Professional Documents

Culture Documents

Experimental Evaluation of Electrolyte Flow Pattern in ECM Tool Using CFD Analysis

Uploaded by

IJAERS JOURNALCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Experimental Evaluation of Electrolyte Flow Pattern in ECM Tool Using CFD Analysis

Uploaded by

IJAERS JOURNALCopyright:

Available Formats

International Journal of Advanced Engineering Research and Science (IJAERS)

[Vol-3, Issue-10, Oct- 2016]

https://dx.doi.org/10.22161/ijaers/3.10.22

ISSN: 2349-6495(P) | 2456-1908(O)

Experimental Evaluation of Electrolyte Flow

Pattern in ECM Tool Using CFD Analysis

Gali Chiranjeevi Naidu, K Dharma Reddy, P V Ramaiah

Department of mechanical engineering, SV University College of engineering, Tirupati, Andhra Pradesh, India

Abstract In this present study, three dimensional flow

pattern of Electrochemical Machining process has been

simulated using Computational Fluid Dynamics (CFD) in

L-shaped tool model. The ANSYS software is used for the

design and analysis of a model. Different process

parameters like volume fraction profile, velocity profile,

pressure profile temperature profile and heat flux profile of

electrolyte flow in the Inter Electrode Gap (IEG) etc. have

been evaluated from the simulation using this model. The

results indicated generation of hydrogen bubbles in which

the turn reduced the volume fraction of brine depending

upon the tool geometry. Reduced brine volume fraction led

to reduction in MRR. As a result of hydrogen bubble

formation, temperature towards the boundaries were

increased rapidly as gaseous hydrogen bubbles possess

sufficiently lower convective heat transfer coefficient as

compared to liquid brine. For validating the simulation

results, a set of experiments have been carried out on ECM

by fabricating the tool geometry. The experimental results

were analyzed by using MINITAB software.

Keywords CFD, ECM, Electrolyte, Flow pattern.

aerospace, aeronautics, defense and medical industries. In

present days, ECM is used in other industries such as

automobile and turbo-machinery because of its various

advantages. In case of complicated shapes of work-piece it

is very difficult to know the machining variables

distribution within the inter electrode gap (IEG). By

studying the flow pattern of electrolyte, we can predict the

machining variable distribution accurately and thus can

avoid the passivation which is the major problem in ECM in

complicated shape cases. Again, two phase effect (hydrogen

bubble generation) has a major role on the machining

variables as well as on the material removal rate and surface

roughness. The flowing electrolyte collects the evolving

hydrogen gas generated at the cathode. Electrolyte has three

main functions in ECM. It carries the current between the

tool and work piece, it removes the products of the reaction

from the cutting region, and it removes heat produced in

operation. Normal electrolyte used for ECM for all common

metals & alloys is solution of Sodium Chloride (NaCl) in

water. They react with the work piece and form a salt which

dissolves in electrolyte.

I.

INTRODUCTION

Electrochemical machining (ECM) is one of the most

potential un-conventional machining processes. The basic

principle may be considered as the reverse of electroplating

with some modifications. Further, it is based on the

principle of electrolysis. In a metal, electricity is conducted

by the free electrons, but it has been established that in an

electrolyte the conduction of electricity is achieved through

the movement of ions. Thus, the flow of current through an

electrolyte is always accompanied by the movement of

matter. Thus ECM can be thought of a controlled anodic

dissolution at atomic level of the electrically conductive

work-piece by a desired shaped tool due to flow of high

current at relatively low potential difference through an

electrolyte which is quite often water based neutral salt

solution. ECM is one of advanced machining technologies

and has been applied in highly specialized fields, such as

II.

EXPERIMENTATION

This deals with the experiment that has been conducted in

the ECM set up. The experiments were conducted with Lshaped tool as per the dimensions of model to find out the

MRR to validate the simulation results.

