Professional Documents

Culture Documents

Heat Transfer Semester Exam QPs

Uploaded by

Goutham R100%(1)100% found this document useful (1 vote)

378 views61 pages..:ANNA UNIVERSITY OLD SEMESTER QUESTION PAPERS- HEAT TRANSFER:..

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document..:ANNA UNIVERSITY OLD SEMESTER QUESTION PAPERS- HEAT TRANSFER:..

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

378 views61 pagesHeat Transfer Semester Exam QPs

Uploaded by

Goutham R..:ANNA UNIVERSITY OLD SEMESTER QUESTION PAPERS- HEAT TRANSFER:..

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 61

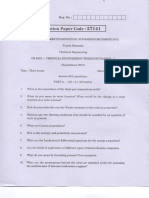

Reg. No.

Question Paper Code : 53093

B.E./B.Tech. DEGREE EXAMINATION, NOVEMBER/DECEMBER 2010

Fifth Semester

Chemical Engineering

CH 2304 HEAT TRANSFER

(Regulation 2008)

Time : Three hours

Maximum : 100 Marks

(Steam Table is permitted)

Answer ALL questions

PART A (10 2 = 20 Marks)

1.

State three modes of heat transfer.

2.

What is thermal conductivity?

3.

What is Natural convection? Explain.

4.

What is overall and individual heat transfer coefficient? Explain.

5.

What is Forced convection?

6.

Give the application of conduction heat transfer?

7.

What is the range of dimension for baffle distance in heat exchanger?

8.

Why LMTD correction factor adopted in heat exchanger?

9.

State the difference between thermal radiation and light radiation.

10.

What is Economy in evaporator? Explain.

PART B (5 16 = 80 Marks)

11.

(a)

(i)

Discuss the analogy between flow of heat and electricity.

(8)

(ii)

A wall of a furnace 0.244 m thick is constructed of material having

thermal conductivity 1.30 w/mK. The wall will be insulated on the

outer side with the material having average thermal conductivity

0.346 w/mK so that the heat loss from the furnace will be equal to

or less than 1830 w/m2. The inner surface of the wall is at 1588K,

while the outer surface is at 299K. Calculate the thickness of

insulation required.

(8)

Or

(b)

12.

(a)

(i)

Derive the steady state heat conduction equation in a rectangular

composite wall comprising three layers.

(8)

(ii)

What is critical thickness of insulation? And derive the related

equation for cylinder.

(8)

(i)

Derive unsteady state heat conduction equation.

(ii)

Discuss graphical method of solving two dimensional steady state

heat conduction.

(8)

Or

(8)

(b)

13.

(a)

(i)

Derive the relevant equation for heat transfer in conduction with

any heat source?

(8)

(ii)

Discuss the analytical method of solving two dimensional steady

state heat conduction.

(8)

(i)

Steam at pressure of 1.2 atm absolute is condensed in a vertical

condenser at the rate of 6100 kg/hr using water at 33C. The out let

temperature of water is 80C. Find out heat load, and cooling water

requirement.

(8)

(ii)

Discuss the heat transfer to molten metal.

(8)

Or

(b)

14.

(a)

Explain

(i)

Pool boiling

(5)

(ii)

Film type condensation

(5)

(iii) Drop wise condensation with a diagram.

(6)

(i)

Explain parallel flow and counter flow heat exchanger.

(8)

(ii)

A reaction mixture having CP = 2.85 KJ/kg K is flowing at a rate of

7260 kg/hr is to be cooled from 377.6 to 344.3 K. Cooling water at

288.8 K is available and the flow rate is 4536 kg/hr. The over-all

Uo = 653 W/m2K.

(1)

(2)

For counter flow, calculate the outlet water temperature and

area of heat exchanger

For co-current flow calculate the area of heat exchanger.

(8)

Or

(b)

(i)

Differentiate

exchanger.

single

pass

exchanger

from

multi-pass

heat

(5)

(ii)

What is plate type heat exchanger and explain with a diagram.

(5)

(iii) What is fouling and how it can be prevented in heat exchanger? (6)

15.

(a)

(b)

(i)

Derive the equation for radiation exchange between large grey

concentric cylinders.

(10)

(ii)

Two parallel gray planes which are having emissivities of

1 = 0.8, 2 = 0.7. The surface is at 866.5 K and surface 2 is at

588.8 K.

(1)

What net radiation from 1 to 2?

(2)

If both surfaces are black, what net radiation from 1 to 2?

