Professional Documents

Culture Documents

Rail Case Study 2015 Vfinal

Uploaded by

rfvz6sCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rail Case Study 2015 Vfinal

Uploaded by

rfvz6sCopyright:

Available Formats

ENVIRONMENTAL CASE STUDY

High-speed rail

The World Steel Association (worldsteel) case studies use a life cycle assessment (LCA) approach to measure the potential

greenhouse gas impacts from all stages of manufacture, product use and end-of-life. worldsteel has developed this case

study to demonstrate the reduction of CO2 emissions through the use of high-performance steels.

High-speed rail networks: A

sustainable steel solution

The need for efficient and sustainable transport infrastructure has

led to significant growth in the development of high-speed rail

networks. High-speed rail offers competitive door-to-door travel

times and reduces traffic congestion on heavily used routes.

Rail helps to reduce the environmental impact of transport and

contributes to a low-carbon economy.

This case study demonstrates the role of high-speed rail in a

sustainable transport system. It highlights the importance of steel,

as a material, in supporting growth in this sector.

The advantages of train travel

The global trend towards urbanisation has resulted in more

movement between cities and towns. Rail is an attractive travel

option for short distances because of the convenience of citycentre railway stations. By contrast, air travel requires access to

airports that are usually located at a significant distance from citycentres. Adding to this, check-in time, security checks and queuing

before boarding contribute to making the journey considerably

longer.

Studies have shown that travel by rail can be faster than air travel

for short journeys. For example, the introduction of a high speed

rail link between Brussels and Paris has reduced door-to-door

travel times by around 50% compared to air travel. For business

travellers, rail is more convenient because it minimises disruption

to the working day. The combination of speed, safety and

convenience result in increased economic activity and sustainable

transport.

The environmental impact of transport

Medium haul

Long haul

Short haul

Air travel

High-speed train, coal-fired electricity

Non-fossil electricity

Passenger train

High-occupancy city bus Low occupancy, high comfort

Buses/Trams

Single-occupant light truck

Two-occupant small car

Cars/Light trucks

50

100

150

200

250

300

350

400

g carbon dioxide per passenger-km

CO2 intensity of passenger transport, adapted from the IPCC special

report, Aviation and the Global Atmosphere1

Transport accounts for nearly 23% of energy-based CO2

emissions worldwide2, mainly due to road traffic. Total CO2

emisssions from transport have constantly increased since 1990

and all transport modes - except railways - have increased their

GHG emissions from fuel combustion.3

The graph above shows the CO2 emissions (grammes of carbon

dioxide per passenger-km) associated with different modes of

transport.

There are clear benefits to rail transport over the alternatives,

especially for regions that use a high proportion of non-fossil fuel

based electricity. The figure shows that (for short-haul distances

of up to 500 km) high-speed electric trains can reduce CO2

emissions by over 50% per passenger and per km compared to a

single occupant vehicle or an aircraft.

The role of steel in high-speed rail

Steel is an essential material in a high speed rail network. Steel

makes up 20-25% of the mass of high speed trains.4 The main

steel components of high speed trains are bogies (the structure

underneath the trains including wheels, axels, bearings and

motors). Freight or goods wagons are made almost entirely

of steel. Steel is also in the rail track sleepers and fasteners,

overhead power lines (catenary poles), bridges and stations.

A TGV train on a high-speed track in France

Rail tracks

worldsteel.org

ENVIRONMENTAL CASE STUDY

Over time, developments in the grades and quality of steels

have allowed the construction of lighter, safer and more efficient

networks. Innovations such as longer and straighter steel rails

mean that trains can now reach much greater speeds.

Environmental benefits

The high-speed network line (Ligne Grande Vitesse - LGV) linking

Dijon to Mulhouse will significantly reduce journey times in the

eastern region of France. Work started on the east branch in

2006. The first section of the track runs 140 km and was opened

in December 2011. When completed, the track will be 190 km

long.

A study of the east branch of the LGV by the French Environment

and Energy Management Agency and French railway operators

showed that there are significant carbon footprint benefits

associated with the transfer of passengers from road and air

transport.5

According to the study, steel applications on the network include:

27,000 tonnes of steel for structures (bridges, viaducts)

600 km of rails, i.e. 46,000 tonnes of steel, including rails and

catenary poles

56,000 tonnes of steel bar for reinforced concrete (civil

works, railway infrastructure).