2.1. ECM Set up

The ECM set up used for the experiment is as shown in the

fig.2.1 and the control panel is as shown in fig.2.2.

www.ijaers.com

Fig.2.1: ECM set up used for the experiment

Page | 138

International Journal of Advanced Engineering Research and Science (IJAERS)

[Vol-3, Issue-10, Oct- 2016]

https://dx.doi.org/10.22161/ijaers/3.10.22

ISSN: 2349-6495(P) | 2456-1908(O)

parameters

Voltage

Flow rate

Concentration

Fig.2.2: Control panel

2.2. Fabrication of Tool and Work-Piece

For doing the experiment, we need to fabricate the tool and

work-piece of exact dimension as that in the modelling. For

fabricating the tool, we have procured a copper rod and cut

the rod into L-shape is produced by facing, filing and

turning operation was done and to polish it, we have used

grinding operation. Again, for the groove, a through hole is

drilled on the tool by the help of the drilling machine. Now,

the L-shape is ready. A pipe having one side threaded end is

used for connecting the tool with the tool holder. The pipe

is fabricated with a through hole of same dimension as that

of the groove in the tool. After generation of L-shape and

the pipe, both of them are aligned properly and brazed as

shown in the fig.2.3. After brazing, the required tool is

ready the bottom of tool is shown in fig.2.4. The work-piece

material used is iron which is procured and is cut in to 9

circular pieces of diameter 60 mm.

Fig. 2.3: Brazing of tool

Fig. 2.4: Bottom of tool

2.3. Taguchi Experimental Design and Analysis

Taguchi design focused at greater understanding of

variations of parameters. Taguchi proposed to extend each

experiment with an "outer array" called the orthogonal

array. In this experiment, Minitab software is used for

Taguchi design. In this study, 3 level designs (3 factors)

with total of 9 numbers of experiments are conducted and

for this orthogonal array L9 is used. The machining

parameters and their levels with details are shown in table

2.1. The experimental observations for tool are shown in

the table 2.2. The iron work-pieces after machining for all

the runs using tool is shown in fig.2.5.

Table.2.1: Machining parameters and their levels

Machining Symbol Unit

Levels

www.ijaers.com

V

F

C

V

m/s

g/L

Level1 Level2 Level 3

10

12.5

15

30

35

40

60

85

110

Table.2.2: Experimental observation table using L9

orthogonal array

Run

1 2 3 4 5 6 7 8 9

12. 12. 12.

Voltage (V) 10 10 10

15 15 15

5 5 5

Flow rate

30 35 40 30 35 40 30 35 40

(m/s)

Concentration(g

60 85 110 85 110 60 110 60 85

/L)

Initial weight

419 379 418 538 454 455 413 414 514

(g)

Final weight

418 377 416 535 452 454 411 413 512

(g)

Time (min) 10 10 5 10 10 5 10 10 5

MRR

12. 25.

38. 25. 25. 25. 12. 50.

50.9

(mm3/min)

7 4

2 4 4 4 7 9

Fig.2.5: Work-pieces after machining

III.

MODELLING AND SIMULATION

The analysis techniques, geometric modeling and boundary

conditions are explained in this work. ECM set up consists

of a work-piece, tool and an electrolyte solution. Workpiece should be electrically conducting material and the tool

may or may not be. Commonly used electrolytes are NaCl

solution and NaNO3. To get required shape in the workpiece, tool should be designed properly. The shape of the

tool affects the critical parameters of machining. Another

important aspect in the modelling of ECM is the flow

Page | 139

International Journal of Advanced Engineering Research and Science (IJAERS)

[Vol-3, Issue-10, Oct- 2016]

https://dx.doi.org/10.22161/ijaers/3.10.

https://dx.doi.org/10.22161/ijaers/3.10.22

ISSN: 2349

2349-6495(P) | 2456-1908(O)

pattern of electrolyte and the various intervening factors

those are affected by the two phase flow pattern of

electrolyte.

3.1. Geometrical Modelling

A finite element based commercial CFD software package

ANSYS is used under the Windows7 64-bit

64

operating

system

tem for the simulation study. In the present simulation

process, the modelling is done with ANSYS software. The

L-shaped

shaped tool with central through hole model is used for

the simulation study. The initial shape of the work-piece

work

is

circular in shape with 60 mm diameter and 20 mm height.