Or

(6)

(i)

A feed of 4535 kg/hr of a 2% by weight salt solution at 311 K enters

continuously a single effect evaporator and being concentrated to

3% by weight. The evaporation is at atmospheric pressure and the

area of the evaporator is 69.7 m2. Saturated steam at 383.2 K is

supplied for heating. Since the solution is dilute, it can be assumed

to have same boiling point of water. Cp, of feed is 4.10 KJ/kg K.

Calculate the overall heat transfer coefficient.

(8)

(ii)

Explain various types of feeding in multiple effect evaporators.

(8)

53093

You might also like

- Dokumen - Tips - l136 T Ti L086ti Ad136 T Ti Ad086ti Mlyr 2005m000456599898 8082b PDFDocument95 pagesDokumen - Tips - l136 T Ti L086ti Ad136 T Ti Ad086ti Mlyr 2005m000456599898 8082b PDFroosseno100% (1)

- Chapter 2 PDFDocument34 pagesChapter 2 PDFrafsanNo ratings yet

- Mil STD 278FDocument128 pagesMil STD 278Fexwhiskeyhouse100% (1)

- Assignment 12Document7 pagesAssignment 12Anonymous mqIqN5zNo ratings yet

- Heat Transfer IES GATE IAS 20 Years Question and Answers PDFDocument97 pagesHeat Transfer IES GATE IAS 20 Years Question and Answers PDFKumar GauravNo ratings yet

- Double Pipe Heat Exchanger - SsDocument72 pagesDouble Pipe Heat Exchanger - SsNathanian100% (2)

- Heat Exchanger Design: Qfuel ContractorDocument27 pagesHeat Exchanger Design: Qfuel ContractorUsama AkramNo ratings yet

- Heat Exchangers MCQsDocument21 pagesHeat Exchangers MCQsahmed abdel-azizNo ratings yet

- Anna University Heat Transfer Question BankDocument12 pagesAnna University Heat Transfer Question BankGoutham R80% (5)

- Wastewater TreatmentDocument61 pagesWastewater TreatmentGoutham R100% (1)

- Heat Transfer Final Exam Problem & SolutionsDocument8 pagesHeat Transfer Final Exam Problem & SolutionsRonard Pa–a0% (1)

- Chapter 5-Compounded Vapor Compression Cyclee-ExamplesDocument65 pagesChapter 5-Compounded Vapor Compression Cyclee-Examplesm_alodat6144100% (1)

- Micro To MACRO Mathematical Modelling in Soil Mechanics (Trends in Mathematics)Document407 pagesMicro To MACRO Mathematical Modelling in Soil Mechanics (Trends in Mathematics)Renova HnNo ratings yet

- Barrons Essential 333 Words PDFDocument5 pagesBarrons Essential 333 Words PDFGoutham RNo ratings yet

- Boiling and Condensation 1Document48 pagesBoiling and Condensation 1hasan bish100% (1)

- Heat Transfer - SK MondalDocument97 pagesHeat Transfer - SK MondalMiguelaTayNo ratings yet

- Aashto T283 PDFDocument7 pagesAashto T283 PDFguru nathNo ratings yet

- Refrigeration Moran Shapiro Solution ManualDocument10 pagesRefrigeration Moran Shapiro Solution ManualNovaCastilloNo ratings yet

- Chemical Process Calculations - Anna UnivDocument10 pagesChemical Process Calculations - Anna UnivGoutham R100% (1)

- Topic 13 Papermaking Forming Text PDFDocument34 pagesTopic 13 Papermaking Forming Text PDFThashna DusoruthNo ratings yet

- Composite Wall ApparatusDocument11 pagesComposite Wall Apparatusjohn paul.jaisonNo ratings yet

- Chapter 4 - Distributed-Parameters Models: Profa. Liliane Lona - em RevisãoDocument39 pagesChapter 4 - Distributed-Parameters Models: Profa. Liliane Lona - em RevisãoMônica CarneiroNo ratings yet

- Heat Transfer:: Differences Between Thermodynamics andDocument11 pagesHeat Transfer:: Differences Between Thermodynamics andNitin KumarNo ratings yet

- Department of Mechanical Engineering Question Bank Subject Name: Heat & Mass Transfer Unit - I Conduction Part - ADocument3 pagesDepartment of Mechanical Engineering Question Bank Subject Name: Heat & Mass Transfer Unit - I Conduction Part - AkarthikNo ratings yet

- Lecture-17: Multi-Stage Vapour Compression Refrigeration SystemsDocument13 pagesLecture-17: Multi-Stage Vapour Compression Refrigeration SystemsMuhaamad TiloNo ratings yet

- Numerical For Practice MidtermDocument3 pagesNumerical For Practice MidtermSiddhant SinhaNo ratings yet

