Professional Documents

Culture Documents

Important Information On Elevator Planning Specifications: Work Not Included in Elevator Contract Capacity and Speed

Uploaded by

FaizalBetawiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Important Information On Elevator Planning Specifications: Work Not Included in Elevator Contract Capacity and Speed

Uploaded by

FaizalBetawiCopyright:

Available Formats

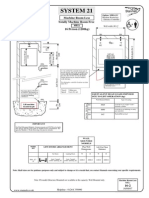

Specifications

Capacity and Speed

Important Information on Elevator Planning

Work Not Included in Elevator Contract

*1

The following items are excluded from Mitsubishi Electrics elevator installation work, and are therefore the responsibility of the building owner or

general contractor:

750

900

1000

1050

1150

1200

1350

1600

1800

2000

2250

2500

3000

10

11

12

13

15

2.0

2.5

3.0

3.5

4.0

5.0

6.0

7.0

8.0

14

17

16

18

20

21

9.0 10.0

24

27

26

30

30

34

33

38

40

46

24

Mitsubishi Electric

standard *2

EN81-1

Access to the elevator machine room sufficient to allow passage of the control panel and traction machine.

Architectural finishing of the machine room floor, and the walls and floors in the vicinity of the entrance hall after installation has been completed.

Construction of an illuminated, ventilated and waterproofed elevator hoistway.

A ladder to the elevator pit.

The provision of cutting the necessary openings and joists.

Separate beams, when the hoistway dimensions markedly exceed the specifications, and intermediate beams when two or more elevators are

installed.

All other work related to building construction.

The machine room power-receiving panel and the electrical wiring for illumination, plus the electrical wiring from the electrical room to the

power-receiving panel.

The laying of conduits and wiring between the elevator pit and the terminating point for the devices installed outside the hoistway, such as the

emergency bell, intercom, monitoring and security devices, etc.

The power consumed in installation work and test operations.

All the necessary building materials for grouting in of brackets, bolts, etc.

The test provision and subsequent alteration as required, and eventual removal of the scaffolding as required by the elevator contractor, and any

other protection of the work as may be required during the process.

The provision of a suitable, locked space for the storage of elevator equipment and tools during elevator installation.

The security system, such as a card reader, connected to Mitsubishi Electrics elevator controller, when supplied by the building owner or general

contractor.

* Work responsibilities in installation and construction shall be determined according to local laws. Please consult our local agents for details.

Elevator Site Requirements

The temperature of the machine room and elevator hoistway shall be below 40C.

The following conditions are required for maintaining elevator performance.

a. The relative humidity shall be below 90% on a monthly average and below 95% on a daily average.

b. Prevention shall be provided against icing and condensation occurring due to a rapid drop in the temperature in the machine room and

Notes:

*1: The symbol shown in the table indicates that a technical inquiry is required.

The symbol shown in the table indicates that a technical inquiry is required depending on conditions.

*2: Based on, but not fully complying with the Building Standard Law of Japan, 2009.

Specifications

elevator hoistway.

c. The machine room and the elevator hoistway shall be finished with mortar or other materials so as to prevent concrete dust.

Voltage fluctuation shall be within a range of +5% to -10%.

*3

2.0

2.5

3.0

3.5

4.0

5.0

6.0

2500 *5

Notes:

*3: Please consult our local agents if the maximum travel exceeds the values specified in the above table.

*4: Excluding the rated capacity 2250kg to 3000kg. Please consult our local agents for maximum travel.

*5: For some elevator specifications, the floor height (distance between floors) must be a minimum of 2500mm.

Please consult our local agents if the floor height is less than Entrance height HH + 700mm.

Operation System

1-car selective collective (1C-2BC)

8.0

9.0

10.0

Please consult our local agents.

250 *4

Door System

7.0

Please consult our local agents.

64

37

Construction of the elevator machine room with proper beams and slabs, equipped with a lock, complete with illumination, ventilation and

waterproofing.

Ordering Information

Please include the following information when ordering or requesting estimates:

The desired number of units, speed and loading capacity.

The number of stops or number of floors to be served.

The total elevator travel and each floor-to-floor height.

Operation system.

Selected design and size of car.

Entrance design.

Signal equipment.

A sketch of the part of the building where the elevators are to be installed.

The voltage, number of phases, and frequency of the power source for the motor and lighting.

Mitsubishi Electric Corporation Inazawa Works has acquired ISO 9001

certification from the International Organization for Standardization based

on a review of quality management.

