Professional Documents

Culture Documents

1952 Tobias Eisenberg Wilke

Uploaded by

ssuarez907Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1952 Tobias Eisenberg Wilke

Uploaded by

ssuarez907Copyright:

Available Formats

Vol. 99, No.

12

ELECTROCHEMISTRY

OF IONIC

DIFFUSION AND CONVECTION

A THEORETICAL

CRYSTALS

359C

IN ELECTROLYSIS-REVIEW

C. W. Tobias, M. Eisenberg, a n d C. R. Wilke ~

Introduction

Mechanisms of Ion Transfer

An electrode reaction proceeding at a finite rate involves

nmvement of reacting materials between the electrode and

the solution surrounding it. In absence of fluid turbulence,

ions are transferred from solution to an electrode by three

principal mechanisms: (a) migration, (b) diffusion, and (c)

convection. For a given species the rate of transfer in the y

direction per unit area perpendicular to y at any point in

the fluid nmy be expressed by the equation:

Nt = CU oy

ay + Vc

Ill

where: Nt = total rate of transfer, gram ions/em~-sec; c =

concentration of given species, gram ions/cma; U = mobility,

cruZ/see-volt; q5 = potential, volts; y = distance in direction

of transfer, cm; D = diffusion coefficient, crab/see; and

V = velocity of bulk fluid movement in direction of transfer,

cnl/see.

The three terms on the right represent, respectively, the

contributions of migration, diffusion, and convection. When

transfer is not unidirectional corresponding equations nmy be

written for each coordinate axis.

For unsteady state processes, changes of concentration

with time must be considered, and the general transfer equation becomes (1)

Oc = _ div(Uc grad r

at

+ div(D grad c) -- V grad c

[2]

where t = time, sec. The potential q) must satisfy the Poisson

equation (1), and the velocity vector V the three NavierStokes equations. Thus a set of nonlinear differential equations is obtained which has been solved only f m ' a rehtively

few cases.

In a fluid in which turbulence has been induced by stirring

or pumping, transfer by diffusion is augmented by eddy

diffusion resulting from turbulent pulsations. Analytical solution of the convection-diffusion equations for such systems is

in general impossible at the present time.

Equations for Steady State Mass Transfer

The term "mass transfer" will be used to denote the transport of ions or molecules by the combined effects of diffusion,

eddy diffusion, and convection, excluding the contribution of

migration to the process. The mass transfer process is commonly designated as "forced convection" when the system

is mechanically agitated by stirring or pumping, and as

"fi'ee convection" when mixing is induced as a result of

density differences accompanying concentration differences

from point to point within the fluid. Mass transfer in the

steady state implies that the transfer rates, current density,

concentrations, temperature, and other variables associated

with cell operation are independent of time at any particular

point in the system.

~Department of Chemistry and Chemical I",ngineertng,

University of California, Berkeley, California. This work has

been supported by the Office of Naval Research.

The different mass transfer mechanisms participate to a

varying degree as material moves from the main body of

solution in contact with an electrode to the electrode-solution

interface, with the natm'e of the process at any distance from

the electrode depending on electrolyte motion, shape and

position of the cell, and other operational variables. As a

result of the participation of diffusion in the transfer process,

it may be stated in general that movement of species toward

or away from the electrode results in a, decreasing concentration of the species in the direction of transfer.

For steady state processes it is convenient to express the

rate of migration as a function of current per unit area perpendicular to the direction of transfer:

N,~ = e U 0 ~ = __PI

Oy

nF

[31

where: N,~ = rate of migration, gram ions/cm2-see; P =

transference number for the given species; n = valence charge

of the ion;'and F = the Faraday, amp-see/gram equivalent.

In sufficient excess of inert electrolyte the transference number of the species participating in the electrode reaction may

be made negligibly small and migration need not be considered. In the general case the rate of mass transfer may be

expressed by the relation:

N4 = Nt -- N,,, =

1(l

-- F)

nF

[4]

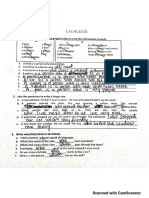

Consider a cell containing at one end a vertical plane

cathode upon which metal ions are being deposited. Assume

that due to mechanical stirring the concentration is uniform

at "dl distances from the floor of the cell at any particular

dist:mee x away from the electrode. For the species deposited

a concentration profile through the main body of solution up

to the electrode-solution interface may prevail as illustrated

in Fig. 1. The exact shape of the profile will depend upon the

mass transfer mechanism predomina~ting at a w place. Asstone further that the concentration in the main body of

solution remains constant. In view of the complicated nature

of the problem it is sometimes convenient to express the

over-all mqss transfer process by equations of simple empirical

form which relate the mass transfer rate to the difference

between the mixed-mean or average concentration of the

transferred species in the nmin body of fluid and the concentration at the electrode-solution interface.

(A) Mass transfer coefficient: the rate of transfer may be

expressed by a coefficient, /eL, defined as follows:

Na = kL(cb -- c~)

[5]

where: Nd = mass transfer rate at any particular point on

the electrode, gram mole/cm2-sec; kL = mass transfer coefficient, cm/see; c~ = average concentration in bulk fluid,

gram mole/cnr~; and c~ = concentration at interface.