- Heat & Mass Transfer Question BankDocument4 pagesHeat & Mass Transfer Question BankBhavesh Kapil50% (2)

- Assignment Answer Scheme PDFDocument17 pagesAssignment Answer Scheme PDFHizami Mohammad Noor100% (2)

- Transport Phenomena - Heat Conduction Through A Composite WallDocument11 pagesTransport Phenomena - Heat Conduction Through A Composite WallFarhan HazeeqNo ratings yet

- Tutorial QuestionsDocument6 pagesTutorial QuestionsLadnilrebNo ratings yet

- CH 7 PowerCyclesDocument12 pagesCH 7 PowerCyclescarleston thurgoodNo ratings yet

- Ques 1Document6 pagesQues 1ANKIT KUMAR0% (1)

- UNIT-1: What Is The Difference Between Refrigeration & Air Conditioning?Document8 pagesUNIT-1: What Is The Difference Between Refrigeration & Air Conditioning?Udit NarayanNo ratings yet

- ME 346 Lab Final ExamDocument9 pagesME 346 Lab Final ExamSaad RasheedNo ratings yet

- Notes On Fluidized Bed Reactors: 1 Kunii-Levenspiel Model DescriptionDocument5 pagesNotes On Fluidized Bed Reactors: 1 Kunii-Levenspiel Model DescriptionarmandNo ratings yet

- Che 415 2018-19 Part 3 PDFDocument66 pagesChe 415 2018-19 Part 3 PDFOsan ThorpeNo ratings yet

- Steam Table PDFDocument16 pagesSteam Table PDFMustafa MohamedNo ratings yet

- Experiment No: 1: Thermal Engineering Lab ManualDocument8 pagesExperiment No: 1: Thermal Engineering Lab ManualmuralidharanNo ratings yet

- Fluid Mechanics Question BankDocument6 pagesFluid Mechanics Question BankDinesh KumarNo ratings yet

- Question Bank - HMTDocument5 pagesQuestion Bank - HMTSUNDARAMAHALINGAM ANo ratings yet

- Two Marks CH 6603 Mass TransferDocument17 pagesTwo Marks CH 6603 Mass Transfersampathkumar100% (1)

- P R o B L e M S o F P R A C T I C e S O F B A S I C A N D A P P L I e D T H e R M o D y N A M I C S I - C - E N G I N eDocument21 pagesP R o B L e M S o F P R A C T I C e S O F B A S I C A N D A P P L I e D T H e R M o D y N A M I C S I - C - E N G I N eAnonymous ncBe0B9bNo ratings yet

- Pressure Drop Calculation in Pipe & AnnulusDocument8 pagesPressure Drop Calculation in Pipe & AnnulusKusmakarNo ratings yet

- Mass TransferDocument122 pagesMass TransferMasita RachmawatiNo ratings yet

- Condensation HMTDocument22 pagesCondensation HMTbalakalees100% (1)

- Design of HEDocument35 pagesDesign of HESaurabh SengarNo ratings yet

- RAC Assignments 24062016 091508AMDocument37 pagesRAC Assignments 24062016 091508AMsakalidhasavasanNo ratings yet

- Experiment No.-1: With Continuous Supply of Fresh Gas and Removal of The Products of DiffusionDocument7 pagesExperiment No.-1: With Continuous Supply of Fresh Gas and Removal of The Products of DiffusionSiddharth MohapatraNo ratings yet

- Heat 4e Chap02 LectureDocument48 pagesHeat 4e Chap02 LectureSubho Samanta100% (4)

- RTD Studies in PFRDocument13 pagesRTD Studies in PFRSiddarthNo ratings yet

- Isothermal Semi-Batch Reactor PPT RJC SirDocument16 pagesIsothermal Semi-Batch Reactor PPT RJC Sirsdjdsf100% (1)

- Common Questions Heat Pipes PDFDocument2 pagesCommon Questions Heat Pipes PDFTeo Pei SanNo ratings yet

- Heat 4e Chap04 LectureDocument39 pagesHeat 4e Chap04 Lectureehdfhdhdfhdh100% (1)

- Gate 1990Document16 pagesGate 1990KapilSahuNo ratings yet

- Applied Electricity CourseDocument4 pagesApplied Electricity CourseZani Bai0% (1)

- Boiling and Condensation PDFDocument11 pagesBoiling and Condensation PDFYeditha Satyanarayana MurthyNo ratings yet

- Lect - 10 External Forced ConvectionDocument45 pagesLect - 10 External Forced ConvectionVivaan SharmaNo ratings yet