Model of work-piece is shown in fig 3.1. Electrolyte used

for this simulation is NaCl solution (20%). The electrolyte

starts flowing with a constant diameter of 3 mm from the

inlet of the tool. The long side of the L-shape

shape is having 30

mm length and short side of 15 mm length and the central

hole has diameter of 3mm. Top view of the tool is shown in

fig 3.2 and 3D view is shown in fig 3.3. Inter electrode gap

(IEG) is kept constant at 0.5 mm. The key dimensional

feature of the physical model is as shown in table 3.1. The

complete physical model of workpiece tool set up is as

shown in fig. 3.4.

piece used for simulation

Fig. 3.1: Work-piece

Fig. 3.2: Top view of tool used for simulation

Fig. 3.4:: Physical model

Table.3.1:

3.1: Element type

Physical

S.NoComponent Material

Shape Dimension(mm)

state

Work1

Iron Solid Cylindrical60 dia. X 20 ht.

piece

Arm 30 X

Width 15 X

2

Tool

Copper Solid L-shaped

Height 50 X

central hole 3

3 Medium Brine Fluid

3.2. L Shaped Tool with Central Through Hole

A simple L shaped tool having a central through hole with a

diameter of 3mm and height of 50 mm. This centre of the

hole is fixed on (-7.5,-7.5)

7.5) coordinate in the XZ plane. Fluid

is flowing through the through hole and flow out through

the IEG. Top view

w of the tool is shown in fig.3.2 and 3D

view is shown in fig 3.3.. Inter electrode gap (IEG) is kept

constant is 0.5mm.

3.2. Boundary Conditions

Before considering the boundary conditions, the

computational domains should be specified. In this

simulation three domains are being used such

suc as two solid

domains and a fluid domain. One solid domain for workwork

piece and other is for tool. Materials of solid domain are

considered as pure solids. Morphology of materials in the

solid domain is given as continuous solid and reference

temperature is given 298K. Electric potential model with

automatic value is chosen from Electromagnetic model.

Fluid domain is constructed for electrolyte. Two materials

are taken for fluid domain as it is a two phase flow analysis.

Morphology for fluid domain is taken as continuous fluid

for brine and dispersed fluid for hydrogen bubbles. The

properties of the materials used in these domains are set as

per the values in the table

able 3.2.

3.

Table.3.2:: Material properties

Properties

Brine Copper

Iron Air

Molar mass

58.44

63.55

55.85

(kg/kmol)

Density (kg/m3) 1050

8933

7860

-

Fig. 3.3: 3D view of tool used for simulation

www.ijaers.com

Page | 140

International Journal of Advanced Engineering Research and Science (IJAERS)

[Vol-3, Issue-10, Oct- 2016]

https://dx.doi.org/10.22161/ijaers/3.10.22

ISSN: 2349-6495(P) | 2456-1908(O)

Specific heat

(J/kg K)

Dynamic

viscosity (Pa s)

Thermal

conductivity

(W/m K)

Electrical

conductivity (S/m)

Convection

coefficient

(W/m2 K)

3760

385

460

0.00

1

0.6

401

80

8.43

1000

5.96E+07 1E+07

-

100

IV.

RESULTS AND DISSCUSSIONS

The analysis of the results and discussion of the model

generated in ANSYS as per the required dimentions. It

shows the crucial parameters affecting overall machining

process of ECM in terms of contours from which we can

predict the variation of these parameters in the IEG and

their effects.

4.1. Volume Fraction Profile

Fig.4.1 shows the volume fraction profiles of the tool

generated. The inlet velocity for this simulation study was

taken as 40 m/s. The volume fraction contour has shown the

volume fraction of brine in the homogenous mixture of

continuous fluid brine and a dispersed fluid hydrogen

bubble.

Fig.4.2: Velocity profile for tool

4.3. Pressure Profile

The pressure profiles describe about the variation in

pressure in the IEG on the plane of machining area. As in

this tool, there is very large amount of production of

hydrogen bubbles and because of cavitation effect, the

pressure increases at a large number of nucleus sites from

the groove outlet towards the outer boundaries showing the

places of hydrogen bubbles and hence high pressure zones

as shown in fig. 4.3.