(B) Equivalent fihn thickness or diffusion layer: this

concept expresses the mass transfer process by the rate equation for steady state diffusion from concentration ca to cl

over a hypothetical layer of stagnant fluid of thickness ~.

The diffusional term of equation [1], i.e., Fick's first law, is

360C

JOURNAL

OF THE

ELECTROCHEMICAL

integrated for this case to give the relation which defines

the equivalent film thickness:

Nd --

D(cb -

c3

[61

where ~t = equivalent film thickness.

This general mathematical formulation was originated by

Nernst (2) who termed ~t the "diffusion layer," a name which

has been used widely throughout the electrochemical literature. The term "equivalent film thickness" has been used

extensively in chemical engineering writings.

SOCIETY

December 1952

Concentration polarization.--During the passage of current,

the concentration of metal ions at the solution-electrode

interface changes from the value at rest, cb, to ci. The corresponding shift in electrode potential, AEo, the concentration

polarization, is equal to the emf of a concentration cell with

transference, in which the electrodes are in contact with

solutions of concentrations Cb and c~, respectively. If transfer

by migration of the potential determining ion is negligible,

and the ratio of ionic activity coefficients is assumed to be

unity,

fi T

c,

~Ec = ~ h~ -

[10]

(b

I/]

l~J

EQUIVALENT

PROFILE

CONCENTRATION

The dependence of concentration polarization on current

density for any current, I, can be found by combining equations [9] and [10]: 2

AEc = ~ - ~ l n

1 -- ~

[111

==

Unsteady

Q:Ci.

l-

I

i , , / ~I

D IFFUSION

LAYER

Z

(3

Z

0

(..)

,-- 8 - , , . I

I

X

DISTANCE

FROM

Diffusion

That concentration changes in solutions of electrolytes in

the vicinity of working electrodes are of importance was

realized as early as 1879 by Weber. In his work on the diffusion of zinc sulfate (3) Weber obtained an equation for the

concentration as a function of time and distance from the

electrode using a cell model of the form of a short cylinder

closed at its ends by a cathode and anode and without liquid

circulation or stirring. For practical calculations, use of this

equation was not convenient since it contained a Fourier

series which did not converge fast enough for large distances

between the electrode and for small time periods.

In 1900, Sand (5) in an attempt to improve Weber's theory

considered a model with only one electrode at the end of a

semi-infinite cylindrical cell. Assuming no motion of the

electrolyte, and the material transfer to occur only by diffusion, with the diffusion coefficient independent of concentration, equation [2] reduces to the form:

I-

I-

State

ELECTRODE

Fro. 1. Illustration of concentration profile in the vicinity

of an electrode during electrolysis.

r = D -O~c

Ot

Ox2"

The relation between current density, concentration and electrode potential.--Taking the example of the deposition of an

n valent metal in the presence of a large excess of "inert"

electrolyte which takes no part in the electrode process,

equation [6] can be expressed as:

Upon integration of equation [12] with the boundary conditions as given below Sand obtained the result expressed by

equation [13].

D(cb

--

Cb.

[S]

The current density can only be increased above this

value if a consecutive electrode process is possible.

If one makes the assumption that ~t is independent of the

rate of diffusion, the concentration at the interface, c~-, can be

related to the current density by combining equations [7]

and [8],

c~

c~

--

~1

DnFcb

- -

oo

Cb

[71

The maximum rate of deposition, or limiting current density,

will be given b y the condition when c~" = 0, and

nFD

Oc

N~ = D ~ x x ; a t t = 0, betweenx = 0

andx

m)

nF

I~ -

A t x = 0,

[12]

----

I

IL"

[9]

where: c~., = concentration at any time and distance x from

the electrode; cb = original uniform concentration; D = diffusion coefficient; Na = rate of removal of ions at the electrode; and t = time.

For x = 0, i.e., at the electrode, this reduces to the simple

equation:

Co,t= c b - - 1 . 1 2 8 5 N d ~ D .

[14]

For a cathodic deposition Nd is given by equation [4].

2 It should be noted that this expression applies only for

electrodeposition. For discussions that include generalized

electrode-reactions, and the effect of migration, see Ref. (4).

DIFFUSION

V o l . 9 9 . N o . 12

AND CONVECTION

By means of equation [14] Sand was able to determine

diffusion coefficients in electrolytes by observing the time

interval necessary for a given current density to cause an ion

depletion at the cathode to zero concentration, i.e., to reach

limiting current density. Sand realized that this procedure

is not rigorous on account of the variations in transference

numbers with concentration. However, on the basis of

Kohlrausch's work (6) he found that such variations result

in an error not exceeding 2.5 per cent for the systems investigated.

An extension of the work of Weber and Sand was given by

Rosebrugh and Miller in 1910 in an excellent paper on the

mathematical treatment of electrolysis with direct and successive currents (7). A cell of uniform cross section provided

with identical metal electrodes at both ends served as the

model. The electrode reactions were assumed to be identical

but opposite in sense (at the cathode, metal depositing; at

the anode, metal going into solution, both with 100 per

cent current efficiency).

Equation [12] was solved for the boundary conditions

at x = 0 (at half distance between the electrodes)

art =0

Oc

Ot

- 0

--0c = 0 .

