Professional Documents

Culture Documents

CIEAM APCC Assets Condition Auditing PDF

Uploaded by

ayad60Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CIEAM APCC Assets Condition Auditing PDF

Uploaded by

ayad60Copyright:

Available Formats

Best Practice in

Integrated Engineering

Asset Management

2008 CIEAM

AAMCoG Best Practice

The Australian Asst Management Collaborative Group (AAMCoG)

The Australian Asset Management Collaborative Group (AAMCoG) was formed in August

2006 by the CRC for Integrated Engineering Asset Management (CIEAM). AAMCoG is a

collaboration of several of Australias peak bodies interested in work programmes in asset

management. AAMCoGs mission - Facilitate collaboration between interested organisations

to promote and enhance asset management for Australia.

Members of AAMCoG aim to:

Collaborate nationally on asset management strategies between all asset management

groups

Coordinate transfer of technology and knowledge sharing of asset management R&D

Promote skills development in asset management

Host the annual National Forum for Asset Management

Act as a communication channel between member bodies

Inform asset owners/custodians of the critical aspects of whole of life asset

management

For further details, please refer to the AAMCoG Website www.aamcog.com

Acknowledgments

The CRC for Integrated Engineering Asset Management (CIEAM) would like to

acknowledge the financial support from the Commonwealth Governments Cooperative

Research Centres Programme and the contributions from our industry, government and

university participants.

CIEAM would also like to acknowledge the following contributions to this project:

Dr. Fred Stapelberg of CIEAM

Mr Graham Carter of the APCC

This project was undertaken under the guidance of Professor Joseph Mathew chair of

AAMCoG and Professor Kerry Brown, Executive Officer, AAMCoG.

Confidentiality

In accordance with Australian freedom of information legislation, all information collected as

part of this study will be retained for seven years in a safe and secure environment. Paperbased data will be stored in a locked filing cabinet, and electronic data will be encrypted and

stored at CIEAM Head Office, Brisbane.

Disclaimer

AAMCoG members make use of this report or any information provided by CIEAM at its

own risk. CIEAM will not be responsible for the results of any actions taken by members or

third parties on the basis of the information in this report, or other information provided, nor

for any errors or omissions that may be contained in this report. CIEAM expressly disclaims

any liability or responsibility to any person in respect of anything done or omitted to be done

by any person in reliance on this report or any information provided.

Enquiries

Communication Officer/ Jane Davis

CRC for Integrated Engineering Asset Management

Level 7, O Block, QUT Gardens Point campus

GPO Box 2434

BRISBANE QLD 4001

2008 CIEAM

Phone: +617 3138 1471

Fax: +617 3138 4459

Email: jane.davis@cieam.com

AAMCoG Best Practice

CONTENTS

Page:

INTRODUCTION

1.

Assets Condition Assessment and Analysis

2.

Assessment Criteria for Assets Condition

16

3.

Conducting Assets Inspections and Surveys

21

4.

Assets Condition Scoping, Profiling and Modelling

47

5.

Assets Health Monitoring and Life Cycle Management

58

6.

Assets Life Cycle Analysis and Life Cycle Costing

71

7.

Assets Usage Life Cycle and Maintenance Planning

76

8.

Assets Maintenance Management and Optimisation

88

9.

Establishing Assets Condition Auditing Benchmarks

107

10.

Assets Condition Audit and Maintenance Reporting

117

REFERENCES

2008 CIEAM

126

AAMCoG Best Practice

P a g e |1

Introduction

Collectively the Commonwealth, State, Territory and Local Government Authorities

are the largest owners of built assets in Australia. The replacement value of

government assets is over $371 billion and each year over $18 billion is spent on

maintenance of the assets. These assets are the major element of governments

balance sheets and underpin their individual credit ratings. Asset maintenance is

therefore clearly a key strategic function that must be properly planned and managed.

At present there is no nationally accepted regime for condition auditing and

maintenance planning. Asset planning and management is a critical issue for the

public sector at all levels of Government. The adoption of a consistent, national model

for condition auditing and maintenance planning would greatly enhance

understanding of this issue and overcome some of the barriers that often result in

inadequate funding being provided for asset maintenance budgets.

The whole of Government and individual Government Agency maintenance plans for

assets needs to be based on a uniform, cyclical assessment of the actual condition of

assets, compared to the desired standard of condition for individual asset portfolios.

This assessment program must provides consistent, quantitative and qualitative

information relating to asset performance in terms of condition and associated risks.

The assessments establish the maintenance necessary to meet the standard, and define

the base-line for determining the adequacy and effectiveness of maintenance over

both the preceding and subsequent cycles. The basic principles of asset management

represent current thinking with national asset owners as well as professional

organisations representing asset owners.

The principle that: Government Agencies must report on the usage, maintenance and

performance of their assets, is among the important asset management principles that

have been developed by the APCC to enable asset management to be integrated into

the mainstream of Government and Government Agency business planning. The

APCC considers the inter-relationship between an assets physical condition,

functionality, and compliance, as criteria for integrated condition auditing and

maintenance planning, where:

Physical Condition can be considered the physical state of the asset including

the weather-tightness, structural stability/integrity and security that is required.

Functionality can be considered the way in which an asset has been designed,

modified and/or developed and the extent to which it currently meets the

contemporary functional needs of the occupants.

Compliance can be considered the extent to which an asset complies with

statutory design and operational requirements.

The assets condition auditing process defines objectives; prioritises assets for which

assets condition assessment and auditing is to be carried out; identifies the asset

degradation and failure modes to determine condition and end-of life criteria;

provides best practices; analyses and assesses asset condition; and verifies/audits that

the asset condition assessment results reflect actual field conditions.

2008 CIEAM

AAMCoG Best Practice

P a g e |2

The overall asset condition auditing plan documents the evaluated condition of the

organisations assets based on condition criteria and end-of-life criteria that are

indicative of the status of the assets condition. Condition audits are also conducted to

establish the condition of physical assets before any decision is made to purchase

(such as pre-acquisition surveys for buildings); to assess degradation after a period of

use; and to establish the maintenance condition of physical assets before asset owners

commit to major maintenance action and/or lump sum maintenance contracts.

When considering condition assessments in the assets condition auditing process, it is

important to understand the differences between defect maintenance management and

regular maintenance planning for assets preservation in contrast to long term

maintenance planning for assets rehabilitation. It is this assessment of assets condition

in the assets condition auditing process that will provide the appropriate types of

assets maintenance, particularly in planning regular maintenance for assets

preservation compared to long term maintenance plans for assets rehabilitation.

Assets condition assessment is an essential part of managing physical assets.