Fig.4.3: Pressure profile for tool

4.4. Temperature Profile

Temperature pattern is a very crucial aspect for this study.

As can be shown in the fig.4.4, the temperature is least at

the groove outlet and goes on increasing rapidly as we

move to outside for tool. It crosses the boiling point of

brine which in turn produces phase change and production

of hydrogen bubbles as secondary dispersed phase.

Fig.4.1: Volume fraction profile for tool

4.2. Velocity Profile

Fig.4.2 shows the velocity profile for tool with an inlet

velocity of 40 m/s, which indicates that velocity of two

phase electrolyte is increased from the groove to the

boundary partly due to reduction in area of flow and partly

due to formation of hydrogen bubbles resulting in more

turbulence.

Fig.4.4: Temperature pattern for tool

4.5. Heat Flux Pattern

Heat is generated in the IEG due to joules heating. By

appropriately designing tool shape, the heat generated and

www.ijaers.com

Page | 141

International Journal of Advanced Engineering Research and Science (IJAERS)

[Vol-3, Issue-10, Oct- 2016]

https://dx.doi.org/10.22161/ijaers/3.10.22

ISSN: 2349-6495(P) | 2456-1908(O)

thus the overheating can be avoided. The fig.4.5, describe

the heat flux pattern for the tool model.

Fig.4.6: Interphase mass transfer profile for tool

Fig.4.5: Heat flux contour for tool

In this simulation, we have assumed that the heat generated

in the IEG is only due to Joules heating. Heat flux is

nothing but the heat generated per unit machining area. For

tool, the value is less near the groove outlet. But as we

proceed towards the outer, the heat flux increases to a very

high amount. This higher value of heat flux exists all over

the outer boundary of L-shape in a comparatively larger

area. The minimum amount of heat flux is -2.823 W/m2 and

maximum amount is 3.763 W/m2.

4.6. Interphase Mass Transfer Profile

Fig.4.6 shows the interphase mass transfer profile for tool.

Interphase mass transfer rate depicts the conversion of

secondary phase from primary one. It may occur due to

bubbling of brine and hence production of hydrogen

bubbles. In this larger amount of conversion from brine to

hydrogen and this conversion goes on increasing from the

groove outlet towards the outer boundaries. This conversion

can be described as nucleus sites formed randomly

throughout the L-shape except at the groove outlet.

4.7. Turbulent Kinetic Energy Profile

Fig.4.7 shows the turbulent kinetic energy contour for tool.

As in this analysis, we have considered k- model for the

turbulence, so there is a variation in k as well as in for a

variation in the turbulence. Turbulence in the k- model

depends on turbulent kinetic energy (k) and turbulent eddy

dissipation (). Roughness of the machined surface has a

direct link with the turbulence. Turbulent kinetic energy

depicts the energy in the turbulence. Turbulent kinetic

energy is produced by fluid shear, friction or buoyancy or

through external forces at low frequency eddy scale. For

this tool the turbulent kinetic energy value is lower near the

groove outlet and increases towards the outer boundaries

because of more turbulence which may be due to the

formation of hydrogen bubbles. The minimum turbulent

kinetic energy is 1.493 X 10-1 m2/s2 near the groove whereas

maximum value is 5.617 X 109 m2/s2 near the outer portions

as depicted from the fig.4.7.

www.ijaers.com

Fig. 4.7: Turbulent kinetic energy contour for tool

V.

CONCLUSION

Three dimensional two phase flow pattern analysis of

electrochemical machining with L-shaped tool provides

fundamental idea of velocity distribution, pressure pattern,

temperature profile, turbulence etc. in the IEG. A

cylindrical Iron work-piece, L-shaped Copper tool and 20%

brine solution as electrolyte was considered in this analysis.

The tool is analysed with inlet velocity of 40 m/s and with a

residual target of 1x10-4. To validate the simulated result,

experimentation was carried out in ECM by fabricating the

tool Model with the same dimension as in simulation. The

experimental results are analysed by using CFD software.