IN ELECTROLYSIS

361C

across which mass transfer is possible only by diffusion and

migration. The magnitude of 8 depends only on hydrodynamic

conditions (r~te of stirring, rotation, etc.) and the viscosity

of the solution.

In the steady state the concentration gradient in this

"diffusion layer" is constant, and the rate of diffusion is equal

to the rate of the electrode process. Thus for the case of metal

deposition, equation [7] applies. For any particular solvent,

geometryand rate of stirring, 8 is a constant, and can be deter-

0

DIRECTIONOF//

DIFFUSIO?/

~y,

=Y

DIRECTIONOFFLOW

Ox

Of most interest is the relation giving the concentration at

the electrode as a function of time. Neglecting migration

D ( c b - ci)nY

1I. L

=

where: y -

8 m__~l. 1 e_m%t

~

[15]

= ,~ --~

m

mined experimentally if (cb - ci) and D are known. Under

limiting current conditions c~ = 0, from which it follows that

~r2D

4L 2 , and L = half the length of the cell.

For yt > 0.6 equation [15] may be approximated by:

D(cb -- c d n F

8

I.L

' ~ 1 - - ~ e- ' t .

nFD

=-/L

[I6]

Similarly for vt < 0.6

D(cb -- c~)nY

X

FIG. 2. Laminar flow past an electrode (Eueken)

~__ 1.129 % / D t .

[17]

Equation [17] shows the concentration at the electrode to be

independent of the length of the cell. This result is identical

to equation [14] indicating that for small v t a cell of finite

length can be treated as a semi-infinite column of electrolyte.

The foregoing equations have been found to agree fairly

well with experimental findings (8, 9) for the deposition of a

metal with the cathode placed horizontally at the top of the

cell. In these experiments natural convection was suppressed.

Forced Convection

The treatment of an electrolytic cell as a slab of electrolyte

free of convection currents, in which ions are transferred only

by diffusion and migration, is not adequate to meet the conditions of actual operation.

Nernst (2, 10) and Brunner (11) developed the qualitatively correct concept of ionic mass transfer by the combined

mechanisms of diffusion and convection. As a result of an

elaborate experimental study of heterogeneous reaction rates

Brunner developed the following argument.

During operation of an electrolytic cell, due to natural

and forced convection the concentration in the bulk of the

solution can be considered to be uniform. I t may be assumed

that a stagnant layer of electrolyte of thickness 8 exists between the bulk of the solution and the electrode surface,

(b.

[18]

Brunner (11) found that the thickness of the diffusion

layer in some geometrical arrangements varied with the rate

of stirring, and suggested the relation

a

8 = R~/--%

[19]

where: R = rate of stirring (rotation), rpm; and a = a constant for a given solvent, geometry, temperature.

In moderately stirred solutions in a number of experiments

8 was found to be 0.02-0.05 mm (11, 12). Glasstone (13)

suggested that a = 0.05 gives a fair agreement with experimental findings?

Brunner realized that the assumption of a stagnant layer of

electrolyte of 8 thickness at the interface is physically incorrect. He also found that 5 depends on the diffusion coefficient. His mass transfer experiments were carried out in a

system of impractical geometry, and, therefore, only qualitative deductions can be made for different experimental

conditions.

Methods of hydrodynamics were applied first by Eucken

(14) to predict the effect of forced convection on mass transfer

rates to electrode surfaces (Fig. 2). The limiting current in

case of laminar flow in the y direction past an electrode of

height h and width yl was evaluated for cases when

the velocity of flow increases linearly with the distance from

the electrode plane.

a In equation [19] 8 is expressed in cm if used with a = 0.05.

Conditions for application of this equation, such as rotor size,

solution properties, etc., are not stated in reference.

362C

JOURNAL

OF THE

ELECTROCHEMICAL

Under steady state conditions the increase in concentration of a volume element dx.dy.dz due to convection will be

balanced by a decrease of concentration due to diffusion in a

direction (x) perpendicular to the electrode.

By solving the differential equation for diffusion and

convection

T

&'

~I l X ~

02c

= D &--~

[20]

with the boundary conditions: at x = 0, c = 0; at x = * ,

c = c~; where W, denotes the constant fluid velocity unit

distance away from the electrode plane, the following expression was obtained for the total linfiting current:

iL = 77,800 hcb "~/D"g{IV~.

[21 ]

Dividing both sides of equation [19] by the surface area

A = h-y~ yields the average limiting current density along

the electrode. The result indicates that I~.=~g decreases with

the .~i power of the length of the electrode in the direction of

a flow, and increases proportional]y to D 2ja. This conclusion

is also supported by the expression obtained for the average

thickness of the diffusion layer:

8,,~ = 1.24 ,a/DYe-.

'V

[22]

0c*

~- q- (~'~grad) c* --- DV2c *

Cl

-

n2

December t 9 5 2

which upon integration yields:

F~

I~;;]-' (~: D1 -- n2D2) c* grad ~b

[251

q- F(D1 -- D2) grad c* ~- 3

I l l 7l 2

wherej represents the vectors of current density and R = gas

constant.

