200HV 50Hz 3Document4 pages05 MGS1200HV 50Hz 3salvador2meNo ratings yet

- IJCRT2201535Document20 pagesIJCRT2201535payal_joshi_14No ratings yet

- DSR Aor For Wet Riser and Sprinkler System 2019Document110 pagesDSR Aor For Wet Riser and Sprinkler System 2019Sambit Pattanaik50% (2)

- Scania DI9 Operator's ManualDocument58 pagesScania DI9 Operator's ManualAmr HelalNo ratings yet

- 4d94e17 Be2 PDFDocument160 pages4d94e17 Be2 PDFdend juandiNo ratings yet