Professional Documents

Culture Documents

Lowering The Bill With Trelleborg Floatover Solutions

Uploaded by

mashanghOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lowering The Bill With Trelleborg Floatover Solutions

Uploaded by

mashanghCopyright:

Available Formats

innovation OFFSHORE

We have invested

in a high-capacity

test press to meet

the increased demand.

J.P. Chia, Engineering Manager,

Trelleborg Singapore

Lowering the bill

FOR PLATFORM

INSTALLATION

The world depends for much of its energy supply on oil and gas extracted from

beneath the seabed. New technology from Trelleborg for installing production

platforms oshore provides a welcome reduction in costs.

TEXT: NICK TERDRE PHOTO & ILLUSTRATION: TRELLEBORG

relleborgs products

leg mating units (lmus),

deck support units, sway

and surge fenders make a

valuable contribution to the

float-over method of installing the

topsides of offshore oil and gas platforms from a barge.

Traditionally the topsides are lifted

onto the support structure or jacket

by a floating crane. But the hire rates

for such cranes are high, sometimes

running into several hundred thousand dollars a day. The float-over

process provides a much less costly

solution. But the crucial challenge,

according to J.P. Chia, Engineering

Manager at Trelleborg Singapore, is

transferring the load from the barge

to the jacket. This must be done in a

controlled manner without causing

damage to either structure, even

though waves, currents or winds are

causing the barge to move.

The lmus steel structures

incorporating rubber elements

make this possible by dampening the

6 TTIME 32010

10TTI3_lmu_3014.indd 6

2010-11-10 09:33:20

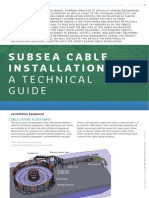

Using LMUs during a float-over process, the loads can be

transferred from the barge to the base structure in a controlled

manner. LMUs consist of a steel structure incorporating rubber

elements to achieve a specified spring rate, depending on

the expected loads and movements.

Qatar. The company performed full

custom design, engineering, fabrication and testing. Each of the lmus

for the 13,000-ton bg topsides

weighed 24 tons, was 2 meters in

diameter and stood 3.7 meters high.

forces created as the topsides load is

transferred to the jacket, Chia

explains. Using data provided by

the client, the rubber elements are

engineered to have the correct spring

stiffness for this task.

The LMUs are placed inside steel

cans known as transition pieces,

which are installed on top of the

jacket legs.

Meanwhile, surge and sway

fenders absorb the impact of the

barge on the jacket as it moves

forward or sideways during the

mating operation.

Once the topsides have been safely

transferred onto the jacket, the two

structures are welded together.

Deck support units, or dsus, come

into play in the fabrication yard.

The topsides are transferred onto

the barge on a deck support frame.

dsus positioned on the deck support

frame absorb the weight of the

topsides as they are placed on the

frame.

Trelleborg Singapore participated

in two float-over projects last year,

including the installation of the

be and bg topsides for Maersk Oil

Trelleborg worked with technical

service provider gl Noble Denton.

In this project, Trelleborg

supplied 12 lmus, which showed

good performance and reliability

during the topside float-over installation, says gl Noble Denton Project

Engineering Manager Andy Wang.

This should be attributed to the

sound engineering work and

comprehensive manufacturing and

testing procedures of Trelleborg,

which we have observed both during

this project and in our visits to the

Trelleborg yard.

One of the key benefits of the

float-over solution is that nearly all

the work on the topsides can be done

in the fabrication yard, where labor

costs are much lower.

A floating crane would have had

to make several lifts to install the bg

topsides, after which extra work

would have been required to hook up

and commission the various

modules.

Following last years successful

projects, Trelleborg Singapore has

received several invitations to tender

for further float-over operations,

Chia says.

Chia explains that all the floatover products have to be fully tested

before use. The load deformation

behavior of the lmu pads has to be

verified, for example.

We have invested in a highcapacity test press to meet the

increased demand, says Chia.

HOW IT WORKS

In float-over operations, the topsides of a production platform, which may vary in size from less than 1,000 tons to

more than 40,000 tons, are installed from a barge. The

barge is towed to the field and positioned between the legs

of the supporting structure or jacket.

The barge is then ballasted down until the topsides make

contact with the jacket legs. When their entire weight has

been transferred to the jacket, the barge is towed away.