The solution of equation [25] allows the determination of the

exact relation betwcen the potential across the electrolytic

cell and the current. This import'mr separation of the convective diffusion from the potential distribution has been shown

to be possible also for a tervalent system when the concentration of one kind of ions is low compared to that of the other

two kinds.

A number of solutions for specific cases of definite geometric

systems and hydrodynamic conditions were given as reviewed

below.

A fiat infinite disk rotating with a constant angular velocity.Using yon Karman's solution for the hydrodynamics of fluid

motion about such a rotating disk the following result was

obtained for steady state conditions in the discharge of one

ion of a binary system:

W1

To obtain the simplified diffusion convection equation [20],

Eucken made the assumption that no velocity component

exists in the x direction. The results derived therefore nmy be

of questionable value for practical applications (1). Eucken

himself met with considerable difficulties trying to achieve

such conditions in experiments designed to test equation [21]

(30).

A fundamental approach to the solution of mass transfer

problems based upon modern theories of fluid mechanics was

initiated in the excellent series of papers by B. Levich (1, 15).

The method involves application of the general equation for

convection, migration, and diffusion (equation I2]), coupled

with the Navier-Stokes equations for fluid motion and the

Poisson equation for charge distribution in the solutions.

Levich succeeded in simplifying these nonlinear partial

differential equations for the case of a bina W electrolyte to

the form

where c* -

SOCIETY

[23]

where: 6

effective

viscosity

second.

Thus for

= diffusion layer thickness (equation [6]); D =

diffusion coefficient fro" the salt; v = kinematic

of the fluid; and Z = number of revolutions per

", system 4 with D = 10-s cm2/sec and v = 10-=

Cln2/sec

0 00647

Using the above value for 6, equations [8] and [11] may be

utilized to give limiting currents or concentr'~tion polarization. Equivalent expressions are presented by Levich.

Flow past a fiat electrode set into a landnar flow of liquid.-Levich developed a general theory of the laminar boundary

layer by considering the analogy of the convective diffusion

equation:

Ox q- V O!j = D \ a x e q- ay'- ]

[281

nl

to the Navier-Stokes equations for the velocity distribution.

The thickness of the diffusion boundary layer, 8, for the

case of "~ flat electrode inserted into a laminar flow of fluid

(16) is given for an)" distance x along the electrode by:

and the effective diffusion coefficient

D = (nl -- n.2) DID.~

1/1D1 - - n2 D~

D1D~. = diffusion coefficients of ions 1 and 2, respectively;

*hn,~ = number of valence charges per ions of species

1 and 2, respectively;

c~, c2 = concentrations of ions 1 and 2, respectively.

Equation [23] from which the potential has been eliminated

applies to the case of convective diffusion and determines for

a known ~ the concentration at any time and point in the

solution. Then the distribution of the potential is obtained

from the distribution of the concentration by the equation:

RT(D1 -- De) V2c.

div (c* grad 4~) = -- F(nlD1 -- n2D2)

[24]

8 = 3 D

LUJ

where U = velocity of the fluid and x = distance along the

electrode from the leading edge.

For the case of the flat electrode equation [29] shows that

for a given fluid velocity U the diffusion layer thickness increases as xl, the square root o f distance from the leading edge

m the direction of fluid flow. This in turn affects the current

0.022

4 In the original paper this equation is given as ~ = ~

which appears to be in error.

Vol. 99, No. 12

DIFFUSION

AND CONVECTION

distribution so that the local limiting current density (IL)x

varies in the x-direction according to the equation:

(I~)~ =

~FDco

~

!~ *FDcb

~x

".

[30]

This is valid if the flow past the electrode and the electrolysis

begin at the same point. Upon integration for an electrode of

width b and length L the total limiting current is found to be:

iL

,~.~ nFDcb D

~L

-v

b.

.~

[3t]

I t should be noted that the development of the Prandtl

hydrodynamic boundary layer at the plate cannot go on

indefinitely in an apparatus of finite size. How far in the x-(tirection its formation will extend, until a steady state boundary

layer of constant thickness is formed, depends not only upon

the geometry of the entire cell (presence of any close parallel

wall, for instance) but also upon the length of the electrode.

Levich's equation [29] is acceptable from the hydrodynamical

viewpoint only for a short electrode at a relatively low fluid

velocity and in the absence of any close parallel boundary.

The problem of current distribution is also complicated.

First, because near an electrode edge submerged into an dectrolyte the current distribution will be nonuniform and the

equipotential surfaces by no means parallel to the electrode

surface. Second, due to depletion of the ions, as the fluid

moves along the electrode the electrode-potential changes

continuously in the x-direction. This nonuniform potential

is, in turn, responsible for a nonuniform current distribution

throughout the electrode. These possible limitations should

be considered in the general application of equations [30]

and [31].

