Professional Documents

Culture Documents

Not For Sale

Uploaded by

Swati SharmaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Not For Sale

Uploaded by

Swati SharmaCopyright:

Available Formats

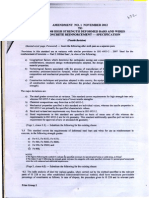

AMENDMENT NO.

3 NOVEMBER 2007

TO

IS 7098 (pART 1) : I ' . SPECIFICATION FOR

CROSSLINKED POLYETHYLENE INSULATED

PVC SHEATHED CABLES

PART1 FOR WORKING VOLTAGE UPTO AND

INCLUDING 1 100VOLTS

( FInt llnlllo" )

[Page 2, clause fi.l(b)] - Substitute 'Galvanized steel formed wire (strip),

or'lor 'Galvanizedsteel strip, or'.

Substitute the following for the existing

ale

(Page 3, clause 6.2, line 1) matter:

'The galvanized roundsteel wires/formed steel wires(strips) used for armouring

shallconform to IS 397S : 1999. t

rs

(Page 3,/00,"01. marked *) - Substitute the following for the existing:

t fo

'-Low carbon plv.i8d steel wires. formed wires and tapes for lI1DOurinl of cables Specification.

(Page S, clause 13.3, line 2) - Insert the following at the end:

"The tolerance on nominal dimensions shaD be as per IS 397S : 1999. However,

for formed steel wires compliance shall be ensured only for dimensions 'A' &

No

'C'."

(PageS,clQU8e 13.5.2)- Insert the following new clausesafter 13.5.2:

13.6 The round steel wireslformed steel wires taken from the cable shall meet

the following requirements.

a)

The tensile strength of round steel wire/formed steel wire shall be not

less than 2S0 N/mm2 and Dot more580 N/mm2

b)

The Elongation at breekofroundsteel wire/formed steel wire shall be

Dot less than 6 percent.

Amend No.3 to IS 7098 (part 1): 1988

c)

Round steel wire shall meet the requirements of tonion test. The

gauge length between Vices and the minimum number of turns

withoutbreak shall be as per Table 6 of IS 397S : 1999.

d)

The zinc coating shall not show any cracks and shall not flake off on

robbing by the bare finger whenthe fonned steel wire is subjected to

windingtest.

e)

The uniformity of zinc coating of round steel wire/formed steel wire

shall comply with the requirements of IS 397S : 1999 subject to the

following:

The minimum number of dips shall be reduced by one half-minute

dip

In case of formed wires, dip test is applicable only for the face.

The mass of zinc coating of round steel wire shall be not less than 9S

percentof the mass specified in Table 2 of IS 4826 : 1979.

ale

f)

rs

The mass of zinc coating of formed steel wire shall be not less than

95 percent of the mass specified in IS 397S : 1999.

g)

The resistivityof the round steel wire/formedsteel wire shall meet the

requirements of IS 397S : 1999.

Substitute the following for the

Tests for round steel wire/fonned steel

wire (strip) annour:

No

b)

t fo

[Page 7, clause 15.1, 51 No. (b)] existing matter:

1)

Dimensions

2)

Physical tests on round/fonned wire:

i) Tensile strength

ii) Elongation at break

iii) Torsion test for round wires

iv) Windingtest for formed wires

2

13.3 of

IS 7098 (Part I)

Part 36 of

IS 10810

13.6(8) of

IS 7098 (Part 1)

13.6(b) of

IS 7098 (part 1)

13.6(c) of

IS 7098 (Part 1)

13.6(d) of

IS 7098 (Part 1)

Part 37 of

IS 10810

Part 37 of

IS 10810

Part 38 of

IS 10810

Part 39 of

IS 10810

Amend No.3 to IS 7098 (part 1): 1988

v) Uniformity of zinc coating

vi) Massof zinc coating

vii) Resistivity

(Page7,footnote marlced

:> -

13.6(e) of

IS 7098 (Part 1)

13.6(f) of

IS 7098 (Part 1)

13.6(g) of

IS 7098 (Part 1)

Part 40 of

IS 10810

Part 41 of

IS 10810

Part 42 of

IS 10810

Substitute the following for the existing:

No

t

for

sa

le

'~Low carbon Ialvanized steel wires, formed wires and tapes for armouring of cables Specification.'