For further information:

julian.wee @trelleborg.com

EASY SKIDDING

In addition to LMUs, DSUs and fenders, Trelleborg also

supplies Orkot bearings to ease the skidding process of

the topside onto the transport barge.

Runners beneath the deck frame fit into grooves along

which the topside is pushed using very strong strand jacks.

The Orkot bearings are placed in the grooves. With their

high load capacity and low friction coefficient, they reduce

the force that has to be applied to move the topsides, which

may weigh tens of thousands of tons.

For further information:

peter.bakker@trelleborg.com

TTIME 32010 7

10TTI3_lmu_3014.indd 7

2010-11-10 09:33:22

You might also like

- Loadout Skid Frame DesignDocument14 pagesLoadout Skid Frame DesignAffiq AimanNo ratings yet

- Crane Boom ReplacementDocument13 pagesCrane Boom ReplacementRavikumar mahadevNo ratings yet

- Horse Shoe Rig ™ Fast Moving Semisubmersible Drilling TenderDocument8 pagesHorse Shoe Rig ™ Fast Moving Semisubmersible Drilling TenderSouadHadjadjNo ratings yet

- DC Sept08 RackandPinionWEBDocument5 pagesDC Sept08 RackandPinionWEBJosé TimanáNo ratings yet

- Tesco Casing Drive System™Document5 pagesTesco Casing Drive System™Citra FerdyanNo ratings yet

- Drilling Strategy in Maureen FieldDocument11 pagesDrilling Strategy in Maureen Fieldmatheus_moreira0990No ratings yet

- Crane Master Project References - Passive Heave Compensation - Shock AbsorberDocument3 pagesCrane Master Project References - Passive Heave Compensation - Shock AbsorberDaniel LiuNo ratings yet

- Brochure Happy S Type - 07 2013Document8 pagesBrochure Happy S Type - 07 2013George DomusciuNo ratings yet

- Design Considerations For Challenging Floatover Installation of Liwan 3-1 Mega Topsides With A T-Shaped BargeDocument10 pagesDesign Considerations For Challenging Floatover Installation of Liwan 3-1 Mega Topsides With A T-Shaped BargeRajat KatyalNo ratings yet

- Compliant TowerDocument4 pagesCompliant Towersooraj901100% (1)

- Compliant TowerDocument4 pagesCompliant TowerjohariakNo ratings yet

- R&D Initiatives: Innovating To Meet Next-Gen ChallengesDocument2 pagesR&D Initiatives: Innovating To Meet Next-Gen ChallengesViswanatham MarellaNo ratings yet

- OTC 19072 State of The Art in FloatoversDocument9 pagesOTC 19072 State of The Art in FloatoversNur ZaidahNo ratings yet

- Innovative Crane Drive Solutions for Heavy-Duty Port LogisticsDocument5 pagesInnovative Crane Drive Solutions for Heavy-Duty Port LogisticsRodolfoTibuNo ratings yet

- Container Crane Recycling Upgrade and Relocation PaperDocument10 pagesContainer Crane Recycling Upgrade and Relocation PaperMAGSTNo ratings yet

- Lessons from Template Installation MethodsDocument13 pagesLessons from Template Installation MethodssarahbstNo ratings yet

- ALE Oil Gas Petrochem BrochureDocument20 pagesALE Oil Gas Petrochem BrochureMaryPoppoNo ratings yet

- 07 Strand Jack Sedition 92834Document7 pages07 Strand Jack Sedition 92834vigobboNo ratings yet

- Container Crane Recycling: Upgrade and RelocationDocument2 pagesContainer Crane Recycling: Upgrade and RelocationAmable FuentesNo ratings yet

- PLET Installation in Deepwater Based On Tension Control and Length ControlDocument13 pagesPLET Installation in Deepwater Based On Tension Control and Length Controlatish_g4100% (1)

- SurfaceHaulTrucks PDFDocument13 pagesSurfaceHaulTrucks PDFmark tower100% (1)

- Cargo HandlingDocument5 pagesCargo HandlingJoao AlmeidaNo ratings yet

- High-Performance Ship Unloaders: The Digger Crane SystemDocument16 pagesHigh-Performance Ship Unloaders: The Digger Crane SystemLeonardo CanditoNo ratings yet

- H2 Folding Hatch Covers - Original - 30544 PDFDocument8 pagesH2 Folding Hatch Covers - Original - 30544 PDFGILL2013No ratings yet