Turbulent flow over a fiat plate electrode.--Levich considered

the boundary layer (region of disturbed velocity) developed

over the plate to be divided into three regions with respect

to transfer of mass and momentmn. In region 1, immediately

adjacent to the surface, turbulent pulsations are sufficiently

damped out so that transfer of momentum occurs by viscous

shear and transfer of mass occurs by molecular diffusion. In

region 2, adjacent to region l, turbulent pulsations are large

enough to cause the transfer of mass to be predominantly by

eddy diffusion or turbulent pulsations, but because of the

relatively high kinematic viscosity of the liquid, momentum is

transferred predominantly by viscous shear. In region 3, the

magnitude of turbulent pulsations is sufficient to cause transfer of both momentum and mass to occur by turbulent pulsations. Within these assumptions by application of the nmss

and momentum transfer analogy an equation was derived

which may be presented in the following expression for limiting current density:

IN ELECTROLYSIS

363C

In general Cz depends upon the shape of the surface, roughness, and Reynolds number so that no complete generalization is possible.

As a more general relation for turbulent flow Levich

suggests:

IL = nFClcouor

Re)

where: ~o(Sc, Re) is a function which must be determined

experimentally; Sc = v/D, the Schmidt number.

Alternate expressions could be based upon the treatment of

yon Karman (6) for heat transfer. For low Schmidt numbers

equation [32] agrees well with a formula obtained by Prandtl

08) for the corresponding case in heat transfer.

At high turbulence the thickness of the diffusion layer will

be practically constant over most of the electrode, and the

current and potential distribution will be correspondingly

uniform.

In a subsequent paper (15) Levich extended the treatment

of turbulent flow to nonstreamlined electrodes (cylinder

placed perpendicularly to the electrolytic flow) and to electrodes of rough surfaces.

Along the lines suggested by Agar (19), Putnam, et al.

(20) correlated limiting current densities for the inner electro(te of an annular cell, with the mass transfer heat transfer

an'dogy. Mass transfer correlations were obtained in terms

of equivalent film resistances using experimental data obtained from measurements with four different electrode reactions. The electrolytes were passed through an annular electrode system at various constant rates of flow. The experiments covered viscous and turbulent regions (Re =

59-30,000).

From the measured limiting currents and the inlet concentrations to the cell, the mass transfer coefficient was obtained

as follows:

]CL

= ( (d.~ - - d~)'~ in - Co

\ 4dlL ]

c, -- 4i/nF(d~ -- d~)V

[33]

where: kL = mass transfer coefficient; d,d2 = diameter of

inner and outer electrode, em; L = length of electrode, cm;

Co = concentration of inlet stream gram mole/cc; I = limiting current, amp; n = number of electrons per molecule or

ion reacted at the electrode; F = Faraday; and V = velocity

tin/see.

For the systems investigated in the laminar flow region the

Leveque ai)proximatiou (21) can be applied in the following

form:

1)

\pDL] \ L ]

[34]

where: CI = coefficient of resistance, or friction factor;

where: & = equivalent diameter, d2 - d~ cm; D = diffusivity,

cmUsec; G = nmss velocity, gram/cm2/sec; and p = density

of electrolyte, gram/cc.

The agreement of experimental data with the Leveque heat

transfer equation was found to be satisfactory (within about

uo = velocity of flow past the plate; Co = bulk concentration

~=3%).

of transferred species; and A, B, a = constants to be evaluated experimentally. For tm'bulent flow over a flat plate

at ordinary Reynolds numbers the coefficient of resistance is

given by:

The mass transfer under turbulent flow conditions was

correlated in terms of the jv parameter, defined by Chilton

and Colburn (22) as:

nFCf7lo Co

IL = 2[A q-(aSca/4--A)B%//(~fl

[32]

CI = 0.07 Re -c 2

where Re = Reynolds nmnber for flow.

5 This equation is essentially equivalent to (12'), p. 287 in

original reference.

where V = velocity, cm/sec, and t~ = viscosity, gram/cin/sec.

A satisfactory correlation of jD as a function of Reynolds

number was obtained. The function was found to agree

364C

JOURNAL OF THE ELECTROCHEMICAL

rather closely with the friction factor data of Carpenter,

Colburn, and Wurster (23), i.e.,

j o = f = 0,023

2

I36]

where f = friction factor.

However, it is doubtful that great significance can be

attached to this apparent agreement between momentum

transfer and mass transfer in view of the high values

of Schmidt numbers prevailing in liquid systems, and possible

differences in surface roughness.

The correlation should be ve~T useful in predicting mass

transfer behavior in electrolytic cells, under flow conditions,

in presence of a large excess of indifferent electrolyte.

Natural Convection

Natural convection or "spontaneous stirring" results when

density changes accompany concentration changes in the

region of the electrode. Fluid motion thus induced aids the

mass transfer process by supplying fresh electrolyte from the

bulk solution.

For a vertical plate electrode Levich 05) derived the following relation for the local limiting current density at any

height X on the electrode surface:

(IL)x = 0.3S2 nFD

cb'

where: a = density coefficient (defined by equation [38]);

g = acceleration of gravity; and c0 = bulk concentration of

species reacting.

The density coefficient, a, relates density changes to concentration changes:

=

l(Op)

po Oc

Pb--Pl

[381

po(cb - cD

-

where Pb and p~ are fluid densities in bulk solution and at the

electrode surface, respectively.

Equation [37] indicates that the limiting current density

varies as the ~ power of bulk concentration and inversely

as the ~ power of height on the electrode.