Condition assessment of physical assets can be defined as the technical assessment of

the operational and physical conditions of an asset, using a systematic method

designed to produce consistent, relevant and useful information. A principal objective

of condition assessment is to provide sufficient information on the condition of

physical assets for strategic assets planning decision-making in order to capitalise and

depreciate physical assets based on residual value, rather than expense them against

earnings. Condition assessment assists in reporting changes in physical asset service

levels, identifying candidate assets for renewal treatment, selecting the optimum

renewal treatment and as an input into modelling of future condition and service

levels and funding scenarios. Condition assessment procedures are intended to

measure asset degradation, the criticality of the degradation, and asset remaining life.

Condition assessment is also often used to assess the useful life of physical assets.

Whilst common condition indicators have been in existence for some years,

converting these indicators to verifiable remaining life and overall useful life remains

a significant difficulty and a source of major variations in practice. Many of the

mechanistic models upon which estimates of remaining life of physical assets are

based, are far from perfect because of the lack of reliable data available to validate

these models. Condition assessment however can be a reliable tool for determining

the remaining life of physical assets, where the assets are nearing the end of their life.

An understanding of the failure as well as degradation processes of physical assets is

necessary to establish sensible condition assessment criteria and to define asset

remaining life. The condition assessment process for physical assets should, as a

minimum, rate asset operational and physical condition, determine the risks associated

with continual usage of an asset in such condition, and identify the type of

maintenance needed to retain or restore an assets required condition. Condition

assessment results, together with asset functionality, utilisation and cost

considerations, are used to support a wide range of strategic assets planning decisions

particularly in relation to assets operational and physical function performance and

assets maintenance strategies.

2008 CIEAM

AAMCoG Best Practice

P a g e |3

An assets condition survey or condition auditing, is a systematic process of evaluating

the condition of physical assets. This is to establish whether the physical assets are

capable of continually supporting service needs and statutory requirements in the

medium and long term. Surveys are also conducted to assess the ability of physical

assets to satisfy internal expectations and external benchmarks. An objective of assets

condition surveys is also to establish any remedial action required to bring physical

assets up to the expected conditions (such as modifications, refurbishment and

replacements), to identify their relative priorities and to propose a programme of

maintenance action. Assets condition surveys help to plan for the necessary resources

to maintain the assets before any functional failure might occur.

The assets condition assessment planning process defines objectives; prioritises assets

for which assets condition assessment is to be carried out; identifies the asset

degradation and failure modes to determine condition and end-of life criteria;

provides industry practices; analyses and assesses asset condition; and verifies/audits

that the asset condition assessment results reflect actual field conditions. The overall

asset condition assessment plan documents the evaluated condition of the

organisations assets, based on condition criteria and end-of-life criteria that are

indicative of asset condition and consistent with industry practices.

When considering assets condition assessment, it is important to understand the

differences between defect maintenance, as well as routine and preventive

maintenance, especially for assets repair, preservation, rehabilitation or replacement.

Defects are usually well defined and associated with failed or defective components

that affect the use and reliability of the asset well before its end-of-life. These do not

normally affect the life of the asset itself, if detected early and corrected. Defects are

regularly identified during inspection and dealt with through maintenance activities to

repair or replace failed components to ensure continued effective use of the asset.

Long term degradation is generally less defined and is not easily determined by

routine inspection. The main purpose of asset condition assessment is to detect and

quantify long-term degradation and provide some means of quantifying remaining

asset life. This includes identifying assets that are of high risk or at their end-of-life,

that will require major capital expenditure to either refurbish, replace, or eliminate

altogether. Condition assessment procedures are intended to measure asset

degradation, the criticality of the degradation, and the remaining asset life. A

reasonable understanding of the degradation and failure processes is required to

establish sensible assessment criteria or to define appropriate end-of-life criteria.

2008 CIEAM

AAMCoG Best Practice

P a g e |4

1. Assets Condition Assessment

and Analysis

Condition Assessment of Physical Assets

Condition Assessment of physical assets can be defined as the technical assessment of

the operational and physical conditions of an asset, using a systematic method

designed to produce consistent, relevant and useful information. A principal objective

of Condition Assessment is to provide sufficient information on the condition of

physical assets for strategic assets planning decision-making in order to capitalize and

depreciate infrastructure assets based on residual value, rather than expense them

against earnings. Condition Assessment procedures are intended to measure asset

degradation, the criticality of the degradation, and asset residual life. An

understanding of the failure as well as degradation processes of physical assets is

necessary to establish sensible Condition Assessment criteria and to define asset

residual life. The Condition Assessment process for physical assets should, as a

minimum, rate asset operational and physical condition, determine the risks associated

with continual usage of an asset in such condition, and identify the type of

maintenance needed to retain or restore an assets required condition. Condition

Assessment results, together with asset functionality, utilisation and cost

considerations, are used to support a wide range of strategic assets planning decisions

particularly in relation to assets operational and physical function performance and

assets maintenance strategies.

Attributes of Assets Condition:

There are a number of attributes that are used to assess the condition of physical or

tangible capital assets, such as (PSAB, 2007):

Physical condition - the condition of an asset that enables it to meet intended

service or operational levels. The physical condition of a tangible asset can be

compared to its ability to meet original design standards. The assessment of

the condition of a physical asset should reference its operational and physical

characteristics and technical, engineering and other specifications. It should

also take into consideration the assets durability; the quality of its design and

manufacture / construction; its use; and the assets design maintainability and

adequacy for required maintenance.

Demand/capacity - the capacity of the asset to meet existing application

requirements. Demand/capacity is related to asset performance. Measuring this

attribute would involve establishing subjective baseline service or operational

levels against which to measure actual performance. The demand/capacity

attribute brings into scope the assets efficiency and effectiveness measures.

Functionality - the ability of the asset to meet service or operational delivery

requirements. Functionality is closely aligned with the assets whole-of-life

performance measures such as early life, useful life, and wear-out or residual

life operational performance.

2008 CIEAM

AAMCoG Best Practice

P a g e |5

It is recognized that none of these attributes are mutually exclusive. For example,

physical condition may have an impact on an assets ability to meet service or

operational delivery requirements.

Benefits and Risks of Condition Assessment:

There are definitive benefits or risks in performing effective or ineffective condition

assessment of physical assets. These are (SAM, 2007):

Benefits - The benefits of performing effective condition assessment include;

the adequacy of existing maintenance and capital funding can be established

and evaluated;

asset condition trends can be analysed;

asset condition can be reported to Government in a consistent format;

maintenance programs can be effectively targeted and prioritised;

current maintenance liabilities and emerging maintenance requirements can be

identified and quantified;

the effectiveness of prevailing maintenance strategies can be assessed and

adjusted if necessary;

strategic asset planning processes can be enhanced by information on future

liabilities.

Risks - The risks associated with non-performance or ineffective condition

assessment include;

declining asset condition is not identified and addressed;

maintenance planning is not related to asset needs;

asset condition cannot be adequately reported;

deferred maintenance liability and provisions for future maintenance

requirements cannot be reported in financial statements;

maintenance demand is not properly identified;

poor quality of data leading to poor decision-making;

serious deficiencies can be overlooked;

information gathered on asset condition could be misleading;

resources are not used effectively.