- Chapter 3 - Deck Handling EquipmentDocument24 pagesChapter 3 - Deck Handling EquipmentKatie PearceNo ratings yet

- Deck Machinery FunctionsDocument31 pagesDeck Machinery FunctionsZarul AshraffNo ratings yet

- 245 - 41000e Casing Drive System WebDocument8 pages245 - 41000e Casing Drive System WebBepdj100% (1)

- Introduction to Offshore StructuresDocument22 pagesIntroduction to Offshore StructuresRUDHRA DHANASEKAR100% (1)

- Cargo Handling PDFDocument12 pagesCargo Handling PDFKarim Abd ElazizNo ratings yet

- FLOAT-OVERS USING DP: CASE STUDIES AND LESSONS LEARNTDocument13 pagesFLOAT-OVERS USING DP: CASE STUDIES AND LESSONS LEARNTSơn Nguyễn-Lê100% (1)

- Innovation in Deepwater Spar TechnologyDocument3 pagesInnovation in Deepwater Spar TechnologyIkhwan ShafiqNo ratings yet

- Offshore Jacket Installation MethodsDocument23 pagesOffshore Jacket Installation MethodslewgneNo ratings yet

- ALE Power Gen BrochureDocument24 pagesALE Power Gen BrochureMarie SaundersNo ratings yet

- Heavy Lifting and Offshore Transportation SolutionsDocument32 pagesHeavy Lifting and Offshore Transportation SolutionsKhoironSyamdatuNo ratings yet

- OTC 24447 Practical Experience Gained Operating A Compact Ultradeepwater Drill ShipDocument13 pagesOTC 24447 Practical Experience Gained Operating A Compact Ultradeepwater Drill ShipEvan FNHNo ratings yet

- Sea Met - Self Installing Meteorological MastDocument11 pagesSea Met - Self Installing Meteorological MastLewis LackNo ratings yet

- Container Ship Size and Fleet Still GrowingDocument19 pagesContainer Ship Size and Fleet Still GrowingLaura Cristiana IacobNo ratings yet

- Macgregor Mooring SystemDocument12 pagesMacgregor Mooring System정재영No ratings yet

- 11 - HMC 5dec Norwegian Society of Lifting TechnologyDocument50 pages11 - HMC 5dec Norwegian Society of Lifting TechnologyarchitectintxNo ratings yet

- A Design of High Efficient Gantry Crane For UltraDocument7 pagesA Design of High Efficient Gantry Crane For UltraFEDERICO ESTEBAN BABICHNo ratings yet

- Research Paper On Eot CraneDocument4 pagesResearch Paper On Eot Craneadyjzcund100% (1)

- Training File On Bucket ElevatorDocument33 pagesTraining File On Bucket Elevatorskynet45088% (8)

- Evolution Subsea TechnologyDocument8 pagesEvolution Subsea TechnologycristianoclemNo ratings yet

- IADC/SPE 87158 Taut Leg Moorings Using Polyester and VLA AnchorsDocument6 pagesIADC/SPE 87158 Taut Leg Moorings Using Polyester and VLA AnchorsmsmsoftNo ratings yet

- Sembmarine Integrated Yard@TuasDocument2 pagesSembmarine Integrated Yard@TuasjgshipNo ratings yet

- Hi Tech Brochure S8 - B FLOAT OVER SOLUTIONSDocument16 pagesHi Tech Brochure S8 - B FLOAT OVER SOLUTIONSTiến Bách PhạmNo ratings yet

- Tesco 250 EMI 400 Top DriveDocument12 pagesTesco 250 EMI 400 Top DriveBrandon Nowlin100% (1)

- L4-Platform Installation (Compatibility Mode)Document37 pagesL4-Platform Installation (Compatibility Mode)Laxmi Kant PrasadNo ratings yet

- Surface Haul TrucksDocument13 pagesSurface Haul TrucksSunilkumar Reddy100% (1)

- Tie Back Liner Casing-1Document18 pagesTie Back Liner Casing-1حسين الفيتوريNo ratings yet

- 9.long Overland ConveyorsDocument14 pages9.long Overland ConveyorsMauricio MpintoNo ratings yet

- 15A10 - Superstructures I (Topside)Document23 pages15A10 - Superstructures I (Topside)Viktor DươngNo ratings yet