An alternate theoretical treatment has been presented by

Wagner (24) who treated the electrolysis of a salt with a large

excess of a "neutral" electrolyte (CuS04 with an excess of

H~SO4). Wagner's derivation indicated the concentration of

H + ions to increase at the cathode surface by ~/~ of the decrease of that of the Cu++-ion, and the S0%-ion concentration

to decrease by the same factor. Using von Karman's (25)

analysis of the boundary layer formed under free convection

he derived for the limiting current density at the height X

from the lower edge of the electrode

I

(IL)x = 4FD(cb)~ X-I

01np

126-D,vOcc.so, --

1.422 01up ~I

3

~,~o,j

Natural convection has also been treated by Agar (19)

who utilized a theoretical solution for the heat loss from a

vertical plate derived by Schmidt, et al. (26) and obtained a

result which may be expressed for limiting current density

as follows:

(IL)x = 0.394 nFD

\ re] X -~ Cb~.

[401

A further expression was derived by Keulegan (17), which

yields for limiting current density:

(It.)x = 0,471 nFD

\.']

X -~ cb~.

[41]

On the basis of experimental studies for deposition of

CuSO4 from sulfuric acid solutions the authors (27) have

found the following equation to be applicable:

(IL)x = 0.505

[g(p0 --e,)r X-"

\1)] L

[421

where

,0-

p~

p,

~r

~so~

[Douso,

r.+ LbH~j

[43]

where ac~so~ and an2so ~ = density coefficients for CuS04 and

H2S04 respectively; and VH+ = transference number for

hydrogen ion.

Thus it may be seen that all of the theories agree in essential form, differing primarily by a numerical constant. It

should be noted that only equations [39] and [42] include the

effects of migration of nonreacting species on the density

difference established between the bulk solution and the

interface.

The total limiting current density (IL)~g, at an electrode

of height Xo is obtained by the relation:

(IL)~ = Xoo

(I~.)x dz =

(IL)~.

[44]

Some authors (13) have attempted to treat free convection

by assuming a constant diffusion layer thickness ~ over the

electrode of 0.05 em. The foregoing theoretical analyses which

have been substantiated by experimental evidence indicate,

however, that ~ depends on the electrolyte composition,

viseosib , diffusion constant, density coefficient, and nature

of the electrode reaction in regard to initiation of density

changes, electrode height, shape, and orientation of the electrode in the solution. Unfortunately use of 6 = 0.05 em, which

can lead to serious error in prediction of limiting currents,

has been furthered in much of the subsequent literature on

polarization phenomena and textbooks of electrochemistry

(28, 29). The concept of diffusion layer with this numerical

value is frequently presented without adequate qualification.

Conclusion

or in a general form

(IL)x = 2nFD(cb) ~X -I [ 1-f~'g

December 1952

SOCIETY

~ Ki OciO

In p Il ]

[39]

where: D = diffusion coefficient of the species participating

in the electrode reaction; c0 = bulk concentration of transferred component; p = density of the solution; and Ki =

dimensionless constants calculated by equations analogous to

[33] to [40] of the original reference.

Wagner obtained a fairly good agreement of his equation

with experiments on a 0.1M H2S04 system.

As described above, the early theoretical developments

have at best provided treatment for ideal cases of diffusional

supply to the electrode. The Nernst concept of a stationary

diffusion layer was fruitful in this early period for a qualitative understanding of the mechanism of ionic transfer in the

vicinity of the electrode. However, the diffusion layer concept

is merely a convenient form for describing the mass transfer

to the electrodes, and its thickness represents no real physical

constant. Misunderstanding of this limitation has often led

to erroneous interpretation of experimental work.

Vol. 99, No. 12

DIFFUSION

AND CONVECTION

I t is unfortunate that the theory of Prandtl's boundai~

layer, patterns of velocity distribution, and other aspects of

hydrodynamic theory have not been introduced into the field

of electrochemistry until recently. Mass, heat and momentum

transfer analogies, and dimensional analysis are valuable

tools in the development of modern theories of electrolysis.

The use of concentration instead of activity in the electrochemical equations may lead to serious errors due to large

changes of the activity coefficients with concentration. The

form of some equations, e.g., those accounting for diffusion

only, may still be acceptable if one merely considers the

symbols for concentration as representing activity. However,

when mass transfer analogies are carried over to electrolysis,

the distribution of concentration is obtained. Therefore, the

prediction of the concentration polarization (which is a function of the activities) is not possible unless the activity coefficients are known for the entire range of concentrations.

A further major difficulty arises from the fact that the methods available at present for activity measurements yield

the mean activity coefficients and not the activity coefficient

of the potential-determining ion. The appreciation of these

facts is essential for future theoretical and experimental

developments in this field.

The variation of the diffusion coefficient with concentration

becomes a serious matter when high currents are applied. For

this reason the validity of the now available relations for

limiting currents, derived with the diffusion coefficient assumed constant, is subject to question. For a given system

the functional dependence of D on concentration can be

established in general only by experiment. Such diffusivity

measurements must be performed under conditions where

only the potential-determining ion diffuses under its own

concentration gradient.

In conclusion it may be stated that the recent developments

which have been reviewed in this paper represent a major

step toward establishment of quantitative theoretical methods

for the prediction of mass transfer effects. This in turn should

facilitate a more complete understanding of other aspects of

electrolysis.