(ET09)

ReprolflPhy Unit. DIS. New Delhi.India

You might also like

- Not For SaleDocument3 pagesNot For SalerickyNo ratings yet

- AMENDMENT 2 (500 KV) (Rev2, Apr2016)Document7 pagesAMENDMENT 2 (500 KV) (Rev2, Apr2016)Jed SrisuthumNo ratings yet

- Cement Concrete PoleDocument30 pagesCement Concrete PoleGeno AgneNo ratings yet

- Technical Specification of Lattice Steel PolesDocument9 pagesTechnical Specification of Lattice Steel PolesCalinB.ACNo ratings yet

- Draft Barbed Wire Is CodeDocument7 pagesDraft Barbed Wire Is Codekavi_prakash6992No ratings yet

- Specifications of T, 40,20081347Document5 pagesSpecifications of T, 40,20081347Ardalan KhoshnawNo ratings yet

- 10 TMSS 05 R0Document0 pages10 TMSS 05 R0renjithas2005No ratings yet

- 10 TMSS 05 R1Document11 pages10 TMSS 05 R1Omar HijaziNo ratings yet

- Is 785 1998 Reinforced Concrete Poles For Overhead Power and Telecommunication Lines - SpecificationDocument10 pagesIs 785 1998 Reinforced Concrete Poles For Overhead Power and Telecommunication Lines - SpecificationDebajani DekabaruahNo ratings yet

- 1729Document52 pages1729praj24083302No ratings yet

- T Proc Notices Notices 040 K Notice Doc 35289 253020834Document8 pagesT Proc Notices Notices 040 K Notice Doc 35289 253020834billy chrisNo ratings yet

- Is 398 2 1996 PDFDocument19 pagesIs 398 2 1996 PDFLakshman KumarNo ratings yet

- Astm A810-01Document4 pagesAstm A810-01ditherNo ratings yet

- Astm B187Document9 pagesAstm B187Plata Elpidio100% (3)

- Indian Standard Radial GateDocument8 pagesIndian Standard Radial GateMirza FadlulahNo ratings yet

- Welding Chart The Complete Reference Guide To WeldingDocument2 pagesWelding Chart The Complete Reference Guide To WeldingJitu JenaNo ratings yet

- A496 97 PDFDocument5 pagesA496 97 PDFJohano Araújo100% (1)

- I S 3024Document9 pagesI S 3024Hariprasad gantyala100% (1)

- Astm B 856 - 03Document8 pagesAstm B 856 - 03phaindikaNo ratings yet

- 11KV TRANSMISSION LINES SpecificationDocument16 pages11KV TRANSMISSION LINES SpecificationIwan Tristiawan0% (1)

- Is 398 Part5 1992Document13 pagesIs 398 Part5 1992skc1234No ratings yet

- C955 09Document4 pagesC955 09jacr27No ratings yet

- Zinc-Coated Steel Wire Rope and Fittings For Highway GuardrailDocument4 pagesZinc-Coated Steel Wire Rope and Fittings For Highway GuardrailCPA BTKNo ratings yet

- Cable Trunking 2016-For ALLDocument46 pagesCable Trunking 2016-For ALLjm.mankavil6230No ratings yet

- COLD FORMED STEEL MEMBERS AND DESIGNDocument14 pagesCOLD FORMED STEEL MEMBERS AND DESIGNMihai MariusNo ratings yet

- A 881Document3 pagesA 881Gustavo SuarezNo ratings yet

- Reinforced Concrete Poles For Overhead Power and Telecommunication Lines - SpecificationDocument10 pagesReinforced Concrete Poles For Overhead Power and Telecommunication Lines - SpecificationKumar AtrayNo ratings yet

- ACSR ConductorDocument13 pagesACSR ConductorHrshiya SharmaNo ratings yet

- Esr 1917Document12 pagesEsr 1917drac_dracNo ratings yet

- Metallic Coated Stranded Steel Core For Aluminum Conductors, Steel Reinforced (ACSR)Document3 pagesMetallic Coated Stranded Steel Core For Aluminum Conductors, Steel Reinforced (ACSR)alanetnNo ratings yet

- Transmission Materials Standard Specification OverviewDocument0 pagesTransmission Materials Standard Specification OverviewhasanmnhNo ratings yet

- TrunkingDocument46 pagesTrunkingirfan vpNo ratings yet

- ST7203 Steel StructuresDocument20 pagesST7203 Steel StructuresVishal RanganathanNo ratings yet

- Global Marketing For Tube & Pipe: JIS C8305 Rigid Steel ConduitsDocument7 pagesGlobal Marketing For Tube & Pipe: JIS C8305 Rigid Steel ConduitsHoangNo ratings yet

- Disclosure To Promote The Right To InformationDocument18 pagesDisclosure To Promote The Right To InformationSantosh KumarNo ratings yet

- CEB Galvanized Iron Pipes SpecificationDocument12 pagesCEB Galvanized Iron Pipes SpecificationaselabollegalaNo ratings yet

- 19.sec.1900 (Structural Steel)Document31 pages19.sec.1900 (Structural Steel)aalignup arc & const. pvt ltdNo ratings yet