The plant has also acquired environmental management system standard

ISO 14001 certification.

38

You might also like

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Dx140w - Shop ManualDocument1,180 pagesDx140w - Shop ManualPhan Văn Định100% (18)

- Manitou MT 625 T Comfort Operator's ManualDocument130 pagesManitou MT 625 T Comfort Operator's ManualAnonymous 1XBCMXNo ratings yet

- Specifications for 750kg passenger liftDocument19 pagesSpecifications for 750kg passenger liftlahiruNo ratings yet

- ELECTRICAL Design Check List NEWDocument16 pagesELECTRICAL Design Check List NEWboomdenNo ratings yet

- Mobile Drilling Rig SpecsDocument52 pagesMobile Drilling Rig SpecsGregory StewartNo ratings yet

- Shellliftingspecsops0055rev1 4Document125 pagesShellliftingspecsops0055rev1 4Marcos TadsioNo ratings yet

- Erection Method StatementDocument32 pagesErection Method StatementDilxan Fdo100% (4)

- Swing MotorDocument16 pagesSwing Motorpaulnunez9389No ratings yet

- WORKS METHOD STATEMENT Ceiling WorksDocument3 pagesWORKS METHOD STATEMENT Ceiling WorksSyafiq ZakiNo ratings yet

- PM 3000 User ManualDocument145 pagesPM 3000 User ManualDaniel Rincón100% (2)

- Otis Gen2 SpecificationsDocument13 pagesOtis Gen2 SpecificationsAnonymous 3v1z9l100% (7)

- Operation Manual: Front/Back Labeler Model CVC 400Document112 pagesOperation Manual: Front/Back Labeler Model CVC 400Brandon MendozaNo ratings yet

- Larsson Quotation SampleDocument6 pagesLarsson Quotation Samplevinay100% (1)

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorFrom EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNo ratings yet

- Elevators and EscalatorsDocument38 pagesElevators and Escalatorsshrikant100% (11)

- M7E02 Installation 02 PDFDocument28 pagesM7E02 Installation 02 PDFlexeberu100% (4)

- Elevator CodesDocument19 pagesElevator CodesMoe Kimo100% (3)

- Session 3-Design Requirements of BMUsDocument37 pagesSession 3-Design Requirements of BMUsRanjit Singh100% (1)

- Substation Civil Design RequirementsDocument3 pagesSubstation Civil Design Requirementsshaikhsajid242No ratings yet

- Red Book # 9105-4 Pontoon Floating Roof General InformationDocument7 pagesRed Book # 9105-4 Pontoon Floating Roof General Informationhamr01100% (1)

- E.6,7 & 8 - EOT Cranes 50, 20 & 10 TDocument33 pagesE.6,7 & 8 - EOT Cranes 50, 20 & 10 TAvijitNo ratings yet

- Double Girder EOT Crane EnquiryDocument3 pagesDouble Girder EOT Crane EnquiryvkNo ratings yet

- Essential guide to building elevator shaftsDocument20 pagesEssential guide to building elevator shaftsBolo BoloNo ratings yet

- IrisDocument40 pagesIrisM Namir HasanNo ratings yet

- Ducted Split ProposalDocument7 pagesDucted Split ProposalSunil Mohammed UsmaniyaNo ratings yet

- Nextra SpecsDocument2 pagesNextra Specsjaikumar505No ratings yet

- Schindler Smart Quick Reference Guide1Document125 pagesSchindler Smart Quick Reference Guide1Paul Ridge71% (7)

- 14 2400 Hydraulic ElevatorsDocument12 pages14 2400 Hydraulic ElevatorsPercy GoitsemangNo ratings yet

- Fire Safety Report 9.1 Purpose: Chapter 9 - 1Document6 pagesFire Safety Report 9.1 Purpose: Chapter 9 - 1Balgo BalgobinNo ratings yet

- Turner Compact Plus Transmission Manual PDFDocument74 pagesTurner Compact Plus Transmission Manual PDFJonathan Pais80% (5)

- Twi CrossflowDocument8 pagesTwi CrossflowDota NgNo ratings yet

- Session 3 PDFDocument37 pagesSession 3 PDFRanjit SinghNo ratings yet

- Tdce01 - 04gb Manual Dce 80-100eDocument317 pagesTdce01 - 04gb Manual Dce 80-100eHariyono Busro100% (3)

- Grhorq Antiguas 393Document1,163 pagesGrhorq Antiguas 393lilyricardoseaman100% (1)