- DEME Offshore Brochure_2022Document16 pagesDEME Offshore Brochure_2022amin32No ratings yet

- 05 Loadout of Offshore PlatformDocument70 pages05 Loadout of Offshore Platformardikurniawan100% (8)

- OffshoreDocument3 pagesOffshorelaleye_olumideNo ratings yet

- Jack Ups in Operation - Types and DifferencesDocument16 pagesJack Ups in Operation - Types and Differencesibnuhary100% (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Motor Truck Logging Methods Engineering Experiment Station Series, Bulletin No. 12From EverandMotor Truck Logging Methods Engineering Experiment Station Series, Bulletin No. 12No ratings yet

- Toranj EL - 220425 - 155019Document1 pageToranj EL - 220425 - 155019mashanghNo ratings yet

- Toranj EL - 220425 - 155019Document1 pageToranj EL - 220425 - 155019mashanghNo ratings yet

- FrenchDocument6 pagesFrenchmashanghNo ratings yet

- Accident Investigation ArticleDocument2 pagesAccident Investigation ArticlemashanghNo ratings yet

- Classification of Drilling EquipmentDocument32 pagesClassification of Drilling EquipmenthshobeyriNo ratings yet

- Design BasketDocument1 pageDesign BasketmashanghNo ratings yet

- Asme B30 6 2010 PDFDocument40 pagesAsme B30 6 2010 PDFYADIR100% (1)

- Emrgency ResponseDocument16 pagesEmrgency ResponsevenkatsubbuNo ratings yet

- BHA Components & Design for Wellbore StabilizationDocument47 pagesBHA Components & Design for Wellbore StabilizationArturo Elizondo100% (1)

- Driick Man Hand Book: Getting Tied Off!Document2 pagesDriick Man Hand Book: Getting Tied Off!mashanghNo ratings yet

- SLB Project Management Essentials 0 IntroductionDocument25 pagesSLB Project Management Essentials 0 IntroductionmashanghNo ratings yet

- BHA Components & Design for Wellbore StabilizationDocument47 pagesBHA Components & Design for Wellbore StabilizationArturo Elizondo100% (1)

- BHA Components & Design for Wellbore StabilizationDocument47 pagesBHA Components & Design for Wellbore StabilizationArturo Elizondo100% (1)

- Chemical Spill Plan NewDocument1 pageChemical Spill Plan NewmashanghNo ratings yet

- Preview WCDocument3 pagesPreview WCmashanghNo ratings yet

- Hydrogen Sulfide ProtocolDocument32 pagesHydrogen Sulfide Protocolmashangh100% (1)

- Oil and Gas Recommended Guidelines For Sampling and Analysis of Produced WaterDocument35 pagesOil and Gas Recommended Guidelines For Sampling and Analysis of Produced WaterhafisjNo ratings yet

- Overview of Safety Management Processes - in High Hazard IndustryDocument20 pagesOverview of Safety Management Processes - in High Hazard IndustrymashanghNo ratings yet

- Maintenance Bulletin 1062-BDocument13 pagesMaintenance Bulletin 1062-BmashanghNo ratings yet

- 3IOSH Mentor Scheme Reward Sept 2016Document1 page3IOSH Mentor Scheme Reward Sept 2016mashanghNo ratings yet

- Advanced Safety Barrier Management With Inclusion ArticleDocument6 pagesAdvanced Safety Barrier Management With Inclusion ArticlemashanghNo ratings yet

- Selection of Suitable Respiratory Protective EquipmentDocument28 pagesSelection of Suitable Respiratory Protective EquipmentmashanghNo ratings yet

- Corrsoin Coupon Retriveal Incident Shell Action Alert May 2012Document1 pageCorrsoin Coupon Retriveal Incident Shell Action Alert May 2012mashanghNo ratings yet

- App Safety AwardsDocument1 pageApp Safety AwardsmashanghNo ratings yet

- QMS11403-1 20160705 Joining-Instruction BOSIET EDocument5 pagesQMS11403-1 20160705 Joining-Instruction BOSIET EmashanghNo ratings yet

- What Is The Danger To Offshore Rigs ArticleDocument8 pagesWhat Is The Danger To Offshore Rigs ArticlemashanghNo ratings yet

- Recent Development in Offshore EvacuationDocument13 pagesRecent Development in Offshore EvacuationmashanghNo ratings yet