Volume fraction profile for brine indicates that more

hydrogen bubbles are generated and the velocity profile

indicate very high value at the outer side of groove due to

the turbulence created because of the generation of

hydrogen bubbles. Pressure profile describes the pressure in

the machining area and it has randomly generated high

pressure spots throughout the machining area except at

groove outlet because of the cavitation effect at the points

of hydrogen bubbles generation. Similarly, temperature

pattern indicates boiling effect in the machining area

resulting in the generation of hydrogen bubbles.

REFERENCES

[1] Tsuboi, R. and Yamamoto, M. (2009) Modeling and

applications of electrochemical machining process.

Proceedings of the ASME International Mechanical

Page | 142

International Journal of Advanced Engineering Research and Science (IJAERS)

[Vol-3, Issue-10, Oct- 2016]

https://dx.doi.org/10.22161/ijaers/3.10.22

ISSN: 2349-6495(P) | 2456-1908(O)

[2]

[3]

[4]

[5]

[6]

[7]

[8]

Engineering Congress & Exposition IMECE,

November 13-19, Lake Buena Vista, Florida, USA.

Bilgi, D.S., Kumar, R., Jain, V.K. and Shekhar, R.

(2008) Predicting radial overcut in deep holes drilled

by shaped tube electrochemical machining.

International journal of advanced manufacturing

technology, Vol. 39, pp. 47-54.

Neto, J., Silva, E. and Silva, M. (2006) Intervening

variables in electrochemical machining. Journal of

Materials Processing Technology, Vol. 289, pp. 92-96.

Mukherjee, S.K., Kumar, S., Srivastava, P.K. and

Kumar, A. (2008) Effect of valency on material

removal rate in electrochemical machining of

aluminium. Journal of materials processing

technology, Vol. 202, pp. 398-401.

T.Haisch, E.Mittemeijer, J.W.Schultze Electrochemical

machining of the steel 100Cr6 in aqueous NaCl and

NaNO3 solutions: microstructure of surface films

formed by carbides, Electrochimica Acta 47 (2001)

235241.

Conner, M.E., Baglietto, E. and Elmahdi, A.M. (2010)

CFD methodology and validation for single-phase

flow in PWR fuel assemblies. Nuclear Engineering

and Design, Vol. 240, pp. 20882095.

Frank, T., Zwart, P.J., Krepper, E., Prasser, H.M. and

Lucas, D. (2008) Validation of CFD models for

mono- and polydisperse airwater two-phase flows in

pipes. Nuclear Engineering and Design, Vol. 238, pp.

647659.

Li, X.G., Liu, D.X., Xu, S.M. and Li, H. (2009)

CFD simulation of hydrodynamics of valve tray.

Chemical Engineering and Processing, Vol. 48,

pp. 145151.

www.ijaers.com

Page | 143

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Climatic Rhythms and Prevalence of Malaria in The Municipality of Sinende in Northern BeninDocument8 pagesClimatic Rhythms and Prevalence of Malaria in The Municipality of Sinende in Northern BeninIJAERS JOURNALNo ratings yet

- Water Quality Assessment Using GIS Based Multi-Criteria Evaluation (MCE) and Analytical Hierarchy Process (AHP) Methods in Yenagoa Bayelsa State, NigeriaDocument11 pagesWater Quality Assessment Using GIS Based Multi-Criteria Evaluation (MCE) and Analytical Hierarchy Process (AHP) Methods in Yenagoa Bayelsa State, NigeriaIJAERS JOURNALNo ratings yet

- Beef Cattle Farmers' Economic Behavior in The Minahasa Tenggara Regency, IndonesiaDocument7 pagesBeef Cattle Farmers' Economic Behavior in The Minahasa Tenggara Regency, IndonesiaIJAERS JOURNALNo ratings yet

- Facing Dengue and Malaria As A Public Health Challenge in BrazilDocument6 pagesFacing Dengue and Malaria As A Public Health Challenge in BrazilIJAERS JOURNALNo ratings yet