REFERENCES

1. B. LEvicn, Acta Physicochim. U.R.S.S., 17,257 (1942).

2. W. NERNST, Z. physik. Chem., 47, 52 (1904).

3. H. F. WEBER, Wied. Ann., 7,539 (1879).

IN ELECTROLYSIS

365C

4. J. N. AGAR AND F. P. BOWOEN,Proc. Roy. Soc., 169A,

2O6 (1938).

5. H. J. S. SAND, Z. physik. Chem., 35, 641 (1900).

6. B. KOHLRAUSCH,Wied. Ann., 62, 209 (1897).

7. T. R. ROSEBRUGH AND L. MILLER,J. Phys. Chem., 14, 816

(191o).

8. L. V. REDMAN,J. Phys. Chem., 29, 548 (1925).

9. J. T. BURT-GERRANS, J. Phys. Chem., 30, 396 (1926).

10. W. NERNST, "Theoretische Chemie," 15th ed., p. 454,

Enke, Stuttgart (1926).

l l . E. BRUNNER,Z. physik. Chem., 47, 56 (1904).

12. W. NERNST AND E. S. MERRIAM, Z. physik. Chem., 53, 235

(1905).

13. S. GLASSTONE ANI) A. HICKLING, "Electrolytic Oxidation

and Reduction," pp. 81-85, Chapman and Hall, Ltd.,

London (1935).

14. A. EUCKEN, Z. Elektrochem., 38, 341 (1932).

15. B. LEVICH, Acta Physicochim. U.R.S.S., 19,117 (1944).

16. B. LEVICH, Disc. Faraday Soc., 37, (1947).

17. G. H. KEULEGAN,J. Res. Natl. Bur. Standards, 47, 156

(1951).

18. L. PRANDTL,Physik. Z., 29, 487 (1928).

19. J. N. AGAR, Disc. Faraday Soc., 26 (1937).

20. C. S. LIN, E. B. DENTON, H. S. GASKILL, AND G.

L. PUTNAM,Ind. Eng. Chem., 45, 2136 (1951).

21. J. LEVEQUE, Ann. mines, 13, 201 (1928).

22. T. H. CHILTON AND i . R. COLBURN, Ind. Eng. Chem., 26,

1183 (1934).

23. E. G. CARPENTER, A. P. COLBURN, AND A. WURSTER,

Trans. Am. Inst. Chem. Engrs., 42,165 (1946).

24. C. WAG~ER, J. (and Trans.) Electrochem. Soe., 95, 161

(1949).

25. TH. VON KARMAN,Z. angew. Math. u. Mech., 1,244 (1921).

26. M. TEN BOSCH, "Waermeuebertragung," p. 159, Springer,

Berlin (1936).

27. C. R. WILKE, C. W. TOBIAS, AND M. EISENBERG, paper presented before the Philadelphia Meeting of The Electrochemical Society, May 5, 1952.

28. S. GLASSTONE,"Introduction to Electrochemistry," pp.

445-458, D. Van Nostrand Co., Inc., New York (1942).

29. G. KORT~L~[AND J. O'M. BOCKRm, "Textbook of Electrochemistry," Vol. II, pp. 400-408, Elsevier Publishing

Co., New York (1951).

30. T. TSUKAMOTO, T. KAMBARA,AND I. TACHI, J. Eleclrochem.

Assoc. Japan, 19, 311 (1950). (Subsequent to the preparation of this manuscript the author's attention was called

to recent experimental and theoretical work dealing with

the problem of the rotating electrode.)

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Havells Wire Catalogue June 2021Document28 pagesHavells Wire Catalogue June 2021Lp BatNo ratings yet

- Clad-Lined Line PipeDocument21 pagesClad-Lined Line PipeAdvis100% (2)

- Waste Water TreatmentDocument3 pagesWaste Water TreatmentSana Saleem100% (1)

- CompressorDocument27 pagesCompressorsoxal100% (1)

- Investigation of Failures of 230KV Copper Conductor BushingsDocument15 pagesInvestigation of Failures of 230KV Copper Conductor BushingscalripkenNo ratings yet

- UOP PX-Plus ™ XPDocument2 pagesUOP PX-Plus ™ XPana_dcz7154No ratings yet

- Project Activity - Katherin PerezDocument1 pageProject Activity - Katherin Perezssuarez907No ratings yet

- EnglishDocument1 pageEnglishssuarez907No ratings yet

- GretaDocument1 pageGretassuarez907No ratings yet

- ParagraphDocument1 pageParagraphssuarez907No ratings yet

- EnglishDocument1 pageEnglishssuarez907No ratings yet

- WRITING - Sebastian Suarez PeñalozaDocument1 pageWRITING - Sebastian Suarez Peñalozassuarez907No ratings yet

- Relative Clauses - CompressedDocument7 pagesRelative Clauses - Compressedssuarez907No ratings yet

- EnglishDocument1 pageEnglishssuarez907No ratings yet

- Unidad3 Ingles5 PDFDocument9 pagesUnidad3 Ingles5 PDFssuarez907No ratings yet

- The Black Cat by Edgar Allan PoeDocument9 pagesThe Black Cat by Edgar Allan PoeDavid Verdugo R.No ratings yet