- ASTM A641 A641M 2003 Standard Specification For Zinc Coated Galvanized Carbon Steel Wire 26 PDFDocument5 pagesASTM A641 A641M 2003 Standard Specification For Zinc Coated Galvanized Carbon Steel Wire 26 PDFRober Moises Chumbe SoveroNo ratings yet

- Amendment 1 of IS - 1786-2008Document11 pagesAmendment 1 of IS - 1786-2008sukanta420No ratings yet

- Accessory Materials For Prestressed ConcreteDocument3 pagesAccessory Materials For Prestressed ConcreteAshley JeyahNo ratings yet

- C 955 - 01 Qzk1ns1sruqDocument6 pagesC 955 - 01 Qzk1ns1sruqHumberto GutierrezNo ratings yet

- PSCC PolesDocument13 pagesPSCC PolesChaitanya Bhargav KotikeNo ratings yet

- Copper Clad Steel Earth Rod AssemblyDocument13 pagesCopper Clad Steel Earth Rod AssemblyprabathnilanNo ratings yet

- Is2062 E350Document12 pagesIs2062 E350Sowmen ChakrobortyNo ratings yet

- 398 - 2 Aluminium Conductors, Galvanized Steel-ReinforcedDocument16 pages398 - 2 Aluminium Conductors, Galvanized Steel-ReinforcedvikasNo ratings yet

- BS 215 Part 1 1970Document11 pagesBS 215 Part 1 1970AnamulKabirNo ratings yet

- Compact Round Stranded Copper Conductors Using Single Input Wire ConstructionDocument3 pagesCompact Round Stranded Copper Conductors Using Single Input Wire ConstructionSix RameshNo ratings yet

- 2 0.2 Acsr Panther Conductor 1 14Document14 pages2 0.2 Acsr Panther Conductor 1 14Anurag SanodiaNo ratings yet

- Is 12592 2002Document20 pagesIs 12592 2002Ratnam SkNo ratings yet

- C 956 Â " 97 QZK1NI1SRUQDocument8 pagesC 956 Â " 97 QZK1NI1SRUQSebastián RodríguezNo ratings yet

- Natsteel BRCDocument8 pagesNatsteel BRClwin_oo2435No ratings yet

- Structural Design of Reinforcements For Fittings in Factory-Made Corrugated Steel Pipe For Sewers and Other ApplicationsDocument18 pagesStructural Design of Reinforcements For Fittings in Factory-Made Corrugated Steel Pipe For Sewers and Other ApplicationsAleksei AvilaNo ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- The Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20From EverandThe Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20No ratings yet

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39From EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39Rating: 5 out of 5 stars5/5 (1)

- Advertisment-R and D Eng LEDDocument1 pageAdvertisment-R and D Eng LEDSwati SharmaNo ratings yet

- RTL Rtgs DetailsDocument1 pageRTL Rtgs DetailsSwati SharmaNo ratings yet

- Jic07 A73Document4 pagesJic07 A73Swati SharmaNo ratings yet

- 7098 1a2Document1 page7098 1a2Swati SharmaNo ratings yet

- 33a2Document1 page33a2Swati SharmaNo ratings yet

- Amendment 4 to IS 7098 Part 1 XLPE Cables SpecificationDocument1 pageAmendment 4 to IS 7098 Part 1 XLPE Cables SpecificationSwati SharmaNo ratings yet

- Indian Standards For LEDDocument1 pageIndian Standards For LEDBejoy ThomasNo ratings yet

- Not For SaleDocument1 pageNot For SaleSwati SharmaNo ratings yet

- Not For Sale: Amendment No. 1 July 2002 TO Is 10810 (Part 33) : 1984 Methods of Test For CablesDocument1 pageNot For Sale: Amendment No. 1 July 2002 TO Is 10810 (Part 33) : 1984 Methods of Test For CablesSwati SharmaNo ratings yet

- Tejas Article - Evaluating The Future of Indian Solar Industry PDFDocument7 pagesTejas Article - Evaluating The Future of Indian Solar Industry PDFSwati SharmaNo ratings yet

- Adaptive Droop Control Applied To Voltage-Source Inverters Operating in Grid-Connected and Islanded ModesDocument9 pagesAdaptive Droop Control Applied To Voltage-Source Inverters Operating in Grid-Connected and Islanded ModesirwintilsonNo ratings yet

- Not For SaleDocument1 pageNot For SaleSwati SharmaNo ratings yet

- Frame and SFRC Cover Design for 560mm Diameter ManholeDocument1 pageFrame and SFRC Cover Design for 560mm Diameter ManholejaipalNo ratings yet

- NLFX65-40-200-7.5 (1) (2) - RemovedDocument4 pagesNLFX65-40-200-7.5 (1) (2) - Removedatheer alaniNo ratings yet