- Placement Q2Document579 pagesPlacement Q2munirajNo ratings yet

- Heat ExchangerDocument33 pagesHeat ExchangerKhloud MadihNo ratings yet

- Chapter 5 SlideDocument25 pagesChapter 5 Slidecanva proNo ratings yet

- RAC Tutorial Sheet 2Document3 pagesRAC Tutorial Sheet 2Ankur Sachdeva0% (1)

- Gujarat Technological University: Bachelor of Engineering Subject Code: 150501Document4 pagesGujarat Technological University: Bachelor of Engineering Subject Code: 150501lata sinsinwarNo ratings yet

- Sheatpoweer Steam Turbine22Document3 pagesSheatpoweer Steam Turbine22Omeed ArtsNo ratings yet

- Unsteady State Heat TransferDocument4 pagesUnsteady State Heat TransferRaghavendra PrasadNo ratings yet

- CH8591 - Heat TransferDocument5 pagesCH8591 - Heat TransferS9048 SUDHARSAN ANo ratings yet

- r05320306 Heat TransferDocument8 pagesr05320306 Heat TransferSrinivasa Rao GNo ratings yet

- T.E. (Mechanical) (Semester - I) Examination, 2011 Heat Transfer (2008 Pattern) (New)Document4 pagesT.E. (Mechanical) (Semester - I) Examination, 2011 Heat Transfer (2008 Pattern) (New)saurabhNo ratings yet

- Kinetics of Reactions PDFDocument9 pagesKinetics of Reactions PDFGoutham RangarajanNo ratings yet

- CHDocument2 pagesCHDebottamSarkarNo ratings yet

- Handout Dimension Less Numbers PrintDocument1 pageHandout Dimension Less Numbers PrintMarco García HernándezNo ratings yet

- Au Coe QP: Question Paper CodeDocument17 pagesAu Coe QP: Question Paper CodeGoutham RangarajanNo ratings yet

- Different Harvesting Techniques - RSCDocument11 pagesDifferent Harvesting Techniques - RSCGoutham RNo ratings yet

- Maximum Internals Minimum ExternalsDocument1 pageMaximum Internals Minimum ExternalsGoutham RNo ratings yet

- Multiple Reactors in NetworksDocument4 pagesMultiple Reactors in NetworksGoutham RNo ratings yet

- Frustrated Lewis PairsDocument42 pagesFrustrated Lewis PairsGoutham RNo ratings yet

- Cyanuric Acid PhotodegradationDocument6 pagesCyanuric Acid PhotodegradationGoutham RNo ratings yet

- Neutral Red DegradationDocument7 pagesNeutral Red DegradationGoutham RNo ratings yet

- 10 1039@c4cy00006dDocument16 pages10 1039@c4cy00006dGoutham RNo ratings yet

- CTL Frustrated Lewis PairsDocument109 pagesCTL Frustrated Lewis PairsGoutham RNo ratings yet

- Unit 1 Mat SciDocument195 pagesUnit 1 Mat SciGoutham RNo ratings yet

- Habibi 2013Document6 pagesHabibi 2013Goutham RNo ratings yet

- New Journal of Chemistry Volume 39 Issue 7 2015 (Doi 10.1039/C5NJ00681C) Tang, Yanfeng Liu, Xinlin Ma, Changchang Zhou, Mingjun Huo, - Enhanced Photocatalytic Degradation of Tetracycline AntibiDocument11 pagesNew Journal of Chemistry Volume 39 Issue 7 2015 (Doi 10.1039/C5NJ00681C) Tang, Yanfeng Liu, Xinlin Ma, Changchang Zhou, Mingjun Huo, - Enhanced Photocatalytic Degradation of Tetracycline AntibiGoutham RNo ratings yet

- Photo-Catalysis Using Titanium Dioxide Nanotube LayersDocument5 pagesPhoto-Catalysis Using Titanium Dioxide Nanotube LayersFlorentin DumitruNo ratings yet

- Habibi 2014Document3 pagesHabibi 2014Goutham RNo ratings yet

- Nature Chemistry Volume 6 Issue 11 2014 (Doi 10.1038/nchem.2093) Stephan, Douglas W. - Frustrated Lewis Pairs - A Metal-Free LandmarkDocument2 pagesNature Chemistry Volume 6 Issue 11 2014 (Doi 10.1038/nchem.2093) Stephan, Douglas W. - Frustrated Lewis Pairs - A Metal-Free LandmarkGoutham RNo ratings yet

- 10 1039@c4ra13734eDocument76 pages10 1039@c4ra13734eGoutham RNo ratings yet

- Chem EnggDocument97 pagesChem EnggpriyakumaranNo ratings yet

- Disaster Management Class 10Document69 pagesDisaster Management Class 10YashVanjani60% (15)