- TLB 890 Tier3 EspecificaçõesDocument24 pagesTLB 890 Tier3 EspecificaçõesTiago Freire100% (1)

- Liebherr RMG Technical Description Rail-Mounted Container Stacking CranesDocument4 pagesLiebherr RMG Technical Description Rail-Mounted Container Stacking CranesMuhammad Jazztyan Indra PradanaNo ratings yet

- Ascensor MitsubishiDocument6 pagesAscensor MitsubishiRicardo ZapataNo ratings yet

- Catalog Design RefDocument10 pagesCatalog Design RefselvampalaniNo ratings yet

- PANORAMA Specifications Feb FINALDocument13 pagesPANORAMA Specifications Feb FINALagmibrahim5055No ratings yet

- Machine Room-Less (MRL)Document13 pagesMachine Room-Less (MRL)rishi070881No ratings yet

- The Most Versatile Range of High Quality Electric Service LiftsDocument4 pagesThe Most Versatile Range of High Quality Electric Service LiftsSelver SalkicNo ratings yet

- Gearless Traction ElevatorDocument12 pagesGearless Traction ElevatorFabian Alberto Mercado TheranNo ratings yet

- Basic SpecDocument1 pageBasic SpecbonongxNo ratings yet

- Standard Lift SpecificationDocument13 pagesStandard Lift SpecificationAhmedNo ratings yet

- Elevator Quotation for 8-10 Passenger Auto Door LiftDocument9 pagesElevator Quotation for 8-10 Passenger Auto Door Liftsrikanth goudNo ratings yet

- Lift Shaft Builders GuideDocument19 pagesLift Shaft Builders Guidesydney augustNo ratings yet

- LIFT SELECTION AND LOCATION FACTORSDocument22 pagesLIFT SELECTION AND LOCATION FACTORSVimal MathivananNo ratings yet

- EPM PM9-Standard Lift SpecificationDocument13 pagesEPM PM9-Standard Lift SpecificationAnsara Pasir TumbohNo ratings yet

- Lift+Shaft+Builders+Guide+ +All+LiftsDocument18 pagesLift+Shaft+Builders+Guide+ +All+LiftsArdeshir MasoudNo ratings yet

- Atrlad Metrix Shoring Documentation Additional HD320Document44 pagesAtrlad Metrix Shoring Documentation Additional HD320Pszem PszemekNo ratings yet

- Happy Elevators India PVT LTD: Sub: Elevator QuotationDocument9 pagesHappy Elevators India PVT LTD: Sub: Elevator Quotationsrikanth goudNo ratings yet

- Mirza & Co.: Executive SummaryDocument4 pagesMirza & Co.: Executive SummaryNiloy Abu NaserNo ratings yet

- ред поворот PDFDocument20 pagesред поворот PDFrenatNo ratings yet

- ILQ Installation Manual Checklist & DimensionsDocument34 pagesILQ Installation Manual Checklist & DimensionsZizo Awad0% (1)

- MRL SM Series Side Machine Roomless ElevatorDocument2 pagesMRL SM Series Side Machine Roomless ElevatorSudheer SudhakaranNo ratings yet

- DU Telephone Regulations 2013 Handbook PDFDocument41 pagesDU Telephone Regulations 2013 Handbook PDFMuraryspottyNo ratings yet

- Lift Mart - Residential Villa On Plot No 37 Sector No MZ39 at 4958Document20 pagesLift Mart - Residential Villa On Plot No 37 Sector No MZ39 at 4958aisahmay04No ratings yet

- Elevators and Escalators: Selection and Design(35Document38 pagesElevators and Escalators: Selection and Design(35sagrikakhandkaNo ratings yet

- Parking Automat Passable: Product DataDocument6 pagesParking Automat Passable: Product DatapoopoopoopooabcdNo ratings yet

- GUJARAT NARMADA VALLEY FERTILIZERS & CHEMICALS LIMITED 50000 MTA PAC PROJECT CONSTRUCTION PHILOSOPHYDocument11 pagesGUJARAT NARMADA VALLEY FERTILIZERS & CHEMICALS LIMITED 50000 MTA PAC PROJECT CONSTRUCTION PHILOSOPHYjeya vasanthNo ratings yet

- Kleemann NewsFax/Mail (082011) English VersionDocument4 pagesKleemann NewsFax/Mail (082011) English VersionKleemmann Hellas SANo ratings yet

- Elevators and EscalatorsDocument38 pagesElevators and EscalatorsFikri RahimNo ratings yet

