Professional Documents

Culture Documents

Balem 531-S (Cooling Tower) PDF

Uploaded by

anon_210074734Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Balem 531-S (Cooling Tower) PDF

Uploaded by

anon_210074734Copyright:

Available Formats

Float Control Valve

HI-LO COMBI Valve(BALEM 531-S)

Special Features

Hydraulic level control valves by differential pressure and

buoyancy of float.

Stainless steel main valve-suitable for demineralizing water

control.

Operates mechanically independent from any external power

sources.

Easy to install without additional pipes.

More safe in high pressure and stronger in water hammer by

differential pressure being applied to piston operating system.

Hi-Lo Combi Valve (BALEM 531-S) is progressed in performance

of BALEM 421 and 531, has great flux quality using efficient internal

design, and can control high and low water level.

All materials are stainless steel, so the valve can be used not only

controlling high and low level but also controlling in drinking water

and demineralizing water.

Flow Chart

Patents

- Korea Patent No. 0839207

- Korea Utility No. 0207682

Applications

- Substitute for level control valve such as floating valve, motorized

valve, and solenoid valve installed under ground / roof top water

reservoir

- Substitute for mechanical valve and electrodes for high and low

water level control

- For water level control at various types of oil tank

Specifications

BALEM 531-S

Model No.

531-S-025

531-S-032

531-S-040

531-S-050

531-S-065

531-S-080

531-S-100

Size

25A(1" )

32A(11/4" )

40A(21/2" )

50A(2" )

65A(21/2" )

80A(3" )

100A(4" )

Operating Pressure

Testing Pressure

Media

End Connections

16 BALEM Co., Ltd.

0.05~0.98 MPa(0.5~10kgf/)

1.72 MPa(17.5kgf/)

Water, Oil(Order-Made)

Temperature : 0~80

Male threaded : KSPT(Standard) / N.P.T, Flanged(Optional Order)

BALEM 531-S

Float Control Valve

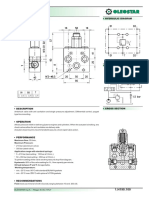

Dimensions

For cooling tower

Materials

For high & low water level control

For high & low water level control

(mm)

Size

H1

H2

H3

L1

L2

25A

64

130

563

58

253

600

32A

75

135

569

72

266

614

40A

80

136

573

80

272

619

50A

100

145

584

85

286

634

65A

114

156

587

98

306

653

80A

145

165

609

120

329

677

100A

167

178

618

145

361

709

D()

110

For cooling tower

No.

Components

Materials

Body

SSC13

300

Cover

SSC13

Piston Assembly

SSC13, N.B.R(S.R)

Spring

STS304

Pilot Tube

STS304

(mm)

Size

H1

H2

H3

L1

L2

25A

64

118

262

58

238

D()

32A

75

124

268

72

251

314

40A

80

128

272

80

257

319

50A

100

139

282

85

271

334

65A

114

143

286

98

291

353

Pilot body Assembly

SSC13, N.B.R, P.T.F.E

80A

145

164

307

120

314

377

Float Assembly

STS304

100A

167

173

316

145

346

409

124

Alam Receiver

Installation Recommendations

Strainer

Cock Valve

POWER

Manhole

Electrode

HI-LO COMBI Valve

Overflow

Water Supply

Union

Alam of Control Fail

High Water Level

Beginning Water Supply

Syphon Braking Hol

Signal of Low Water Level

Outlet

- Refer to the standard piping diagram when installing the

valve.

- Before install, you have to flush pipeline for inside

clean.

- For early detection you need an alarm system.

- The valve should be installed near manhole for

maintenance.

- Do not twist and turn with holding Float Assembly.

- To prevent waves filling, an induction tube with siphon

breaking hole must be installed.

- Connection flange is optional order.