The Assets Condition Assessment Process:

A whole-of-government Maintenance Management Framework (MMF) has been

introduced in Queensland, from the second half of 1999. The MMF has established a

framework for the maintenance of government assets (i.e. buildings) to ensure

consistency in the planning, implementation and reporting of a physical Assets

Maintenance Plan. The whole-of-government reporting mechanism is based on input

from public assets maintenance performance which flows through to maintenance

policy, standards and strategy setting; maintenance strategic planning; and

maintenance implementation. Condition assessment, along with budget allocation,

stem from the policy, standards, planning and strategy framework, to make up a

maintenance works program.

2008 CIEAM

AAMCoG Best Practice

P a g e |6

Figure 1 illustrates the Maintenance Management Framework (MMF) flow diagram.

Figure 1. Maintenance Management Framework Flow Diagram

(SAM, 2007)

The condition assessment process can be separated into a series of four phases aimed

at providing useful information on the physical condition of an asset. The phases are

interrelated and the success of each phase impacts on, and contributes to, the success

of succeeding phases. Figure 2 illustrates the four phases of the condition assessment

process.

Figure 2. The Four Phases of the Condition Assessment Process

(SAM, 2007)

Define Condition Assessment Objectives:

Defining the objectives of condition assessment is essential in providing a clear

direction for the assessment process. Government Agencies need to have a clear

understanding of why the assessment is being undertaken, and how the findings are

intended to be used.

2008 CIEAM

AAMCoG Best Practice

P a g e |7

This will allow the outcomes and specific outputs of the assessment process to be

properly defined. Well defined assessment objectives will assist in determining;

the type of information required

the level of accuracy necessary

the assessment method to be used

the frequency with which data should be collected

the manner in which the assessment will be conducted.

Condition data can be expensive to collect and manage, and has a limited useful life.

Therefore, only data essential to the assessment objectives should be collected.

Define Condition Assessment Standards:

Government Agency core service strategies enable asset service requirements and

future service potential to be determined. Performance standards for an asset can then

be established based on the significance that an asset has in supporting core business.

Factors such as criticality, utilisation and functionality are key considerations in

determining asset performance standards. Once a performance standard for an asset is

determined, a corresponding minimum standard for asset condition can be defined.

Planning for Condition Assessment:

Condition assessment is generally a planned activity, involving a number of persons

in a systematic review of a physical asset that has been identified for assessment.

Planning for condition assessment of physical assets usually includes a determination

of the assets to be initially inspected and the inspection intervals. The objectives of

the assessment and the type of asset will determine the approach to be employed and

the items that need to be inspected.

Assets Condition Inspection:

Asset inspection is the primary activity undertaken as part of a condition assessment.

The level of detail and accuracy of information that can be obtained from an

inspection can vary depending on the assessment method used. Assessment methods

can range from a survey, which provides fairly broad information, to a detailed audit,

which provides a more comprehensive level of detail. The depth of asset inspection

will be guided by the assessment objectives and resources available. The assessment

method chosen should produce the outputs required as per the objectives, deliver

consistent results, and be cost effective.

Some of the key activities that need to be considered when planning for assets

condition inspection are;

allocating sufficient and appropriately skilled resources;

reviewing the asset register, drawings, manuals, etc and outstanding

maintenance tasks;

consulting the asset occupants to arrange access at an appropriate time;

determining how inspection will be carried out;

selecting an appropriate data collection method;

choosing the method for data processing and analysis.

2008 CIEAM

AAMCoG Best Practice

P a g e |8

Items to be inspected - Where funds are limited and an indicative assessment is

required, a survey of an asset can yield quick results without a detailed inspection of

individual components. However, in many instances, assessing the condition of an

asset will be more manageable if an asset is broken down into smaller components.

The level to which an asset may need to be broken down will depend on the degree of

accuracy and detail that needs to be achieved. Items that would normally be

individually assessed can be broadly grouped into the physical asset structure and

constituency; related support services (electrical, mechanical, hydraulics, etc.); and

related infrastructure support/services. These items can then be individually inspected,

assessed and the results aggregated to give an overall indication of asset condition.

The Cost Control Manual of the Australian Procurement and Construction Council

(APCC), formerly known as the National Public Works Council, provides an accepted

industry standard for the breakdown of an asset into elements and sub-elements and

may be used for this purpose. Conducting trials on sample assets can be a useful

means to test proposed inspection and assessment techniques. Results can be

compared for quality and consistency, and techniques reviewed if necessary.

Inspection intervals - If a number of assessments are to be undertaken over time, an

initial inspection should be undertaken as early as possible in the life of an asset, to

determine a baseline condition which can be used as a reference point for future

comparisons. The interval between subsequent inspections, which can be used to

reveal a trend in asset condition over time, needs to be carefully planned. The

inspection interval needs to ensure that inspections capture any significant changes in

asset condition before they can impact on asset performance. Factors that can affect

the required interval include;

complexity;

age;

location;

environmental factors;

asset usage.

Government Agencies should formulate asset inspection requirements, taking the

above factors into consideration. Since the data from inspections may be used for

maintenance work programs, asset life cycle planning, assets strategic planning, assets

usage logistic support, as well as reporting requirements, an asset should be assessed

on a cyclical basis which supports these needs.

Assets Condition Assessment Surveys:

A survey usually involves a broad appraisal which produces a relatively fast scan of

asset condition. It is generally used where a quick result is required, funding is

limited, and assets are less complex. The inspection can be carried out by technical or

non-technical personnel. A survey can be conducted using a questionnaire process in

which asset occupants or appraisers provide feedback, particularly about the state and

maintenance needs of assets. The results of the survey can then be analysed. However,

caution is required when using the results of this approach due to the limited depth of

the inspection. Survey results can be subjective and inconsistent according to the

varying interest and expertise of the respondents.

2008 CIEAM

AAMCoG Best Practice

P a g e |9

Assets Condition Assessment Audits:

An audit is a more structured inspection approach which provides consistent,

quantitative and qualitative information relating to asset performance in terms of

condition and associated risk. The audit involves a detailed appraisal of an asset by

competent qualified personnel. Detailed audits are recommended where an asset is

complex or when comprehensive information is required. An audit of a complex asset

is normally carried out by assessing an assets individual elements. Elements are

inspected and their actual condition relative to the desired condition standards is then

reported in detail. Any deficiencies in asset condition, together with the associated

risks, can then be evaluated.

Assets Condition Rating:

Inspections should be performed to enable a rating for asset condition to be applied.