- The Role of Situation Awareness in Accidents of Large-Scale Technological SystemsDocument12 pagesThe Role of Situation Awareness in Accidents of Large-Scale Technological Systemsssuarez907No ratings yet

- WRITING - Sebastian Suarez PeñalozaDocument1 pageWRITING - Sebastian Suarez Peñalozassuarez907No ratings yet

- Appendices: Scenedesmus ObliquusDocument4 pagesAppendices: Scenedesmus Obliquusssuarez907No ratings yet

- NTC 1486 - NTC 5613Document197 pagesNTC 1486 - NTC 5613ssuarez907No ratings yet

- Aga RosaDocument6 pagesAga Rosassuarez907No ratings yet

- Renewable and Sustainable Energy ReviewsDocument18 pagesRenewable and Sustainable Energy Reviewsssuarez907No ratings yet

- Renewable and Sustainable Energy ReviewsDocument18 pagesRenewable and Sustainable Energy Reviewsssuarez907No ratings yet

- Li 2013Document27 pagesLi 2013ssuarez907No ratings yet

- Demostraciones Prácticas de Los Retos y Oportunidades de La Producción de Bioetanol de Primera y Segunda Generación A Partir de Cultivos TropicalesDocument6 pagesDemostraciones Prácticas de Los Retos y Oportunidades de La Producción de Bioetanol de Primera y Segunda Generación A Partir de Cultivos TropicalesBrayant Ninahuanca ParraNo ratings yet

- 12734Document21 pages12734ssuarez907No ratings yet

- 1 SR Star Jee Main GTM 02 - 03 01 2024 KeyDocument14 pages1 SR Star Jee Main GTM 02 - 03 01 2024 Keyjahnavimogarala9No ratings yet

- Problem #2b: Chromium Crystallizes With A Body-Centered Cubic Unit Cell. The Radius of ADocument8 pagesProblem #2b: Chromium Crystallizes With A Body-Centered Cubic Unit Cell. The Radius of ARadica AyuNo ratings yet

- CMB Chapter 15Document32 pagesCMB Chapter 15cyorogNo ratings yet

- Curl Activator GelDocument1 pageCurl Activator GelNemanja NikolicNo ratings yet

- Maintaining Boiler Water Quality (35 charactersDocument3 pagesMaintaining Boiler Water Quality (35 characterskcp1986No ratings yet

- Mechanical Properties For Stainless Steel FastenersDocument3 pagesMechanical Properties For Stainless Steel FastenersGonzalo MazaNo ratings yet

- Presentation 01Document28 pagesPresentation 01Rexona KhanomNo ratings yet

- B.pharm. Class NotesDocument817 pagesB.pharm. Class NotesMukesh TiwariNo ratings yet

- LP2 SCI-12 MICROBIO LABORATORY-fINALDocument21 pagesLP2 SCI-12 MICROBIO LABORATORY-fINALJOHNERROL CARCELLARNo ratings yet

- Paper 4 Jun 2001 PhysicsDocument2 pagesPaper 4 Jun 2001 Physicssolarixe100% (1)

- Chemistry, Mathematics & Physics: All India Internal Test SeriesDocument15 pagesChemistry, Mathematics & Physics: All India Internal Test Seriesmadhav aggarwalNo ratings yet

- ZN ProtocolDocument262 pagesZN ProtocolLavina D'costaNo ratings yet

- Summary KH2134 Fluid MechanicsDocument4 pagesSummary KH2134 Fluid MechanicsAzman SamerNo ratings yet

- Glass Fibre: Historical BackgroundDocument11 pagesGlass Fibre: Historical Backgroundapi-19731065100% (1)

- N52 Grade Neodymium Magnets DataDocument1 pageN52 Grade Neodymium Magnets DataSteve HsuNo ratings yet

- SodaPDF-converted-Exercise No. 7 - Soil Sample Collection and PreparationDocument30 pagesSodaPDF-converted-Exercise No. 7 - Soil Sample Collection and PreparationJacky Lou GermanoNo ratings yet

- Selective Bromination With Copper (I1) Bromide - King - JOC 29 (1964)Document3 pagesSelective Bromination With Copper (I1) Bromide - King - JOC 29 (1964)dextroenantiomerNo ratings yet

- CV en - Op - Gill Giovani Awonguino oDocument1 pageCV en - Op - Gill Giovani Awonguino oAuguste SuelieNo ratings yet

- Corrosion of Iron: An Electrochemical ProcessDocument5 pagesCorrosion of Iron: An Electrochemical ProcessVickyNo ratings yet

- ANTHE 2021 (Engineering) Sample PaperDocument17 pagesANTHE 2021 (Engineering) Sample PaperDida CowernNo ratings yet

- Combustion in SI & CI EnginesDocument25 pagesCombustion in SI & CI EnginesVenkatesh KabraNo ratings yet

- AG SR SecondaryDocument33 pagesAG SR SecondaryDeepikaNo ratings yet

- Effect of Sugarmill On Soil of DoiwalaDocument11 pagesEffect of Sugarmill On Soil of DoiwalaBilal BhatNo ratings yet

- Turton - Appb 30 37Document8 pagesTurton - Appb 30 37asadNo ratings yet