Installed Alone

BALEM Valve Series 17

You might also like

- INBAL GeralDocument10 pagesINBAL GeralAlisson Gustavo KalilNo ratings yet

- Inbal - Deluge Valve Pressure Control 03 - 13 CR01Document4 pagesInbal - Deluge Valve Pressure Control 03 - 13 CR01gustavosalvatoNo ratings yet

- 50B4KGDocument2 pages50B4KGonin007No ratings yet

- Electrohydraulic: Solenoid ValvesDocument16 pagesElectrohydraulic: Solenoid ValvesluisbottonNo ratings yet

- WW 770-UDocument4 pagesWW 770-UAhmad NasserNo ratings yet

- Inbal - Deluge Valve Pressure Control 03-13 CR01Document4 pagesInbal - Deluge Valve Pressure Control 03-13 CR01pvalverdea2014No ratings yet

- Cash Valve E-55 SeriesDocument4 pagesCash Valve E-55 SeriesByron PanchiNo ratings yet

- E 50B 4KG1 - Fire PDFDocument2 pagesE 50B 4KG1 - Fire PDFdocrafiNo ratings yet

- Valvula Reductora de Presion Bermad Area 675 720-ULDocument4 pagesValvula Reductora de Presion Bermad Area 675 720-ULChristian FherNo ratings yet

- Series 825Y Specification SheetDocument2 pagesSeries 825Y Specification SheetFEBCONo ratings yet

- Valvulas Plasticas DorotDocument8 pagesValvulas Plasticas DorotBook menNo ratings yet

- Valvula WW-820Document4 pagesValvula WW-820Anonymous Iic1fi49uENo ratings yet

- 4 Water FloodDocument6 pages4 Water FloodEduardoWire100% (1)

- Main Relief ValveDocument2 pagesMain Relief ValveJesseNo ratings yet

- Series 825YD Specification SheetDocument2 pagesSeries 825YD Specification SheetFEBCONo ratings yet

- Feed Water Heater - Isolation System: Features & BenefitsDocument9 pagesFeed Water Heater - Isolation System: Features & BenefitsAkash PatilNo ratings yet

- Cla-Val, Relief VanaDocument2 pagesCla-Val, Relief Vanadeyson galeanoNo ratings yet

- Speader Valves Hk66b102Document12 pagesSpeader Valves Hk66b102seaqu3stNo ratings yet

- PLL 2144Document80 pagesPLL 2144Amit TandelNo ratings yet

- Bermad: Pressure Reducing and Sustaining ValveDocument4 pagesBermad: Pressure Reducing and Sustaining ValvePerlita M. A SebastianNo ratings yet

- HytrolDocument44 pagesHytrolMark Mach AllenNo ratings yet

- Bermad IrrigationDocument48 pagesBermad Irrigationemongclooney11No ratings yet

- ISO 9001 Certified Digital Control Valve GuideDocument8 pagesISO 9001 Certified Digital Control Valve Guidecnrk777100% (1)

- PVR-108-2 Fueling Model SheetDocument2 pagesPVR-108-2 Fueling Model SheetLetycia RosalesNo ratings yet

- Valvula Control de Nivel Bermad Andina Modelo 750+66+BDocument6 pagesValvula Control de Nivel Bermad Andina Modelo 750+66+BEduardo Hurtado Palacios100% (1)

- On - Off ValveDocument5 pagesOn - Off Valvekresimir.mikoc9765No ratings yet

- Electronic Hydrometer Valve with GSM ControlDocument12 pagesElectronic Hydrometer Valve with GSM ControlSlobodan AnticNo ratings yet

- Regulator3 4 DSDocument4 pagesRegulator3 4 DSargaNo ratings yet

- Ratio Pressure Reducing ValvesDocument4 pagesRatio Pressure Reducing Valveskanem1No ratings yet

- CROWN Esd Brochure Usa 3 2Document4 pagesCROWN Esd Brochure Usa 3 2Ahmed Ayman Yassin100% (1)

- Dual Plate Check Valve WeightDocument1 pageDual Plate Check Valve WeightbisworupmNo ratings yet