- Design and Building of Servo Motor Portable Coconut Peller MachineDocument5 pagesDesign and Building of Servo Motor Portable Coconut Peller MachineIJAERS JOURNALNo ratings yet

- Breastfeeding and Factors Associated With The Prevention of Childhood Obesity: An Integrative Literature ReviewDocument16 pagesBreastfeeding and Factors Associated With The Prevention of Childhood Obesity: An Integrative Literature ReviewIJAERS JOURNALNo ratings yet

- Business Logistics and The Relationship With Organizational SuccessDocument4 pagesBusiness Logistics and The Relationship With Organizational SuccessIJAERS JOURNALNo ratings yet

- Enhancing Cybersecurity: The Power of Artificial Intelligence in Threat Detection and PreventionDocument6 pagesEnhancing Cybersecurity: The Power of Artificial Intelligence in Threat Detection and PreventionIJAERS JOURNALNo ratings yet

- Impacts On The Mental Health of Professionals in A Prisonal System in Alagoas During The Covid-19 PandemicDocument7 pagesImpacts On The Mental Health of Professionals in A Prisonal System in Alagoas During The Covid-19 PandemicIJAERS JOURNALNo ratings yet

- Study of The Extraction Process of The Pleurotus Citrinopileatus Mushroom and Evaluation of The Biological Activity of The ExtractDocument8 pagesStudy of The Extraction Process of The Pleurotus Citrinopileatus Mushroom and Evaluation of The Biological Activity of The ExtractIJAERS JOURNALNo ratings yet

- The Economic Impact of Coronavirus Disease (COVID-19) : A Study On Tourism Indicators in The Kingdom of Saudi ArabiaDocument4 pagesThe Economic Impact of Coronavirus Disease (COVID-19) : A Study On Tourism Indicators in The Kingdom of Saudi ArabiaIJAERS JOURNALNo ratings yet

- VCO Rancidity Analysis Refers To Fermentation Time That Produced by Gradual Heating MethodDocument6 pagesVCO Rancidity Analysis Refers To Fermentation Time That Produced by Gradual Heating MethodIJAERS JOURNAL100% (1)

- The Economic Impact of Coronavirus Disease (COVID-19) : A Study On Tourism Indicators in The Kingdom of Saudi ArabiaDocument4 pagesThe Economic Impact of Coronavirus Disease (COVID-19) : A Study On Tourism Indicators in The Kingdom of Saudi ArabiaIJAERS JOURNALNo ratings yet

- Analysis of The Thermal Behavior of Masonry Concrete Block With Internal Natural Element CoatingDocument11 pagesAnalysis of The Thermal Behavior of Masonry Concrete Block With Internal Natural Element CoatingIJAERS JOURNALNo ratings yet

- Constructed Wetlands: Technology For Removing Drug Concentration From WaterDocument12 pagesConstructed Wetlands: Technology For Removing Drug Concentration From WaterIJAERS JOURNALNo ratings yet

- Associativism As Strategy of Reaching Territorial Rights, Programs, Projects and Public Policies of Rural Development: The Case of The São Francisco Do Mainã Community, Manaus, AMDocument9 pagesAssociativism As Strategy of Reaching Territorial Rights, Programs, Projects and Public Policies of Rural Development: The Case of The São Francisco Do Mainã Community, Manaus, AMIJAERS JOURNALNo ratings yet

- Process Sequence Optimization and Structural Analysis of Nanoscale Heterostructure Using Compound Semiconductors AlAsSb/In0.59Ga0.41As/GaAs0.53Sb0.47Document5 pagesProcess Sequence Optimization and Structural Analysis of Nanoscale Heterostructure Using Compound Semiconductors AlAsSb/In0.59Ga0.41As/GaAs0.53Sb0.47IJAERS JOURNALNo ratings yet

- Childhood/ Pediatric Cancer: Nursing Care in Oncopediatrics With A Central Focus On HumanizationDocument12 pagesChildhood/ Pediatric Cancer: Nursing Care in Oncopediatrics With A Central Focus On HumanizationIJAERS JOURNALNo ratings yet