For the lifetime of the rail line (30 years), the carbon footprints in

the various life cycle phases were calculated as follows:

There are further benefits with respect to lowering the local

environmental impact of building the LGV line. Measures have

been taken to reduce the impact on biodiversity and natural

resources, to reduce potential noise impacts, and to minimise the

impact on the landscape. The use of steel for the civil engineering

works here has the advantage of adopting dry construction

methods and minimising on-site waste.

Reuse and recycling

Steels durability enables rails to be reused by swapping over

the left and right rails on the track. When no longer suitable for

main-line use, rails can be tested for cracks and then reused on

secondary lines with lower traffic. Rails can also be recapped or

redesigned to extend their useful life.

Another important attribute of steel is that it is infinitely recyclable

without loss of properties. By recycling the steel track at the end

its life there is a significant reduction in the environmental impact

and energy cost associated with the material. When the rail and

track components reach the end of their useful life (typically 30

years6), almost 100% of the steel will be recovered.

Did you know?

On 21 April 2015, a Japanese bullet train set a new

world record by travelling at 603 km/h.

High-speed steel rail can be manufactured in

planning phase: 22 ktCO2 equivalent

continuous lengths of 120m, which reduces the

number of welds and joints and allows trains to travel

at greater speeds.

construction phase: 1.17 MtCO2 equivalent

Rail track is regularly reused by swapping over the

operation and maintenance phase: 685 ktCO2 equivalent

(including 635 ktCO2 equivalent for traction energy, based on

the French electricity mix).

left and right rails on a track.

Last updated: September 2015

The total carbon footprint of the rail line over 30 years of operation

is therefore estimated to be 1.87 MtCO2 equivalent.

There is a clear carbon footprint benefit from the east branch

of the LGV compared to the regions existing transport system.

Throughout the lifetime of the track, carbon savings from the

displacement of alternative transport options is approximately

4 MtCO2 equivalent emissions. Taking into account the carbon

footprint of the materials, construction and maintenance, the shift

in transport mode saves 2 MtCO2 equivalent emissions. This

saving is equivalent to the annual CO2 emissions from a large

French city with 200,000 inhabitants, such as Dijon.

Footnotes

1.

2.

3.

4.

5.

6.

IPCC Special Report on Aviation and the Global Atmosphere, 1999, http://www.ipcc.ch/ipccreports/sres/aviation, accessed April 2013.

International Energy Agency, CO2 Emissions from Fuel Combustion Highlights, 2014 Edition, p 10.

Railway Handbook 2012, Energy Consumption and CO2 Emissions, International Energy Agency (IEA) and the International Union of Railways (UIC).

Email 26 April, 2012, Siemens AG, Rail Systems Deivision, Communications.

1er Bilan Carbone ferroviaire global, ADEME, RFF and SNCF, first presented in 2009, Besanon, France.

Le Journal de Saint-Germain, No. 506, 6 April 2007, p.20. Corus, now Tata Steel.

worldsteel.org

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- 1 Medical Board Format ESE 091216Document6 pages1 Medical Board Format ESE 091216rfvz6sNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- (Referred To in Paragraphs 10.2.12, 10.2.15 and 10.2.28) : Hand ReceiptDocument2 pages(Referred To in Paragraphs 10.2.12, 10.2.15 and 10.2.28) : Hand Receiptrfvz6sNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Form21a PDFDocument1 pageForm21a PDFrfvz6sNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Form18 PDFDocument1 pageForm18 PDFrfvz6sNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- FORM24Document3 pagesFORM24Fayaz KhanNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Tools and Plant Ledger: (Referred To in Paragraphs 7.3.7 and 7.3.8)Document3 pagesTools and Plant Ledger: (Referred To in Paragraphs 7.3.7 and 7.3.8)rfvz6sNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- FORM23ADocument4 pagesFORM23Adinesh543No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- FORM27ADocument9 pagesFORM27AFayaz KhanNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- RAB, PaymentsDocument7 pagesRAB, Paymentsagrawalbs0% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- (Referred To in Paragraph 10.2.4 (H) ) : Casual Labour RollDocument1 page(Referred To in Paragraph 10.2.4 (H) ) : Casual Labour Rollrfvz6sNo ratings yet