- EmS Implmention ShellDocument58 pagesEmS Implmention ShellmashanghNo ratings yet

- Nor Scot BrochureDocument218 pagesNor Scot BrochureHaridevNo ratings yet

- Harris ER90S B3Document2 pagesHarris ER90S B3Mingo EvaNo ratings yet

- Datasheet For: Material Housing MountingDocument2 pagesDatasheet For: Material Housing MountingRaju MarendraNo ratings yet

- Wiring and Replacement Float Switch For Low Water Cut-Offs Installation InstructionsDocument2 pagesWiring and Replacement Float Switch For Low Water Cut-Offs Installation InstructionsWattsNo ratings yet

- Eurosun2014-Proceedings - ImportentDocument1,524 pagesEurosun2014-Proceedings - ImportentAkhileshkumar PandeyNo ratings yet

- Iso 22628Document14 pagesIso 22628David SouthgateNo ratings yet

- Wet Granulation End-Point DeterminationDocument18 pagesWet Granulation End-Point DeterminationPreeti Wavikar-PanhaleNo ratings yet

- Technical & Service ManualDocument90 pagesTechnical & Service ManualStefano FerrariNo ratings yet

- FBR15 80Document6 pagesFBR15 80Akar BuahNo ratings yet

- Maximal Forklift LineUp Brochure PDFDocument10 pagesMaximal Forklift LineUp Brochure PDFJose Luis GarciaNo ratings yet

- Risk Assessment for Motor MaintenanceDocument1 pageRisk Assessment for Motor MaintenanceAbdul HadiNo ratings yet

- Usbs - 27-1PS y 27-2PSDocument5 pagesUsbs - 27-1PS y 27-2PSKathy HolguinNo ratings yet

- DeforestationDocument4 pagesDeforestationPeggopoulouNo ratings yet

- Siemens Mobilett XP Products Safety Information Performing The Checks in Accordance With Iec 62353Document34 pagesSiemens Mobilett XP Products Safety Information Performing The Checks in Accordance With Iec 62353Félix Enríquez0% (1)

- Light Energy Lesson Plan: Students Will Students Will Describe HowDocument3 pagesLight Energy Lesson Plan: Students Will Students Will Describe HowolamhenNo ratings yet

- Chapter Fluid MachineryDocument50 pagesChapter Fluid MachineryWan AimanNo ratings yet

- Application HydrostaticsDocument23 pagesApplication HydrostaticsHASSAN ARSHADNo ratings yet

- SolidWorks Simulation Professional TrainingDocument104 pagesSolidWorks Simulation Professional TrainingAnonymous NonQwK3qL275% (4)

- National Resilience - 2016Document2 pagesNational Resilience - 2016my oneNo ratings yet

- Calibration DescriptionDocument4 pagesCalibration DescriptionNascimento Junior100% (1)

- Tutorial 19 - Thermal Stress - SwitchDocument11 pagesTutorial 19 - Thermal Stress - SwitchKelvin HewNo ratings yet

- Led Taxi Light TestingDocument2 pagesLed Taxi Light Testingajaydce05No ratings yet

- QST30 High Pressure Fuel Line Failures ReportDocument18 pagesQST30 High Pressure Fuel Line Failures ReportEvan AT Yoel67% (3)

- CSE Engineering Course DetailsDocument233 pagesCSE Engineering Course DetailsVenkatesh Kumar0% (1)

- Energy Transfer Forms and MeasurementDocument4 pagesEnergy Transfer Forms and MeasurementAlberto CasiniNo ratings yet

- Why Is The Sky BlueDocument2 pagesWhy Is The Sky BlueTongboNo ratings yet

- LR HAZID Study For LNG Fuel SupplyDocument116 pagesLR HAZID Study For LNG Fuel SupplyMatteo ConciNo ratings yet

- Lab Manual for Ionization Isomer SynthesisDocument8 pagesLab Manual for Ionization Isomer SynthesisDhika AmeliaNo ratings yet

- HV Generation and Testing 1.0 Slides PDFDocument43 pagesHV Generation and Testing 1.0 Slides PDFzuhairulNo ratings yet

- FM400 8X4 Tipper With Rock Body Specs & DetailsDocument4 pagesFM400 8X4 Tipper With Rock Body Specs & DetailsHaneefa ChNo ratings yet