The rating provides an indication of the gap between actual asset condition and that

which has been specified. In the case where the condition assessment findings are to

be used in the development of an asset maintenance program, the following

information should be collected;

the presence of any defect (existing or potentially arising within the period

of the maintenance plan, usually three to five years);

the nature of the defect;

the location of the defect;

how the defect should be corrected (e.g. adjust, repair, replace etc.);

the quantity of corrective work (for estimation and specification purposes);

the remedial cost for each defect;

when the defect should be addressed (i.e. immediately, or when required).

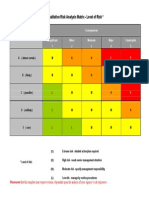

Assessing the Risk of Asset Condition:

The direct risks associated with asset condition should also be assessed. This

assessment should be based on both the likely impact and the probability of an event

occurring as a direct result of asset condition. The need to bridge the gap between

existing and desired conditions can then be considered, taking into account the risks

associated with leaving an asset to remain in its existing condition. A risk rating is

assigned based on an assessment of the risks resulting from the condition of the asset

inspected. Risks that must be considered include those that relate to workplace health

and safety; security; functionality; financial impacts (including cost of consequential

damage); and legal exposure.

Condition Assessment Standards:

Condition Assessment initially includes a physical inspection of the asset equipment

(sub-systems, assemblies and components) using specialised NDT tools such as

ultrasonic and laser techniques as well as magnetic field measurements that produce

data describing the condition of the equipment providing evidence of various types of

wear or damage on a macro- and micro-scale. The data is usually analysed to

characterise the variability of operating parameters such as potential, flow,

temperature, pressure or capacity fluctuations, from which related physical damage

can be assessed.

2008 CIEAM

AAMCoG Best Practice

P a g e | 10

Condition Assessments are fundamentally evaluations of a physical assets service or

operating inefficiency, evaluation of asset equipment damage, and prediction of asset

residual life. This includes a determination of what possibly caused the operational

inefficiency or physical damage; what exactly the damage is and through which

mechanisms the damage developed; if the asset equipment has not yet failed, then

what the estimated residual life would be, considering a specific damage mechanism;

and what operating recommendations would prevent damage in the future, or allow

continued operation in the short term.

Condition Assessments also include engineering evaluation of the physical condition

of an assets equipment in which a flaw has been detected. The focus of such an

evaluation is to determine if the assets equipment can continue in service, and if so,

for how long. Industry standards such as API 579-1/ASME FFS-1 specify a

quantitative procedure for determining fitness-for-service (FFS) of different types of

industrial asset equipment, however not all equipment are covered by such standards.

In cases where no standards exist, a semi-quantitative or qualitative approach to

residual life prediction is used to determine whether the equipment could continue in

service (API, 2007).

Assessment methods and procedures in Standard API 579-1/ASME FFS-1 can be

used for fitness-for-service assessments and/or re-rating of asset equipment designed

and manufactured/constructed to recognised codes and standards. The Standard has

broad application since the assessment procedures are based on allowable stress

methods and plastic collapse loads for non-crack-like flaws, as well as applying the

Failure Assessment Diagram (FAD) approach for crack-like flaws. Fitness-for-service

assessment procedures cover both the present integrity of an assets equipment, given

a current state of damage, and the projected remaining or residual life. The assessment

procedures in the Standard can be used to evaluate flaws commonly encountered in

pressure vessels, piping and tankage.

Assessment techniques are included to evaluate flaws including general and localised

corrosion; widespread and localized pitting; blisters and hydrogen damage; weld

misalignment and shell distortions; crack-like flaws including environmental

cracking, laminations, dents and gouges; and remaining life assessment procedures for

components operating in the creep range. In addition, evaluation techniques are

provided for condition assessment of asset equipment including resistance to brittle

fracture, long-term creep damage, and fire damage. The procedures are not intended

to provide a definitive guideline for every possible situation that may be encountered.

However, flexibility is provided in the form of an advanced assessment level to

handle uncommon situations that may require a more detailed analysis.

The Standard API 579-1/ASME FFS-1 is intended to supplement and augment the

requirements in the following standards;

API 510 - Pressure Vessel Inspection Code;

API 570 - Inspection, Repair, Alterations and Re-rating In-Service Piping

Systems; API 653 Tanks Inspection, Repair, Alterations and

Reconstruction;

Post construction codes that reference FFS evaluations such as NB-23.

2008 CIEAM

AAMCoG Best Practice

P a g e | 11

Record, Analyse and Report Findings:

Recorded data needs to be appropriately stored where it can be readily accessed for

analysis, planning and reporting purposes. A suitable method for recording the data

would have been established in the planning phase. There is increasing use of

electronic devices which enable data transfer to occur quickly and accurately. Data

should be stored within a management system capable of handling the quantity of

information to be collected both at time of inspection and in the future.

If assets condition assessments are being carried out by different persons, particularly

in different geographic locations, it is important that data collected is checked for

consistency, and any variations or discrepancies rectified. The objectives of the

condition assessment will determine the type of data analysis to be undertaken.

Examples of analyses include:

Statistical analysis of condition ratings to identify an average condition across

a portfolio of assets, and the range from worst to best condition

Sorting of data into particular categories, e.g. asset location or type, to enable

comparisons to be made

Analysing condition trends over time to assess the effectiveness of

maintenance strategies, detect asset deterioration, or evaluate the adequacy of

works program budgets

Prioritisation of identified remedial works to enable the development of works

programs (e.g. maintenance, capital improvements, refurbishment, etc).

Presentation of the assessment results should focus on establishing a priority of the

works. Priority ranking should result in works with the greatest deviation between

desired and actual condition and the largest risk being allocated the highest priority.

Condition assessment findings can be reported on and used in a range of strategic

asset planning and management processes. For example, findings are used in the

development of maintenance plans, capital investment strategic plans, disposal plans,

and in asset portfolio planning.

Condition Assessment Performance Measurement:

Condition assessment plays a crucial role in the strategic management of assets. It is

important therefore that the performance of the assessment is evaluated against

predetermined performance indicators.

Some useful indicators are;

achievement of condition assessment objectives;

cost of assessment, including any variations from expected costs;

time taken to complete assessment against projected time frame;

quality of information gathered, including accuracy and consistency;

disruptions or inconvenience to building occupants;

level of building occupant input into assessment.

2008 CIEAM

AAMCoG Best Practice

P a g e | 12

Analysis of Assets Condition Assessment

Attributes of Assets Condition:

There are a number of attributes that may be used to analyse condition assessments of

physical (tangible) capital assets, such as (PSAB, 2007):

Physical condition the condition of an asset that enables it to meet intended

service levels.

Demand/capacity the capacity of the asset to meet existing service

requirements.

Functionality the ability of the asset to meet program delivery

requirements.

It is recognised that none of these attributes are mutually exclusive. For example,

physical condition may have an impact on an assets ability to meet service and

program delivery requirements.