- Association of Bacterial Vaginosis To Atypia in Squamous Cells of The CervixDocument15 pagesAssociation of Bacterial Vaginosis To Atypia in Squamous Cells of The CervixIJAERS JOURNALNo ratings yet

- Multiprofessional Care For A Patient With Gestational DiabetesDocument12 pagesMultiprofessional Care For A Patient With Gestational DiabetesIJAERS JOURNALNo ratings yet

- Morphometric Analysis of The Ekole River As A Consequence of Climate Change: A Case Study in Yenagoa, Bayelsa State, NigeriaDocument9 pagesMorphometric Analysis of The Ekole River As A Consequence of Climate Change: A Case Study in Yenagoa, Bayelsa State, NigeriaIJAERS JOURNALNo ratings yet

- Komla Uwolowudu Amegna: International Journal of Advanced Engineering Research and Science (IJAERS)Document9 pagesKomla Uwolowudu Amegna: International Journal of Advanced Engineering Research and Science (IJAERS)IJAERS JOURNALNo ratings yet

- Morphometric Analysis of The Ekole River As A Consequence of Climate Change: A Case Study in Yenagoa, Bayelsa State, NigeriaDocument9 pagesMorphometric Analysis of The Ekole River As A Consequence of Climate Change: A Case Study in Yenagoa, Bayelsa State, NigeriaIJAERS JOURNALNo ratings yet

- Sociodemographic and Clinical Profile of Women With Uterine Cervical Cancer Attended in An Oncological Hospital in The State of Acre, BrazilDocument9 pagesSociodemographic and Clinical Profile of Women With Uterine Cervical Cancer Attended in An Oncological Hospital in The State of Acre, BrazilIJAERS JOURNALNo ratings yet

- Modeling of Geological and Geophysical Data, Onshore Field of Potiguar Basin, Northeastern BrazilDocument5 pagesModeling of Geological and Geophysical Data, Onshore Field of Potiguar Basin, Northeastern BrazilIJAERS JOURNALNo ratings yet

- Humanization in Undergraduate Medical Education: The Brazilian Learner's PerspectiveDocument12 pagesHumanization in Undergraduate Medical Education: The Brazilian Learner's PerspectiveIJAERS JOURNALNo ratings yet

- Mining and Its Impacts On Environment and Health With Special Reference To Ballari District, Karnataka, IndiaDocument7 pagesMining and Its Impacts On Environment and Health With Special Reference To Ballari District, Karnataka, IndiaIJAERS JOURNALNo ratings yet

- Assessment of The Risk of Cardiovascular Diseases and Its Relationship With Heart Rate Variability in Physically Active and Sedentary IndividualsDocument13 pagesAssessment of The Risk of Cardiovascular Diseases and Its Relationship With Heart Rate Variability in Physically Active and Sedentary IndividualsIJAERS JOURNALNo ratings yet

- Does Blended Learning Approach Affect Madrasa Students English Writing Errors? A Comparative StudyDocument12 pagesDoes Blended Learning Approach Affect Madrasa Students English Writing Errors? A Comparative StudyIJAERS JOURNALNo ratings yet

- The Psychologist's Role in The Process of Listening To Children Victims of Sexual Violence in Legal ProceedingsDocument8 pagesThe Psychologist's Role in The Process of Listening To Children Victims of Sexual Violence in Legal ProceedingsIJAERS JOURNALNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- JEE Class Companion Physics: Module-9Document227 pagesJEE Class Companion Physics: Module-9RupakNo ratings yet

- Amateur's Telescope Was First Published in 1920. However, Unlike Ellison's TimeDocument4 pagesAmateur's Telescope Was First Published in 1920. However, Unlike Ellison's Timemohamadazaresh0% (1)

- Design Guide Handbook For EN 1996 Design of Masonry StructuresDocument46 pagesDesign Guide Handbook For EN 1996 Design of Masonry Structuresbusyspider100% (1)

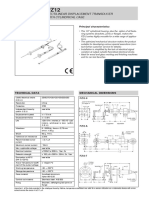

- Rectilinear Displacement Transducer With Cylindrical Case: Technical Data Mechanical DimensionsDocument2 pagesRectilinear Displacement Transducer With Cylindrical Case: Technical Data Mechanical Dimensionsl561926No ratings yet