- Directional Control Valve GuideDocument11 pagesDirectional Control Valve GuideDaniel VillarroelNo ratings yet

- Claval Deluge Valve TM 134-89 ManualDocument24 pagesClaval Deluge Valve TM 134-89 ManualEnoch TwumasiNo ratings yet

- 8-1 3750 Pressurisation Unit BrochureDocument8 pages8-1 3750 Pressurisation Unit BrochureAmeet Gupte0% (1)

- 04BR05Document6 pages04BR05martiguada1No ratings yet

- A075 Valve Operation Guide PDFDocument130 pagesA075 Valve Operation Guide PDFedhy_03No ratings yet

- Hi Flow Control Valves.iDocument3 pagesHi Flow Control Valves.iGilberto Meneses NavarroNo ratings yet

- Check ValveDocument2 pagesCheck ValveVidyasenNo ratings yet

- LFN223F Specification SheetDocument2 pagesLFN223F Specification SheetWattsNo ratings yet

- Modulating Float ValvesDocument4 pagesModulating Float ValvesJayakrishnan RadhakrishnanNo ratings yet

- Danfoss Non Return ValvesDocument28 pagesDanfoss Non Return Valveskostaviga777No ratings yet

- CLA-VAL 136-07 & - 38: Dual Solenoid Control ValveDocument1 pageCLA-VAL 136-07 & - 38: Dual Solenoid Control Valvesergethomas2010No ratings yet

- Valves BarendsenDocument63 pagesValves BarendsenidontlikeebooksNo ratings yet

- Universal Rainwater Pumps - High Performance Multi-Stage PumpsDocument4 pagesUniversal Rainwater Pumps - High Performance Multi-Stage PumpsmozaryuNo ratings yet

- BRAQBSTDocument8 pagesBRAQBSTerrenmayNo ratings yet

- 1.eurospartan Ve411 ValvesDocument5 pages1.eurospartan Ve411 Valvesoep1969No ratings yet

- Series 826YD Specification SheetDocument2 pagesSeries 826YD Specification SheetFEBCONo ratings yet

- Three Way Valve Technical OverviewDocument8 pagesThree Way Valve Technical OverviewWalter JosephNo ratings yet

- Valve and Actuator CatalogueDocument60 pagesValve and Actuator Catalogueashfaq-matte-79930% (1)

- Choke E Series MasterFloDocument14 pagesChoke E Series MasterFloianherzogNo ratings yet

- FP 730-59 Data Sheet PDFDocument4 pagesFP 730-59 Data Sheet PDFCarlos TarquinoNo ratings yet

- Automatically Balanced Combination Valves Ab-Qm: Data SheetDocument12 pagesAutomatically Balanced Combination Valves Ab-Qm: Data SheetbatazivoNo ratings yet

- Float Valves for Tanks and PipelinesDocument28 pagesFloat Valves for Tanks and PipelinescartarNo ratings yet

- E 90 48Document4 pagesE 90 48Agus Qupink Luph AriaNo ratings yet

- Aks 38Document8 pagesAks 38Tran Ngoc HaNo ratings yet

- Vaa /ru /DL 38: Pressure Relief ValvesDocument2 pagesVaa /ru /DL 38: Pressure Relief ValvesLibinNo ratings yet

- Model LFL111 Specification SheetDocument2 pagesModel LFL111 Specification SheetWattsNo ratings yet

- Series LFN223B, LFN223BS Specification SheetDocument2 pagesSeries LFN223B, LFN223BS Specification SheetWattsNo ratings yet

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Mcs 2010Document196 pagesMcs 2010rvillgNo ratings yet

- Semiconductor Devices Fabrication WorkshopDocument1 pageSemiconductor Devices Fabrication WorkshopSaniaNo ratings yet