Analysis of Physical Condition Assessment of Tangible Capital Assets:

Reporting on physical asset condition is useful information that is currently missing

from financial reports. It will assist in drawing conclusions about the effect that

funding of maintenance and renewal is having on the overall physical condition of

tangible capital assets. It is also the first step to drawing conclusions about the

management of resources and future revenue requirements to maintain, renew and

replace tangible capital assets, and the affordability and sustainability of services.

The benefits of performing physical condition assessments on tangible capital assets

are that it;

provides information for assessing the adequacy of existing maintenance,

renewal and replacement funding;

provides information for the analysis of asset physical condition trends;

reports on asset physical condition in a consistent format;

assists in targeting and prioritising asset management strategies;

provides information for identifying and quantifying maintenance, renewal

and replacement requirements;

allows for assessment of the effectiveness of asset management strategies;

provides information for strategic asset planning processes.

The physical condition of a tangible capital asset can be compared to its ability to

meet original design standards. Examples of assessments of physical asset condition

are typical for infrastructure assets. An assessment of the physical condition of

infrastructure assets form part of expense budgeting and costing of capital assets.

Subjectivity of physical condition assessment will be reduced and consistency and

comparability improved when based on a detailed physical inspection using

standardised, clearly defined methodology, pre-defined defect conditions, and

measurement scales to determine physical impairment of the tangible capital asset.

2008 CIEAM

AAMCoG Best Practice

P a g e | 13

Analysis of the asset condition assessment should be reliable and verifiable. Reliable

and verifiable analysis can be replicated to produce similar results, whereby

concurrence of the data is achieved with a reasonable degree of precision. Evaluation

of an assets physical condition should be completed with specific knowledge of the

asset, its performance capacity, and the expectations for its continued performance.

Analysis of an assessment of the physical condition of a tangible capital asset should

be completed by reference to physical characteristics and technical, engineering and

other specifications of the asset. Such analysis should take into consideration;

the quality of its design and construction;

the assets durability versus use or pattern of usage;

the adequacy of maintenance that has been performed.

It may not be possible to complete a physical examination of all tangible capital

assets. For example, it is not always possible to physically examine sub-surface pipes.

However, physical condition could be based on a combination of age, construction

materials and methods, breaks per kilometre, geological and soil conditions, etc.

Whatever predictive tool is used, a standardised, clearly defined methodology with

pre-established logical relationships between attributes and predicted condition

assessment should be employed. The results should be defensible using industry

standard best practice to predict asset conditions where they exist.

Physical Condition Assessment Scores:

Appropriate condition indicators can be developed for each type of asset equipment.

Condition indicators are qualitative scores based on tests, measurements, and

inspections that are performed during the condition assessment process. Results are

combined into a Condition Index with a scale of 1-10. Mid-to low-range values may

trigger actions such as a repair or physical condition evaluation. Such an evaluation

includes in-depth, non-routine tests that may be invasive and/or require specialised

equipment and expertise however, when performed, physical condition evaluation

adds confidence to the assessment results and conclusions. These results are used to

adjust the Condition Index score (either up or down). Figure 3 shows a typical

Condition Index score chart with suggested action (HAMP, 2006).

Figure 3. Condition Index Score Chart

2008 CIEAM

AAMCoG Best Practice

P a g e | 14

Demand/Capacity Analysis of Tangible Capital Assets:

Demand/capacity analysis is related to asset performance. For example, a bridge may

be in good physical condition, but is causing traffic congestion and delays during rush

hours because the current volume exceeds the bridges original design capacity.

Measuring this attribute would involve establishing subjective baseline service levels

against which to measure actual performance. Acceptable service levels can be

influenced by government policy making it difficult to establish consistency in

performance measures. As a result, it would affect the comparability of information

and consistency in reporting about asset condition. The demand/capacity analysis

attribute may also bring into scope efficiency and effectiveness measures. For

example, it might include information about how an existing water treatment plant is

working compared to new water treatment technology.

Functionality Analysis of Tangible Capital Assets:

Functionality analysis is often excluded from the scope of reporting on the condition

of assets. Functionality is closely aligned with asset usage measures. It is related to

issues such as whether or not tangible capital assets are meeting user expectations.

Such usage expectations are typically found in public transport and public facilities

(i.e. crowded public transport systems or waiting times in hospital emergency rooms).

Analysing these attributes would be based on acceptable service levels. Some

expectations of public infrastructure assets service could be over-optimistic and

unsustainable and governments would need to manage the expectations of the public.

It would thus be difficult to establish consistency in asset usage quality measures. As

a result, it would affect the comparability of information and reporting consistency of

assets condition.

Assets Performance Analysis:

Protecting service delivery potential and addressing health and safety concerns are

priorities when making decisions about asset use and maintenance. It is very

important, therefore, that asset performance be appropriately reviewed and evaluated

to verify that required outcomes are being achieved. The results of any performance

assessment need to be reported to management to identify any actions to be taken; and

to comply with the ongoing reporting requirements of Government, as well as with

corporate, business and asset planning processes. In addition to the assets usage

ability as a result of its physical condition, there are a number of measures used to

analyse the assessment of asset performance, specifically utilisation and functionality.

The following paragraphs describe the usage ability as a result of physical condition,

utilisation and functionality of physical assets as measures to analyse the assessment

of asset performance (VAMS, 2006).

Usage Ability as a Result of Physical Condition:

An asset should be able to be used safely and effectively. This means that it needs to

be maintained in a condition that is adequate for the purpose for which it is intended,

and that it complies with the relevant health and safety standards. If this is not the

case, the asset's ability to deliver services to the level and standard required will be

compromised. Physical condition assessments provide important inputs for

compliance with legislation and in planning for asset maintenance.

2008 CIEAM

AAMCoG Best Practice

P a g e | 15

A proper condition assessment of an asset will involve:

Setting the required condition of the asset relative to its service delivery needs

Inspecting the asset and comparing its condition with that required

Forecasting the future condition of the asset.

Utilisation of a Physical Asset:

Asset utilisation is a measure of how intensively an asset is being used to meet the

entity's service delivery objectives, in relation to the asset's potential capacity. To

assess utilisation, criteria and benchmarks appropriate to the services being delivered

and to the class of asset being considered, firstly need to be established. The criteria

should have regard to:

The value of the assets unit of service potential that is being used relative to

the units of service being delivered (e.g. the future economic benefit)

The physical measures of asset capacity relative to the units of service being

delivered (e.g. floor space relative to the type of activity)

The use being made of the asset relative to the optimal availability for the type

of asset (e.g. the number of hours used relative to the hours available).

The utilisation criteria should be based, wherever appropriate, on best practice data as

well as on the results of analyses undertaken either by the entity or elsewhere in the

private and public sectors. Under-utilised assets should be identified, and the reasons

for this examined. It may be, for example, that the asset is no longer effective in

performing the activities required of it or that it is in less than optimum condition. It

may also be that the need for the services it delivers or supports has reduced. The

following examples illustrate some of the technical reasons for under-utilisation;

physical constraints;

technological obsolescence.