- Anna University Question Paper ThermodynamicsDocument22 pagesAnna University Question Paper ThermodynamicsGoutham R50% (4)

- University Question Paper 2009-2015Document22 pagesUniversity Question Paper 2009-2015Goutham RNo ratings yet

- Applications of Ionic Liquids in Organic Synthesis: OutlineDocument9 pagesApplications of Ionic Liquids in Organic Synthesis: OutlineMathias PradoNo ratings yet

- Issue103 PDFDocument84 pagesIssue103 PDFHS itNo ratings yet

- Spare Parts Manual: Solidc PumpDocument12 pagesSpare Parts Manual: Solidc PumpDaniel FernándezNo ratings yet

- 05 CE134P-2 Design Principles of Tension Members by ASD and LRFD MethodDocument10 pages05 CE134P-2 Design Principles of Tension Members by ASD and LRFD MethodPzynae FlorentinoNo ratings yet

- ASTM A194-A 194M-05b, Carbon and Alloy Steel Nuts For Bolts For High Pressure or High TemperatureDocument13 pagesASTM A194-A 194M-05b, Carbon and Alloy Steel Nuts For Bolts For High Pressure or High TemperaturetariqkhanNo ratings yet

- Pneumatic Valve - Viking Xtreme Series - Catalogue PDE2569TCUKDocument64 pagesPneumatic Valve - Viking Xtreme Series - Catalogue PDE2569TCUKBranko BabicNo ratings yet

- Lesson 06 Potential Flow and Elementary FlowsDocument23 pagesLesson 06 Potential Flow and Elementary FlowsAlmukhtar AlkinanyNo ratings yet

- Homestyle Stacked Washer/Dryer: Refer To Page 3 For Model NumbersDocument78 pagesHomestyle Stacked Washer/Dryer: Refer To Page 3 For Model NumbersJose RANo ratings yet

- Lec 15 - Fluidity of Liquid MetalDocument16 pagesLec 15 - Fluidity of Liquid MetalZakaria AguezzarNo ratings yet

- Technical Data of The Fan: RZR 13-1250: To Motor: Siemens-IE3 1LE1003-1CC03-4AB4/IE3Document3 pagesTechnical Data of The Fan: RZR 13-1250: To Motor: Siemens-IE3 1LE1003-1CC03-4AB4/IE3mahmadwasiNo ratings yet

- 6614 SKF Agri Hub For Tillage DisksDocument8 pages6614 SKF Agri Hub For Tillage DisksAlvaro MunozNo ratings yet

- Gears: Pinion Gear, Step Down DriveDocument42 pagesGears: Pinion Gear, Step Down DriveIshan VermaNo ratings yet

- JCOUSER01Document1 pageJCOUSER01jalajNo ratings yet

- المواسيرDocument15 pagesالمواسيرshamashergyNo ratings yet

- Pros & Cons of Centralized Vacuum SystemsDocument66 pagesPros & Cons of Centralized Vacuum SystemsDjapaNo ratings yet

- Audi 6.3l W12 FSI Engine: Self Study Programme 490Document44 pagesAudi 6.3l W12 FSI Engine: Self Study Programme 490georgescuriosNo ratings yet

- Thriller EnglishDocument69 pagesThriller EnglishJorge GonzaNo ratings yet

- Ultrasonic Cleaner S-700 - HM, 230VDocument2 pagesUltrasonic Cleaner S-700 - HM, 230VSlava KopytovNo ratings yet

- Motion and Machinery: Displacement, Velocity and Acceleration, Linkage and ConstraintsDocument41 pagesMotion and Machinery: Displacement, Velocity and Acceleration, Linkage and ConstraintsJhEan LoUiseNo ratings yet

- Industrial AutomationDocument2 pagesIndustrial Automationsarath kcNo ratings yet

- Commercial CO Refrigeration Systems: Guide For Subcritical and Transcritical CO ApplicationsDocument44 pagesCommercial CO Refrigeration Systems: Guide For Subcritical and Transcritical CO ApplicationsChrise5502No ratings yet

- Haulm Cutter: Solves Problems Before Mechanical Harvesting!Document6 pagesHaulm Cutter: Solves Problems Before Mechanical Harvesting!FabianoNo ratings yet

- Sistem Pegas MassaDocument40 pagesSistem Pegas MassaLisaFu98No ratings yet

- Lecture PDFDocument7 pagesLecture PDFRitikNo ratings yet

- Intellisys SSR SeriesDocument50 pagesIntellisys SSR SeriesJesus GCNo ratings yet

- Units and Measurements. NEET 01docxDocument2 pagesUnits and Measurements. NEET 01docxWesNo ratings yet