- Elevators TechnologyDocument25 pagesElevators Technologyengineer63No ratings yet

- 16 Person - 1200kgDocument1 page16 Person - 1200kgopulitheNo ratings yet

- GB Lorry LoaderDocument2 pagesGB Lorry LoaderDoubleFive SevenNo ratings yet

- F37 RecallDocument36 pagesF37 RecallchdorseyNo ratings yet

- Electrical Distribution Service: Statement of WorkDocument8 pagesElectrical Distribution Service: Statement of WorkFranck VoisinNo ratings yet

- BAYNE TL Manual 2200Document51 pagesBAYNE TL Manual 2200stainless31620039126100% (1)

- Trendvario: Product DataDocument6 pagesTrendvario: Product DataadasjkasdNo ratings yet

- Hoja Tecnica Dumper AtlasDocument4 pagesHoja Tecnica Dumper AtlasRoferq Fernandez QuichuaNo ratings yet

- Flower DictionaryDocument2 pagesFlower DictionaryFaizalBetawiNo ratings yet

- Soil Test PDFDocument30 pagesSoil Test PDFFaizalBetawiNo ratings yet

- ORD 24-2007 Zoning - LandscapeDocument15 pagesORD 24-2007 Zoning - LandscapeFaizalBetawiNo ratings yet

- Lelang 1467278436Document1 pageLelang 1467278436FaizalBetawiNo ratings yet

- Proposal Bumi Cileres Asri 140908125035 Phpapp02Document4 pagesProposal Bumi Cileres Asri 140908125035 Phpapp02FaizalBetawiNo ratings yet

- ORD 24-2007 Zoning - LandscapeDocument15 pagesORD 24-2007 Zoning - LandscapeFaizalBetawiNo ratings yet

- Analisa Harga BOWDocument12 pagesAnalisa Harga BOWArif PandiNo ratings yet

- Material Handling Equipment Selection - New ClassificationDocument8 pagesMaterial Handling Equipment Selection - New ClassificationReda MokhtatarNo ratings yet

- Safety Web FPA Form PDFDocument6 pagesSafety Web FPA Form PDFraj kumarNo ratings yet

- Grammatical Structures For Describing Diagrams: Test Section - Academic Writing Task 1Document12 pagesGrammatical Structures For Describing Diagrams: Test Section - Academic Writing Task 1echaNo ratings yet

- TSplus Lift Transfer UnitsDocument10 pagesTSplus Lift Transfer UnitsHelena Nadine Mendes FerreiraNo ratings yet

- Finl MNCDocument15 pagesFinl MNCTabbasum Shaikh0% (1)

- Low energy trucks optimized for performance and efficiencyDocument8 pagesLow energy trucks optimized for performance and efficiencyMA TotalforkliftNo ratings yet

- PC800 Hydraulic Excavator Specs & FeaturesDocument9 pagesPC800 Hydraulic Excavator Specs & FeaturesMohammed Azhar67% (3)

- Catalogue Durapac PDFDocument144 pagesCatalogue Durapac PDFMarita VillezaNo ratings yet

- Purchaser's DeedDocument12 pagesPurchaser's DeedShayak DasguptaNo ratings yet

- Guidelines For Planning A TownshipDocument6 pagesGuidelines For Planning A TownshipAniket DhakeNo ratings yet

- Code of Practice: For The Safe Operation of Powered Lift TrucksDocument22 pagesCode of Practice: For The Safe Operation of Powered Lift TrucksAcacio NetoNo ratings yet

- Microcontroller Based Multilevel Car Parking SystemDocument5 pagesMicrocontroller Based Multilevel Car Parking Systemdarshanv99100% (4)

- 914G It14g PDFDocument20 pages914G It14g PDFMA TotalforkliftNo ratings yet

- Voice Based Lift ControlDocument6 pagesVoice Based Lift ControlIJRASETPublicationsNo ratings yet

- Agri ProcessDocument63 pagesAgri ProcessAlfredo Jr FortuNo ratings yet

- KONE TranSys DX-brochure Soisof 222-WEB tcm59-86410Document8 pagesKONE TranSys DX-brochure Soisof 222-WEB tcm59-86410YANETH ALCANTARANo ratings yet

- Atlas & Fpa (Downsize)Document16 pagesAtlas & Fpa (Downsize)kelvinjunilsonNo ratings yet

- Architectural Barriers Assessment and PaperDocument10 pagesArchitectural Barriers Assessment and Paperapi-227486914No ratings yet