- Ausmelt SmeltingDocument6 pagesAusmelt SmeltingMarcelo SerranoNo ratings yet

- Sp168f PDFDocument10 pagesSp168f PDFAmbar SolangeNo ratings yet

- Diagnostic Exam for Aeronautical Engineering StudentsDocument4 pagesDiagnostic Exam for Aeronautical Engineering StudentsBerns DulamNo ratings yet

- Sitren PSR 100 0209 en 2000 IfDocument2 pagesSitren PSR 100 0209 en 2000 IfSuryasai RednamNo ratings yet

- Chapter 41Document9 pagesChapter 41Shridhar KulkarniNo ratings yet

- Hitatchi ProfileDocument15 pagesHitatchi ProfileAbdul AleemNo ratings yet

- Pruthwiraj PPT On Low Cost HousingDocument14 pagesPruthwiraj PPT On Low Cost HousingpruthwipaikarayNo ratings yet

- Citric Acid Rust Removal GuideDocument4 pagesCitric Acid Rust Removal GuideDewi AnggrainiNo ratings yet

- Group 5 Part 2Document22 pagesGroup 5 Part 2Prila Sarmiento AbejoNo ratings yet

- Asme CCase N-432Document4 pagesAsme CCase N-432julianmorantesNo ratings yet

- Social Icons: C-80 GradeDocument3 pagesSocial Icons: C-80 GradeEdward OropezaNo ratings yet

- 3ap1 FG: High-Voltage Circuit-BreakerDocument2 pages3ap1 FG: High-Voltage Circuit-BreakerFernando VacaNo ratings yet

- 750V DC Traction SystemDocument26 pages750V DC Traction SystemShashi Bhusan Singh100% (2)

- BurnerDocument33 pagesBurnertoficNo ratings yet

- Cameron Compressor OperationDocument13 pagesCameron Compressor Operationfructora0% (1)

- 500 Grinders: What I LearnedDocument19 pages500 Grinders: What I LearnedMbah SajanNo ratings yet

- Mechanical Engineering McqsDocument319 pagesMechanical Engineering McqsMuhammad AslamNo ratings yet

- Specification for glass fiber yarn, cordage, sleeving, cloth, and tapeDocument37 pagesSpecification for glass fiber yarn, cordage, sleeving, cloth, and tapeMichael SkrableNo ratings yet

- STL FileDocument60 pagesSTL FileR RAJESWARINo ratings yet

- NSH KBR Skop e 009 - Bus Duct Installation and TestingDocument7 pagesNSH KBR Skop e 009 - Bus Duct Installation and TestingFrancisco Severino Gatoc Jr.No ratings yet

- Advanced Energy Materials High Entropy Energy Materials in The Age of Big DataDocument18 pagesAdvanced Energy Materials High Entropy Energy Materials in The Age of Big Dataemerson_kohlNo ratings yet

- Kaeser SK Installation Data Sheet File-1466182088Document3 pagesKaeser SK Installation Data Sheet File-1466182088ANDRESNo ratings yet

- wf-04 - EnglishDocument2 pageswf-04 - EnglishLeonardoNo ratings yet

- Erection and Painting of Steel StructureDocument11 pagesErection and Painting of Steel StructureomarcadNo ratings yet

- Chapter 21 22 - Chemical Reactions Balancing Chemical EquationsDocument34 pagesChapter 21 22 - Chemical Reactions Balancing Chemical EquationsAlwielland BelloNo ratings yet

- Calculation of Sio Diffusion Coefficients Based On Kinetic Curves of Silica Grain DissolutionDocument3 pagesCalculation of Sio Diffusion Coefficients Based On Kinetic Curves of Silica Grain DissolutionNallely CasasNo ratings yet

- Dupont Vespel Cr-6100: Application and Installation Guide For Centrifugal Pump Stationary Wear PartsDocument12 pagesDupont Vespel Cr-6100: Application and Installation Guide For Centrifugal Pump Stationary Wear PartsMagali OsorioNo ratings yet

- Warriorfeed 404Document70 pagesWarriorfeed 404JUANNo ratings yet