- Form 19 Sale AccountDocument1 pageForm 19 Sale Accountrfvz6sNo ratings yet

- Register of muster rolls form 20Document1 pageRegister of muster rolls form 20rfvz6sNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- TOOLS AND PLANT INDENT FORMDocument1 pageTOOLS AND PLANT INDENT FORMrfvz6sNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Road metal rate book formDocument1 pageRoad metal rate book formrfvz6sNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Form 10 Summary of Indents Stock CreditsDocument1 pageForm 10 Summary of Indents Stock Creditsrfvz6sNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- (Referred To in Paragraph 7.2.31) : Priced Stores LedgerDocument3 pages(Referred To in Paragraph 7.2.31) : Priced Stores Ledgerrfvz6sNo ratings yet

- Form 10 Summary of Indents Stock CreditsDocument1 pageForm 10 Summary of Indents Stock Creditsrfvz6sNo ratings yet

- Form13 PDFDocument1 pageForm13 PDFrfvz6sNo ratings yet

- Referred To in Paragraphs 7.2.29, 22.4.2, 22.4.5 and 22.4.14 of CPWA CodeDocument1 pageReferred To in Paragraphs 7.2.29, 22.4.2, 22.4.5 and 22.4.14 of CPWA Coderfvz6sNo ratings yet

- Referred To in Paragraphs 7.2.29, 22.4.2, 22.4.5 and 22.4.14 of CPWA CodeDocument1 pageReferred To in Paragraphs 7.2.29, 22.4.2, 22.4.5 and 22.4.14 of CPWA Coderfvz6sNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Cash Balance Report: (Referred To in Paragraph 6.6.6)Document2 pagesCash Balance Report: (Referred To in Paragraph 6.6.6)rfvz6sNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Form08 PDFDocument2 pagesForm08 PDFrfvz6sNo ratings yet

- Government Receipt FormsDocument3 pagesGovernment Receipt Formsrfvz6sNo ratings yet

- Form 7 Stores IndentDocument3 pagesForm 7 Stores Indentrfvz6sNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Form 4: Register of Remittances Into Accredited BanksDocument1 pageForm 4: Register of Remittances Into Accredited Banksrfvz6sNo ratings yet

- W.E.F. - To - Certified That This Cash Book Contains - Pages Numbered From 1 ToDocument6 pagesW.E.F. - To - Certified That This Cash Book Contains - Pages Numbered From 1 Torfvz6sNo ratings yet

- FORM06Document2 pagesFORM06rfvz6sNo ratings yet

- Government Cash Memo FormDocument1 pageGovernment Cash Memo Formrfvz6sNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Imprest Cash Account FormDocument5 pagesImprest Cash Account FormrkthbdNo ratings yet

- W.E.F. - To - Certified That This Cash Book Contains - Pages Numbered From 1 ToDocument6 pagesW.E.F. - To - Certified That This Cash Book Contains - Pages Numbered From 1 Torfvz6sNo ratings yet

- High Speed Rail London To The West Midlands and Beyond HS2 Technical SpecificationsDocument104 pagesHigh Speed Rail London To The West Midlands and Beyond HS2 Technical SpecificationsHighSpeedRailNo ratings yet

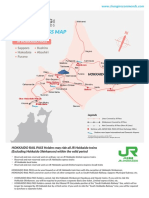

- HokkaidocontentmapDocument1 pageHokkaidocontentmapTee Shi FengNo ratings yet

- High Speed in WorldDocument6 pagesHigh Speed in Worldmehmet nedimNo ratings yet

- Japan Report - UICDocument7 pagesJapan Report - UICSujith SurendranNo ratings yet

- Engineering PaperDocument4 pagesEngineering Paperapi-378489409No ratings yet

- 520EDocument67 pages520EminchanmonNo ratings yet

- Altamont Revival Press ReleaseDocument3 pagesAltamont Revival Press ReleaserobertianNo ratings yet

- Dallas City Council High Speed Rail PresentationDocument38 pagesDallas City Council High Speed Rail PresentationKBTXNo ratings yet

- Magnetic Levitation AbstractDocument6 pagesMagnetic Levitation Abstractkkkoundi0% (1)

- KCJB Property Development - Potential PartnersDocument29 pagesKCJB Property Development - Potential PartnersAndrie IstiyaNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Between Permeability and IsolationDocument24 pagesBetween Permeability and IsolationYassir El aidouniNo ratings yet