- Job Description Job Description: Acheron TechnologiesDocument1 pageJob Description Job Description: Acheron Technologiess_subbulakshmiNo ratings yet

- Past Simple VS Past ContinuousDocument4 pagesPast Simple VS Past ContinuousJosep Barrera Testar100% (1)

- Induction Programme August 2019 For WeeblyDocument7 pagesInduction Programme August 2019 For Weeblyapi-323457666No ratings yet

- AutoCAD layers, colors, linetypes, lineweights, and plot stylesDocument5 pagesAutoCAD layers, colors, linetypes, lineweights, and plot stylesFRANCISCO JERHYL KEITH G.No ratings yet

- Telco Cloud - 01. Introduction To Telco CloudDocument10 pagesTelco Cloud - 01. Introduction To Telco Cloudvikas_sh81No ratings yet

- AQUALERT 6051 Hardness Analyze RDocument2 pagesAQUALERT 6051 Hardness Analyze RSarmiento HerminioNo ratings yet

- Series BootsDocument2 pagesSeries Bootsvictor laraNo ratings yet

- ITT420 TEST1 2020-HidayahDocument3 pagesITT420 TEST1 2020-HidayahHaf HarunNo ratings yet

- How To Make Tilted OWCDocument10 pagesHow To Make Tilted OWCminahlehNo ratings yet

- Focus4 2E Unit Test Dictation Listening Reading Unit7 GroupADocument3 pagesFocus4 2E Unit Test Dictation Listening Reading Unit7 GroupAАнтон ТімофєєвNo ratings yet

- Android Sensor Development: Measure Motion, Orientation & EnvironmentDocument41 pagesAndroid Sensor Development: Measure Motion, Orientation & EnvironmentAnonn NymousNo ratings yet

- Roverbook Explorer E510L Compal - La-2251 - r1 - SchematicsDocument48 pagesRoverbook Explorer E510L Compal - La-2251 - r1 - SchematicsEdson HenriqueNo ratings yet

- ELEN2021: Microprocessors: Digital Logic and DesignDocument25 pagesELEN2021: Microprocessors: Digital Logic and DesignKuzivashe KudzeremaNo ratings yet

- C320 - Tunnelling Under The Thames: September 2003Document5 pagesC320 - Tunnelling Under The Thames: September 2003Jorge Baños LloredoNo ratings yet

- The Schematic Structure of Computer Science Research ArticlesDocument11 pagesThe Schematic Structure of Computer Science Research ArticlesAlfin KarimahNo ratings yet

- Doing More With Slurm Advanced CapabilitiesDocument31 pagesDoing More With Slurm Advanced CapabilitiesSudhakar LakkarajuNo ratings yet

- ISDN Question BankDocument3 pagesISDN Question Bankmaithuong85No ratings yet

- Jeppview For Windows: General Information General InformationDocument12 pagesJeppview For Windows: General Information General Informationİ. Çağlar YILDIRIMNo ratings yet

- Alphabets and ElementsDocument4 pagesAlphabets and ElementsLaura TashmanNo ratings yet

- 2022 - 3 - Prakddp - Tugas 12 - 12D2 - 211210041 - Hildegardis Kristina SakaDocument19 pages2022 - 3 - Prakddp - Tugas 12 - 12D2 - 211210041 - Hildegardis Kristina Sakadhea ferdiana merpatikaNo ratings yet

- Infiniti G35 Coupe Workshop Manual (V6-3.5L (VQ35DE) (2003) )Document10 pagesInfiniti G35 Coupe Workshop Manual (V6-3.5L (VQ35DE) (2003) )Yann MenNo ratings yet

- MM 302 - Digital & Social Media MarketingDocument12 pagesMM 302 - Digital & Social Media MarketingDr. Arunava MookherjeeNo ratings yet

- HRMS User ManualDocument30 pagesHRMS User ManualNino Joshua CastinoNo ratings yet

- Grid Innovation Fund Portfolio Feb 15 2019Document25 pagesGrid Innovation Fund Portfolio Feb 15 2019randiaNo ratings yet

- B ACI Best PracticesDocument232 pagesB ACI Best PracticesNdaru PrakosoNo ratings yet

- Instructions To Users: A Run 500 M Sq. MM 3 Allow V DropDocument26 pagesInstructions To Users: A Run 500 M Sq. MM 3 Allow V DropjjspenceNo ratings yet

- Business Plan MVNO Project Final PresentationDocument35 pagesBusiness Plan MVNO Project Final PresentationDeepak_Agarwal_188971% (7)

- Lecture - 04 - Control StructureDocument52 pagesLecture - 04 - Control StructureSiti AzzaharahNo ratings yet