Action should be taken either to improve the assets utilisation or to redeploy it

(provided that service delivery needs can be met by alternative means). Where asset

utilisation is low, entities should consider whether the cost of holding the asset

exceeds the cost of transferring the services it delivers, and whether there is a more

economical way of delivering the services. Alternative or additional uses of assets

should also be considered. The utilisation of each asset should be reviewed annually.

Functionality of a Physical Asset:

The functionality of an asset is a measure of the effectiveness of the asset in

supporting the activities to be carried out. To assess (and monitor) functionality, it is

necessary to determine:

The role that the asset plays in achieving service delivery outcomes

The functional characteristics required to support specified activities.

The functionality of assets should be regularly reviewed. This will enable any

significant impacts on services to be identified. It will also allow timely changes to be

made to improve both service delivery and functional standards. Furthermore, the

results of regular functionality reviews are used in the formulation of asset strategies.

2008 CIEAM

AAMCoG Best Practice

P a g e | 16

2. Assessment Criteria for

Assets Condition

Asset Physical Condition Assessment Methodologies

There are numerous methodologies to assess asset physical condition in use today by

engineers and asset managers for most long-lived tangible capital assets that are of

great value in managing tangible capital assets. Generally, they have developed to the

point that consistent methods and measurement scales can be used to assess condition

on a reliable and consistent basis. The objective is selecting a method of measuring

asset physical condition that will indicate whether tangible capital assets are being

preserved so that they continue to provide a service and achieve expected life.

Condition assessments should be based on generally accepted methods and standards

and consistently applied. Methods of measurement should be an easy-to-understand

reference that can be updated regularly to track the results of an organisations asset

management strategies. It should also allow users to predict the status of assets into

the future, based on current asset management policies.

Characteristics of a good condition assessment methodology may include;

(a) use of standardised indicators to identify deficiencies;

(b) recording of deficiencies in terms of severity and frequency;

(c) prompts for the inventory and inspection process ensuring that all pertinent

data is collected, guiding the inspector through each step of the process;

(d) predefined measurement scale for each type or category of asset (for example,

calculating a numerical condition index on a numerical scale of zero to 100);

(e) utilization of knowledgeable inspectors with well-documented inspection

procedures;

(f) predetermined inspection schedules for tangible capital assets (components,

subsystems or networks).

Different condition assessment methodologies may be used for major categories. The

asset condition assessment methodology does not have to be consistently applied

across all categories of assets. Organisations should provide information about the

condition assessment methodologies used and the relevant measurement scales. The

information may include a description of the methodologies used in the assessment of

the physical condition of tangible capital assets, the general acceptance of assessment

methodologies used, the qualifications of evaluators and the description of asset

management systems that may be used. Once methodologies and measurement scales

have been determined, it is desirable but not required, that methods and standards be

applied consistently from period to period. Consistency in application is important

when comparing assessments of tangible capital assets between periods or at different

points in time. Consistency helps prevent misconceptions that might result from the

application of different methodologies and measurement scales in different periods.

When a change of methodology or measurement scale is deemed to be appropriate,

disclosure of the effects of the change is necessary to maintain comparability. Any

2008 CIEAM

AAMCoG Best Practice

P a g e | 17

changes should be described, including the reasons for the change and the

implications of such a change. Where possible, prior period assessments would be

restated for consistent comparison or differences between current and previously

reported assessments must be clearly articulated.

Assessment of the physical condition of tangible capital assets relies heavily on

managements judgment as to the acceptable level of service. It involves a

determination of the condition level at which tangible capital assets must be preserved

in order to meet the acceptable level of service. At present, there are no standards that

provide a basis for assessing the condition level at which assets begin to lose future

economic benefit or service potential, and consequently it would be difficult to

ascertain whether the pre-established level selected is appropriately representative.

Assessment of the physical condition of tangible capital assets would require

obtaining expert assistance from internal or external sources. The physical condition

should be measured using the experts best estimates based on assumptions that

reflect the most probable asset physical condition. When a material change in an

assessment of tangible capital assets is reasonably possible in the near term, the

organisation should provide information about the nature and extent of uncertainty.

Disclosure of the nature of the measurement of uncertainty should include a

description of the circumstances giving rise to the uncertainty, and relevant

information about its anticipated resolution. Assessments of tangible capital assets

should include any additional evidence provided by subsequent events occurring after

the reporting date. Other relevant information that should be provided includes;

(a) a description of the key assumptions used in preparing the assessment of

physical condition and whether the assumptions are susceptible to change;

(b) an explanation of the changes made to past assumptions used in previous

assessments of the physical condition;

(c) information about the effect of a change in the underlying assumptions used to

prepare the assessment of physical condition; and

(d) the sensitivity of the assessment of physical condition to changes in the

assumptions used and the reason for the sensitivity.

The organisation should provide information as to what has been done to ensure the

reliability of the assessment of the physical condition of tangible capital assets.

Information about reliability may be integrated throughout the Assets Condition

Assessment report. Reliability may be demonstrated by including descriptions of asset

management systems, the general acceptance of assessment methodologies used, and

the qualifications of evaluators. The organisation should also provide a discussion of

limitations of assessments and any gaps in the information used for assessing assets.

2008 CIEAM

AAMCoG Best Practice

P a g e | 18

Additional Information on Assets Replacement Costs:

Organisations may choose to provide information on the current replacement cost of

tangible capital assets by category. Current replacement costs represent the amount in

todays money necessary to acquire, develop or construct assets similar to those

already owned. Information on tangible capital asset replacement costs gives users a

benchmark against which to assess the total replacement costs of all assets relative to

the amount being invested in maintenance, renewals and replacements. It also gives

users an estimate of the total replacement costs of assets in relation to historical cost.

Organisations should acknowledge that the replacement costs do not represent a need

to replace all assets in any one particular year. The provision of a replacement value

on all assets has limitations in meeting the information needs of users.

Because of the longevity of infrastructure assets, it is difficult to make accurate

projections of replacement values. For example, new infrastructure assets can last up

to 75 years or more. Replacement values are a snapshot at a particular point in time of

the total current value of tangible capital assets. The provision of replacement values

does not provide users with any indication of the timing of renewal and replacement

expenditures or the effect it will have on future revenue requirements. It is, however,

good practice for organisations to determine replacement costs for internal

management and planning purposes. Summary information should be presented for

each major category in tabular form.

Organisations may choose to provide financial information about the tangible capital

assets deficit/debt/gap. The information should include:

(a) a definition of the tangible capital assets;

(b) details of the types of expenditures included in the calculation of the tangible

capital assets deficit such as

(i) deferred maintenance and renewal to bring existing tangible capital assets

back to desired condition

(ii) replacement of existing assets

(iii)enhancing functionality of existing assets

(iv) increasing capacity of existing assets

(v) meeting new environmental standards

(vi) new assets to meet growth service requirements

(c) minimum or expected service levels;

(d) minimum or expected asset condition levels required to meet service levels;

(e) period over which the tangible capital assets deficit is calculated;

(f) measurement methodology.