- Design Project: SEV200 - Geotechnical Investigation and Design Last Update: 09/05/2020Document12 pagesDesign Project: SEV200 - Geotechnical Investigation and Design Last Update: 09/05/2020abdulqadirghoriNo ratings yet

- Lecture2 Semiconductor StatisticsDocument13 pagesLecture2 Semiconductor StatisticsRakib KhanNo ratings yet

- Installation Operation Maintenance Manual (Harvest Series)Document36 pagesInstallation Operation Maintenance Manual (Harvest Series)berkahharianNo ratings yet

- Reciprocating compressor performance analysis using computer simulationDocument9 pagesReciprocating compressor performance analysis using computer simulationLeandro Garcia VelaNo ratings yet

- Inline Desilter ManualDocument18 pagesInline Desilter ManualdesaviniciusNo ratings yet

- 37eb PDFDocument29 pages37eb PDFZikriaKMuhammadNo ratings yet

- Dr. Mezmer's Psychopedia of Bad PsychologyDocument378 pagesDr. Mezmer's Psychopedia of Bad PsychologyArt Marr100% (5)

- Physics Grade 11 Gas Laws and WavesDocument6 pagesPhysics Grade 11 Gas Laws and WavesNatalia WhyteNo ratings yet

- Internal Resistance and Combinations of CellsDocument10 pagesInternal Resistance and Combinations of CellsSukoon Sarin67% (3)

- 5th Grade 13-14 Math Common Core Standards by QuarterDocument3 pages5th Grade 13-14 Math Common Core Standards by QuartermrkballNo ratings yet

- MIT OCW Principles of Inorganic Chemistry II Lecture on Octahedral ML6 Sigma ComplexesDocument7 pagesMIT OCW Principles of Inorganic Chemistry II Lecture on Octahedral ML6 Sigma Complexessanskarid94No ratings yet

- Design Steel Compression MembersDocument42 pagesDesign Steel Compression MembersFayyazAhmadNo ratings yet

- NCHRP RPT 242 PDFDocument85 pagesNCHRP RPT 242 PDFDavid Drolet TremblayNo ratings yet

- CNC CONTOUR VALIDATION WITH LASER BALL BARDocument15 pagesCNC CONTOUR VALIDATION WITH LASER BALL BARNitin DaduNo ratings yet

- CGN 3421 - Numerical Methods Lecture 3Document15 pagesCGN 3421 - Numerical Methods Lecture 3sori1386No ratings yet

- ASTM STP1385 Durability 2000 Accelerated and Outdoor Weathering TestingDocument186 pagesASTM STP1385 Durability 2000 Accelerated and Outdoor Weathering TestingKYAW SOENo ratings yet

- Direct Determination of The Flow Curves of NoDocument4 pagesDirect Determination of The Flow Curves of NoZaid HadiNo ratings yet

- Modeling Arterial Blood Flow With Navier-StokesDocument15 pagesModeling Arterial Blood Flow With Navier-Stokesapi-358127907100% (1)

- A Simple Lamina Flow Engine PDFDocument2 pagesA Simple Lamina Flow Engine PDFSelva KumarNo ratings yet

- Design Procedure of Centrifugal CompressorsDocument16 pagesDesign Procedure of Centrifugal CompressorsSrujana KandagatlaNo ratings yet

- Astm A82 1979Document6 pagesAstm A82 1979yoki_triwahyudiNo ratings yet

- Control System (136-248) PDFDocument113 pagesControl System (136-248) PDFmuruganNo ratings yet

- Introduction To XAFSDocument270 pagesIntroduction To XAFSEric William CochranNo ratings yet

- Mechanics WorksheetDocument64 pagesMechanics WorksheetyeosiewliNo ratings yet

- Review Beer AgeingDocument25 pagesReview Beer AgeingTimothy WestNo ratings yet

- A First Course in Optimization Theory - ContentDocument8 pagesA First Course in Optimization Theory - ContentSuraj KumarNo ratings yet