- ERTMS/ETCS - Indian Railways Perspective: P Venkata Ramana, IRSSE, MIRSTE, MIRSEDocument6 pagesERTMS/ETCS - Indian Railways Perspective: P Venkata Ramana, IRSSE, MIRSTE, MIRSENitheesh Omanakuttan NairNo ratings yet

- Optimum Speed For High Speed LinesDocument159 pagesOptimum Speed For High Speed Lineshoneydew0No ratings yet

- Uddevalla Railway Noise Conference ProgrammeDocument12 pagesUddevalla Railway Noise Conference ProgrammeSajid IqbalNo ratings yet

- Russia Infrastructure Report - Q1 2023Document44 pagesRussia Infrastructure Report - Q1 2023saim siamNo ratings yet

- HSRA14 - Petition Coram Nobis - With ExhibitsDocument55 pagesHSRA14 - Petition Coram Nobis - With ExhibitsStuart M. FlashmanNo ratings yet

- "PAULVÉ" Switch Position Detector: "The Most Reliable Detection, Is Always The Closest To The Switch Rail"Document2 pages"PAULVÉ" Switch Position Detector: "The Most Reliable Detection, Is Always The Closest To The Switch Rail"David GalanNo ratings yet

- Eurnex Whoswho FinalDocument75 pagesEurnex Whoswho FinalArif YilmazNo ratings yet

- Us Bahasa Dan Sastra Inggris 2020 Soal ADocument13 pagesUs Bahasa Dan Sastra Inggris 2020 Soal ANickolaus NicNicNo ratings yet

- Fitch Egypt Country Risk Report - 2023-05-24Document55 pagesFitch Egypt Country Risk Report - 2023-05-24SwissFm Cleaning CaptainsNo ratings yet

- KcicDocument22 pagesKcicRaymond Pakur100% (2)

- Municator Sample Paper 2Document18 pagesMunicator Sample Paper 2Cesar A. MartinezNo ratings yet

- Simply Supported Composite Railway Bridge: A Comparison of Ballasted and Ballastless Track AlternativesDocument175 pagesSimply Supported Composite Railway Bridge: A Comparison of Ballasted and Ballastless Track AlternativesdeathesNo ratings yet

- Full Catalogue HiwinDocument128 pagesFull Catalogue Hiwingraham4877100% (1)

- Teaching any child to become talented in music or sportDocument13 pagesTeaching any child to become talented in music or sportReaz MorshedNo ratings yet

- MaglevDocument10 pagesMaglevCaramihai DenisNo ratings yet

- GC7 Eng LODocument36 pagesGC7 Eng LOdmitry esaulkovNo ratings yet

- Chinese Railways in the Era of High-Speed by Zhenhua Chen, Kingsley E. Haynes (z-lib.org)Document279 pagesChinese Railways in the Era of High-Speed by Zhenhua Chen, Kingsley E. Haynes (z-lib.org)genico_68No ratings yet

- Competition Between High-Speed Rail and Air Transport in Iran - The Case of Tehran – IsfahanDocument29 pagesCompetition Between High-Speed Rail and Air Transport in Iran - The Case of Tehran – IsfahanFADIL ABDULLAHNo ratings yet

- High Speed Rail Assessment, Phase IIDocument412 pagesHigh Speed Rail Assessment, Phase IImarinaNo ratings yet

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingFrom EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingRating: 5 out of 5 stars5/5 (4)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingFrom EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingRating: 3.5 out of 5 stars3.5/5 (33)

- Wayfinding: The Science and Mystery of How Humans Navigate the WorldFrom EverandWayfinding: The Science and Mystery of How Humans Navigate the WorldRating: 4.5 out of 5 stars4.5/5 (18)

- World of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsFrom EverandWorld of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsRating: 4 out of 5 stars4/5 (221)

- Eels: An Exploration, from New Zealand to the Sargasso, of the World's Most Mysterious FishFrom EverandEels: An Exploration, from New Zealand to the Sargasso, of the World's Most Mysterious FishRating: 4 out of 5 stars4/5 (30)

- The Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorFrom EverandThe Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorRating: 4.5 out of 5 stars4.5/5 (137)

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseFrom EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseRating: 3.5 out of 5 stars3.5/5 (69)