Computer programs exist that can assist in asset condition assessment information.

For example, computerised maintenance management systems provide information to

manage work orders, store inventory and preventive maintenance schedules.

Condition assessment survey systems help identify the existing condition of various

components of tangible capital assets and produce benchmarks for comparisons and

projecting repair and replacement costs. Facility condition assessment systems help

organizations plan and prioritise the renewal of physical assets using life cycle

planning principles.

2008 CIEAM

AAMCoG Best Practice

P a g e | 19

Asset Condition Assessment Plans

Organisations may choose to provide details of assets condition in any asset

management plan that may exist. Information in such plans may include:

(a) assets strategic plans with directions to be taken, given factors such as needs

assessments and growth expectations;

(b) asset tactical plans, given the existing deployment of resources;

(c) long-term financing needs, including determining whether additional

resources are needed;

(d) operational plans which would include life-cycle costing together with

estimates of useful life, required maintenance and timing of major repair and

replacements;

(e) condition assessments for identifying performance, funding requirements;

(f) any business risk associated with deteriorating tangible capital asset condition.

Providing Required Asset Condition Levels:

Determining what constitutes acceptable asset condition may vary both across

organisations as well as for different types of tangible capital assets held within an

organisation. It may not be either possible or desirable to maintain assets in perfect

condition. It may therefore be useful for users to understand managements targets for

physical condition of tangible capital assets by major category. An organisation may

establish the minimum or target condition level for each asset category against which

actual condition assessment measures can be compared. This will give users access to

information that will allow them to determine whether assets are being preserved at

the target condition level established by the organisation. Organisations may also

provide the minimum or expected condition level for each asset category.

The assessment of the physical condition and life expectancy of tangible capital assets

should be included in the Asset Condition Assessment Plan report. Assessments

should be done as close to the related reporting date as is practical. Most organisations

may not perform detailed assessments of physical condition annually on all categories

of tangible capital assets because of the magnitude of the information gathering and

processing required. An organisation may choose to complete a detailed assessment

on major categories of tangible capital assets on a cyclical or rotational basis. It may

decide to do annual assessments on critical assets and cyclical assessments on other

assets. Tangible capital assets may be regarded as living assets in that they change

over time due to various factors, and therefore assessments presented in the report

should be updated on an ongoing basis to provide information about effects of these

factors between assessments. It is important to provide new information, not just

reproduce previously completed assessments. In the years between actual assessments

of physical condition, an extrapolation of the previous assessments of physical

condition could be used to provide an assessment as at the current reporting date.

Each year, an organisation should consider the effects of factors such as age,

maintenance and renewal policies, expenditures, utilization, etc., on the physical

condition of tangible capital assets and determine adjustments required to update

previous assessments.

2008 CIEAM

AAMCoG Best Practice

P a g e | 20

For example, asset management systems may be used that can extrapolate the current

physical condition of assets at the reporting date by taking into account factors such as

previously completed assessments, expenditures since the previously completed

assessment, maintenance records, utilization and age. An organisation should provide

information about which assets have been assessed in the reporting period, the

rationale for, and frequency of, the assessments of physical condition. Where an

actual assessment of physical condition has not been completed in the period, a

discussion of the basis upon which previous assessments have been updated, and the

changes in the previous assessments resulting from new information, should be

included. For example, the discussion may provide information on the impact that

expenditures have had on the overall asset physical condition assessment. Where an

actual assessment of physical condition has not been completed and it is impractical

to update previous assessments, an organisation should provide information about the

most recent assessment.

The level of assessment does not have to be consistent for all categories. For example,

an organisation could provide detailed assessments of physical condition on

categories of tangible capital assets that are critical to providing essential services

while completing only minimal assessments to satisfy management and reporting

needs on assets that are of minor significance to attainment of the objectives and goals

of the organisation. An organisation should provide the basis and rationale for which

categories they are providing assessments. An organisation may not have sufficient

information on all of its major categories to complete an assessment. This does not

negate the need for the organisation to provide an assessment on all major categories

of tangible capital assets judged critical to the provisions of services and programs. In

a situation where the organisation does not have the data, it should provide

information on its plans to complete an assessment on all major categories of assets.

The level of detail disclosed in the assessment of tangible capital assets should reflect

the highly aggregated nature of summary financial statements. In deciding the level of

detail to disclose about an assessment of the physical condition of tangible capital

assets, an organisation should consider the usefulness of the information to the user in

assessing the condition of tangible capital assets. The initial assessment of the

physical condition and life expectancy of tangible capital assets will require

considerable effort. In addition, while the recommended practices are equally

applicable to organisations of varying sizes, the capacity of an organisation to apply

the recommended practices will vary. Therefore, it is anticipated that the assessment

of physical condition and life expectancy of all major tangible capital assets will be

achieved over time. Organisations should provide the information for those categories

of tangible capital assets for which assessments have been done. Organisations should

also provide information about those categories for which an assessment has not been

completed, whether or not an assessment is planned and the timing of reporting.

2008 CIEAM

AAMCoG Best Practice

P a g e | 21

3. Conducting Assets Inspections

and Surveys

Assets Condition Inspections

Identifying Asset Categories:

Assigning the appropriate asset category prior to conducting assets inspections is

designed to achieve consistent and comparable results. The method can also be used

in cases where there is still uncertainty as to the appropriate category for a particular

asset or class of assets. A checklist is used to identify key elements critical to the

successful functioning or operation of a physical asset. Table 1 shows a table of

typical physical infrastructure assets categories as applied in the public sector.

Table 1. Physical Infrastructure Assets Categories in the Public Sector

(VSG, 1996)

Asset Category

Description

1 (Superior)

Assets of national significance that are critical to state functions; that is, key

national and state infrastructure, and heritage assets that are national icons.

major national highways

major dams and bridges etc.

2 (High)

Key assets with major state significance; key heritage assets; and assets that

must meet very rigorous special requirements.

major infrastructure such as main sewers, national railway lines, major

transmission towers, major water supply mains, key bridges, interstate

highways

major hospitals etc.

3 (Above Average)

Assets very important to state operations, including significant infrastructure

and heritage assets, and assets needing to meet special requirements.

major power supply grid, trunk drainage mains, freeways, important

bridges, major gas supply mains

interstate railway stations etc.

4 (Average)

Non-critical assets, including most buildings supporting typical government

service delivery functions. The lowest possible category for important

infrastructure and heritage assets.

underground drainage, railway lines and sidings, power distribution grid,

major piers, gas mains, major roads, bridges

government buildings such as offices, schools, tertiary institutions, courts

public housing etc.

5 (Below Average)

Non-critical assets where purely functional performance is acceptable to the

public.

piers

railway stations

bus shelters

minor roads etc.

6 (Low)

Assets that can reasonably operate in very basic conditions.

workshops

car parks

lanes

sheds etc.

2008 CIEAM

AAMCoG Best Practice

P a g e | 22

The most fundamental feature of an asset is its function. Function decides strategic

importance. In the condition assessment process, particularly in conducting assets

inspections, this is taken into account so that an informed judgement can be made

about the priority of each asset. Priority is judged not only in relation to other assets,

such as those controlled by Government Agencies making the assessment, but also in

relation to all other State-owned assets. The six-point Asset Category Scale indicated

in Table 7.8 has been developed for this purpose. The first step in conducting assets

inspections in the assets condition assessment process is to assign each asset to the

Asset Category that best reflects its significance.

Identifying Required Condition:

Before assessing the actual condition of an asset during asset inspections, it is

important to be clear on what condition the asset needs to be in to perform at an

appropriate level of efficiency and service. The Required Condition will vary between

assets according to the asset's strategic importance, its specific function and its

particular physical requirements. The purpose of establishing Required Condition is to

provide a benchmark against which Actual Condition can be compared. Required

Condition is the acceptable physical condition needed of an asset for effective service

delivery. It should perform its functions without unacceptable disruption; provide the

expected level of service appropriate for its functions; and provide a safe environment

that meets statutory requirements. Required Condition varies according to function. It

will vary not only between Asset Categories but also between individual assets within

the same Asset Category. Variations within a single asset can arise as a result of assets

that have a number of functions. Physical infrastructure assets or constructed assets

are often complex and support a number of functions. Required Condition is simply a

judgement of the main physical requirements that must be met. It will depend on the

specific functions and physical requirements of those features of the asset with most

strategic importance. However, careful and objective identification of Required

Condition is a very important part of conducting assets inspections in the assets

condition assessment process. If the Required Condition identified is too high or low,

the result can be either unnecessary expenditure on maintenance or refurbishment, or

deterioration of the asset and loss of value through under-expenditure. Basically, in

establishing Required Condition, the emphasis should be on those elements of the

asset most important in meeting business needs.

Identifying Actual Condition:

Assessing the actual condition of an asset is the active part of conducting assets

inspections in the assets condition assessment process, in preparation for analysis. An

asset's actual physical condition and the acceptability of that condition can fluctuate

considerably over its useful life, particularly if there is a change in its function.

Information on Actual Condition is needed at any time to be able to make effective

decisions on the management of assets. The focus of Actual Condition assessment

during assets inspections is on key elements. All physical assets consist of a number

of elements or components that can be identified and measured. In assessing Actual

Condition it is important to identify and focus on those elements of the asset most

important to business needs. Table 2 provides a useful checklist of the elements

important to an asset's effective operation. The checklist can be adapted to apply to

most infrastructure and other constructed assets.

2008 CIEAM

AAMCoG Best Practice

P a g e | 23

Table 2. Physical Infrastructure Asset Elements

(VSG, 1996)

Physical infrastructure asset elements have potentially different life cycles. Different

elements of a single asset can therefore be at different stages of deterioration. The

asset's overall Actual Condition is the result of independent examination through

assets inspections of the condition of its key elements. When the key asset elements

have been identified, they should be assessed against a limited number of clear

criteria. These may vary according to the function of the asset. Thus, in conducting

assets inspections, it is important to assess asset elements against the following

criteria;

the purpose of the assessment;

the key asset elements;

the appropriate assessment criteria;

the way the condition information is to be obtained.

In assessing asset elements against these criteria, it is advisable to include details on

how well the criteria are met. There should be enough detail to describe both the

condition and any major risks that would be associated with a failure to take action.

2008 CIEAM

AAMCoG Best Practice

P a g e | 24

Methods of Assessing Actual Condition:

Assessing Actual Condition does not always need detailed inspection of an asset.

Methods of assessment are either based on prediction or direct inspection. They can

vary from a study that comments on specific details of individual assets to a sample

survey identifying broad trends. The particular situation for conducting assets

inspections determines the appropriate method of condition assessment. In many

cases a broad assessment is adequate. More than one method may be needed where a

wide range of assets requires information to make strategic and operational decisions.

Direct inspection can range from superficial to detailed physical examination. When

direct inspection of the asset or one of its key elements is not practical, physical

measurement and non-destructive testing can be used for elements of the asset that

cannot be reliably assessed by direct inspection; or when the level of detail required

warrants such measurements. The inspection cycle varies depending on the condition

of the physical asset. An asset judged to be below its Required Condition should be

inspected more frequently than one considered to be above its Required Condition.

Inspection cycles for elements that involve moving parts should be reasonably short.

A predictive method of condition assessment involves modelling, estimating or

approximation of asset condition and makes predictions about future assets condition.

Establishing a Relative Condition Level:

Relative Condition Level is a direct comparison of an asset's Actual Condition with its

Required Condition, expressed in a Relative Condition Level scale as in Table 3.

Table 3. Relative Condition Level Scale

(VSG, 1996)

2008 CIEAM

AAMCoG Best Practice

P a g e | 25

The purpose of comparing actual and required condition is to:

examine the level of fitness for purpose;

assess the extent of under or over-provision;

set maintenance, refurbishment, replacement or disposal requirements.

Where the Relative Condition Level shows a significant variation between Actual

Condition and Required Condition, there is likely to be a significant impact on the

operation of the asset. There may also be financial impacts. These need to be clearly

identified as they are important in making decisions and setting priorities. Assets

condition impacts considered with Asset Category are a major determinant of the

priority and urgency of action to be taken in respect of a particular physical asset.

Identifying the Appropriate Action:

The diagnostic information needed for making decisions is now available. The

questions that remain to be answered are:

Remedial Action:

Does remedial action needs to be taken? Remedial action is the repairs and/or

refurbishment needed to rectify the problems found in the assessment of Actual

Condition and restore the asset to its Required Condition.

Costs:

How much will it cost? Estimated costs need to be provided at this stage. Urgent

works have budget priority. Costs will be an important factor in balancing other

expenditure over the asset planning cycle.

Identifying Priorities:

What is its priority? The most critical factors in evaluating the information and

deciding on priorities are:

Asset Category: how important is the asset ?

Condition Impacts: how serious is the risk ?

A time frame for action should be decided based on an evaluation of the critical

factors in each case.

Calculating the Condition Index:

The Condition Index is a weighted average of the condition of a group of assets. It is

calculated using the Relative Condition Level of assets multiplied by the relevant unit

of measure. The unit of measure used for a group of assets depends on the nature of

the physical assets. In infrastructure assets such as buildings the unit of measure is

gross area in square metres. The relevant unit of measure for drains is metre length.

The Condition Index has three key values; a positive value, a 0 value, and a negative

value. A positive value indicates that the current condition of assets in the group is on